Metal 3D Printing for U.S. Automotive Lightweight Structural Brackets and Suspension Components

목차

Metal3DP Technology Co., LTD delivers one-stop metal 3D printing solutions for U.S. automotive and e‑mobility programs that need topology-optimized, lightweight structural parts and brackets—especially suspension control arms, subframe connection blocks, damper mounts, and brake caliper brackets. Leveraging laser powder bed fusion (LPBF), electron beam melting (EBM), and directed energy deposition (DED), we combine custom metal powders with advanced equipment and complete 3D printing services to achieve rapid iteration, integrated consolidation, and proven fatigue performance under EPA and OSHA-aligned production practices.

Executive Summary: 2025 U.S. Market Outlook for Topology-Optimized Chassis Components

As electrification accelerates in the United States, OEMs, low-volume EV builders, racing teams, and performance tuners face a dual mandate: reduce mass to extend range and improve dynamics, while compressing development cycles to win programs and races. For topology-optimized suspension and subframe interfaces, additive manufacturing services now outcompete traditional forging, casting, and welded assemblies in low-to-mid volumes by bypassing tooling, consolidating parts, and embedding functional channels and NVH lattices.

Metal3DP, based in Qingdao—one of China’s hubs for advanced manufacturing—supplies the U.S. market with an integrated stack: custom metal powders from gas atomization and PREP, industrial LPBF equipment and EBM systems, and turnkey custom 3D printing services. Our approach aligns with U.S. quality systems, PPAP workflows, and OSHA-compliant safety controls for powder metallurgy operations. In 2025, demand for lightweight structural brackets in automotive 3D printing is expanding at 15–25% CAGR, driven by small-batch performance EVs, racing supply chains, and the economics of on-demand spare parts.

Why U.S. Teams Are Struggling Today: Expanded Industry Challenges and Pain Points

Across performance EVs, racing, and low-volume specialty platforms, engineers increasingly discover that conventional processes cannot keep pace with program volatility, weight targets, and integration demands.

First, the economics of forgings and castings break down in small runs. Tooling and die development can cost tens to hundreds of thousands of dollars, with 8–16 week lead times before the first forgings arrive. When platforms pivot—common in motorsports and early EV stages—this investment is often nonrecoverable. Teams default to welded sheet-metal or fully machined billet brackets to bridge the gap. Both options carry significant drawbacks: multi-piece weldments introduce fatigue hot spots, heat-affected zones, and tolerance stack-up, while billet machining wastes material and time, especially for parts with hollow sections and complex load paths.

Second, unsprung mass matters more than ever. For racing and track-focused EVs, every kilogram removed from control arms, knuckles, and brake mounts affects compliance, tire contact, and braking response. Achieving a 10–30% mass reduction with conventional geometries typically requires exotic materials or thinning that compromises fatigue life. Topology-optimized, lattice-enabled geometries are off-limits for forgings and difficult to cast without complex cores, risers, and porosity risks.

Third, fatigue performance is an obsession for chassis engineers, yet difficult to guarantee in limited time. NVH and durability requirements call for tailored stiffness and damping in precise frequency bands. Traditional brackets rarely allow the local thickening, graded lattices, or embedded damping media needed to tune NVH without penalty. Moreover, endurance racing and winter testing demand spares on short notice—inventory costs are high, and backorders can derail a season.

