블로그

모든 컬렉션

Precision Robotic Joints 3D Printed in Aluminum

Introduction: Revolutionizing Robotics with Additively Manufactured Aluminum Joints The relentless march of automation across industries like aerospace, automotive, medical technology, and industrial manufacturing hinges significantly on the performance and capabilities of robotic systems. At the heart of these sophisticated machines lie the robotic arm joints – critical components dictating precision,

Patient-Specific Orthopedic Implants via Metal 3D Printing

Revolutionizing Orthopedics: The Power of Metal 3D Printing for Patient-Specific Implants The field of orthopedic surgery stands on the cusp of a profound transformation, driven by the convergence of advanced medical imaging, computational design, and groundbreaking manufacturing technologies. For decades, surgeons and patients have largely relied on standardized, off-the-shelf implants

3D Printing Dental Crowns with Cobalt-Chrome Alloy

Introduction: The Digital Evolution of Dental Crowns with CoCr Alloys The field of dentistry has perpetually sought advancements that enhance patient outcomes, improve clinical efficiency, and streamline laboratory workflows. For decades, the lost-wax casting technique dominated the fabrication of metal substructures for crowns and bridges, particularly those utilizing robust Cobalt-Chrome

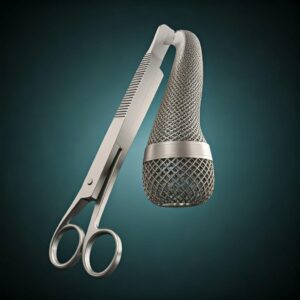

3D Printed Surgical Tools with Stainless Steel and Titanium

Revolutionizing Surgery: The Rise of 3D Printed Surgical Tools in Stainless Steel and Titanium The operating room is a theatre of precision, where the skill of the surgeon is paramount, but the quality and design of their instruments are equally critical. For centuries, surgical tools have been crafted using traditional

3D Printing Injection Mold Inserts with Maraging Steel

Revolutionizing Tooling: An Introduction to 3D Printed Maraging Steel Injection Mold Inserts Injection molding remains a cornerstone of mass production, enabling the creation of complex plastic parts with remarkable speed and repeatability. However, the efficiency and quality of the injection molding process are heavily reliant on the design and performance

3D Printed Intake Manifolds for High-Performance Vehicles

Introduction: Revolutionizing Performance with 3D Printed Intake Manifolds The relentless pursuit of performance in the automotive industry demands constant innovation. Engineers and designers are perpetually seeking ways to extract more power, enhance efficiency, reduce weight, and optimize every component for maximum effect. Within the intricate dance of engine components, the

Precision Robotic Joints 3D Printed in Aluminum

Introduction: Revolutionizing Robotics with Additively Manufactured Aluminum Joints The relentless march of automation across industries like aerospace, automotive, medical technology, and industrial manufacturing hinges significantly

Patient-Specific Orthopedic Implants via Metal 3D Printing

Revolutionizing Orthopedics: The Power of Metal 3D Printing for Patient-Specific Implants The field of orthopedic surgery stands on the cusp of a profound transformation, driven

3D Printing Dental Crowns with Cobalt-Chrome Alloy

Introduction: The Digital Evolution of Dental Crowns with CoCr Alloys The field of dentistry has perpetually sought advancements that enhance patient outcomes, improve clinical efficiency,

3D Printed Surgical Tools with Stainless Steel and Titanium

Revolutionizing Surgery: The Rise of 3D Printed Surgical Tools in Stainless Steel and Titanium The operating room is a theatre of precision, where the skill

3D Printing Injection Mold Inserts with Maraging Steel

Revolutionizing Tooling: An Introduction to 3D Printed Maraging Steel Injection Mold Inserts Injection molding remains a cornerstone of mass production, enabling the creation of complex

3D Printed Intake Manifolds for High-Performance Vehicles

Introduction: Revolutionizing Performance with 3D Printed Intake Manifolds The relentless pursuit of performance in the automotive industry demands constant innovation. Engineers and designers are perpetually

제품

인기 판매 제품

3D 프린팅 및 적층 제조용 금속 분말

문의 정보

- 칭다오시, 산둥성, 중국

- [email protected]

- [email protected]

- +86 19116340731