Comment l'impression 3D révolutionne les composants des voitures de course au Mans

Table des matières

1. Introduction: 3D Printing in Motorsports & Le Mans

The 24 Hours of Le Mans is one of the most prestigious endurance racing events in the world, where cutting-edge engineering and materials science play a crucial role in performance. Over the last decade, Impression 3D (fabrication additive) has emerged as a game-changer in motorsports, enabling teams to push the limits of innovation and efficiency.

From lightweight titanium suspension components to intricate échangeurs de chaleur, additive manufacturing allows racing teams to create complex, high-performance parts faster than ever before. This shift towards 3D-printed racing car components is transforming the way teams approach design, testing, and manufacturing.

2. The Role of Additive Manufacturing in High-Performance Racing

Additive manufacturing provides plusieurs avantages that are crucial for endurance racing, where durability, weight reduction, and aerodynamics make a difference between victory and failure.

Key Advantages of 3D Printing in Motorsports:

| Avantage | Impact on Racing |

|---|---|

| Composants légers | Reduces car weight, improving speed and fuel efficiency |

| Prototypage rapide | Allows teams to test and refine designs quickly |

| Géométries complexes | Enables production of intricate designs that are impossible with machining |

| Fabrication à la demande | Reduces reliance on large inventories and shortens supply chains |

| Efficacité des matériaux | Minimizes waste compared to traditional subtractive methods |

Au Le Mansoù reliability and efficiency sont primordiales, Pièces métalliques imprimées en 3D have become indispensable. Many teams are now turning to poudres métalliques à haute performance tels que titanium alloys, Inconel, and stainless steel to create stronger and lighter components.

3. Key 3D-Printed Racing Car Components

Several critical components in modern Le Mans race cars are now being manufactured using impression 3D de métaux. Some of the most commonly 3D-printed parts include:

A. Suspension & Steering Components

- Titanium wishbones and uprights for reduced weight and increased strength

- Aluminum steering knuckles for improved handling

- Lightweight shock absorber mounts

B. Engine and Powertrain Parts

- Boîtiers de turbocompresseurs fabriqué à partir de Inconel 718 for high-temperature resistance

- Lightweight pistons with optimized cooling channels

- 3D-printed intake manifolds for improved air-fuel mixture distribution

C. Heat Management Systems

- Titanium heat exchangers for better cooling efficiency

- Customized brake cooling ducts

- Exhaust manifolds made from heat-resistant superalloys

D. Aerodynamic Components

- Wind tunnel models for rapid testing

- Custom air intakes and diffusers for optimized airflow

- Carbon-reinforced 3D-printed winglets

En tirant parti 3D-printed racing components, Le Mans teams can reduce weight, improve aerodynamics, and enhance durability, giving them a significant advantage on the track.

4. Benefits of 3D Printing for Racing Teams

L'adoption de impression 3D de métaux in racing has revolutionized the way race cars are designed and manufactured. At Le Mans, where endurance and efficiency are paramount, teams are increasingly relying on fabrication additive to improve performance and reliability.

Key Benefits of 3D Printing for Motorsport Applications

| Bénéfice | Impact on Racing Performance |

|---|---|

| Réduction du poids | Lighter components improve acceleration and fuel efficiency |

| Liberté de conception | Enables complex geometries that are impossible with machining |

| Rapid Prototyping & Testing | Speeds up design iterations and innovation cycles |

| Rapport résistance/poids élevé | Stronger materials like titanium improve durability without adding weight |

| Customization & Optimization | Tailored parts for specific car configurations enhance aerodynamics |

| Réduction des délais d'exécution | Faster production cycles mean quicker part replacements |

| Efficacité des matériaux | Less waste compared to traditional subtractive manufacturing |

Case Study: Titanium Suspension Components

A Le Mans racing team recently integrated 3D-printed titanium wishbones into their suspension system. The result? A 40% reduction in weight while maintaining the same structural integrity, leading to improved handling and reduced tire wear over long races.

5. Met3DP: A Reliable Supplier of Metal Powders for Motorsport Applications

For teams to fully leverage métal Impression 3D, they need access to poudres métalliques de haute qualité that ensure precision, durability, and performance. This is where Met3DP plays a crucial role.

Why Choose Met3DP for Motorsport Applications?

✅ Industry-Leading Metal Powders:

Met3DP specializes in poudres métalliques à haute performance tels que titanium alloys, Inconel, and stainless steel, all of which are essential for motorsport applications.

