AM 파우더

모든 컬렉션

Ti-6Al-4V 분말: 2025년을 위한 궁극의 가이드

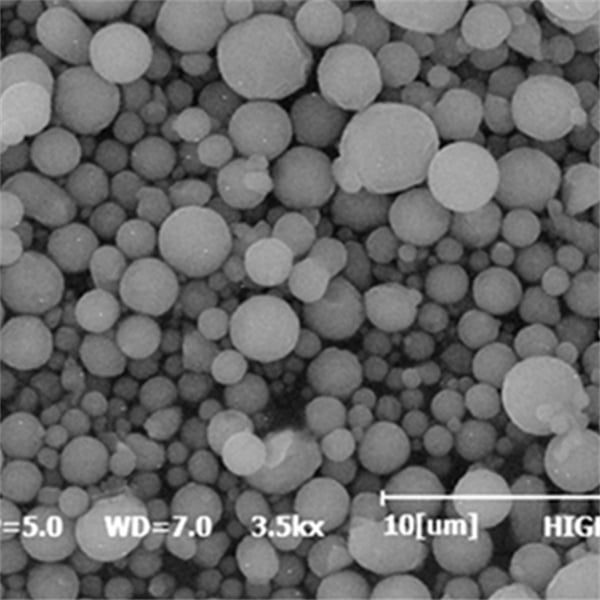

개요 Ti-6Al-4V 분말은 5등급 티타늄 합금 분말이라고도 하며 항공우주, 의료 및 산업 분야에서 가장 널리 사용되는 티타늄 합금입니다. 이 합금은 90% 티타늄, 6% 알루미늄 및 4% 바나듐으로 구성되어 고강도, 저중량, 내식성 및 생체 적합성의 뛰어난 조합을 제공합니다.

FSX-414 파우더: 2025년을 위한 궁극의 가이드

개요 FSX-414 파우더는 뛰어난 고온 강도, 산화 저항성 및 내식성으로 알려진 코발트 기반 초합금입니다. 가스터빈, 항공우주 부품, 석유화학 응용 분야 및 산업용 공구에 널리 사용되며, 극한의 열, 기계적 응력 및 내마모성이 중요합니다. 이 합금은 특히 적층 제조에 가치가 있습니다.

CoNi7 파우더: 2025년을 위한 궁극의 가이드

개요 CoNi7 파우더는 뛰어난 내마모성, 고온 안정성 및 우수한 내식성으로 유명한 코발트-니켈 기반 초합금입니다. 항공우주, 자동차, 에너지 및 산업용 툴링 응용 분야에서 널리 사용되며, 구성 요소는 높은 기계적 응력, 산화 및 극한 온도를 견뎌야 합니다. 이 합금은 특히 적층 제조에 가치가 있습니다.

트라이발로이 T800 파우더: 2025년을 위한 궁극의 가이드

개요 Triballoy T800 파우더는 매우 까다로운 환경에서 극한의 내마모성, 높은 경도 및 우수한 내식성을 위해 설계된 코발트 기반 초합금입니다. 마찰, 마모 및 고온이 끊임없는 과제인 항공우주, 석유 및 가스, 화학 처리 및 산업용 코팅에 널리 사용됩니다. Triballoy T400과 비교했을 때,

트라이발로이 T400 분말: 2025년을 위한 궁극의 가이드

개요 Triballoy T400 파우더는 극한의 내마모성, 높은 경도, 혹독한 환경에서 뛰어난 내식성을 위해 특별히 설계된 코발트 기반 합금입니다. 이 소재는 항공우주, 석유 및 가스, 화학 처리, 산업용 코팅에 널리 사용되며, 구성 요소가 심한 마찰, 마모 및 고온을 견뎌야 합니다. 주요 특성

Haynes 25 Powder: 2025년을 위한 궁극의 가이드

개요 Haynes 25 파우더는 L-605로도 알려져 있으며, 뛰어난 고온 강도, 산화 저항성 및 우수한 내마모성으로 유명한 코발트 기반 초합금입니다. 극한 환경에서 기계적 무결성을 유지하는 능력으로 인해 항공우주, 가스터빈, 산업용 코팅 및 의료 분야에서 널리 사용됩니다. 주요 특성

Stellite 6 Powder: 2025년을 위한 완벽한 가이드

개요 스텔라이트 6 파우더는 뛰어난 내마모성, 내식성 및 고온 안정성으로 알려진 코발트 기반 합금입니다. 이 합금은 뛰어난 기계적 특성, 자체 윤활성 및 극한 환경을 견딜 수 있는 능력으로 인해 항공우주, 발전, 의료 및 산업 분야에서 널리 사용됩니다. 주요 특성 ✔ 뛰어남

