Poudres métalliques pour semi-conducteurs

Table des matières

Dans le monde en constante évolution des semi-conducteurs, le rôle des poudres métalliques est crucial. De la création de microprocesseurs au développement de mémoires avancées, les poudres métalliques sont les héros méconnus qui ont permis ces merveilles technologiques. Cet article explore les subtilités de ces technologies. poudres métalliques pour semi-conducteurs, leurs types, compositions, applications, spécifications, et plus encore. Découvrons ensemble ce sujet fascinant.

Présentation de la poudre métallique pour semi-conducteurs

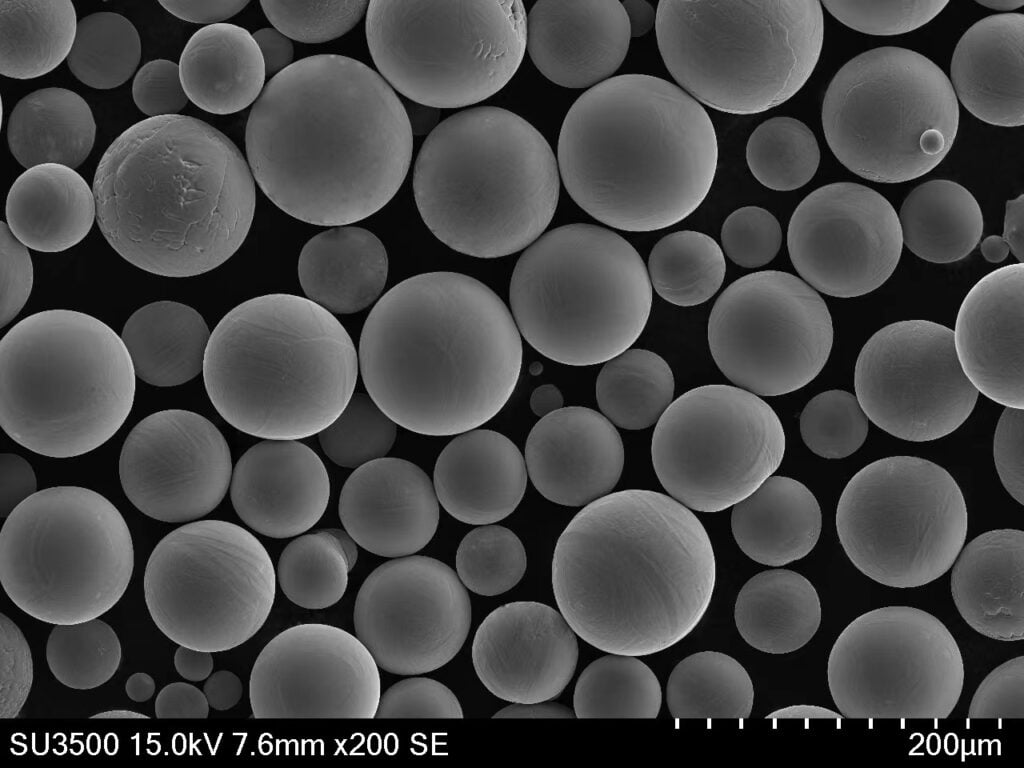

Les poudres métalliques sont des particules métalliques finement divisées utilisées dans diverses applications, notamment dans l'industrie des semi-conducteurs. Leur importance réside dans leurs propriétés uniques, telles qu'une grande pureté, une granulométrie contrôlée et une surface spécifique, qui les rendent idéales pour la fabrication de semi-conducteurs.

Points clés :

- Les poudres métalliques sont essentielles dans le processus de fabrication des semi-conducteurs.

- Ils offrent une grande pureté et des tailles de particules contrôlées.

- Utilisé dans la création de microprocesseurs, de stockage de mémoire et d'autres dispositifs semi-conducteurs.