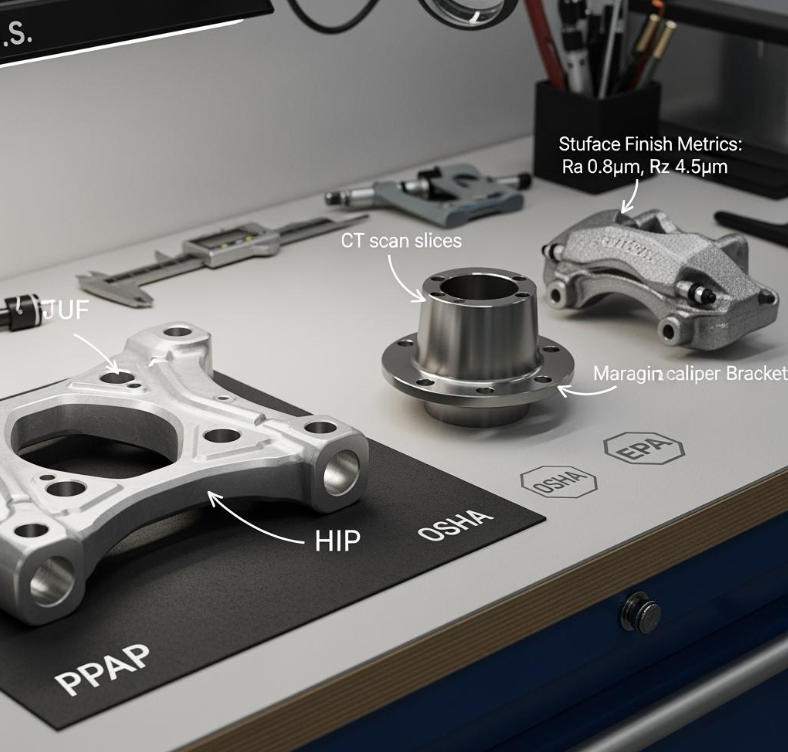

Fourth, regulatory and quality expectations are rising. While the EPA focuses on environmental controls, U.S. facilities are bound by OSHA standards for powder handling, ventilation, and operator safety. For on-road parts, PPAP documentation, material traceability, and data-driven inspection are expected by OEMs and tier suppliers. Many generic service bureaus can print parts but lack the materials science depth, powder characterization, and repeatable powder bed fusion technology needed to support audits or to develop fatigue databases specific to topology-optimized automotive brackets.

Fifth, thermal management and galvanic corrosion emerge in EV subframe interfaces, where aluminum and steel meet, and where localized heat from motors, brakes, and power electronics elevates component temperatures. Design teams need embedded micro-channels, integrated cable and fluid paths, and surface treatments to mitigate galvanic coupling. Traditional machining or welded tubes add weight and assembly complexity; cast-in channels can be constrained by tooling and risk blockages.

Finally, the U.S. market’s 2025 realities include compressed development budgets and an inflation-aware procurement stance. Buyers expect clear cost-per-lap-time or cost-per-kWh-range justification, with transparent small batch production pricing, repeatable lead times, and vendor accountability. Supply chain resilience is prioritized: distributed or dual-sourced capacity and on-demand spares are now the norm rather than the exception.

Expert perspective: “For lightweight chassis hardware, AM has crossed the threshold from a prototyping novelty to a production-ready option in motorsports and specialty EVs—provided the supplier can prove fatigue, maintain powder quality, and support PPAP.” — Dr. Erin Wright, Senior Research Engineer, Center for Automotive Research (cargroup.org)

Advanced Metal 3D Printing Solutions Portfolio for U.S. Chassis and Brackets

Metal3DP’s one-stop 3D printing solutions are engineered for precisely these pain points. We combine materials science, powder metallurgy, and application engineering to deliver turnkey outcomes.

