Fusion par induction sous vide

Table des matières

Vue d'ensemble

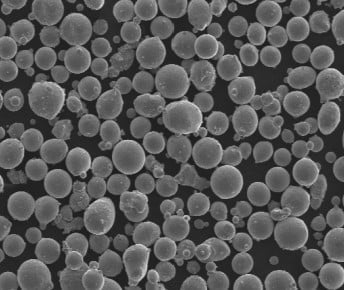

Fusion par induction sous vide (VIM) est un procédé sophistiqué et extrêmement précis permettant de produire des alliages et des poudres métalliques de haute qualité. Cette méthode est essentielle pour les applications exigeant une pureté exceptionnelle et une composition précise, ce qui la rend indispensable dans des secteurs comme l'aérospatiale, les dispositifs médicaux et l'ingénierie de haute performance. Découvrons les subtilités du VIM en explorant ses procédés, ses applications, ses avantages, ses inconvénients et des informations détaillées sur les différents modèles de poudres métalliques produits grâce à cette technique.

Qu'est-ce que la fusion par induction sous vide ?

La fusion par induction sous vide consiste à fondre des métaux sous vide par induction électromagnétique. Cette technique minimise la contamination par les gaz et les impuretés, garantissant ainsi la production de métaux d'une pureté et d'une homogénéité supérieures. En fondant les métaux sous vide, la fusion par induction sous vide prévient l'oxydation et permet un contrôle précis de la composition du produit final.

Détails clés de VIM :

- Processus : Fusion des métaux par induction électromagnétique sous vide.

- Objet : Production d'alliages et de poudres métalliques de haute pureté.

- Applications : Aérospatiale, dispositifs médicaux, ingénierie de haute performance.

Comment fonctionne la fusion par induction sous vide

Imaginez une cuisine high-tech où vous cuisinez votre plat préféré dans un environnement parfaitement contrôlé, exempt d'odeurs et de contaminants indésirables. Voilà ce qu'est le VIM en résumé, mais pour les métaux ! Le processus commence par le placement des matières premières dans un creuset à l'intérieur de la chambre à vide. Une bobine d'induction entoure le creuset et génère un champ magnétique lorsqu'un courant électrique le traverse. Ce champ magnétique induit des courants de Foucault dans le métal, provoquant son échauffement et sa fusion.

Une fois le métal atteint la température souhaitée, des éléments d'alliage peuvent être ajoutés pour obtenir la composition spécifique requise. L'environnement sous vide garantit qu'aucun gaz n'est emprisonné dans la masse fondue, ce qui produit un alliage plus propre et plus homogène.

Types de métaux et d'alliages produits

Le VIM est polyvalent et permet de produire une large gamme de métaux et d'alliages. Voici quelques modèles spécifiques de poudres métalliques :

- Superalliages à base de nickel (par exemple, INCONEL 718)

- Composition : Nickel, chrome, fer et autres éléments.

- Propriétés : Haute résistance, résistance à la corrosion et excellentes performances à haute température.

- Applications : Aubes de turbine, composants aérospatiaux.

- Alliages de titane (par exemple, Ti-6Al-4V)

- Composition : Titane, Aluminium, Vanadium.

- Propriétés : Rapport résistance/poids élevé, excellente résistance à la corrosion.

- Applications : Aérospatiale, implants médicaux.

- Alliages cobalt-chrome (par exemple, CoCrMo)

- Composition : Cobalt, Chrome, Molybdène.

- Propriétés : Haute résistance à l'usure, biocompatibilité.

- Applications : Implants médicaux, dispositifs dentaires.

- Aciers inoxydables (par exemple, 316L)

- Composition : Fer, Chrome, Nickel, Molybdène.

- Propriétés : Résistance à la corrosion, résistance mécanique.

- Applications : Instruments chirurgicaux, applications marines.

- Alliages d'aluminium (par exemple, AlSi10Mg)

- Composition : Aluminium, Silicium, Magnésium.

- Propriétés : Léger, bonnes propriétés thermiques.

- Applications : Pièces automobiles, composants aérospatiaux.

- Alliages de magnésium (par exemple, AZ91D)

- Composition : Magnésium, Aluminium, Zinc.

- Propriétés : Léger, haute résistance.

- Applications : Automobile, électronique.

- Alliages de cuivre (par exemple, CuCrZr)

- Composition : Cuivre, Chrome, Zirconium.

- Propriétés : Haute conductivité électrique, bonnes propriétés mécaniques.

- Applications : Composants électriques, échangeurs de chaleur.

- Aciers à outils (par exemple, acier rapide M2)

- Composition : Fer, tungstène, molybdène, chrome.

- Propriétés : Dureté élevée, résistance à l'usure.

- Applications : Outils de coupe, moules.

- Alliages de métaux précieux (par exemple, PtIr)

- Composition : Platine, Iridium.

- Propriétés : Haute résistance à la corrosion, bonnes propriétés mécaniques.

- Applications : Bijoux, dispositifs médicaux.

