Équipement VIGA à foyer unique

Table des matières

Bienvenue dans le guide ultime sur Équipement VIGA (atomisation gazeuse par induction sous vide) à foyer unique. Si vous vous intéressez au monde de la métallurgie avancée et de la production de poudres métalliques, vous êtes au bon endroit. Nous allons vous présenter tout ce que vous devez savoir sur les systèmes VIGA à four unique, en abordant leur fonctionnalité, leurs avantages, leurs applications et bien plus encore.

Vue d'ensemble Équipement VIGA à foyer unique

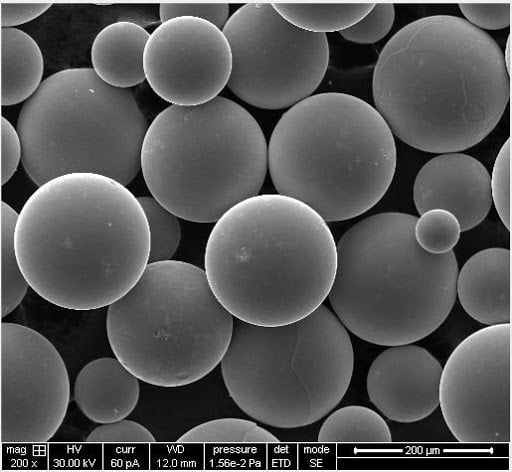

Les équipements VIGA à four unique constituent une méthode de pointe pour la production de poudres métalliques de haute qualité. Ces systèmes utilisent la fusion par induction sous vide combinée à l'atomisation de gaz pour créer des poudres fines et sphériques aux propriétés supérieures. Cette technique est essentielle pour les industries exigeant des caractéristiques matérielles précises, telles que l'aérospatiale, l'automobile et les secteurs biomédicaux.

Types de poudres métalliques produites par le système VIGA à four unique

Commençons par examiner quelques modèles spécifiques de poudres métalliques produites par l'équipement VIGA à four unique. Voici une liste détaillée pour vous familiariser :

| Modèle de poudre métallique | Composition | Propriétés principales | Applications |

|---|---|---|---|

| Acier inoxydable 316L | Fe, Cr, Ni, Mo | Résistance à la corrosion, haute résistance | Implants médicaux, équipements marins |

| Acier inoxydable 17-4 PH | Fe, Cr, Ni, Cu, Nb | Haute résistance, résistance à la corrosion | Pièces pour l'aérospatiale, traitement chimique |

| Alliage de titane Ti-6Al-4V | Ti, Al, V | Rapport résistance/poids élevé, biocompatibilité | Composants aérospatiaux, dispositifs médicaux |

| Inconel 718 | Ni, Cr, Fe, Nb, Mo | Résistance à la chaleur, résistance à l'oxydation | Pièces de moteurs à réaction, réacteurs nucléaires |

| Alliage de cobalt et de chrome | Co, Cr, Mo, W | Résistance à l'usure, dureté élevée | Implants dentaires, dispositifs orthopédiques |

| Alliage d'aluminium AlSi10Mg | Al, Si, Mg | Léger, bonnes propriétés de coulée | Pièces automobiles, structures aérospatiales |

| Acier maraging | Fe, Ni, Co, Mo | Haute résistance, excellente ténacité | Outillage, structures aérospatiales |

| Haynes 282 | Ni, Cr, Co, Mo, Ti | Résistance au fluage, stabilité thermique | Turbines à gaz, échangeurs de chaleur |

| Alliage de cuivre C18150 | Cu, Cr, Zr | Conductivité électrique élevée, bonne résistance | Composants électriques, électrodes de soudage |

| Superalliage de nickel Nimonic 90 | Ni, Cr, Co, Ti, Al | Résistance à l'oxydation, résistance aux températures élevées | Aubes de turbine, soupapes d'échappement |

