Fabrication additive d'alliages de tungstène à Berlin : Un guide complet pour les acheteurs B2B

Table des matières

1. Introduction à la fabrication additive d'alliages de tungstène

La fabrication additive (FA) d'alliages de tungstène révolutionne les industries nécessitant des composants à haute densité, à haute résistance et résistants à la chaleur. Cette technologie permet la production de conceptions complexes que les méthodes de fabrication traditionnelles ne peuvent pas réaliser, ce qui la rend idéale pour les applications dans les secteurs de l'aérospatiale, du médical, de la défense et de l'énergie.

Pourquoi l'alliage de tungstène ?

Les alliages de tungstène sont connus pour :

✔ Haute densité – Idéal pour le blindage contre les radiations et les contrepoids

✔ Résistance exceptionnelle à la chaleur – Résiste aux températures extrêmes dans les applications aérospatiales et nucléaires

✔ Propriétés mécaniques supérieures – Haute résistance et dureté pour les composants résistants à l'usure

Alors que Berlin émerge comme un centre de fabrication de pointe, les entreprises exploitent de plus en plus l'impression 3D d'alliages de tungstène pour améliorer l'efficacité de la production, réduire les délais et permettre la personnalisation de masse.

2. Tendances du marché et potentiel de croissance à Berlin

Berlin devient rapidement un acteur clé du secteur de la fabrication de pointe en Europe, la fabrication additive d'alliages de tungstène gagnant du terrain de manière significative.

Principales tendances du marché

📈 Augmentation de la demande dans l'aérospatiale et la défense – L'industrie aérospatiale allemande investit massivement dans la fabrication additive pour produire des composants légers et durables.

📈 Progrès médicaux – L'alliage de tungstène est largement utilisé dans le blindage contre les radiations et les implants médicaux.

📈 Applications énergétiques – Les secteurs de l'énergie nucléaire et renouvelable nécessitent des pièces en alliage de tungstène haute performance.

📈 Adoption croissante des technologies d'impression 3D – De plus en plus d'entreprises intègrent la FA dans les chaînes de production pour réduire les coûts et augmenter l'efficacité.

Potentiel du marché à Berlin

- L'Allemagne est le plus grand centre de fabrication industrielle d'Europe

- Berlin abrite des institutions de recherche de premier plan spécialisées dans la fabrication additive

- Les initiatives gouvernementales soutiennent l'adoption des technologies de l'Industrie 4.0

Avec la demande croissante de matériaux haute performance, les entreprises de Berlin ont une forte incitation à adopter la fabrication additive d'alliages de tungstène.

3. Facteurs clés à prendre en compte lors du choix d'un fournisseur d'impression 3D en alliage de tungstène

Choisir le bon fournisseur est crucial pour garantir des composants en alliage de tungstène de haute qualité.

Principales considérations

| Facteur | Pourquoi c'est important |

|---|---|

| Qualité des matériaux | Les alliages de tungstène de haute pureté garantissent durabilité et performance. |

| Technologie d'impression | Des méthodes avancées comme le SEBM (Selective Electron Beam Melting) et le SLM (Selective Laser Melting) améliorent la précision. |

| Capacité de production | Une production évolutive assure une livraison rapide pour les commandes en gros. |

| Certifications de l'industrie | La conformité aux normes ISO, AS9100 et aux normes de qualité médicale garantit la fiabilité. |

| Capacités de personnalisation | Capacité à créer des géométries complexes et des solutions sur mesure. |

| Délai d'exécution et logistique | Des délais d'exécution rapides et des options d'expédition fiables sont essentiels pour les acheteurs B2B. |

| Rapport coût-efficacité | Des prix compétitifs sans compromis sur la qualité |

Comment Metal3DP excelle dans ces facteurs

Métal3DP est un fournisseur leader de solutions de fabrication additive en alliage de tungstène. Avec une technologie de pointe Fusion sélective par faisceau d'électrons (SEBM) et des poudres métalliques de haute pureté, Metal3DP garantit des pièces en alliage de tungstène de qualité supérieure pour les applications industrielles.

En choisissant un fournisseur fiable comme Metal3DP, les entreprises de Berlin peuvent bénéficier de solutions de fabrication additive de pointe adaptées à leurs besoins.