✅ Advanced Powder Production Technology:

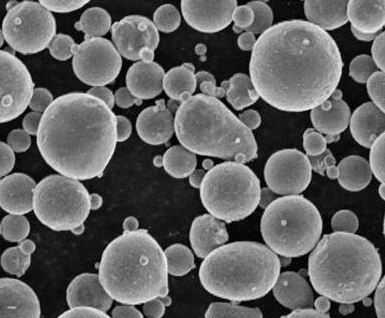

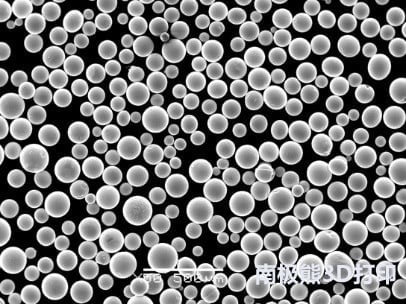

En utilisant atomisation de gaz et PREP (procédé d'électrode rotative à plasma), Met3DP produces spherical metal powders with high purity, excellent flowability, and superior mechanical properties.

✅ Optimized for Additive Manufacturing:

Met3DP’s powders are tailored for Fusion sélective par faisceau d'électrons (SEBM) et Fusion laser sur lit de poudre (LPBF), en veillant à ce que pièces à haute densité et sans défaut for racing applications.

✅ Proven Performance in High-Stress Environments:

Met3DP’s materials are used in industries aérospatiales, médicales et automobilesIls sont donc idéaux pour extreme racing conditions at Le Mans.

Popular Metal Powders for Racing Components

| Matériau | Commonly Used For |

|---|---|

| Ti-6Al-4V | Suspension components, engine parts, and lightweight chassis elements |

| Inconel 718 | Turbocharger housings, exhaust manifolds, and heat exchangers |

| CoCrMo | High-performance brake components and wear-resistant parts |

| Acier inoxydable 316L | Strong but lightweight structural elements |

En s'associant avec Met3DP, racing teams can access superior materials that enable faster, stronger, and more efficient 3D-printed components.

🔗 Explore Met3DP’s Poudres métalliques de haute qualité for motorsport applications.

6. How Teams Use Metal 3D Printing to Gain a Competitive Edge

Le Mans is all about pushing the limits of technologyet Impression 3D gives teams the edge they need to succeed.

Success Stories: How 3D Printing is Changing the Game

A. Lightweight Engine Components for Improved Performance

- 3D-printed pistons with optimized cooling channels improve heat dissipation and efficiency.

- Titanium intake manifolds enhance airflow, increasing horsepower.

B. Rapid Prototyping for Faster Development

- Teams can 3D print and test aerodynamic parts in wind tunnels within days instead of weeks.

- Quick modifications to brake ducts and cooling systems allow for real-time performance tuning.

C. On-Demand Manufacturing for Replacement Parts

- Instead of relying on traditional supply chains, teams can print spare parts on-site, reducing downtime.

- Inconel exhaust manifolds can be printed overnight for mid-season improvements.

Table: Traditional Manufacturing vs. 3D Printing in Motorsports

| Facteur | Fabrication traditionnelle | Impression 3D |

|---|---|---|

| Temps de production | Des semaines à des mois | Days to hours |

| Déchets matériels | High waste due to machining | Un minimum de déchets |

| Flexibilité de la conception | Limité par les outils d'usinage | Unlimited, complex geometries |

| Personnalisation | Coûteux et chronophage | Rapide et économique |

| Rapport coût-efficacité | High for low-volume parts | Coûts réduits pour les petits lots |

By utilizing poudres métalliques à haute performance and advanced technologies d'impression 3D de métaux, racing teams can achieve lighter, stronger, and more efficient components in a fraction of the time.

🔗 En savoir plus sur Méthodes d'impression used in motorsport engineering.

7. The Future of 3D Printing in Endurance Racing

Le future of endurance racing at Le Mans and beyond is being shaped by fabrication additive. As Technologie d'impression 3D advances, racing teams will continue to unlock new possibilities in design, performance, and efficiency.

Key Trends in 3D Printing for Motorsports

| Tendance | Impact on Racing |

|---|---|

| Impression 3D multi-matériaux | Combines metals and composites for enhanced performance |

| AI-Optimized Designs | Generative design creates ultra-lightweight, high-strength components |

| On-Site 3D Printing | Reduces dependency on external suppliers, enabling real-time part replacement |

| Fully 3D-Printed Engines | Future race cars may feature fully optimized, 3D-printed powertrains |

| Sustainable Materials | Eco-friendly metal powders improve sustainability in motorsports |

How 3D Printing Can Redefine Le Mans Regulations

Le FIA and ACO (Automobile Club de l’Ouest), which govern Le Mans, continue to evolve regulations to accommodate new manufacturing technologies. In the near future:

- More teams will use 3D-printed titanium and Inconel parts to enhance performance.