Applications de Équipement VIGA à foyer unique

La polyvalence de l'équipement VIGA à foyer unique est évidente au vu de sa large gamme d'applications. Voici quelques utilisations spécifiques :

| L'industrie | Application | Avantages |

|---|---|---|

| Aérospatiale | Aubes de turbines, composants structurels | Rapport résistance/poids élevé, résistance aux températures élevées |

| Automobile | Pièces de moteur, structures légères | Amélioration de l'efficacité énergétique et de la durabilité |

| Biomédical | Implants, instruments chirurgicaux | Biocompatibilité, précision |

| L'énergie | Composants de réacteurs nucléaires, échangeurs de chaleur | Résistance à la corrosion et aux températures élevées |

| Outillage | Moules, matrices | Résistance à l'usure, longévité |

| Électronique | Composants conducteurs | Conductivité électrique élevée, fiabilité |

Spécifications détaillées, dimensions et normes

Il est essentiel de comprendre les spécifications et les normes des poudres métalliques produites par les équipements VIGA pour sélectionner le matériau adapté à vos besoins. En voici un aperçu :

| Modèle de poudre métallique | Gamme de taille des particules | Normes | Applications typiques |

|---|---|---|---|

| Acier inoxydable 316L | 15-45 µm | ASTM F138, ISO 5832-1 | Médical, maritime |

| Acier inoxydable 17-4 PH | 20-63 µm | AMS 5643, ASTM A693 | Aérospatiale, chimie |

| Alliage de titane Ti-6Al-4V | 15-45 µm | ASTM F1472, ISO 5832-3 | Aérospatiale, médecine |

| Inconel 718 | 20-53 µm | AMS 5662, ASTM B637 | Moteurs à réaction, nucléaire |

| Alliage de cobalt et de chrome | 10-50 µm | ASTM F1537, ISO 5832-12 | Dentaire, orthopédique |

| Alliage d'aluminium AlSi10Mg | 20-60 µm | ISO 3522, ASTM B85 | Automobile, aérospatiale |

| Acier maraging | 10-45 µm | AMS 6514, ASTM A538 | Outillage, aérospatiale |

| Haynes 282 | 20-53 µm | AMS 5918, ASTM B637 | Turbines à gaz, échangeurs de chaleur |

| Alliage de cuivre C18150 | 15-45 µm | ASTM B820, AMS 4596 | Électricité, soudage |

| Superalliage de nickel Nimonic 90 | 20-53 µm | AMS 5829, ASTM B637 | Aubes de turbine, soupapes d'échappement |

Fournisseurs et détails des prix

Lorsqu'il s'agit d'acheter des poudres métalliques produites par équipement VIGA à foyer uniqueIl est donc essentiel de connaître ses fournisseurs et leurs tarifs. Voici une liste de quelques fournisseurs importants et de leurs prix approximatifs :

| Fournisseur | Modèles en poudre métallique | Prix (par kg) | Services complémentaires |

|---|---|---|---|

| Höganäs | 316L, Ti-6Al-4V, Inconel 718 | $50-$200 | Taille sur mesure, assistance technique |

| Technologie des charpentiers | 17-4 PH, acier maraging | $60-$250 | Conseil métallurgique, alliages sur mesure |

| Sandvik | Cobalt-Chrome, Haynes 282 | $80-$300 | Tests de qualité, soutien à la R&D |

| Technologie LPW | AlSi10Mg, alliage de cuivre C18150 | $40-$150 | Gestion du cycle de vie des poudres, traçabilité |

| AP&C (GE Additive) | 316L, Ti-6Al-4V, Inconel 718 | $55-$220 | Caractérisation avancée, services de recyclage |

| Praxair Surface Technologies | Inconel 718, Nimonic 90 | $70-$280 | Ingénierie d'application, solutions de revêtement |