Types de poudres métalliques pour semi-conducteurs

Différents métaux sont utilisés sous forme de poudres pour diverses applications de semi-conducteurs. Chaque poudre métallique possède des propriétés distinctes qui la rendent adaptée à des usages spécifiques.

| Poudre de métal | Composition | Propriétés | Caractéristiques |

|---|---|---|---|

| Cuivre (Cu) | Cuivre pur | Conductivité élevée | Résistance à la corrosion, ductilité |

| Aluminium (Al) | Aluminium pur | Léger et haute conductivité | Réflectivité, malléabilité |

| Argent (Ag) | Argent pur | Conductivité électrique la plus élevée | Résistance au ternissement, antimicrobien |

| Or (Au) | Or pur | Excellente conductivité | Non réactif, ductilité |

| Nickel (Ni) | Nickel pur | Résistance à la corrosion | Magnétisme, point de fusion élevé |

| Titane (Ti) | Titane pur | Solidité, légèreté | Résistance à la corrosion, biocompatibilité |

| Tungstène (W) | Tungstène pur | Point de fusion élevé | Densité, dureté |

| Molybdène (Mo) | Molybdène pur | Haute résistance | Conductivité thermique élevée, faible dilatation thermique |

| Palladium (Pd) | Palladium pur | Résistance à la corrosion | Bonne conductivité, propriétés catalytiques |

| Cobalt (Co) | Cobalt pur | Propriétés magnétiques | Point de fusion élevé, résistance |

Applications de la poudre métallique pour les semi-conducteurs

Les poudres métalliques sont utilisées dans diverses applications de l'industrie des semi-conducteurs. Voici un aperçu de leur utilisation et de leur utilisation.

| Application | Poudres métalliques utilisées | Description |

|---|---|---|

| Microprocesseurs | Cuivre, or, argent | Chemins conducteurs et interconnexions |

| Stockage de mémoire | Aluminium, nickel | Couches de stockage de données et enregistrement magnétique |

| Capteurs | Palladium, Cobalt | Éléments sensibles dans les capteurs |

| Transistors | Tungstène, molybdène | Matériaux de grille et d'interconnexion |

| Condensateurs | Titane, Nickel | Matériaux diélectriques et d'électrodes |

| LED | Aluminium, Or | Chemins conducteurs et dissipateurs de chaleur |

| Dispositifs d'alimentation | Cuivre, Argent | Composants porteurs de courant élevé |

| Cellules solaires | Argent, aluminium | Grilles et contacts conducteurs |

Spécifications, tailles, qualités et normes

La compréhension des spécifications, des tailles, des qualités et des normes des poudres métalliques est essentielle pour leur application efficace dans les semi-conducteurs.

| Poudre de métal | Tailles (µm) | Notes | Normes |

|---|---|---|---|

| Cuivre (Cu) | 0.1 – 10 | Haute pureté (99,99%) | ASTM B170-99 |

| Aluminium (Al) | 0.5 – 15 | Grade électronique | ISO 8000 |

| Argent (Ag) | 0.2 – 5 | 99,999% Pur | ASTM B779-99 |

| Or (Au) | 0.1 – 3 | Qualité semi-conductrice | ISO 9208 |

| Nickel (Ni) | 1 – 20 | 99,98% pur | ASTM B330-03 |

| Titane (Ti) | 2 – 30 | Haute pureté (99,6%) | ASTM B348-19 |

| Tungstène (W) | 0.3 – 15 | Haute pureté | ISO 2768-1 |

| Molybdène (Mo) | 0.5 – 10 | 99,95% Pur | ASTM B386-03 |

| Palladium (Pd) | 0.1 – 5 | 99,9% Pur | ISO 6284 |

| Cobalt (Co) | 1 – 25 | 99,8% pur | ASTM B330-03 |

Fournisseurs et détails des prix

Savoir où s'approvisionner en poudres métalliques et comprendre leur prix est essentiel pour la planification et la budgétisation de la fabrication de semi-conducteurs.

| Fournisseur | Poudres métalliques disponibles | Prix (par kg) |

|---|---|---|

| Éléments américains | Cuivre, or, nickel, argent | $300 – $10,000 |

| NanoAmor | Aluminium, tungstène, titane | $200 – $8,000 |

| SkySpring Nanomatériaux | Palladium, Cobalt, Molybdène | $500 – $12,000 |

| Tekna | Aluminium, cuivre, nickel | $250 – $9,000 |

| Goodfellow | Or, argent, titane | $400 – $15,000 |

Comparaison des avantages et des inconvénients des poudres métalliques

Chaque poudre métallique présente ses avantages et ses limites. Voici une analyse comparative pour vous aider à déterminer laquelle est la plus adaptée à des applications spécifiques.

