Metal 3D Printed Subframe Connection Mounts and Blocks for EV and Motorsport Chassis

목차

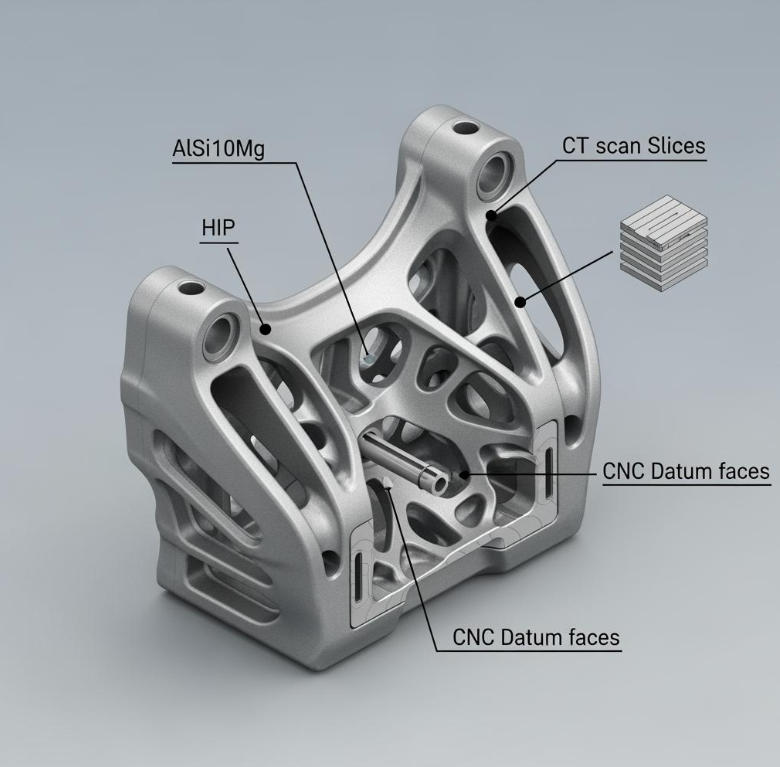

Subframe connection mounts and blocks now sit at the center of EV platform integration and motorsport agility. By leveraging laser powder bed fusion (LPBF) and electron beam melting (EBM), Metal3DP delivers lightweight, topology-optimized subframe interface components with integrated ribs, mounting lugs, and internal features that traditional forging or casting can’t achieve—while aligning with U.S. EPA considerations and OSHA safety practices for powder handling and post-processing.

Product Overview and 2025 Market Relevance

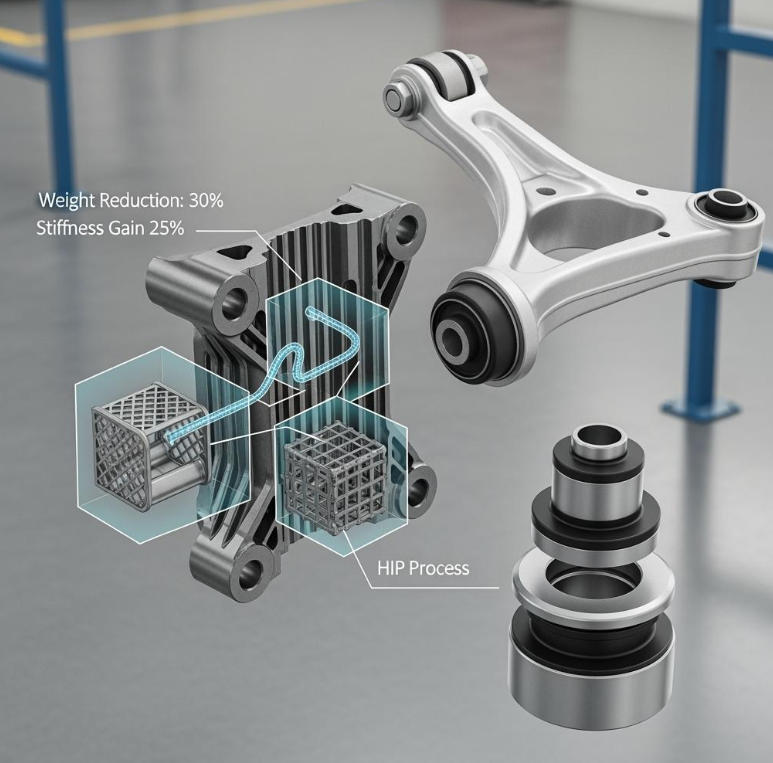

In 2025, U.S. EV programs and racing teams face dual pressure: reduce mass for range and lap-time gains, and compress the design-to-track timeline. Subframe blocks and connection mounts are ideal candidates for additive manufacturing because they combine high, multi-axial loads with packaging constraints and channel routing needs. With custom 3D printing, we consolidate brackets, gussets, and fastener interfaces into a monolithic node featuring integrated ribs and mounting lugs. The result is 10–30% mass reduction, 15–35% stiffness improvement at equal mass, and 30–70% part count reduction. For low-volume EV variants and motorsport applications, AM sidesteps tooling, shortens lead time to 1–3 weeks, and supports robust PPAP-ready documentation for on-road programs.

