Blog

Toutes les collections

Custom Exhaust Manifolds: Revolutionizing Performance with Metal 3D Printing

The relentless pursuit of enhanced performance and efficiency drives innovation across industries, from the high-octane world of automotive racing to the stringent demands of aerospace engineering. A critical component in achieving these goals is the engine exhaust manifold. Traditionally manufactured through casting and welding, these intricate parts are now being

3D Printing Fuel Pumps: Revolutionizing Aerospace Manufacturing

Introduction – The Ascent of Additive Manufacturing in Aerospace Fuel Systems In the demanding realm of aerospace, where precision, reliability, and weight reduction are paramount, the integration of advanced manufacturing technologies is continuously pushing the boundaries of engineering. Among these innovations, metal 3D printing, also known as metal additive manufacturing

Drone Electronics Enclosures

Introduction – The Critical Role of Metal 3D Printed Enclosures in Drone Technology The rapid evolution of drone technology has ushered in an era of unprecedented capabilities across various sectors, from aerial photography and surveillance to logistics and industrial inspections. At the heart of every sophisticated drone lies its intricate

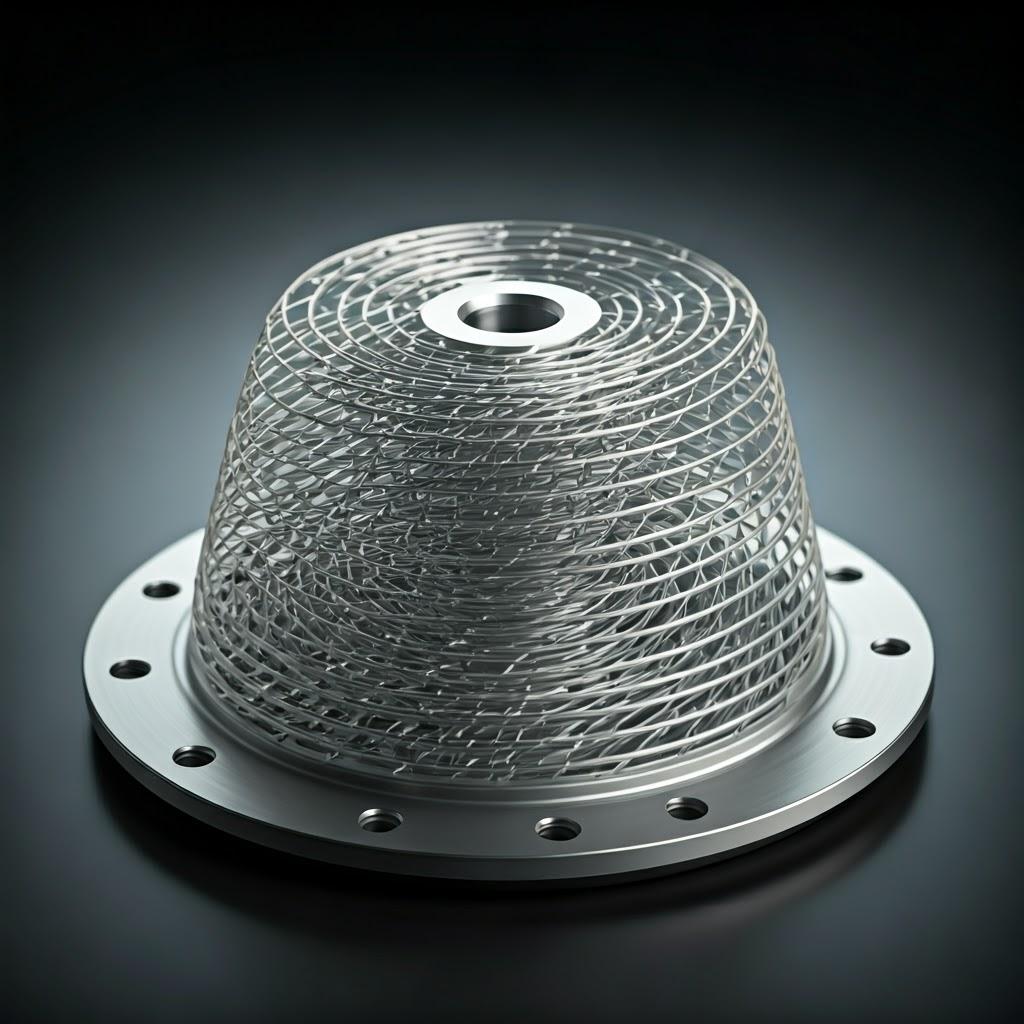

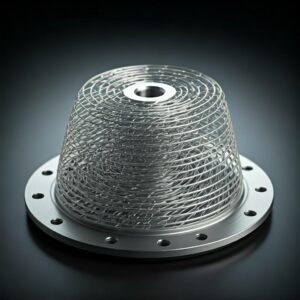

Conformal Cooling Plates

Introduction to Aerospace Conformal Cooling Plates In the demanding realm of aerospace engineering, thermal management stands as a critical factor influencing the performance, efficiency, and longevity of various components. Among the sophisticated solutions employed for heat dissipation, conformal cooling plates have emerged as a highly effective technology. These intricately designed

3D Printing Lightweight Struts: Revolutionizing Automotive Performance with Metal Additive Manufacturing

Introduction – The Critical Role of Lightweight Struts in Modern Automotive Design In the relentless pursuit of enhanced fuel efficiency, improved handling, and reduced emissions, the automotive industry is constantly innovating in material science and manufacturing processes. One critical component in achieving these goals is the automotive strut, a vital

3D Printed High-Load Robot Links

Introduction to High-Strength Robot Links via Metal 3D Printing In the ever-evolving landscape of industrial automation, the demand for robust, lightweight, and precisely engineered components is paramount. Robot links, the structural elements connecting a robot’s joints and enabling its movement, are critical for performance and reliability. Traditionally manufactured through subtractive

Custom Exhaust Manifolds: Revolutionizing Performance with Metal 3D Printing

The relentless pursuit of enhanced performance and efficiency drives innovation across industries, from the high-octane world of automotive racing to the stringent demands of aerospace

3D Printing Fuel Pumps: Revolutionizing Aerospace Manufacturing

Introduction – The Ascent of Additive Manufacturing in Aerospace Fuel Systems In the demanding realm of aerospace, where precision, reliability, and weight reduction are paramount,

Drone Electronics Enclosures

Introduction – The Critical Role of Metal 3D Printed Enclosures in Drone Technology The rapid evolution of drone technology has ushered in an era of

Conformal Cooling Plates

Introduction to Aerospace Conformal Cooling Plates In the demanding realm of aerospace engineering, thermal management stands as a critical factor influencing the performance, efficiency, and

3D Printing Lightweight Struts: Revolutionizing Automotive Performance with Metal Additive Manufacturing

Introduction – The Critical Role of Lightweight Struts in Modern Automotive Design In the relentless pursuit of enhanced fuel efficiency, improved handling, and reduced emissions,

3D Printed High-Load Robot Links

Introduction to High-Strength Robot Links via Metal 3D Printing In the ever-evolving landscape of industrial automation, the demand for robust, lightweight, and precisely engineered components

Notre produit

PRODUIT EN VENTE À CHAUD

CONTACTEZ-NOUS

Vous avez des questions ? Envoyez-nous un message dès maintenant ! Nous répondrons à votre demande avec toute une équipe dès réception de votre message.

Poudres métalliques pour l'impression 3D et la fabrication additive

PRODUIT

cONTACT INFO

- Ville de Qingdao, Shandong, Chine

- [email protected]

- [email protected]

- +86 19116340731