Polvo AM

todas las colecciones

Co puro en polvo: la guía definitiva para 2025

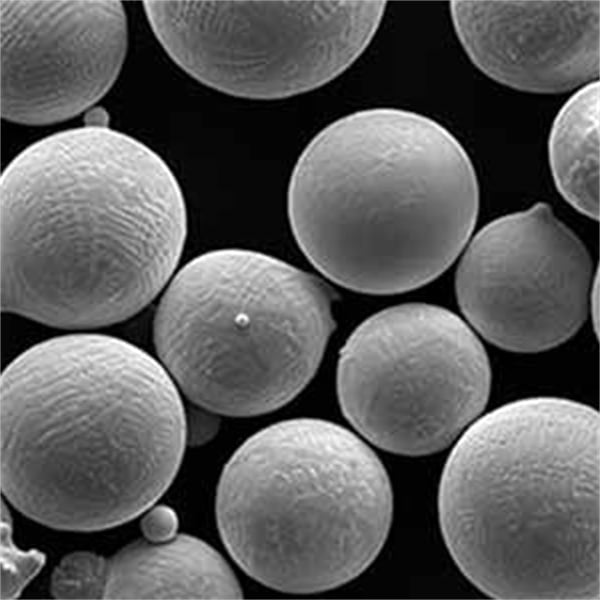

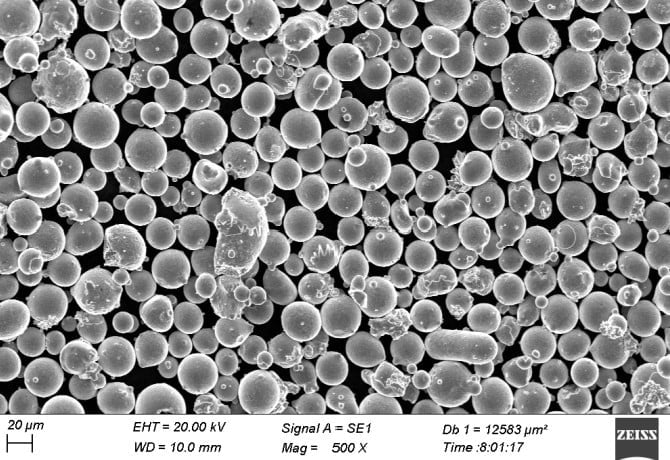

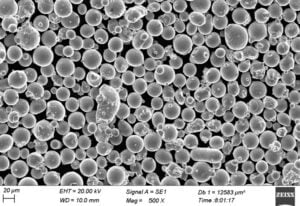

El polvo de cobalto (Co) puro es un polvo metálico de alto rendimiento que se utiliza en aplicaciones aeroespaciales, médicas, de almacenamiento de energía y de fabricación aditiva (FA). Conocido por su excelente resistencia al desgaste, estabilidad a altas temperaturas, propiedades magnéticas y biocompatibilidad, el polvo de cobalto puro desempeña un papel crucial en aleaciones duras, recubrimientos, baterías y materiales magnéticos. Propiedades clave

Polvo CMSX-4: La guía definitiva para 2025

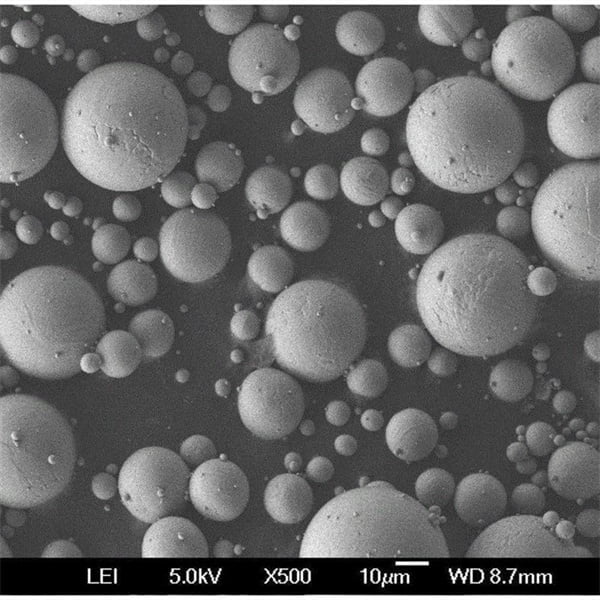

El polvo CMSX-4 es una superaleación monocristalina a base de níquel diseñada para aplicaciones de alta temperatura en las industrias aeroespacial, de turbinas de gas y de generación de energía. Es conocido por su excepcional resistencia a la fluencia, resistencia a la oxidación y resistencia mecánica a temperaturas extremas, lo que lo convierte en un material predilecto para álabes de motores a reacción, álabes de turbinas y otros materiales sometidos a altas tensiones.