| Poudre de métal | Avantages | Inconvénients |

|---|---|---|

| Cuivre (Cu) | Haute conductivité, économique | Sensible à l'oxydation |

| Aluminium (Al) | Léger, bonne conductivité | Point de fusion plus bas |

| Argent (Ag) | Conductivité maximale, résistant au ternissement | Coûteux |

| Or (Au) | Non réactif, excellente conductivité | Très cher |

| Nickel (Ni) | Résistant à la corrosion, magnétique | Conductivité modérée |

| Titane (Ti) | Solide, léger, biocompatible | Cher, réactif |

| Tungstène (W) | Point de fusion élevé, dur | Très dense, difficile à traiter |

| Molybdène (Mo) | Haute résistance, conductivité thermique | Fragile, coûteux |

| Palladium (Pd) | Bonne conductivité, résistant à la corrosion | Très cher |

| Cobalt (Co) | Propriétés magnétiques, point de fusion élevé | Coûteux, peut être toxique |

Composition de la poudre métallique pour semi-conducteur

La composition des poudres métalliques joue un rôle crucial dans leur efficacité et leur application dans les dispositifs semi-conducteurs. Voici un aperçu plus approfondi de ces compositions et de leurs impacts.

Poudre de cuivre (Cu) :

- Composition : Cuivre pur (99,99%)

- Impact: Fournit une excellente conductivité électrique, essentielle pour les interconnexions et les chemins conducteurs dans les microprocesseurs et les dispositifs de mémoire.

Poudre d'aluminium (Al) :

- Composition : Aluminium pur (99,98%)

- Impact: Léger et réfléchissant, idéal pour les grilles conductrices dans les cellules solaires et les dissipateurs thermiques LED.

Poudre d'argent (Ag) :

- Composition : Argent pur (99,999%)

- Impact: Conductivité électrique la plus élevée, utilisée dans les appareils haute fréquence et haute puissance pour une résistance minimale.

Poudre d'or (Au) :

- Composition : Or pur (99,99%)

- Impact: Conducteur non réactif et excellent, utilisé dans les applications critiques où la fiabilité et la durabilité sont primordiales.

Poudre de nickel (Ni) :

- Composition : Nickel pur (99,98%)

- Impact: Résistant à la corrosion et magnétique, adapté au stockage de données et aux capteurs.

Poudre de titane (Ti) :

- Composition : Titane pur (99,6%)

- Impact: Solide et léger, utilisé dans les condensateurs et les dispositifs d'alimentation avancés.

Poudre de tungstène (W) :

- Composition : Tungstène pur (99,95%)

- Impact: Point de fusion et densité élevés, idéal pour les transistors et les applications à haute température.

Poudre de molybdène (Mo) :

- Composition : Molybdène pur (99,95%)

- Impact: Haute résistance et conductivité thermique, utilisé dans les dispositifs d'alimentation et la gestion thermique.

Poudre de palladium (Pd) :

- Composition : Palladium pur (99,9%)

- Impact: Excellente conductivité et résistance à la corrosion, utilisé dans les capteurs hautes performances et les applications catalytiques.

Poudre de cobalt (Co) :

- Composition : Cobalt pur (99,8%)

- Impact: Propriétés magnétiques et point de fusion élevé, utilisés dans le stockage magnétique et les applications de capteurs avancés.

Caractéristiques de la poudre métallique pour semi-conducteurs

Les caractéristiques uniques de chaque poudre métallique la rendent adaptée à différentes applications de semi-conducteurs. Voici un aperçu de ces caractéristiques.