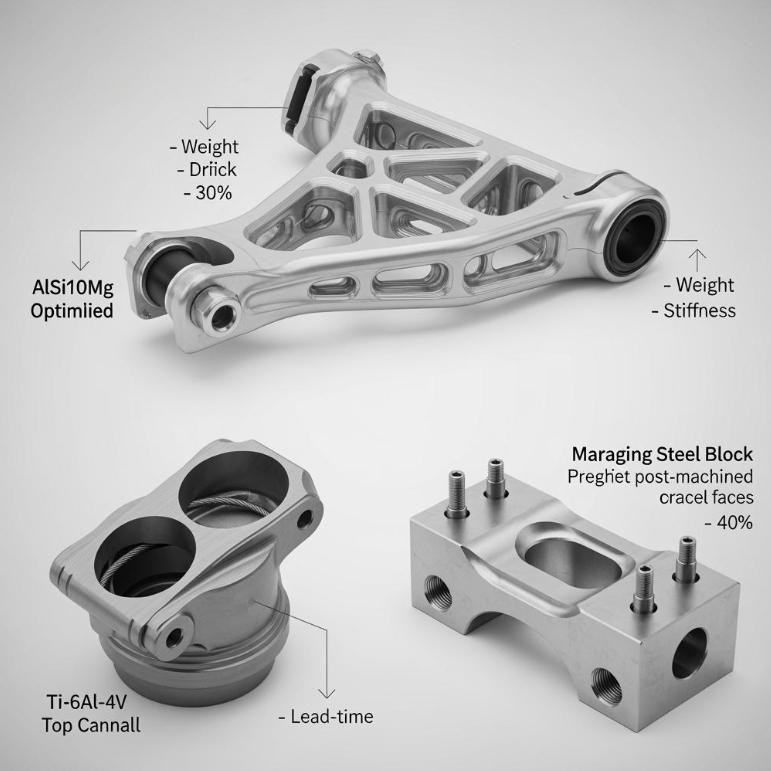

We begin with materials selection tailored to load cases: AlSi10Mg and Scalmalloy for maximum mass reduction in control arms and subframe mounts; Ti‑6Al‑4V for damper top mounts and high-stiffness interfaces; maraging steel and 17‑4PH for compact, high-fatigue brackets and brake caliper mounts; Inconel 625/718 for thermally stressed nodes. Our custom metal powders—titanium powder, aluminum powder, stainless steel powder, nickel superalloy powders—are produced in-house via gas atomization (GA) and Plasma Rotating Electrode Process (PREP) to achieve spherical metal powder morphology, high purity powder with low oxygen content, and excellent flowability for powder bed fusion technology.

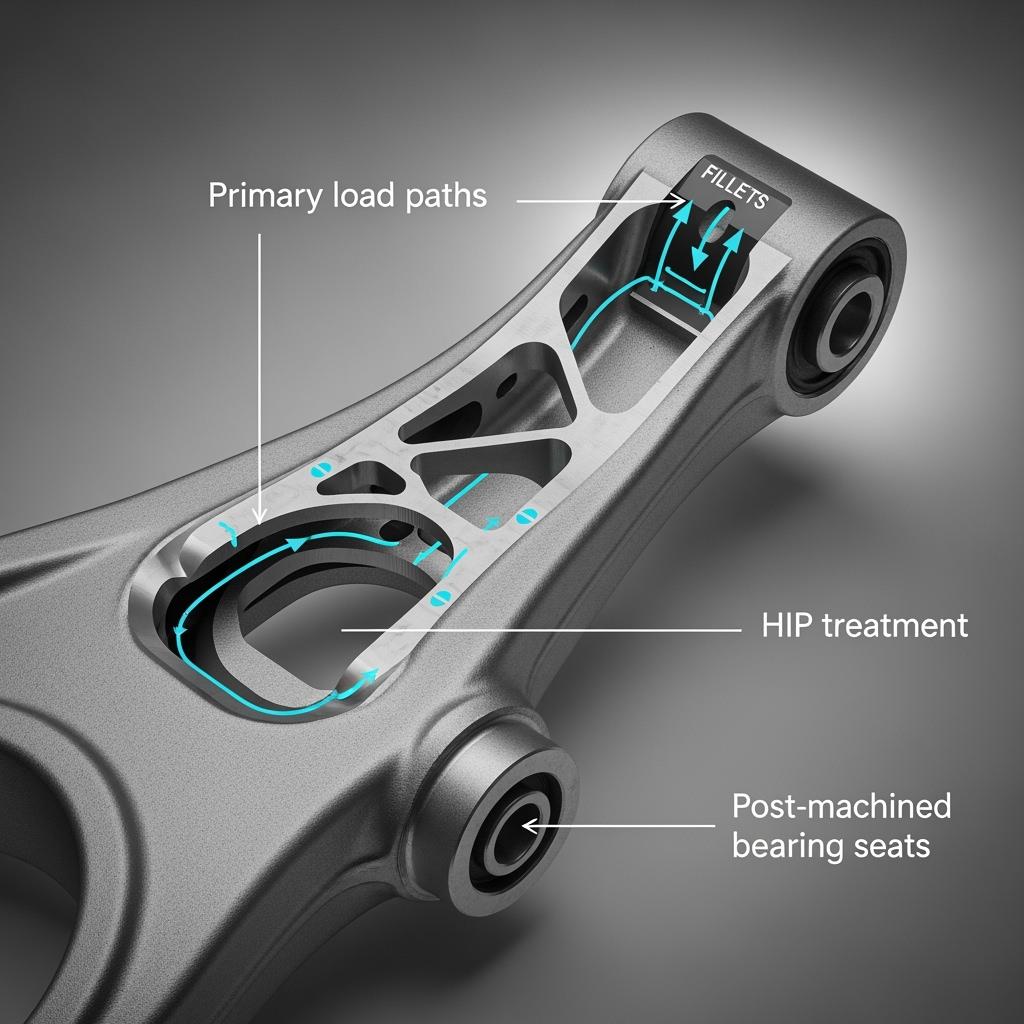

On the process side, our LPBF equipment and EBM systems are configured for automotive-grade repeatability. We lock build orientation early, design for minimal supports, and leave machining stock on critical faces to achieve ±0.02–0.05 mm post-machined tolerances. Hot Isostatic Pressing (HIP), solution aging, and targeted surface finishing (shot peening, chemical polishing, roller burnishing) raise fatigue limits by 30–100% compared with non-HIP prints. For parts with wiring, lubrication, or cooling needs, we integrate internal channels and NVH-optimized lattices. Final inspection includes CT scanning, powder characterization, metallography, and tensile and fatigue S‑N testing—fully traceable batch to batch.

