Poudres d'acier inoxydable pour la fabrication additive

Table des matières

Poudres d'acier inoxydable Les poudres inoxydables permettent l'impression de géométries complexes à l'aide de techniques additives inégalées par la fabrication conventionnelle de métaux. Ce guide couvre les variantes d'alliages, les spécifications des particules, les données sur les propriétés, les informations sur les prix et les comparaisons afin d'éclairer l'achat de poudres inoxydables.

Introduction aux poudres d'acier inoxydable

Principales possibilités offertes par les poudres d'acier inoxydable :

- Fabriquer des composants complexes et légers

- Résistance supérieure à la corrosion

- Permettre un prototypage et une personnalisation rapides

Les alliages couramment utilisés sont les suivants

- 304L - Economique avec une excellente résistance à la corrosion

- 316L - Superbe résistance à la corrosion grâce à l'ajout de molybdène

- 17-4PH - Poudre inoxydable la plus dure et la plus résistante

Ce guide présente les éléments à prendre en compte lors de la sélection des poudres inoxydables :

- Compositions d'alliages et méthodes de production

- Propriétés mécaniques Données d'essai

- Recommandations relatives à la distribution de la taille des particules

- Morphologie, débit et densité apparente

- Fourchettes de prix des fournisseurs basées sur les volumes

- Comparaisons de la résistance à la corrosion

- Avantages et inconvénients par rapport aux barres pleines

- FAQ sur l'optimisation des paramètres d'impression

Compositions de poudres d'acier inoxydable

Tableau 1 montre les compositions des alliages de poudres d'acier inoxydable par ajouts d'éléments primaires, avec quelques variations selon les fabricants de poudres :

| Alliage | Principaux éléments d'alliage |

|---|---|

| 304L | Cr, Ni |

| 316L | Cr, Ni, Mo |

| 17-4PH | Cr, Ni, Cu |

Le carbone est limité (≤0,03%) en 304L et 316L pour empêcher la précipitation de carbure et maintenir la résistance à la corrosion et la soudabilité.

Le carbone plus élevé dans le 17-4PH augmente la résistance grâce à des traitements thermiques de durcissement martensitique.

Propriétés mécaniques et méthodes d'essai

| Propriété | Description | Test Method (Standard) | Importance for Additive Manufacturing (AM) |

|---|---|---|---|

| Densité apparente | Mass of powder per unit volume in its loose, uncompacted state | ASTM B922 | Influences powder flowability and ease of handling in AM processes |

| Capacité d'écoulement | Ease with which powder particles flow under gravity | ASTM B2132 | Affects packing density and powder layer uniformity in AM builds |

| Densité du robinet | Density of powder after a standardized tapping routine | ASTM B854 | Provides a basic assessment of powder packing efficiency |

| Green Density | Density of a compacted powder body before sintering | ASTM B970 | влияет (vliyaniyet) on final density and dimensional accuracy of AM parts (influyats na final’nuyu plotnost’ i razmernuyu tochnost’ detaley AM) |

| Densité frittée | Density of a powder body after sintering | ASTM B962 | Critical for achieving desired mechanical properties and corrosion resistance in AM parts |

| Distribution de la taille des particules | Range of sizes present in a powder population | ASTM B822 | Impacts powder flowability, packing behavior, and final microstructure of AM parts |

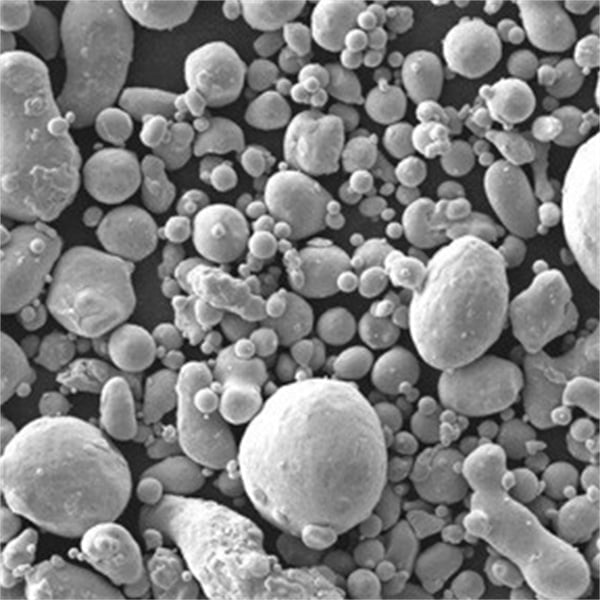

| Forme des particules | Morphological characteristics of individual powder particles (spherical, angular, etc.) | Microscopie électronique à balayage (MEB) | влияет (vliyaniyet) on packing density, inter-particle bonding, and flowability (influyats na plotnost’ upakovki, mezhchastichnoe svyazyvanie i tekuchest’) |