- Alliages à haute entropie (par exemple, CoCrFeNiMn)

- Composition : Cobalt, Chrome, Fer, Nickel, Manganèse.

- Propriétés : Excellentes propriétés mécaniques, haute résistance à la corrosion.

- Applications : Applications d'ingénierie avancées.

Les avantages de Fusion par induction sous vide

Pourquoi le VIM est-il si apprécié dans le monde de la métallurgie ? Voici quelques avantages clés :

- Haute pureté : L'environnement sous vide élimine la contamination gazeuse, ce qui permet d'obtenir des métaux d'une pureté exceptionnelle.

- Composition précise : Permet un contrôle précis des éléments d'alliage, produisant des matériaux aux propriétés sur mesure.

- Propriétés mécaniques améliorées : Les métaux produits par VIM présentent des caractéristiques mécaniques supérieures.

- Homogénéité : Assure une répartition uniforme des éléments d’alliage dans tout le métal.

- Polyvalence : Capable de faire fondre une large gamme de métaux et d’alliages.

Inconvénients de la fusion par induction sous vide

Comme tout processus, VIM présente des inconvénients. En voici quelques-uns :

- Coût : Les coûts d’équipement et d’exploitation du VIM sont relativement élevés.

- La complexité : Le processus nécessite une technologie et une expertise sophistiquées.

- Échelle: Généralement adapté aux lots de plus petite taille par rapport aux autres méthodes de fusion.

Applications de Fusion par induction sous vide

Le VIM révolutionne de nombreux secteurs. Explorons ses principales applications :

Aérospatiale :

- Composants: Aubes de turbine, pièces de moteur.

- Avantages : Performances à haute température, durabilité.

Dispositifs médicaux :

- Composants: Implants, instruments chirurgicaux.

- Avantages : Biocompatibilité, résistance à la corrosion.

Ingénierie de haute performance :

- Composants: Composants à fortes contraintes, outils spécialisés.

- Avantages : Résistance, résistance à l'usure.

Types de métaux et d'alliages produits par VIM

| Métal/Alliage | Composition | Propriétés | Applications |

|---|---|---|---|

| INCONEL 718 | Nickel, chrome, fer | Haute résistance, résistance à la corrosion | Aubes de turbine, composants aérospatiaux |

| Ti-6Al-4V | Titane, Aluminium, Vanadium | Rapport résistance/poids élevé, résistance à la corrosion | Aérospatiale, implants médicaux |

| CoCrMo | Cobalt, chrome, molybdène | Résistance élevée à l'usure, biocompatibilité | Implants médicaux, dispositifs dentaires |

| Acier inoxydable 316L | Fer, chrome, nickel, molybdène | Résistance à la corrosion, résistance mécanique | Instruments chirurgicaux, applications marines |

| AlSi10Mg | Aluminium, Silicium, Magnésium | Léger, bonnes propriétés thermiques | Pièces automobiles, composants aérospatiaux |

| AZ91D | Magnésium, aluminium, zinc | Léger, très résistant | Automobile, électronique |

| CuCrZr | Cuivre, chrome, zirconium | Haute conductivité électrique, bonnes propriétés mécaniques | Composants électriques, échangeurs de chaleur |

| Acier rapide M2 | Fer, tungstène, molybdène, chrome | Dureté élevée, résistance à l'usure | Outils de coupe, moules |

| PtIr | Platine, Iridium | Résistance élevée à la corrosion, bonnes propriétés mécaniques | Bijoux, dispositifs médicaux |

| CoCrFeNiMn | Cobalt, Chrome, Fer, Nickel, Manganèse | Excellentes propriétés mécaniques, haute résistance à la corrosion | Applications techniques avancées |

Applications des métaux produits par VIM

| L'industrie | Composants | Avantages |

|---|---|---|

| Aérospatiale | Aubes de turbine, pièces de moteur | Performances à haute température, durabilité |

| Dispositifs médicaux | Implants, instruments chirurgicaux | Biocompatibilité, résistance à la corrosion |

| Ingénierie de haute performance | Composants à fortes contraintes, outils spécialisés | Solidité, résistance à l'usure |

Spécifications et normes

| Métal/Alliage | Standard | Grade | Spécifications |

|---|---|---|---|

| INCONEL 718 | ASTM B637 | Première année | Haute résistance à des températures élevées |

| Ti-6Al-4V | ASTM B348 | 5e année | Rapport résistance/poids élevé |

| CoCrMo | ASTM F1537 | Première année | Haute résistance à l'usure |

| Acier inoxydable 316L | ASTM A240 | Grade 316L | Résistance à la corrosion |

| AlSi10Mg | ASTM B928 | Première année | Léger, bonnes propriétés thermiques |

| AZ91D | ASTM B93 | Grade AZ91D | Léger, très résistant |

| CuCrZr | ASTM B224 | Première année | Conductivité électrique élevée |

| Acier rapide M2 | ASTM A600 | Niveau M2 | Dureté élevée, résistance à l'usure |