- Hybrid and hydrogen-powered race cars will utilize lightweight 3D-printed components for efficiency.

- Aerospace-grade metal powders will become standard in endurance racing.

🔗 Découvrez comment Impression 3D de métaux is shaping the future of manufacturing.

8. How to Source High-Quality Metal Powders for Racing Components

For motorsport teams looking to integrate Pièces métalliques imprimées en 3D, approvisionnement poudres métalliques de haute qualité est essentielle.

Factors to Consider When Selecting Metal Powders for Racing

| Facteur | Pourquoi c'est important |

|---|---|

| Pureté de la poudre | High-purity powders ensure strong, defect-free printed components |

| Distribution de la taille des particules | Consistent particle size improves flowability and print accuracy |

| Propriétés des matériaux | Strength, heat resistance, and weight must match racing requirements |

| Méthode de production | Gas atomization and PREP technologies ensure high-quality powders |

| Fiabilité des fournisseurs | Trusted suppliers like Met3DP provide consistent, top-tier materials |

Why Choose Met3DP for Motorsport 3D Printing?

✅ Industry-Leading Gas Atomization & PREP Technology – Ensures high-purity, spherical metal powders.

✅ Développement d'alliages sur mesure – Tailored powders for high-performance racing applications.

✅ Proven Track Record in Aerospace & Automotive – Approuvé par leading engineering teams worldwide.

✅ Optimisé pour la fabrication additive – Designed for SEBM (fusion sélective par faisceau d'électrons) et LPBF (Laser Powder Bed Fusion).

🔗 Find Poudres métalliques hautes performances for motorsport applications.

9. FAQs: Common Questions About 3D-Printed Racing Car Parts

Q1: Why are Le Mans teams using 3D-printed metal parts?

A : Impression 3D allows teams to create des composants plus légers, plus résistants et plus complexes that improve aerodynamics, durability, and fuel efficiency.

Q2: What materials are commonly used in 3D-printed racing parts?

A: Racing teams primarily use Titanium (Ti-6Al-4V), Inconel 718, Stainless Steel 316L, and CoCrMo, depending on the part’s function.

Q3: Can 3D printing replace traditional manufacturing in motorsports?

A: While méthodes traditionnelles like CNC machining are still used, Impression 3D is gradually taking over complex, lightweight, and high-performance components.

Q4: How do 3D-printed parts perform under extreme conditions?

A : Metal 3D-printed components maintenir high strength and heat resistanceIls sont donc idéaux pour turbochargers, exhaust manifolds, and suspension parts.

Q5: Where can I source high-quality metal powders for racing applications?

A : Met3DP fournit poudres métalliques à la pointe de l'industrie optimisé pour motorsports, aerospace, and high-performance engineering.

🔗 En savoir plus sur Met3DP’s Metal 3D Printing Solutions.

Conclusion: The Future of Racing is 3D Printed

En tant que Le Mans and other endurance racing series continue to evolve, Impression 3D will remain at the forefront of innovation. From lightweight titanium suspension components à heat-resistant Inconel turbochargers, additive manufacturing is redefining how race cars are built.

For teams looking to gain a competitive edge, poudres métalliques de haute qualité et technologies d'impression 3D avancées are essential. With Met3DP’s cutting-edge materials and expertise, the future of motorsports is being shaped layer by layer.

Ready to explore 3D-printed racing components? Contact Met3DP aujourd'hui !

Explorez notre Solutions d'impression 3D en métal pour les applications à haute performance.

Partager sur

MET3DP Technology Co. est un fournisseur de premier plan de solutions de fabrication additive dont le siège se trouve à Qingdao, en Chine. Notre société est spécialisée dans les équipements d'impression 3D et les poudres métalliques de haute performance pour les applications industrielles.

Articles connexes

Supports imprimés en 3D pour les capteurs radar automobiles : Précision et performance

Lire la suite "À propos de Met3DP

Mise à jour récente

Notre produit

CONTACTEZ-NOUS

Vous avez des questions ? Envoyez-nous un message dès maintenant ! Nous répondrons à votre demande avec toute une équipe dès réception de votre message.

Obtenir les informations de Metal3DP

Brochure du produit

Obtenir les derniers produits et la liste des prix

Poudres métalliques pour l'impression 3D et la fabrication additive

PRODUIT

cONTACT INFO

- Ville de Qingdao, Shandong, Chine

- [email protected]

- [email protected]

- +86 19116340731