4. Top 5 des fournisseurs d'impression 3D d'alliage de tungstène à Berlin

Pour les entreprises qui cherchent à s'approvisionner fabrication additive d'alliages de tungstène services à Berlin, choisir le bon fournisseur est essentiel pour garantir une production de haute qualité, rentable et évolutive. Voici les top 5 des fournisseurs leaders du marché à Berlin.

| Nom du fournisseur | Principaux points forts | Secteurs d'activité |

|---|---|---|

| Métal3DP | Poudres de tungstène de haute pureté, technologie SEBM, production à grande échelle | Aérospatiale, Médical, Énergie, Automobile |

| EOS GmbH | Technologie SLM avancée, forte orientation R&D | Aérospatiale, Médical, Outillage |

| Fraunhofer IAPT | Fabrication additive axée sur la recherche, impression métallique de haute précision | Universitaire, Défense, Industriel |

| Groupe de fabrication additive FIT | Solutions AM personnalisées, innovation de matériaux | Automobile, aérospatiale, industrie |

| Concept Laser (additif GE) | AM métallique à base de laser, production certifiée | Médical, Énergie, Aérospatial |

Pourquoi Metal3DP se démarque

Parmi ceux-ci principaux fournisseurs, Métal3DP offre une expertise inégalée en fabrication additive d'alliages de tungstène avec:

✔ Volume et précision d'impression de pointe

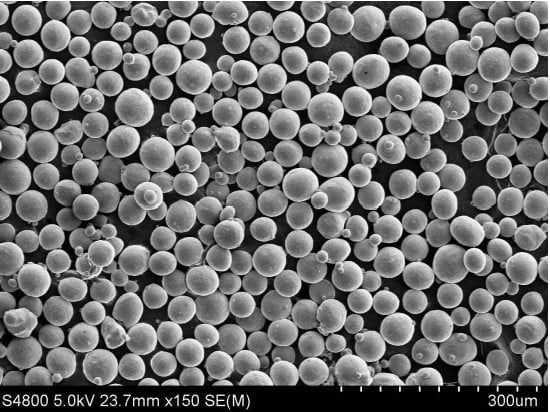

✔ Poudres de tungstène à haute sphéricité optimisées pour l'AM

✔ Capacités de production évolutives pour les commandes B2B en gros

Les entreprises qui ont besoin de composants en tungstène haute performance peuvent compter sur Metal3DP pour la qualité, l'efficacité et l'innovation.

5. Pourquoi de plus en plus d'entreprises adoptent la fabrication additive d'alliage de tungstène

La fabrication additive d'alliage de tungstène gagne en popularité en raison de ses avantages uniques par rapport aux méthodes de fabrication traditionnelles.

Principales raisons du changement

📌 Géométries complexes – L'AM permet la création de pièces complexes que l'usinage traditionnel ne peut pas réaliser.

📌 Efficacité des matériaux – Réduit les déchets par rapport à la fabrication soustractive conventionnelle.

📌 Des délais de production plus rapides – Réduit les délais et permet un prototypage rapide.

📌 Économies de coûts – Minimise les coûts d'outillage et de main-d'œuvre.

📌 Intégrité structurelle améliorée – Assure une distribution uniforme des matériaux et des propriétés mécaniques supérieures.

Industries bénéficiant de l'AM en alliage de tungstène

| L'industrie | Applications |

|---|---|

| Aérospatiale et défense | Blindage contre les radiations, composants de propulsion |

| Médical et soins de santé | Blindage contre les rayons X, instruments chirurgicaux, implants |

| Énergie et nucléaire | Composants de réacteurs à haute température, blindage neutronique |

| Automobile et outillage | Outils résistants à l'usure, pièces structurelles à haute résistance |

Les entreprises de Berlin investissent de plus en plus dans fabrication additive d'alliages de tungstène pour garder une longueur d'avance en ingénierie de précision, rentabilité et durabilité.

6. Pourquoi choisir Metal3DP pour la fabrication additive d'alliage de tungstène ?

Lors de la sélection d'un fournisseur de fabrication additive d'alliage de tungstène, les entreprises ont besoin d'un partenaire qui offre des matériaux de haute qualité, une technologie de pointe et un service fiableVoici pourquoi Métal3DP est le choix préféré pour les acheteurs B2B.