CoCrW 파우더: 2025년을 위한 완벽한 가이드

개요 CoCrW 파우더(코발트-크롬-텅스텐)는 뛰어난 내마모성, 고온 안정성 및 뛰어난 내식성으로 알려진 고성능 금속 합금입니다. 이 합금은 뛰어난 기계적 특성과 극한 환경에서의 내구성으로 인해 항공우주, 의료용 임플란트, 산업용 코팅 및 적층 제조(AM)에 널리 사용됩니다. 주요 특성 ✔

CoCrMoW 파우더: 2025년을 위한 궁극의 가이드

개요 CoCrMoW 파우더(코발트-크롬-몰리브덴-텅스텐)는 극한의 내마모성, 고온 안정성 및 우수한 내식성을 위해 설계된 고성능 금속 합금입니다. 이 합금은 뛰어난 기계적 특성과 혹독한 환경에서의 내구성으로 인해 항공우주, 의료용 임플란트, 산업용 코팅 및 적층 제조(AM)에 널리 사용됩니다. 주요 특성 ✔ 우수

CoCrMo 파우더: 2025년을 위한 궁극의 가이드

개요 CoCrMo 분말(코발트-크롬-몰리브덴)은 항공우주, 의료용 임플란트, 적층 제조(AM)에 널리 사용되는 고성능 금속 합금입니다. 뛰어난 내마모성, 높은 내식성, 우수한 생체 적합성으로 알려진 CoCrMo는 정형외과 임플란트, 치과 보철물, 터빈 구성 요소, 고응력 산업 응용 분야에 이상적인 소재입니다. 주요 특성 ✔

Ti-6Al-4V 분말: 2025년을 위한 궁극의 가이드

개요 Ti-6Al-4V 분말은 5등급 티타늄 합금 분말로도 알려져 있으며 항공우주, 의료 및 산업 분야에서 가장 널리 사용되는 티타늄 합금입니다.

FSX-414 파우더: 2025년을 위한 궁극의 가이드

개요 FSX-414 파우더는 뛰어난 고온 강도, 산화 저항성 및 내식성으로 알려진 코발트 기반 초합금입니다. 가스터빈에 널리 사용됩니다.

CoNi7 파우더: 2025년을 위한 궁극의 가이드

개요 CoNi7 분말은 뛰어난 내마모성, 고온 안정성 및 우수한 내식성으로 유명한 코발트-니켈 기반 초합금입니다. 항공우주 분야에서 널리 사용됩니다.

트라이발로이 T800 파우더: 2025년을 위한 궁극의 가이드

개요 Triballoy T800 파우더는 매우 까다로운 환경에서 극한의 내마모성, 높은 경도 및 우수한 내식성을 위해 설계된 코발트 기반 초합금입니다.

트라이발로이 T400 분말: 2025년을 위한 궁극의 가이드

개요 Triballoy T400 파우더는 혹독한 환경에서 극한의 내마모성, 높은 경도 및 우수한 내식성을 위해 특별히 설계된 코발트 기반 합금입니다. 이 소재는

Haynes 25 Powder: 2025년을 위한 궁극의 가이드

개요 Haynes 25 파우더는 L-605로도 알려져 있으며, 뛰어난 고온 강도, 산화 저항성 및 우수한 내마모성으로 유명한 코발트 기반 초합금입니다.

Stellite 6 Powder: 2025년을 위한 완벽한 가이드

개요 Stellite 6 파우더는 뛰어난 내마모성, 내식성 및 고온 안정성으로 알려진 코발트 기반 합금입니다. 이 합금은 널리 사용됩니다.

CoCrW 파우더: 2025년을 위한 완벽한 가이드

개요 CoCrW 파우더(코발트-크롬-텅스텐)는 뛰어난 내마모성, 고온 안정성 및 뛰어난 내식성으로 알려진 고성능 금속 합금입니다. 이 합금은 널리

CoCrMoW 파우더: 2025년을 위한 궁극의 가이드

개요 CoCrMoW 파우더(코발트-크롬-몰리브덴-텅스텐)는 극한의 내마모성, 고온 안정성 및 우수한 내식성을 위해 설계된 고성능 금속 합금입니다. 이 합금은 널리 사용됩니다.

CoCrMo 파우더: 2025년을 위한 궁극의 가이드

개요 CoCrMo 분말(코발트-크롬-몰리브덴)은 항공우주, 의료용 임플란트, 적층 제조(AM)에 널리 사용되는 고성능 금속 합금입니다. 뛰어난 내마모성으로 유명합니다.

제품

인기 판매 제품

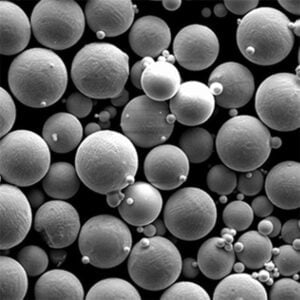

3D 프린팅 및 적층 제조용 금속 분말

문의 정보

- 칭다오시, 산둥성, 중국

- [email protected]

- [email protected]

- +86 19116340731