Avantages et inconvénients de la Équipement VIGA à foyer unique

Examinons les avantages et les inconvénients des systèmes VIGA à four unique pour la production de poudres métalliques :

| Avantages | Inconvénients |

|---|---|

| Haute pureté: L'environnement sous vide minimise la contamination. | Coût: Investissement initial et coûts d'exploitation élevés. |

| Taille uniforme des particules: Qualité constante de la poudre. | Complexité: Nécessite des opérateurs qualifiés et de la maintenance. |

| Polyvalence: Convient à une large gamme d'alliages métalliques. | Consommation d'énergie: Consommation d'énergie importante. |

| Propriétés améliorées des matériaux: Amélioration des propriétés mécaniques des poudres. | Capacité limitée: Un seul four limite le volume de production par rapport aux installations à plusieurs fours. |

FAQ

| Question | Répondre |

|---|---|

| À quoi servent les appareils VIGA à foyer unique ? | Il est utilisé pour produire des poudres métalliques de haute qualité pour diverses industries telles que l'aérospatiale, l'automobile et le biomédical. |

| Comment fonctionne un appareil VIGA à foyer unique ? | Il utilise la fusion par induction sous vide combinée à l'atomisation de gaz pour produire des poudres métalliques fines et sphériques. |

| Quels sont les avantages de l'utilisation de VIGA pour la production de poudres métalliques ? | Les avantages sont notamment une grande pureté, une taille de particule uniforme et de meilleures propriétés des matériaux. |

| Quels sont les métaux qui peuvent être traités avec l'équipement VIGA ? | Une large gamme comprenant des aciers inoxydables, des alliages de titane, des superalliages de nickel, etc. |

| Existe-t-il des limitations à l'utilisation d'un équipement VIGA à foyer unique ? | Oui, notamment en raison du coût élevé, de la complexité et de la capacité de production limitée. |

| Quelles sont les industries qui bénéficient le plus des poudres produites par VIGA ? | Industries aérospatiale, automobile, biomédicale, énergétique, outillage et électronique. |

| Quelles sont les tailles de particules typiques des poudres produites par VIGA ? | La taille des particules varie généralement de 10 à 63 microns, en fonction de l'alliage et des exigences spécifiques. |

| Comment VIGA se compare-t-il aux autres méthodes de production de poudres ? | La VIGA offre une plus grande pureté et un meilleur contrôle de la taille des particules, mais elle peut être plus coûteuse et plus complexe que d'autres méthodes telles que l'atomisation de l'eau. |

Conclusion

Les équipements VIGA à four unique changent la donne dans le domaine de la production de poudres métalliques, car ils offrent une pureté, une cohérence et une polyvalence inégalées. Que vous travailliez dans l'aérospatiale, l'automobile ou les industries biomédicales, comprendre les subtilités de la technologie VIGA peut vous aider à prendre des décisions éclairées et à tirer parti des avantages des poudres métalliques de haute qualité.

Si vous avez d'autres questions ou si vous avez besoin d'informations spécifiques, n'hésitez pas à nous contacter. Plongez dans le monde de la métallurgie avancée avec l'équipement VIGA à four unique et élevez vos capacités matérielles à de nouveaux sommets !

Partager sur

MET3DP Technology Co. est un fournisseur de premier plan de solutions de fabrication additive dont le siège se trouve à Qingdao, en Chine. Notre société est spécialisée dans les équipements d'impression 3D et les poudres métalliques de haute performance pour les applications industrielles.

Articles connexes

Supports imprimés en 3D pour les capteurs radar automobiles : Précision et performance

Lire la suite "À propos de Met3DP

Mise à jour récente

Notre produit

CONTACTEZ-NOUS

Vous avez des questions ? Envoyez-nous un message dès maintenant ! Nous répondrons à votre demande avec toute une équipe dès réception de votre message.

Obtenir les informations de Metal3DP

Brochure du produit

Obtenir les derniers produits et la liste des prix

Poudres métalliques pour l'impression 3D et la fabrication additive

PRODUIT

cONTACT INFO

- Ville de Qingdao, Shandong, Chine

- [email protected]

- [email protected]

- +86 19116340731