| Rugosité de surface | Microscopic variations on the surface of a powder particle | Atomic Force Microscopy (AFM) | Can influence inter-particle bonding and sintering behavior |

| Composition chimique | Elemental makeup of the powder material | X-Ray Fluorescence (XRF) | Determines final material properties, corrosion resistance, and suitability for specific applications |

| Résistance à la traction | Maximum stress a powder metallurgy (PM) specimen can withstand before pulling apart | ASTM E8 | Crucial for applications requiring high load-bearing capacity |

| Limite d'élasticité | Stress level at which a PM specimen exhibits plastic deformation | ASTM E8 | Important for understanding material’s elastic limit and predicting permanent deformation |

| Élongation | Percentage increase in length a PM specimen experiences before fracture in a tensile test | ASTM E8 | Indicates material’s ductility and ability to deform without breaking |

| Résistance à la compression | Maximum stress a PM specimen can withstand before crushing under compressive load | ASTM E9 | Essential for applications experiencing compressive forces |

| Dureté | Resistance of a material to indentation by a harder object | ASTM E384 | Relates to wear resistance and surface properties |

| Résistance à la fatigue | Maximum stress a PM specimen can endure under repeated loading and unloading cycles without failure | ASTM E466 | Critical for components subjected to cyclic stresses |

| Résistance à la rupture | Material’s ability to resist crack propagation | ASTM E399 | Important for safety-critical applications where sudden failure cannot be tolerated |

Recommandations relatives à la taille des particules de poudre d'acier inoxydable

| Application | Median Particle Size (D₅₀) | Distribution de la taille des particules (PSD) | Forme | Principales considérations |

|---|---|---|---|---|

| Metal Additive Manufacturing (Laser Melting, Electron Beam Melting) | 15-45 microns | Narrow (Tight distribution around D₅₀) | Sphérique | – Fluidité : Spherical particles flow more easily, enabling consistent layer formation. – Densité de l'emballage : Smaller particles can pack more tightly, reducing porosity in the final product. – Finition de la surface : Extremely fine particles (<10 microns) can cause surface roughness. – Absorption laser : Particle size can influence laser absorption efficiency, impacting melting behavior. |

| Moulage par injection de métal (MIM) | 10-100 microns | Broad (Wider distribution for packing and sintering) | Irrégulier | – Flux de poudre : Irregular shapes can interlock, improving powder flow during injection molding. – Densité de l'emballage : A broader size distribution allows for better packing, reducing shrinkage during sintering. – Sintering Efficiency: Larger particles can hinder complete sintering, affecting mechanical properties. – Débouclage : Large particles and broad distributions can trap debinding agents, leading to residual porosity. |

| Pulvérisation de plasma | 45-150 microns | Broad (Similar to MIM) | Irrégulier | – Impact Resistance: Larger particles improve impact resistance in the final coating. – Deposition Efficiency: Irregular shapes can enhance mechanical interlocking, improving coating adhesion. – Morphologie du splat : Particle size influences splat formation during spraying, impacting coating microstructure. – Recoatability: Broader distributions may improve the ability to create smooth, layered coatings. |

| Thermal Spraying (High Velocity Oxygen Fuel, Detonation Gun) | 45-250 microns | Broad (Similar to MIM) | Irrégulier | – Deposition Rate: Larger particles allow for faster deposition rates. – Particle Velocity: High-velocity processes require robust particles to minimize in-flight fracturing. – Coating Density: Broader distributions can promote denser coatings, but particle size can also affect packing efficiency. – Résistance à l'oxydation : Larger particle sizes can reduce surface area, potentially improving oxidation resistance. |

| Additive Manufacturing (Binder Jetting) | 10-50 microns | Narrow (Similar to Laser Melting) | Sphérique | – Résolution : Smaller particles enable finer feature details in the printed part. – Force verte : Particle size and distribution can influence the strength of the unfired part. – Binder Compatibility: Particle surface area can affect binder adhesion and printability. – Sensibilité à l'humidité : Extremely fine powders may be more susceptible to moisture absorption, impacting handling. |

