Machines VIGA

Table des matières

Lorsque nous parlons de Machines VIGANous plongeons dans l'univers des technologies avancées de production de poudres métalliques, qui ont révolutionné de nombreux secteurs. Dans cet article, nous explorerons tout ce que vous devez savoir sur les machines VIGA : présentation, spécifications détaillées, applications et même une FAQ. Alors, c'est parti !

Présentation des machines VIGA

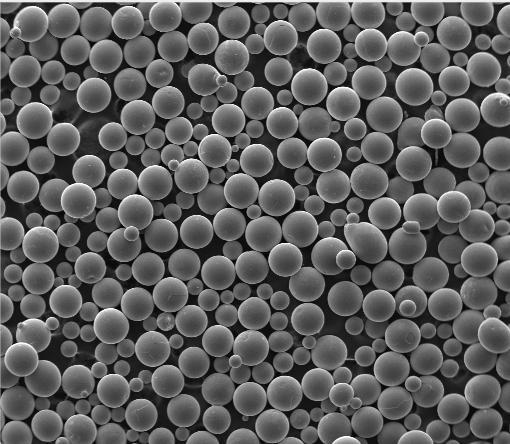

Les machines VIGA (Atomisation sous vide sous gaz inerte) sont des équipements de pointe utilisés pour la production de poudres métalliques de haute qualité. Ces poudres sont essentielles pour des applications dans les secteurs de l'aérospatiale, de l'automobile, du biomédical et de la fabrication additive. La technologie VIGA se distingue par sa capacité à produire des poudres présentant une excellente fluidité, une forme sphérique et une granulométrie contrôlée.

Principales caractéristiques des machines VIGA

- Poudres métalliques de haute pureté : Les machines VIGA fonctionnent dans un environnement sous vide ou sous gaz inerte, minimisant ainsi la contamination.

- Particules sphériques : Assure une excellente fluidité et une excellente densité de remplissage.

- Taille de particules contrôlée : Paramètres d'atomisation réglables pour des caractéristiques de poudre sur mesure.

- Large gamme de matériaux : Convient à divers métaux et alliages, notamment le titane, l'acier inoxydable et les superalliages.

Types et modèles de poudres métalliques produites par Machines VIGA

Voici des modèles spécifiques de poudre métallique produits par les machines VIGA, ainsi que leurs descriptions :

| Modèle de poudre métallique | Composition | Propriétés | Applications |

|---|---|---|---|

| Ti-6Al-4V | Alliage de titane | Haute résistance, résistant à la corrosion, biocompatible | Aérospatiale, implants médicaux |

| Acier inoxydable 316L | Alliage Fe-Cr-Ni-Mo | Excellente résistance à la corrosion, bonnes propriétés mécaniques | Dispositifs biomédicaux, applications marines |

| IN718 | Superalliage à base de nickel | Résistance aux hautes températures, résistant à l'oxydation | Aubes de turbine, composants aérospatiaux |

| AlSi10Mg | Alliage d'aluminium | Léger, bonnes propriétés thermiques | Automobile, aérospatiale |

| CoCrMo | Alliage de cobalt-chrome-molybdène | Haute résistance à l'usure, biocompatible | Implants médicaux, prothèses dentaires |

| CuCrZr | Alliage cuivre-chrome-zirconium | Haute conductivité électrique, bonne résistance mécanique | Composants électriques, électrodes de soudage |

| Acier maraging (18Ni300) | Alliage Fe-Ni-Co-Mo-Ti | Très haute résistance, bonne ténacité | Outillage, engrenages à haute performance |

| FeNiCo | Alliage fer-nickel-cobalt | Propriétés magnétiques, bonne résistance mécanique | Composants magnétiques, aérospatiale |

| NiTi (Nitinol) | Alliage de nickel et de titane | Mémoire de forme, superélasticité | Dispositifs médicaux, actionneurs |

| Hastelloy X | Alliage nickel-chrome-molybdène | Résistance à haute température, résistant à la corrosion | Composants de turbines à gaz, traitement chimique |

Applications des machines VIGA

Les machines VIGA sont utilisées dans de nombreux secteurs industriels grâce à leur capacité à produire des poudres métalliques de haute qualité. Voici un aperçu détaillé de leurs applications :

| L'industrie | Applications |

|---|---|

| Aérospatiale | Aubes de turbines, composants structurels, fixations |

| Automobile | Composants légers, pièces de moteur |

| Biomédical | Implants, prothèses, instruments chirurgicaux |

| Fabrication additive | Impression 3D de poudres, prototypage, géométries complexes |

| L'énergie | Composants de turbines, pièces de réacteurs nucléaires |

| Électronique | Pâtes conductrices, composants magnétiques |

Avantages des machines VIGA

- Haute pureté et propreté : Le fonctionnement dans un environnement sous vide ou sous gaz inerte réduit la contamination, ce qui permet d’obtenir des poudres métalliques de haute pureté.