| Poudre de métal | Caractéristique | Description |

|---|---|---|

| Cuivre (Cu) | Conductivité | Conductivité électrique élevée, essentielle pour les microprocesseurs. |

| Aluminium (Al) | Léger | Réduit le poids global de l'appareil, bénéfique pour l'électronique portable. |

| Argent (Ag) | Conductivité | Conductivité électrique la plus élevée, optimale pour les appareils haute fréquence. |

| Or (Au) | Non réactif | Ne ternit pas et ne se corrode pas, idéal pour les connexions critiques. |

| Nickel (Ni) | Magnétisme | Propriétés magnétiques, utiles pour le stockage de données. |

| Titane (Ti) | La force | Rapport résistance/poids élevé, utilisé dans les composants durables. |

| Tungstène (W) | Point de fusion élevé | Convient aux applications à haute température comme les transistors. |

| Molybdène (Mo) | Conductivité thermique | Excellent pour la gestion thermique des appareils électriques. |

| Palladium (Pd) | Résistance à la corrosion | Résistant à la corrosion, utilisé dans les capteurs et les appareils hautes performances. |

| Cobalt (Co) | Propriétés magnétiques | Point de fusion et magnétisme élevés, utiles pour les applications de stockage. |

Qualités de poudre métallique pour semi-conducteurs

Les qualités des poudres métalliques indiquent leur pureté et leur adéquation à diverses applications. Voici un aperçu détaillé des qualités disponibles pour différentes poudres métalliques.

| Poudre de métal | Grade | La pureté | Application |

|---|---|---|---|

| Cuivre (Cu) | Haute pureté | 99.99% | Interconnexions, chemins conducteurs |

| Aluminium (Al) | Grade électronique | 99.98% | Cellules solaires, LED |

| Argent (Ag) | 99,999% Pur | 99.999% | Appareils à haute fréquence |

| Or (Au) | Qualité semi-conductrice | 99.99% | Connexions critiques |

| Nickel (Ni) | 99,98% pur | 99.98% | Stockage de données, capteurs |

| Titane (Ti) | Haute pureté | 99.6% | Condensateurs, dispositifs de puissance |

| Tungstène (W) | Haute pureté | 99.95% | Transistors, applications à haute température |

| Molybdène (Mo) | 99,95% Pur | 99.95% | Gestion thermique |

| Palladium (Pd) | 99,9% Pur | 99.9% | Capteurs hautes performances |

| Cobalt (Co) | 99,8% pur | 99.8% | Stockage magnétique, capteurs |

Fournisseurs et tarifs de poudre métallique pour semi-conducteurs

Comprendre où s’approvisionner en poudres métalliques et leur prix est essentiel pour la fabrication de semi-conducteurs.

| Fournisseur | Poudres métalliques disponibles | Prix (par kg) |

|---|---|---|

| Éléments américains | Cuivre, or, nickel, argent | $300 – $10,000 |

| NanoAmor | Aluminium, tungstène, titane | $200 – $8,000 |

| SkySpring Nanomatériaux | Palladium, Cobalt, Molybdène | $500 – $12,000 |

| Tekna | Aluminium, cuivre, nickel | $250 – $9,000 |

| Goodfellow | Or, argent, titane | $400 – $15,000 |

Comparaison Poudres métalliques pour semi-conducteurs: Avantages et limites

Chaque poudre métallique présente ses propres avantages et inconvénients. Voici une analyse comparative pour vous aider à choisir la poudre métallique la mieux adaptée à vos besoins.

| Poudre de métal | Avantages | Inconvénients |

|---|---|---|

| Cuivre (Cu) | Haute conductivité, économique | Sensible à l'oxydation |

| Aluminium (Al) | Léger, bonne conductivité | Point de fusion plus bas |

| Argent (Ag) | Conductivité maximale, résistant au ternissement | Coûteux |

| Or (Au) | Non réactif, excellente conductivité | Très cher |

| Nickel (Ni) | Résistant à la corrosion, magnétique | Conductivité modérée |

| Titane (Ti) | Solide, léger, biocompatible | Cher, réactif |

| Tungstène (W) | Point de fusion élevé, dur | Très dense, difficile à traiter |

| Molybdène (Mo) | Haute résistance, conductivité thermique | Fragile, coûteux |

| Palladium (Pd) | Bonne conductivité, résistant à la corrosion | Très cher |

| Cobalt (Co) | Propriétés magnétiques, point de fusion élevé | Coûteux, peut être toxique |

FAQ

Q1 : Quelles sont les poudres métalliques les plus couramment utilisées dans la fabrication de semi-conducteurs ?