Polvo GRCop-42: la guía definitiva para 2025

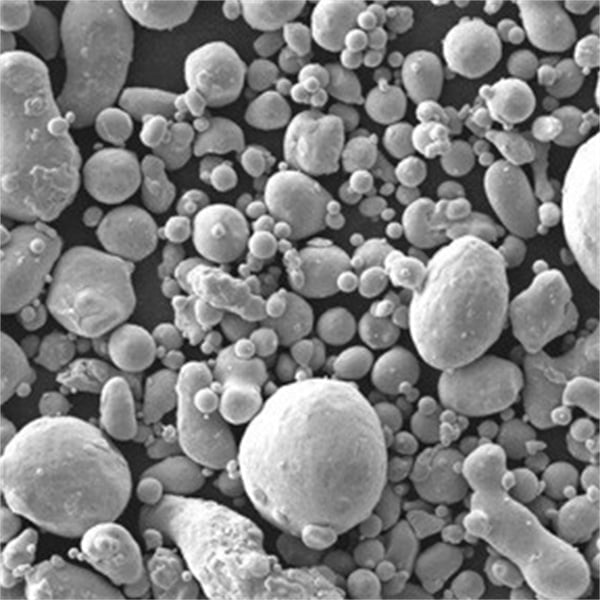

Descripción general: El polvo GRCop-42 es una aleación de cobre de alto rendimiento compuesta por niobio 4% y cromo 2%, diseñada específicamente para componentes de motores de cohetes, intercambiadores de calor y aplicaciones de fabricación aditiva. Desarrollada por la NASA, esta aleación ofrece una conductividad térmica, resistencia a la oxidación y resistencia mecánica excepcionales a temperaturas elevadas, lo que la hace ideal para la industria aeroespacial y...

Polvo NiTi50: la guía definitiva para 2025

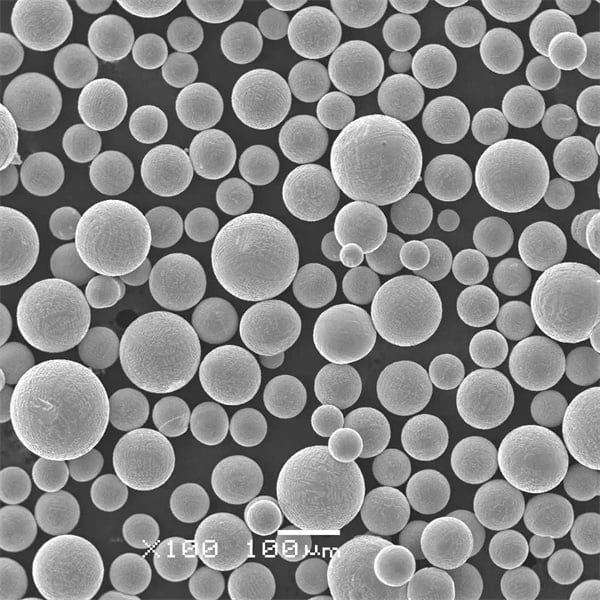

El polvo NiTi50, también conocido como polvo de aleación de níquel-titanio con memoria de forma (SMA), contiene níquel 50% y titanio 50%. Es ampliamente reconocido por su efecto de memoria de forma, superelasticidad y biocompatibilidad, lo que lo convierte en un material indispensable en aplicaciones aeroespaciales, médicas, automotrices y de fabricación aditiva (impresión 3D). Propiedades clave ✔ Memoria de forma

Polvo de NiFe50: la guía definitiva para 2025

El polvo NiFe50 es una aleación de níquel-hierro que contiene níquel 50%, conocido por sus excelentes propiedades magnéticas, resistencia a la corrosión y estabilidad a altas temperaturas. Esta aleación se utiliza ampliamente en aplicaciones de magnetismo suave, aeroespacial, automotriz, electrónica y fabricación aditiva (impresión 3D) gracias a su baja coercitividad, alta permeabilidad y control de la expansión térmica. Clave

Polvo NiAl20: la guía definitiva para 2025

El polvo NiAl20 es una aleación de níquel-aluminio de alto rendimiento que contiene aluminio 20%, ampliamente utilizada en recubrimientos por pulverización térmica, la industria aeroespacial, turbinas de gas y fabricación aditiva (impresión 3D). Esta aleación es conocida por su excepcional resistencia a la oxidación, estabilidad a altas temperaturas y excelentes propiedades de adhesión, lo que la hace ideal para recubrimientos protectores y aplicaciones estructurales.

Polvo de NiCrMoSiNb: la guía definitiva para 2025

El polvo de NiCrMoSiNb es una aleación de níquel-cromo-molibdeno-silicio-niobio de alto rendimiento, conocida por su excepcional resistencia a la corrosión y a la oxidación, y su estabilidad a altas temperaturas. Esta aleación se utiliza ampliamente en los sectores aeroespacial, de procesamiento químico, marítimo, de generación de energía y de fabricación aditiva (impresión 3D) gracias a su capacidad para soportar entornos extremos. Propiedades clave: ✔ Resistencia superior a la corrosión.