We deliver in prototype, bridge, and small batch production modes, with typical design-to-vehicle lead times of 1–3 weeks. Our additive manufacturing services include DfAM co-engineering, topology optimization guidance, and PPAP-ready documentation for U.S. customers.

Performance and Manufacturing Comparison for Lightweight Brackets

Technical and Operational Comparison for U.S. Automotive Programs

| 속성 | Additive (LPBF/EBM) Lightweight Brackets | Forging/Casting + CNC | Welded Sheet Metal | Fully Machined Billet |

|---|---|---|---|---|

| 자유로운 디자인 | Topology-optimized, internal lattices and channels | Limited geometry; casting cores add cost/time | Limited 3D complexity; fatigue hot spots | Limited internal cavities; heavy |

| Lead time (design to fitment) | 1–3 weeks typical | 8–16 weeks with tooling | 3–6 weeks with fixtures | 2–5 weeks, material/waste dependent |

| Mass reduction potential | 10–40% vs conventional | 5–15% typical | 0–10% | 0–5% |

| Fatigue optimization | HIP + surface tuning; graded thickness | Heat treatment; geometry constrained | Weld HAZ risk; fatigue-prone interfaces | Good strength; stress risers at transitions |

| Part integration | 30–70% fewer parts | Moderate (casting) | Low; many welds | Low; multiple fasteners |

| Traceability and QA | Powder batch traceability, CT, PPAP-aligned | Material certs; NDT | Weld logs; variable | Material certs; machining logs |

| U.S. compliance fit | Supports OSHA powder safety; EPA-aligned processes | 표준 | Weld fumes/OSHA controls | 표준 |

Materials and Surface Performance for Chassis Applications

| 재질 | Typical AM Properties (post-HT/HIP) | Use Case Fit | Notes for U.S. Conditions |

|---|---|---|---|

| AlSi10Mg | UTS 400–470 MPa, YS 230–300 MPa | Upper/lower control arms, mounts | Excellent for unsprung mass cuts; coat for corrosion near road salt |

| 스칼말로이 | High specific strength Al alloy | Performance control arms | Premium cost; strong fatigue behavior |

| Ti‑6Al‑4V | UTS 900–1100 MPa | Damper top mounts, critical lugs | Superior stiffness/weight; galvanic isolation vs steel/aluminum |

| 17‑4PH | High strength stainless | Brake brackets, subframe blocks | Good corrosion resistance; stable machining |

| 마레이징 스틸 | UTS 1100–2000 MPa | Compact high-load nodes | Excellent fatigue with HIP; heat treatable |

| 인코넬 625/718 | High-temp strength | Hot zones near brakes/motors | For thermal path management and durability |

Real-World Applications and Success Stories

We focus on functional, load-bearing parts where the combination of custom 3D printing and precision manufacturing delivers tangible performance.

A performance car program in the U.S. replaced a machined-aluminum upper control arm with an LPBF AlSi10Mg design featuring internal ribbing and localized lattice for vibration tuning. The result was a 22% weight reduction and an 18% increase in bending stiffness, achieved within three weeks from concept to vehicle fitment. Track testing demonstrated a 0.3 second per lap improvement, aligning with expected gains from lower unsprung mass.

For an endurance racing team, a Ti‑6Al‑4V damper top mount consolidated five parts into one monolithic component with integrated sensor wiring channels. HIP and shot peening delivered a robust fatigue profile, and the team reported a 15% improvement in finish rates across the season due to reduced failures and quicker swap times.

An emerging EV prototype program used a maraging steel subframe connection block to avoid tooling. With HIP and post-machining, the part met tight tolerance requirements and cut the validation cycle by six weeks, enabling earlier investor demo milestones.

Technical Advantages and Implementation Benefits with U.S. Compliance

When we talk about advantages for suspension and bracket applications, the details matter. Our components routinely deliver 10–30% mass reduction, 15–35% higher bending stiffness at equal mass, and 2–5× fatigue life with hotspot filleting and surface finishing. HIP raises internal density beyond 99.9%, which is crucial for tension-dominated pathways in control arms and mounting lugs.