Morphologie, débit et densité des poudres

| Propriété | Description | Importance in Powder Processing |

|---|---|---|

| Morphologie des poudres | The size, shape, and surface characteristics of individual powder particles. | Morphology significantly impacts packing density, flowability, and laser absorptivity in Additive Manufacturing (AM). Ideally, spherical particles with smooth surfaces offer the best packing density and flow characteristics. However, atomization processes can introduce variations. Gas-atomized powders tend to be more spherical, while water-atomized powders exhibit a more irregular, splattered morphology. Additionally, surface features like satellites (small particles attached to larger ones) and satellites can hinder flow and affect laser melting behavior in AM. |

| Distribution de la taille des particules (PSD) | A statistical representation of the variation in particle sizes within a powder batch. It is typically expressed as a cumulative distribution curve or by reporting specific percentiles (e.g., d10 – 10% of particles are smaller than this size, d50 – median particle size). | PSD plays a crucial role in powder bed packing and influences the final density and mechanical properties of AM parts. A narrow PSD with a well-defined median size (d50) is preferred for consistent packing and laser melting depth. Conversely, a broad distribution can lead to segregation (larger particles separating from finer ones) during handling and uneven melting in the AM process. |

| Densité apparente et densité au robinet | * Apparent density: The mass of powder per unit volume when poured freely into a container. * Tap density: The density achieved after a standardized tapping or vibration protocol. | These properties reflect the packing behavior of the powder and are crucial for efficient powder handling and storage. Apparent density represents the loose packing state, while tap density indicates a denser packing achieved through mechanical agitation. The difference between these values, known as the Carr angle, is an indirect measure of flowability. Powders with a lower Carr angle (higher tap density closer to apparent density) exhibit better flow characteristics. |

| Débit | The rate at which powder flows under gravity through an orifice or hopper. | Flow rate is critical for consistent material feed in various powder processing techniques like AM and metal injection molding (MIM). Good flowability ensures smooth powder layer formation and avoids disruptions during the build process. Irregular particle shapes, presence of satellites, and moisture content can hinder flow rate. Manufacturers often employ flowability additives like lubricants to improve powder flow. |

| Densité de la poudre | The mass of powder per unit volume of the solid particles themselves, excluding voids between particles. | Powder density is a material property inherent to the specific stainless steel composition. It influences the final density achievable in the finished product after sintering or melting. Higher powder density typically translates to higher final product density and improved mechanical properties. |

Prix de la poudre d'acier inoxydable

| Facteur | Description | Impact sur le prix |

|---|---|---|

| Grade | The specific type of stainless steel, designated by a three-digit number (e.g., 304, 316L, 17-4PH). Different grades offer varying degrees of corrosion resistance, strength, and formability. | Higher-grade stainless steel powders, like 316L with molybdenum for enhanced corrosion resistance, typically command a premium price compared to basic grades like 304. |

| Taille et distribution des particules | The size and uniformity of the powder particles. Measured in microns (μm) or mesh size (number of openings per linear inch in a sieve), particle size significantly influences the final product’s properties and manufacturing process. | Finer powders (smaller microns/higher mesh size) generally cost more due to the additional processing required to achieve a narrower particle size distribution. However, finer powders can enable intricate details and smoother surface finishes in 3D printed parts. |

| Surface | Closely linked to particle size, the total surface area of the powder particles per unit weight. Powders with higher surface areas tend to be more reactive and require stricter handling protocols. | Powders with high surface areas may incur additional costs due to specialized handling and storage requirements to prevent contamination or moisture absorption. |

| Processus de fabrication | The method used to produce the stainless steel powder. Common techniques include atomization (gas or water) and chemical vapor deposition (CVD). | Atomization processes are generally more established and cost-effective, while CVD yields finer and purer powders but at a higher price point. |

| La pureté | The chemical composition of the powder, with minimal presence of unwanted elements. | Higher purity powders, with lower levels of oxygen, nitrogen, and other impurities, often come at a higher cost due to stricter manufacturing controls. |

| Morphologie sphérique | The shape of the powder particles. Spherical particles offer superior flow characteristics and packing density, leading to improved printability and material utilization. | Spherical stainless steel powders are generally more expensive compared to irregular-shaped particles due to the additional processing steps involved. |

| Quantité | The amount of stainless steel powder purchased. | Bulk purchases typically benefit from significant price reductions due to economies of scale offered by suppliers. |

| Fluctuations du marché | The global supply and demand dynamics for raw materials like chromium and nickel, which significantly impact the base price of stainless steel feedstock. | Periods of high demand or supply chain disruptions can cause price increases for stainless steel powders. |

| Fournisseur | The reputation and expertise of the powder manufacturer. Established brands with rigorous quality control procedures may command a slightly higher price compared to lesser-known suppliers. | Reputable suppliers often provide additional services like technical support and material certifications, which can justify a slight price premium. |