A1 : Les poudres métalliques les plus couramment utilisées dans la fabrication de semi-conducteurs comprennent le cuivre (Cu), l'aluminium (Al), l'argent (Ag), l'or (Au), le nickel (Ni), le titane (Ti), le tungstène (W), le molybdène (Mo), le palladium (Pd) et le cobalt (Co).

Q2 : Pourquoi la pureté est-elle importante dans poudres métalliques pour semi-conducteurs?

A2 : La pureté est cruciale, car les impuretés peuvent affecter les propriétés électriques, les performances et la fiabilité des semi-conducteurs. Les poudres métalliques de haute pureté garantissent une conductivité optimale et minimisent les défauts.

Q3 : Comment les poudres métalliques sont-elles utilisées dans les microprocesseurs ?

A3 : Les poudres métalliques telles que le cuivre et l'or sont utilisées pour créer des chemins conducteurs et des interconnexions au sein des microprocesseurs, garantissant des connexions électriques efficaces entre différents composants.

Q4 : Quels sont les avantages de l’utilisation de poudre d’or dans les semi-conducteurs ?

A4 : La poudre d'or offre une excellente conductivité, n'est pas réactive et ne ternit pas ni ne se corrode, ce qui la rend idéale pour les connexions critiques où la fiabilité et la longévité sont essentielles.

Q5 : Pouvez-vous expliquer le rôle de la poudre de tungstène dans les dispositifs semi-conducteurs ?

A5 : La poudre de tungstène est utilisée dans les dispositifs semi-conducteurs en raison de son point de fusion et de sa densité élevés, ce qui la rend adaptée aux applications à haute température telles que les transistors et les dispositifs de puissance.

Q6 : Quels facteurs influencent le choix de la poudre métallique pour une application spécifique de semi-conducteur ?

A6 : Les facteurs incluent la conductivité électrique et thermique requise, le point de fusion, la résistance, la résistance à la corrosion et les besoins spécifiques de l'application tels que le poids et les propriétés magnétiques.

Q7 : Existe-t-il des préoccupations environnementales liées à l’utilisation de poudres métalliques dans les semi-conducteurs ?

A7 : Oui, la production et l'élimination des poudres métalliques peuvent avoir des impacts environnementaux. Il est essentiel d'adopter des pratiques durables et des mesures de recyclage pour minimiser ces effets.

Q8 : Comment la taille des particules des poudres métalliques affecte-t-elle leur application dans les semi-conducteurs ?

A8 : La taille des particules affecte la surface, la densité de tassement et les propriétés électriques des poudres métalliques, influençant leurs performances dans les applications de semi-conducteurs.

Q9 : Quels sont les défis du traitement des poudres métalliques pour semi-conducteurs ?

A9 : Les défis comprennent l’obtention d’une distribution uniforme de la taille des particules, le maintien d’une pureté élevée, la prévention de l’oxydation et la garantie d’une qualité constante pendant la production et le traitement.

Q10 : Où puis-je acheter des poudres métalliques de haute qualité pour les applications de semi-conducteurs ?

A10 : Des poudres métalliques de haute qualité peuvent être obtenues auprès de fournisseurs tels que American Elements, NanoAmor, SkySpring Nanomaterials, Tekna et Goodfellow.

Partager sur

MET3DP Technology Co. est un fournisseur de premier plan de solutions de fabrication additive dont le siège se trouve à Qingdao, en Chine. Notre société est spécialisée dans les équipements d'impression 3D et les poudres métalliques de haute performance pour les applications industrielles.

Articles connexes

Supports imprimés en 3D pour les capteurs radar automobiles : Précision et performance

Lire la suite "À propos de Met3DP

Mise à jour récente

Notre produit

CONTACTEZ-NOUS

Vous avez des questions ? Envoyez-nous un message dès maintenant ! Nous répondrons à votre demande avec toute une équipe dès réception de votre message.

Obtenir les informations de Metal3DP

Brochure du produit

Obtenir les derniers produits et la liste des prix

Poudres métalliques pour l'impression 3D et la fabrication additive

PRODUIT

cONTACT INFO

- Ville de Qingdao, Shandong, Chine

- [email protected]

- [email protected]

- +86 19116340731