1. Poudres d'alliage de tungstène haute performance

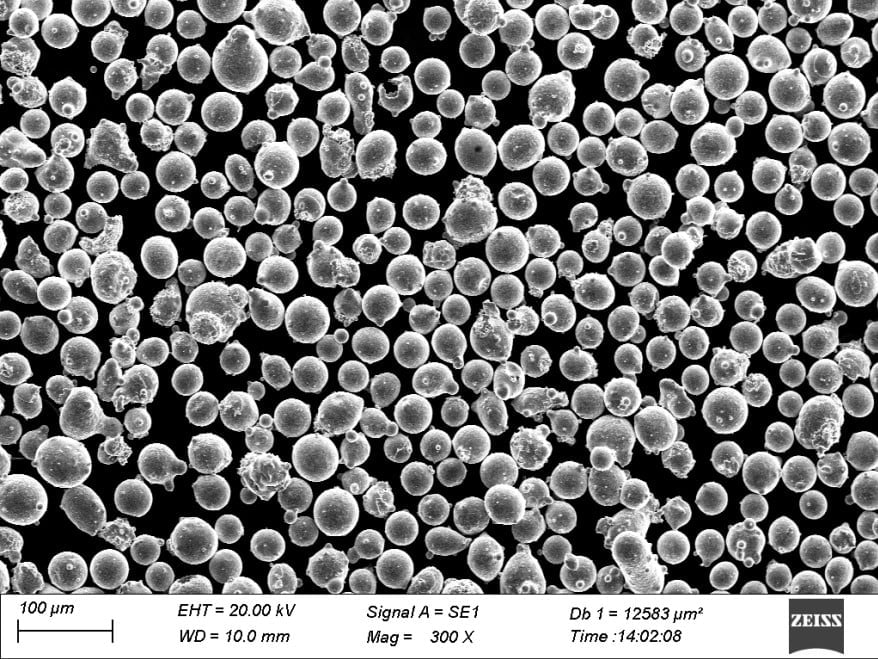

✔ Fabriqué en utilisant technologie avancée d'atomisation de gaz et de PREP

✔ Haute sphéricité et fluidité pour des performances d'impression 3D optimales

✔ Disponible dans une variété de compositions personnalisées

2. Technologie de fabrication additive (AM) de pointe

✔ Fusion sélective par faisceau d'électrons (SEBM) pour des pièces en tungstène de haute précision

✔ Précision et densité d'impression supérieures par rapport aux méthodes traditionnelles

✔ Production évolutive pour les commandes en petites et grandes séries

3. Expertise et certifications du secteur

✔ Des années d'expérience dans la fabrication additive de métaux

✔ Conformité aux normes de l'industrie aérospatiale et médicale

✔ Approuvé par les fabricants mondiaux pour les applications critiques

4. Solutions rentables pour les acheteurs B2B

✔ Remises sur les commandes en gros disponibles

✔ Délais d'exécution rapides pour les besoins de production urgents

✔ Un soutien complet de la sélection des matériaux au produit final

En s'associant avec Métal3DP, les entreprises de Berlin peuvent accéder à des solutions de fabrication additive d'alliages de tungstène de premier ordre adaptées à leurs besoins spécifiques.

7. Comment commander des services d'impression 3D d'alliage de tungstène en gros à Berlin

Pour les entreprises souhaitant s'intégrer fabrication additive d'alliages de tungstène dans leurs opérations, trouver un fournisseur fiable et comprendre le processus de commande est crucial. Vous trouverez ci-dessous un guide étape par étape pour commander de l'alliage de tungstène en gros Impression 3D services de Métal3DP.

Étape 1 : Définissez vos besoins

Avant de passer une commande, déterminez :

✔ Spécifications des matériaux – Choisissez l'alliage de tungstène approprié en fonction de l'application (par exemple, aérospatiale, médicale, énergie).

✔ Conception et complexité des pièces – Fournissez des modèles CAO ou demandez une assistance pour la conception personnalisée.

✔ Taille du lot et quantité – Indiquez si vous avez besoin de prototypage, de petites séries ou d'une production à grande échelle.

Étape 2 : Contacter Metal3DP pour un devis

📩 Demander un devis en visitant Page produit de Metal3DP et en fournissant les détails de votre projet.

📌 Incluez des informations telles que les exigences en matière de matériaux, les fichiers de conception et le calendrier de livraison.

Étape 3 : Prototypage et production d'échantillons

✔ Prototypage disponible pour les entreprises qui ont besoin d'échantillons fonctionnels avant la production à grande échelle.

✔ Tests et validation des matériaux pour garantir que le produit répond aux normes de l'industrie.

Étape 4 : Production en vrac et assurance qualité

✔ La technologie SEBM avancée de Metal3DP garantit des composants en alliage de tungstène de haute précision et de haute densité.

✔ Mesures strictes de contrôle de la qualité garantissent la conformité aux normes aérospatiales, médicales et de défense.

