Blog

todas las colecciones

Satellite Optical Benches: Revolutionizing Aerospace with Metal 3D Printing

Introduction – The Critical Role of Satellite Optical Benches in Modern Aerospace Satellite optical benches serve as the stable and precise foundation for critical instruments aboard satellites, including telescopes, cameras, and spectrometers. These intricate structures demand exceptional dimensional stability, lightweight design, and thermal management properties to ensure the accurate collection

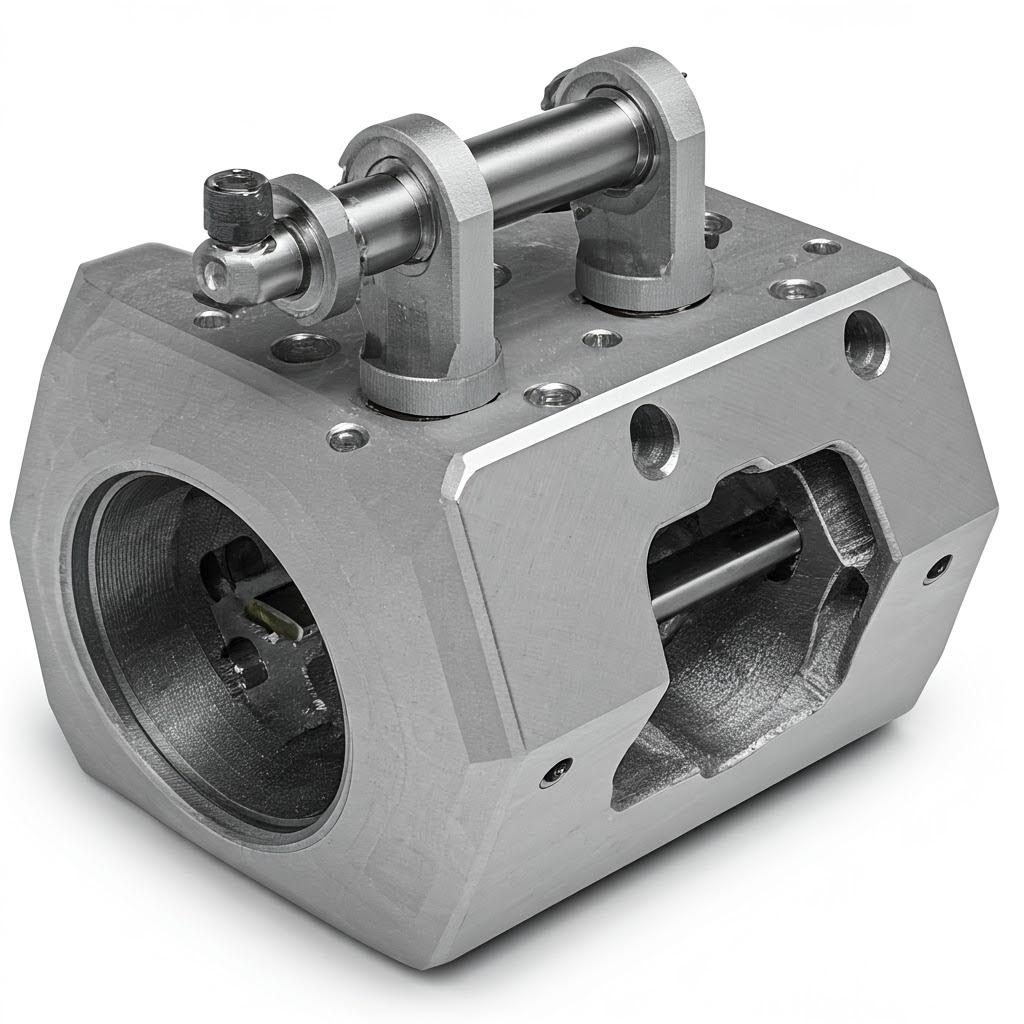

Jet Turbine Blade Roots: Revolutionizing Aerospace Manufacturing with Metal 3D Printing

Introduction to Jet Turbine Blade Roots Jet turbine blades stand as critical components within aircraft engines, enduring extreme conditions of temperature, pressure, and rotational forces. The root of these blades, the attachment point to the turbine disk, is paramount for ensuring the structural integrity and operational efficiency of the entire

Aerospace-Grade Cooling Shrouds

Introduction – The Critical Role of Custom Cooling Shrouds in Aerospace Applications In the demanding realm of aerospace engineering, where precision, reliability, and performance are paramount, even seemingly minor components can play a crucial role in the overall functionality and safety of aircraft and spacecraft. Among these vital elements are