Poudre d'acier inoxydable Résistance à la corrosion

| Propriété | Description | Impact on Corrosion Resistance |

|---|---|---|

| Teneur en chrome | The key element in stainless steel’s corrosion resistance. It forms a thin, invisible layer of chromium oxide on the surface when exposed to oxygen, acting as a barrier against further oxidation (rust). | Higher chromium content (typically above 10.5%) translates to better corrosion resistance. Different grades of stainless steel powder have varying chromium levels, catering to specific environments. |

| Molybdène | Often added to improve resistance to pitting corrosion, a localized form of attack that creates deep holes in the metal. Molybdenum enhances the stability of the chromium oxide layer, particularly in environments containing chlorides (e.g., seawater). | Stainless steel powders with molybdenum are ideal for marine applications, chemical processing involving chlorides, and high-salinity environments. |

| Nickel | Contributes to overall corrosion resistance, particularly in high-temperature settings. Nickel helps maintain the stability of the passive oxide layer and improves resistance to reducing acids. | Nickel-containing stainless steel powders are well-suited for applications involving hot acidic environments or high-pressure steam. |

| Powder Manufacturing Method | The process used to create the powder can influence its microstructure and, consequently, corrosion resistance. Gas atomization, a common method, can trap oxygen within the particles, potentially leading to localized corrosion. | Choosing powders produced with methods minimizing internal oxidation, like water atomization, can enhance corrosion performance. |

| Porosité | Sintering, the process of bonding powder particles, can leave behind tiny pores within the final product. These pores can act as initiation sites for corrosion if they trap contaminants or moisture. | Selecting powders with optimized particle size distribution and proper sintering parameters minimizes porosity, leading to improved corrosion resistance. |

| Finition de la surface | The surface topography of the finished component can influence how readily it interacts with the environment. Rougher surfaces offer more area for contaminants and moisture to adhere, increasing the risk of corrosion. | Smoother surface finishes, achievable through polishing or specific manufacturing techniques, enhance corrosion resistance by minimizing these potential sites. |

| Taille d'un grain | The size of individual metal grains within the sintered component can affect corrosion behavior. Finer grain sizes generally offer better corrosion resistance as they present a less permeable barrier to corrosive agents. | Selecting powders optimized for achieving fine grain structures during sintering can enhance the component’s ability to resist corrosion. |

Avantages et inconvénients : poudres ou barres pleines

Tableau 7

| Avantages | Inconvénients | |

|---|---|---|

| Poudre d'acier inoxydable | Formes complexes | Coût plus élevé |

| Excellentes propriétés de résistance à la corrosion | Post-traitement | |

| Allègement | Optimisation des paramètres d'impression | |

| Barre massive en acier inoxydable | Rentabilité | Limites de forme |

| Disponibilité | Beaucoup plus lourd | |

| Usinabilité | Déchets de matériaux |

En général, la poudre d'acier inoxydable justifie des prix plus élevés pour les composants complexes de faible volume où la résistance à la corrosion et la réduction du poids sont vitales. Les barres offrent un prix abordable pour des formes simples dans des cas d'utilisation à forte production.

FAQ

Tableau 8 - Questions courantes :

| FAQ | Répondre |

|---|---|

| Dois-je examiner les rapports d'essai ? | Oui, il faut examiner attentivement les données relatives à la certification des poudres |

| Quelle est la taille des particules de poudre avec lesquelles je dois commencer ? | 25-45 microns pour une impression robuste |

| Quels sont les facteurs qui influencent la cohérence ? | La technique de production de la poudre brute affecte la variabilité |

| Quelle quantité de poudre dois-je acheter au départ ? | Commencer à petite échelle pour valider le processus d'impression |

Tableau 9 - Des conseils axés sur les applications :

| FAQ | Répondre |

|---|---|

| Comment dois-je ajuster les paramètres d'impression du matériel inoxydable de qualité alimentaire ? | Optimiser la rugosité de la surface et éliminer les crevasses |

| Quel post-traitement permet de réduire la porosité des pièces marines ? | Envisager le pressage isostatique à chaud pour maximiser la résistance à la corrosion. |

| Quel est l'alliage qui maximise la limite d'élasticité des pièces porteuses ? | 17-4PH inoxydable durci par précipitation |

| Quelle est la poudre inoxydable optimale pour les pièces de four à haute température ? | La poudre 316L offre une excellente résistance à l'oxydation |

Partager sur

MET3DP Technology Co. est un fournisseur de premier plan de solutions de fabrication additive dont le siège se trouve à Qingdao, en Chine. Notre société est spécialisée dans les équipements d'impression 3D et les poudres métalliques de haute performance pour les applications industrielles.

Articles connexes

Supports imprimés en 3D pour les capteurs radar automobiles : Précision et performance

Lire la suite "À propos de Met3DP

Mise à jour récente

Notre produit

CONTACTEZ-NOUS

Vous avez des questions ? Envoyez-nous un message dès maintenant ! Nous répondrons à votre demande avec toute une équipe dès réception de votre message.

Obtenir les informations de Metal3DP

Brochure du produit

Obtenir les derniers produits et la liste des prix

Poudres métalliques pour l'impression 3D et la fabrication additive

PRODUIT

cONTACT INFO

- Ville de Qingdao, Shandong, Chine

- [email protected]

- [email protected]

- +86 19116340731