| PtIr | ASTM B563 | Première année | Haute résistance à la corrosion |

| CoCrFeNiMn | ASTM E2209 | Première année | Excellentes propriétés mécaniques |

Avantages et inconvénients de Fusion par induction sous vide

Avantages

| Avantage | Description |

|---|---|

| Haute pureté | Élimine la contamination du gaz pour une pureté supérieure. |

| Composition précise | Contrôle précis des éléments d'alliage pour des propriétés sur mesure. |

| Propriétés mécaniques améliorées | Caractéristiques mécaniques supérieures dans les produits finis. |

| Homogénéité | Répartition uniforme des éléments d'alliage. |

| Polyvalence | Convient à une large gamme de métaux et d'alliages. |

Inconvénients

| Inconvénient | Description |

|---|---|

| Coût | Coûts d'équipement et d'exploitation élevés. |

| Complexité | Nécessite une technologie et une expertise sophistiquées. |

| Échelle | Généralement limité à des lots plus petits par rapport aux autres méthodes. |

Fournisseurs et détails des prix

Principaux fournisseurs d'équipements VIM

| Fournisseur | Gamme de produits | Tarification | Région |

|---|---|---|---|

| Groupe Inductotherm | Fours VIM, accessoires | $100,000 – $1,000,000 | Mondial |

| ALD Vacuum Technologies | Systèmes VIM, solutions personnalisées | $150,000 – $2,000,000 | Mondial |

| Seco/Warwick | Fours VIM, services après-vente | $120,000 – $900,000 | Amérique du Nord, Europe |

| Consarc | Fours VIM et VAR | $200,000 – $1,500,000 | Mondial |

| ECM Technologies | Systèmes VIM | $100,000 – $850,000 | Europe, Asie |

Comparaison du VIM et d'autres méthodes de fusion

| Aspect | Fusion par induction sous vide (VIM) | Fusion à l'arc | Refusion sous laitier électroconducteur (ESR) |

|---|---|---|---|

| La pureté | Élevé en raison de l'environnement sous vide | Modéré | Haut |

| Coût | Haut | Plus bas | Haut |

| Complexité | Haut | Modéré | Haut |

| Taille du lot | Petite à moyenne | Moyen à grand | Moyen |

| Application | Alliages à haute performance | Usage général | Applications de haute pureté |

FAQ

| Question | Répondre |

|---|---|

| Qu'est-ce que la fusion par induction sous vide (VIM) ? | Le VIM est un procédé qui fait fondre les métaux par induction électromagnétique sous vide pour produire des alliages de haute pureté. |

| Pourquoi utiliser VIM plutôt que d’autres méthodes de fusion ? | VIM offre une pureté supérieure, un contrôle précis de la composition et des propriétés mécaniques améliorées. |

| Quels métaux peuvent être produits à l’aide de VIM ? | VIM peut produire une large gamme de métaux, notamment des superalliages à base de nickel, des alliages de titane, etc. |

| Quelles sont les principales applications de VIM ? | Les principales applications comprennent les composants aérospatiaux, les dispositifs médicaux et les pièces d’ingénierie haute performance. |

| Quels sont les inconvénients de VIM ? | Les inconvénients comprennent le coût élevé, la complexité et des tailles de lots généralement plus petites. |

| Quels sont les principaux fournisseurs d’équipements VIM ? | Les principaux fournisseurs sont Inductotherm Group, ALD Vacuum Technologies et Seco/Warwick. |

| Comment VIM se compare-t-il à Arc Melting ? | Le VIM offre une pureté supérieure mais à un coût et une complexité plus élevés par rapport à la fusion à l'arc. |

Conclusion

La fusion par induction sous vide est un sommet de la métallurgie moderne, offrant une pureté et une précision inégalées dans la production de métaux. Ses applications couvrent des secteurs critiques où la performance et la fiabilité sont essentielles. Malgré des coûts et une complexité plus élevés, les avantages l'emportent souvent sur les défis, faisant de la fusion par induction sous vide un procédé précieux pour la fabrication de matériaux de pointe.

Partager sur

MET3DP Technology Co. est un fournisseur de premier plan de solutions de fabrication additive dont le siège se trouve à Qingdao, en Chine. Notre société est spécialisée dans les équipements d'impression 3D et les poudres métalliques de haute performance pour les applications industrielles.

Articles connexes

Supports imprimés en 3D pour les capteurs radar automobiles : Précision et performance

Lire la suite "À propos de Met3DP

Mise à jour récente

Notre produit

CONTACTEZ-NOUS

Vous avez des questions ? Envoyez-nous un message dès maintenant ! Nous répondrons à votre demande avec toute une équipe dès réception de votre message.

Obtenir les informations de Metal3DP

Brochure du produit

Obtenir les derniers produits et la liste des prix

Poudres métalliques pour l'impression 3D et la fabrication additive

PRODUIT

cONTACT INFO

- Ville de Qingdao, Shandong, Chine

- [email protected]

- [email protected]

- +86 19116340731