Étape 5 : Logistique et livraison

✔ Délais d'exécution rapides pour les commandes en nombre.

✔ Options d'expédition dans le monde entier disponibles pour les acheteurs internationaux.

Pourquoi commander chez Metal3DP ?

📌 Prix compétitifs – Production en vrac rentable pour les acheteurs B2B.

📌 Évolutivité – Capacité à gérer des commandes importantes avec des délais d'exécution courts.

📌 Personnalisation – Solutions sur mesure pour répondre aux besoins spécifiques de l'industrie.

En suivant ce processus simplifié, les entreprises de Berlin peuvent s'approvisionner efficacement en Services d'impression 3D en alliage de tungstène de haute qualité de Metal3DP.

8. FAQ : Questions fréquentes sur la fabrication additive d'alliages de tungstène

Q1 : Pourquoi l'alliage de tungstène est-il utilisé dans la fabrication additive ?

L'alliage de tungstène est choisi pour sa haute densité, sa résistance à la chaleur et sa résistance mécanique, ce qui le rend idéal pour les applications aérospatiales, de défense, médicales et énergétiques.

Q2 : Quelles technologies de fabrication additive sont utilisées pour l'impression d'alliages de tungstène ?

Les technologies les plus courantes incluent Fusion sélective par faisceau d'électrons (SEBM) et fusion sélective par laser (SLM), qui garantissent toutes deux des pièces de haute densité et de précision.

Q3 : Comment Metal3DP assure-t-elle la qualité des pièces en alliage de tungstène ?

Metal3DP utilise technologies avancées d'atomisation de gaz et de PREP pour produire des poudres de tungstène sphériques de haute pureté. Leurs Machines SEBM garantissent une qualité constante, et tous les produits subissent un contrôle de qualité rigoureux avant la livraison.

Q4 : Puis-je commander des compositions personnalisées d'alliages de tungstène ?

Oui ! Métal3DP offres des formulations d'alliages de tungstène personnalisées adaptées aux besoins spécifiques de l'industrie.

Q5 : Quelles industries bénéficient le plus de la fabrication additive d'alliages de tungstène ?

Les industries telles que l'aérospatiale, l'énergie, le médical et l'automobile bénéficient de la haute résistance, la résistance à l'usure et la stabilité thermique.

Pour toute autre question, les entreprises peuvent contacter l'équipe d'assistance technique de Metal3DP pour obtenir des conseils d'experts.

9. Conclusion et appel à l'action

Pourquoi la fabrication additive d'alliages de tungstène est l'avenir

✔ Précision et complexité – Permet la production de géométries complexes.

✔ Efficacité des matériaux – Réduit les déchets et améliore la rentabilité.

✔ Évolutivité – Convient au prototypage et à la production de masse.

✔ Adoption par l'industrie – De plus en plus utilisé dans les secteurs de l'aérospatiale, de la médecine et de l'énergie.

Pourquoi choisir Metal3DP ?

✅ Technologie de pointe – Impression d'alliages de tungstène basée sur SEBM.

✅ Poudres métalliques de haute pureté – Fabriqué par atomisation avancée au gaz.

✅ Solutions personnalisées – Adaptées aux besoins spécifiques des entreprises.

✅ Partenaire B2B fiable – Approuvé par les fabricants du monde entier.

Pour les entreprises de Berlin qui souhaitent intégrer la fabrication additive d'alliages de tungstène, le moment est venu d'agir !

Obtenez un devis dès aujourd'hui : Visitez Metal3DP pour explorer des solutions d'impression 3D d'alliages de tungstène personnalisées.

Associez-vous à Metal3DP et faites passer votre fabrication au niveau supérieur !

Partager sur

MET3DP Technology Co. est un fournisseur de premier plan de solutions de fabrication additive dont le siège se trouve à Qingdao, en Chine. Notre société est spécialisée dans les équipements d'impression 3D et les poudres métalliques de haute performance pour les applications industrielles.

Articles connexes

Metal 3D Printed Subframe Connection Mounts and Blocks for EV and Motorsport Chassis

Lire la suite "

Metal 3D Printing for U.S. Automotive Lightweight Structural Brackets and Suspension Components

Lire la suite "À propos de Met3DP

Mise à jour récente

Notre produit

CONTACTEZ-NOUS

Vous avez des questions ? Envoyez-nous un message dès maintenant ! Nous répondrons à votre demande avec toute une équipe dès réception de votre message.

Obtenir les informations de Metal3DP

Brochure du produit

Obtenir les derniers produits et la liste des prix