- Distribution contrôlée de la taille des particules : Permet la personnalisation pour des applications spécifiques, améliorant ainsi les performances.

- Particules sphériques : Améliore la fluidité et la densité de remplissage, essentielles pour la fabrication additive.

- Gamme de matériaux polyvalents : Peut traiter une variété de métaux et d’alliages, ce qui les rend adaptés à diverses industries.

Inconvénients de la Machines VIGA

- Coût initial élevé : Les machines VIGA sont coûteuses à acquérir et à installer.

- Opération complexe : Nécessite des opérateurs qualifiés et un entretien régulier.

- Intensif en énergie : Le processus exige une énergie considérable, ce qui augmente les coûts opérationnels.

Spécifications détaillées des machines VIGA

| Spécifications | Détails |

|---|---|

| Capacité matérielle | Titane, acier inoxydable, alliages de nickel, alliages d'aluminium, alliages cobalt-chrome, etc. |

| Gaz d'atomisation | Argon, azote, hélium |

| Pression de fonctionnement | Jusqu'à 150 bars |

| Gamme de taille des particules | 10 – 200 microns |

| Taux de production | Jusqu'à 500 kg/heure |

| Niveau de vide | Jusqu'à 10^-5 mbar |

| Consommation électrique | 100 – 500 kW |

| Système de refroidissement | Refroidi par eau |

Comparaison des avantages et des inconvénients de Machines VIGA

| Avantages | Inconvénients |

|---|---|

| Poudres métalliques de haute pureté | Coût initial élevé |

| Particules sphériques | Opération complexe |

| Taille des particules contrôlée | Énergivore |

| Gamme de matériaux polyvalente | Nécessite des opérateurs qualifiés |

| Excellente fluidité | Un entretien régulier est nécessaire |

FAQ

| Question | Répondre |

|---|---|

| A quoi servent les machines VIGA ? | Production de poudres métalliques de haute qualité pour diverses industries, notamment l'aérospatiale, l'automobile et le biomédical. |

| Comment fonctionnent les machines VIGA ? | Ils utilisent le vide ou un gaz inerte pour atomiser le métal en fusion en fines poudres avec des particules sphériques. |

| Quels métaux les machines VIGA peuvent-elles traiter ? | Titane, acier inoxydable, alliages de nickel, alliages d'aluminium et plus encore. |

| Quelle est la gamme granulométrique des poudres produites ? | Généralement entre 10 et 200 microns. |

| Les machines VIGA sont-elles chères ? | Oui, leur coût initial est élevé, allant de 900 000 TP4T à plus de 2 500 000 TP4T. |

| Quels sont les avantages d’utiliser les machines VIGA ? | Haute pureté, granulométrie contrôlée, excellente fluidité et polyvalence dans le traitement des matériaux. |

| Quelles industries bénéficient des poudres VIGA ? | Aérospatiale, automobile, biomédical, fabrication additive, énergie et électronique. |

| Les machines VIGA peuvent-elles produire des poudres pour l’impression 3D ? | Oui, ils sont idéaux pour produire des poudres de haute qualité pour la fabrication additive. |

| Les machines VIGA nécessitent-elles un entretien particulier ? | Oui, ils nécessitent un entretien régulier et des opérateurs qualifiés pour garantir des performances optimales. |

| Quels sont les gaz d’atomisation couramment utilisés ? | L’argon, l’azote et l’hélium sont couramment utilisés pour l’atomisation. |

Conclusion

Les machines VIGA représentent le summum de la technologie de production de poudres métalliques, fournissant des poudres de haute qualité essentielles aux industries modernes. Leur capacité à produire des poudres sphériques, de haute pureté et contrôlées avec précision les rend indispensables pour des applications allant de l'aérospatiale aux dispositifs biomédicaux. Malgré leur coût initial élevé et leur complexité, elles offrent des avantages inégalés en termes de propriétés des matériaux et de performances. Si vous souhaitez vous lancer dans la production de poudres métalliques de haute qualité, comprendre et utiliser les machines VIGA peut changer la donne.

Partager sur

MET3DP Technology Co. est un fournisseur de premier plan de solutions de fabrication additive dont le siège se trouve à Qingdao, en Chine. Notre société est spécialisée dans les équipements d'impression 3D et les poudres métalliques de haute performance pour les applications industrielles.

Articles connexes

Supports imprimés en 3D pour les capteurs radar automobiles : Précision et performance

Lire la suite "À propos de Met3DP

Mise à jour récente

Notre produit

CONTACTEZ-NOUS

Vous avez des questions ? Envoyez-nous un message dès maintenant ! Nous répondrons à votre demande avec toute une équipe dès réception de votre message.

Obtenir les informations de Metal3DP

Brochure du produit

Obtenir les derniers produits et la liste des prix

Poudres métalliques pour l'impression 3D et la fabrication additive

PRODUIT

cONTACT INFO

- Ville de Qingdao, Shandong, Chine

- [email protected]

- [email protected]

- +86 19116340731