Polvo de monel K500: la guía definitiva para 2025

Descripción general: El polvo Monel K500 es una superaleación de níquel-cobre que ofrece una combinación única de resistencia, resistencia a la corrosión y dureza. Es una versión avanzada del Monel 400, reforzada con aluminio y titanio para mayor resistencia y dureza, manteniendo al mismo tiempo su excepcional resistencia a la corrosión. Gracias a estas propiedades, el polvo Monel K500...

Polvo Hastelloy C-276: la guía definitiva para 2025

El polvo Hastelloy C-276 es una superaleación de níquel-molibdeno-cromo que proporciona una excepcional resistencia a la corrosión, especialmente en entornos altamente agresivos como el procesamiento químico, las industrias marinas y los reactores nucleares. Se utiliza ampliamente en la fabricación aditiva (impresión 3D), el moldeo por inyección de metal (MIM), la industria aeroespacial y las aplicaciones médicas gracias a su alta resistencia y excepcional...

Polvo de Hastelloy X: la guía definitiva para 2025

El polvo de Hastelloy X, una superaleación a base de níquel, es ampliamente reconocido por su excelente resistencia a la oxidación, resistencia a altas temperaturas y resistencia superior a la corrosión. Se utiliza ampliamente en la industria aeroespacial, turbinas de gas, procesamiento químico y fabricación aditiva (impresión 3D) gracias a sus excelentes propiedades mecánicas a temperaturas extremas de hasta 1200 °C. En este...

Co puro en polvo: la guía definitiva para 2025

Descripción general El polvo de cobalto (Co) puro es un polvo metálico de alto rendimiento que se utiliza en aplicaciones aeroespaciales, médicas, de almacenamiento de energía y de fabricación aditiva (FA). Conocido por su excelente

Polvo CMSX-4: La guía definitiva para 2025

Descripción general El polvo CMSX-4 es una superaleación monocristalina a base de níquel diseñada para aplicaciones de alta temperatura en las industrias aeroespacial, de turbinas de gas y de generación de energía. Es conocido por su

Polvo GRCop-42: la guía definitiva para 2025

Descripción general El polvo GRCop-42 es una aleación a base de cobre de alto rendimiento que consta de niobio 4% y cromo 2%, diseñada específicamente para componentes de motores de cohetes, intercambiadores de calor y aditivos.

Polvo NiTi50: la guía definitiva para 2025

El polvo NiTi50, también conocido como polvo de aleación de níquel-titanio con memoria de forma (SMA), contiene níquel 50% y titanio 50%. Es ampliamente reconocido por su forma.

Polvo de NiFe50: la guía definitiva para 2025

El polvo NiFe50 es una aleación de níquel-hierro que contiene níquel 50%, conocido por sus excelentes propiedades magnéticas, resistencia a la corrosión y estabilidad a altas temperaturas. Esta aleación es ampliamente utilizada.

Polvo NiAl20: la guía definitiva para 2025

Descripción general El polvo NiAl20 es una aleación de níquel-aluminio de alto rendimiento que contiene aluminio 20%, ampliamente utilizado en recubrimientos por pulverización térmica, industria aeroespacial, turbinas de gas y fabricación aditiva (impresión 3D).

Polvo de NiCrMoSiNb: la guía definitiva para 2025

El polvo de NiCrMoSiNb es una aleación de níquel-cromo-molibdeno-silicio-niobio de alto rendimiento, conocida por su excepcional resistencia a la corrosión y a la oxidación, y su estabilidad a altas temperaturas. Esta aleación se utiliza ampliamente en

Polvo de monel K500: la guía definitiva para 2025

Descripción general: El polvo Monel K500 es una superaleación de níquel-cobre que ofrece una combinación única de resistencia, resistencia a la corrosión y dureza. Es una versión avanzada de...

Polvo Hastelloy C-276: la guía definitiva para 2025

Descripción general El polvo Hastelloy C-276 es una superaleación de níquel-molibdeno-cromo que proporciona una resistencia excepcional a la corrosión, particularmente en entornos altamente agresivos como el procesamiento químico, las industrias marinas y

Polvo de Hastelloy X: la guía definitiva para 2025

El polvo de Hastelloy X, una superaleación a base de níquel, es ampliamente reconocido por su excelente resistencia a la oxidación, resistencia a altas temperaturas y resistencia superior a la corrosión. Su uso es amplio.

Nuestro producto

PRODUCTO DE VENTA CALIENTE

CONTACTO

¿Tiene alguna pregunta? ¡Envíenos un mensaje ahora! Atenderemos su solicitud con todo un equipo tras recibir su mensaje.

Polvos metálicos para impresión 3D y fabricación aditiva

PRODUCTO

cONTACT INFO

- Ciudad de Qingdao, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731