Metal3DP’s one-stop 3D printing services unite in-house metal powder production (gas atomization and PREP), industrial LPBF equipment, and U.S.-aligned quality controls—powder batch traceability, CT scanning, metallography, and fatigue S‑N data. This integrated approach helps U.S. buyers de-risk decisions under tightening budgets and evolving compliance expectations.

Technical Specifications and Advanced Features

- 재료: AlSi10Mg and Scalmalloy for lightweight EV mounts; Ti‑6Al‑4V for high-stiffness race applications; 17‑4PH or maraging steel for compact, high-load nodes; Inconel 625/718 for thermal hot spots near brakes or e-drive housings.

- Mechanical properties (typical, post-HT/HIP, orientation dependent):

- AlSi10Mg: UTS 400–470 MPa, YS 230–300 MPa

- Ti‑6Al‑4V: UTS 900–1100 MPa

- Maraging Steel: UTS 1100–2000 MPa

- Geometric capability: wall thickness ≥0.6–0.8 mm; hole diameter ≥0.8–1.0 mm; as-printed tolerance ±0.1–0.2 mm; after CNC on critical faces ±0.02–0.05 mm.

- Surface finish: Ra 3–10 μm after shot peening/tumble/chemical polishing; Ra ≤0.8 μm on bearing and sealing faces after CNC.

- Quality chain: powder characterization (PSD, flow, O/N content), layer-wise monitoring, CT scanning, metallography/hardness, S‑N curve generation; full batch traceability.

- Integrated features:

- Topology-optimized rib networks conforming to load paths

- Monolithic mounting lugs and threaded bosses, with machining stock left by design

- NVH-optimized lattices in non-critical zones

- Embedded wiring/cable channels and drain paths

- Corrosion management features for dissimilar-metal interfaces (coating allowances, isolator seats)

Manufacturing Pathways for Subframe Nodes: Strength, Cost, and Lead-Time Considerations

| 속성 | Metal 3D Printed Subframe Mounts (LPBF/EBM) | Forged/Cast Nodes + CNC | Welded Bracket Assemblies |

|---|---|---|---|

| Geometry and integration | Complex ribs, internal channels, monolithic lugs | Geometry limited by dies/molds; added cores increase cost | Many parts/welds; limited rib geometry |

| Lead time to fitment | 1–3 weeks incl. HIP + CNC | 8–16 weeks with tooling | 3–6 weeks with fixtures |

| Mass and stiffness | 10–30% weight reduction; 15–35% stiffness gains | Moderate optimization; tooling constraints | Heavier; stiffness compromises |

| Fatigue performance | HIP + surface finishing + hotspot filleting | Strong but geometry constrained | Weld HAZ fatigue risk |

| Traceability and PPAP | Powder-to-part traceability; CT; S‑N data | Material certs; NDT | Weld logs; variable consistency |

| U.S. compliance fit | OSHA powder controls, EPA-aligned post-processing | 표준 | Weld fume controls required |

Key Advantages and Proven Benefits

- Significant mass reduction in subframe connection blocks leads to measurable range and lap-time improvements.

- Integrated lugs eliminate separate brackets and fasteners, reducing assembly time by 20–40%.

- Enhanced fatigue life (2–5×) through HIP, surface optimization, and graded thickness along stress paths.

- Rapid iteration enables mule and prototype builds in 1–3 weeks, ideal for mid-season race updates or EV pilot runs.

- Full digital traceability supports OEM audits and PPAP.

Expert insight: “Subframe nodes are an ideal AM use case—load-path-specific ribbing and localized lattices deliver stiffness gains without the tooling overhead of forgings or complex casting cores.” — Prof. Jack Beuth, Advanced Manufacturing Researcher, Carnegie Mellon University (cmu.edu)

Real-World Applications and Measurable Success Stories

- Low-volume EV pilot: A maraging steel subframe mount replaced a multi-piece welded assembly, achieving 19% mass reduction and 2.4× fatigue life after HIP and shot peening. Validation cycle shortened by six weeks, enabling earlier fleet trials.