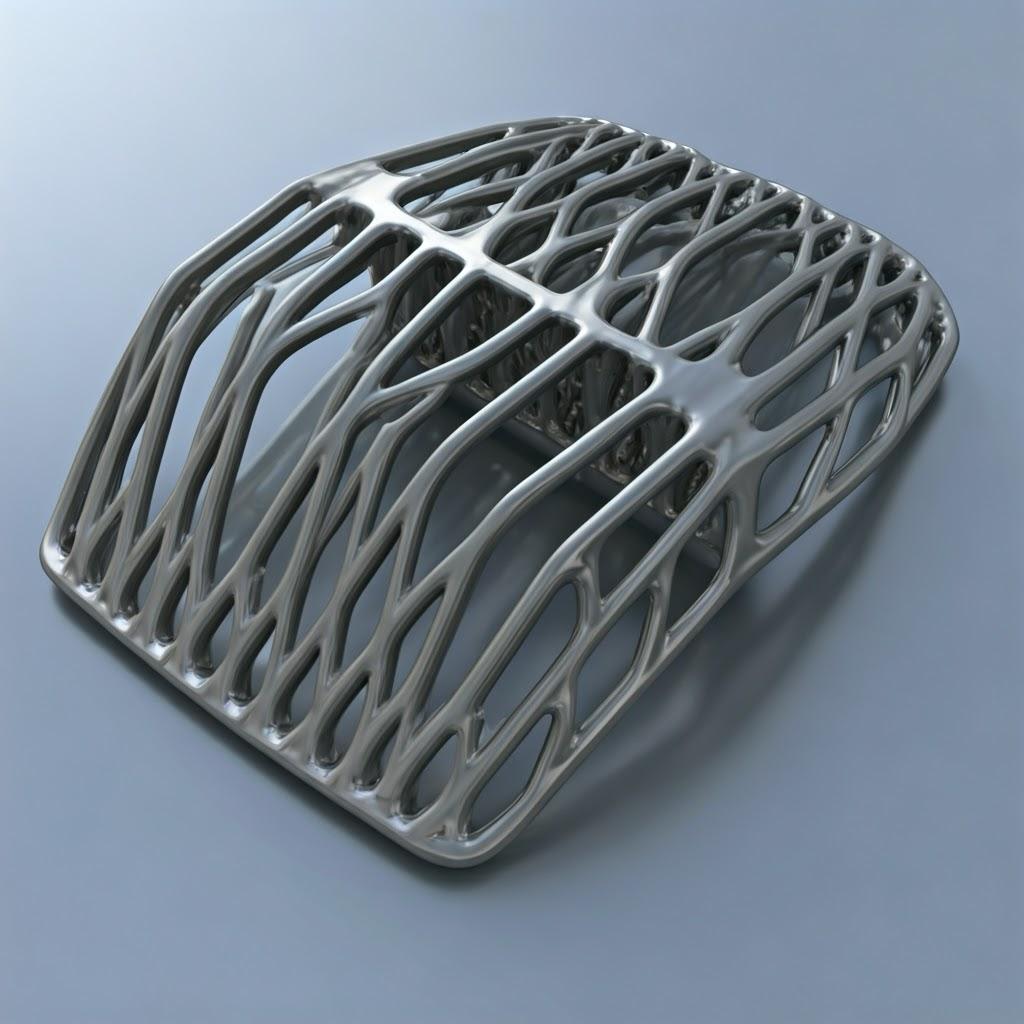

Lattice-Optimized Aerospace Ribs

Introduction – The Backbone of Aerospace: Understanding Structural Ribs In the demanding realm of aerospace engineering, every component plays a critical role in ensuring the safety, efficiency, and performance of aircraft and spacecraft. Among these essential elements are structural ribs, internal frameworks designed to provide crucial support and maintain the

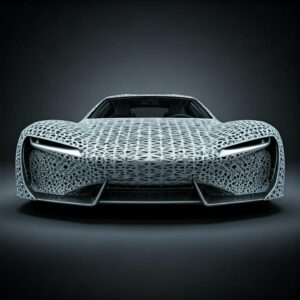

3D Printed Chassis Nodes for EVs: Revolutionizing Electric Vehicle Manufacturing

Introduction The electric vehicle (EV) industry is at the forefront of innovation, constantly seeking lighter, stronger, and more efficient components to enhance vehicle performance, range, and sustainability. Among these critical components, the chassis node plays a vital role in connecting various structural elements, influencing the vehicle’s overall integrity and safety.

Custom Fixtures for Aerospace Assembly

Introduction to Custom Aerospace Assembly Fixtures via Metal 3D Printing In the high-stakes world of aerospace manufacturing, precision and efficiency are not just goals; they are absolute necessities. Every component, every assembly, must adhere to stringent standards to ensure the safety and performance of aircraft. Traditional manufacturing methods for creating

Satellite Optical Benches: Revolutionizing Aerospace with Metal 3D Printing

Introduction – The Critical Role of Satellite Optical Benches in Modern Aerospace Satellite optical benches serve as the stable and precise foundation for critical instruments

Jet Turbine Blade Roots: Revolutionizing Aerospace Manufacturing with Metal 3D Printing

Introduction to Jet Turbine Blade Roots Jet turbine blades stand as critical components within aircraft engines, enduring extreme conditions of temperature, pressure, and rotational forces.

Aerospace-Grade Cooling Shrouds

Introduction – The Critical Role of Custom Cooling Shrouds in Aerospace Applications In the demanding realm of aerospace engineering, where precision, reliability, and performance are

Lattice-Optimized Aerospace Ribs

Introduction – The Backbone of Aerospace: Understanding Structural Ribs In the demanding realm of aerospace engineering, every component plays a critical role in ensuring the

3D Printed Chassis Nodes for EVs: Revolutionizing Electric Vehicle Manufacturing

Introduction The electric vehicle (EV) industry is at the forefront of innovation, constantly seeking lighter, stronger, and more efficient components to enhance vehicle performance, range,

Custom Fixtures for Aerospace Assembly

Introduction to Custom Aerospace Assembly Fixtures via Metal 3D Printing In the high-stakes world of aerospace manufacturing, precision and efficiency are not just goals; they

Nuestro producto

PRODUCTO DE VENTA CALIENTE

CONTACTO

¿Tiene alguna pregunta? ¡Envíenos un mensaje ahora! Atenderemos su solicitud con todo un equipo tras recibir su mensaje.

Polvos metálicos para impresión 3D y fabricación aditiva

PRODUCTO

cONTACT INFO

- Ciudad de Qingdao, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731