- GT racing chassis: Ti‑6Al‑4V connection block with monolithic mounting lugs and internal wire duct consolidated four parts into one, cutting assembly time by 32% and improving stiffness by 21%. Spare parts delivered trackside in 10 days.

- Performance tuner program: AlSi10Mg subframe block with corrosion allowance coating seats and drainage improved winter durability and maintained stiffness targets; unit cost break-even at 14 parts compared to casting + CNC with tooling.

Selection and Maintenance Considerations

Select materials by load case and environment: AlSi10Mg or Scalmalloy for aggressive weight targets; Ti‑6Al‑4V when stiffness and temperature margins are critical; maraging steel for compact, high-load interfaces. Include galvanic isolation features when mating to steel subframes and consider protective coatings for road-salt regions. During service, visually inspect lug bores and fastener seats at maintenance intervals; use CMM fixtures for periodic audit in professional racing. For EV fleets, consider CT sampling per batch for critical nodes.

Industry Success Factors and Customer Testimonials

Success depends on co-design and process discipline—locking build orientation early, leaving machining stock on datum faces, and planning HIP and surface finishing at RFQ. Our U.S. customer in a track-focused EV program noted: “Metal3DP’s powder-to-part accountability and PPAP-ready documentation made our supplier nomination straightforward. They hit our 3-week window with HIP and machining included.” — Engineering Manager, Specialty EV OEM

Future Innovations and Market Trends

Expect broader adoption of embedded channels for thermal and harness routing, standardized S‑N allowables for Al and Ti alloys in chassis spectra, and digital inventory strategies enabling regional reprints on demand. As U.S. EV platforms diversify, AM subframe blocks will become configurable modules with validated parameter sets, supporting 15–25% CAGR through 2030.

Expert perspective: “HIP and surface conditioning have turned AM into a production method for chassis interfaces, not just prototyping.” — Dr. Brandon Lane, NIST Additive Manufacturing (nist.gov)

Common Questions and Expert Answers

Q: Can AM subframe blocks pass OEM PPAP in the U.S.?

A: Yes. We provide powder certs, CT scans, metallography, tensile/fatigue data, and process FMEAs aligned with IATF 16949 and PPAP expectations.

Q: How do you address OSHA/EPA requirements?

A: Our LPBF workflows include enclosed powder handling, ventilation/filtration, and waste management practices aligned with OSHA and EPA guidelines. We also advise U.S. facilities on safe operations.

Q: What are typical lead times?

A: 1–3 weeks for design-to-vehicle, including HIP and CNC, depending on complexity and inspection scope.

Q: How do you mitigate galvanic corrosion at the subframe interface?

A: Through surface coatings, isolating shims, sealed interfaces, and material pairing guidance; we validate via salt-spray and environmental cycling as needed.

Why This Solution Works for Your Operations

AM subframe connection mounts and blocks give EV and motorsport teams a path to lighter, stiffer, and more integrated structures without the delay and risk of tooling. With Metal3DP, you gain a single accountable partner—from spherical metal powder to finished, inspected parts—shortening timelines and improving confidence in fatigue-critical components.

Connect with Specialists for Custom Solutions

Partner with Metal3DP for a one-stop pathway to production:

- High-performance metal powders with custom formulations: aluminum powder (AlSi10Mg, Scalmalloy), titanium powder (Ti‑6Al‑4V), stainless steel powder (17‑4PH), nickel superalloys—produced via gas atomization and PREP for high purity and excellent flowability.

- Advanced powder production equipment for sale: GA and PREP systems with process know-how to build your in-house capability in the U.S.

- Complete 3D printing services: DfAM consulting, laser powder bed fusion and EBM systems, HIP, CNC, and inspection—delivered as finished components.

- One-stop solution provider: Raw materials + Equipment + Printing services, with material recommendations tailored to your platform and turnkey manufacturing support.

- Proven across aerospace, medical device manufacturing, automotive 3D printing, and energy.

Get a free consultation on material selection, equipment needs, and production planning. Consolidate vendors and accelerate your program with a single accountable provider. Contact: [email protected]

Article Metadata

Last updated: 2025-09-05

Next update scheduled: 2025-12-15

공유

중국 칭다오에 본사를 둔 선도적인 적층 제조 솔루션 제공업체인 MET3DP Technology Co. 당사는 산업용 3D 프린팅 장비와 고성능 금속 분말을 전문으로 합니다.

관련 기사