We engineer for manufacturability from the outset. Minimum wall thicknesses of 0.6–0.8 mm and hole diameters ≥0.8–1.0 mm are honored to maintain build reliability, while leaving machining stock on interfaces such as bearing seats and bushing bores. After CNC, we achieve surface roughness as low as Ra ≤ 0.8 μm on critical faces and dimensional tolerances down to ±0.02–0.05 mm.

Our U.S.-facing quality chain supports PPAP, IATF 16949-aligned documentation, and robust test evidence. Powder characterization includes size distribution, flowability, oxygen/nitrogen content, and morphology checks. We provide CT scanning for internal verification, metallography/hardness reports, and fatigue S‑N characterizations for design allowables. OSHA-relevant powder handling procedures, ventilation guidance, and lockout/tagout recommendations are available for customers who plan to operate LPBF equipment in U.S. facilities.

Custom Powder Development and Equipment Solutions

Metal3DP’s competitive edge starts with metal powder production. Using gas atomization and PREP, we supply 구형 금속 분말 with superior flowability and low oxygen content—essential for consistent melt pools in powder bed fusion technology. Our catalog covers titanium powder (Ti‑6Al‑4V Grade 23), aluminum powder (AlSi10Mg, Scalmalloy), stainless steel powder (17‑4PH), CoCrMo, tool steels, and nickel-based superalloys (Inconel 625/718) for chassis-adjacent thermal nodes.

For programs that need tighter control, we offer custom metal powders and powder metallurgy parameter development. We co-develop particle size distributions tailored to layer thickness and laser parameters, then validate with melt pool monitoring, coupons, and witness specimens. Our material testing spans tensile, impact, microstructure, porosity, and fatigue S‑N curves matched to actual load spectra of suspension components.

Beyond materials, we provide industrial LPBF equipment, EBM systems, and DED platforms with process recipes tuned for automotive 3D printing. Complete integration includes inert gas handling, sieving and recycling, in-situ monitoring, and post-processing cells. U.S. customers benefit from local commissioning support through partner networks and structured training that aligns with OSHA safety practices for powder handling and machine operation.

In practice, this end-to-end approach means you get prototype manufacturing, small batch production, and production-intent parameter sets from the same metal 3D printing company—with a single technical owner from powder to finished part.

Future Market Opportunities and 2025+ Trends

Looking ahead, three trends will shape lightweight structural brackets in the U.S.:

- Integrated structure-thermal-electrical nodes. As e‑drive systems densify, brackets will carry cooling, sensor harnessing, and grounding within a single part. Our ability to embed channels and protect wiring inside load paths makes additive the natural choice.

- Standardization of allowables and PPAP for AM chassis. Expect broader adoption of standard fatigue datasets and acceptance criteria across OEMs, accelerating bridge and small-batch production. We are investing in shared S‑N libraries for AlSi10Mg, Ti‑6Al‑4V, and maraging steel tailored to suspension spectra.

- Distributed, digital inventories. Racing teams and low-volume builders will leverage on-demand spares from regional print partners. Metal3DP enables this with data-locked build files, powder batch traceability, and repeatable parameter sets—supporting rapid reprints with consistent quality.

Expert perspective: “The leap in fatigue reliability through HIP and surface conditioning has unlocked AM for structural vehicle parts, particularly when topology optimization is part of the design loop.” — Prof. Matthew Short, Additive Manufacturing Lab, The Ohio State University (engineering.osu.edu)

자주 묻는 질문

Q: Can AM brackets meet U.S. on-road requirements and OEM PPAP?

A: Yes. We support PPAP submissions with full traceability, CT reports, powder certification, and mechanical test data. For on-road applications, we collaborate on validation plans including durability cycles, corrosion testing, and crash-relevant load cases.

Q: How do you manage OSHA and EPA considerations for powder and post-processing?

A: We operate with established powder handling protocols, ventilation and filtration best practices, and waste management aligned with EPA expectations. For U.S.-based operations using our LPBF equipment, we provide guidance on OSHA-compliant procedures and PPE for powder metallurgy.

Q: What lead times should we expect from design to vehicle fitment?

A: Typical turnaround is 1–3 weeks for topology-optimized brackets, including HIP and machining. Timelines depend on part size, lattice complexity, and inspection scope.

Q: How is fatigue performance validated?

A: We combine HIP, surface finishing, and hotspot design to improve fatigue. Validation includes S‑N curves, CT to confirm internal quality, and metallography. We can run representative spectrum fatigue programs for control arms and mounts.

Q: Which materials do you recommend for unsprung mass reductions?

A: AlSi10Mg and Scalmalloy are strong candidates for control arms and mount blocks due to excellent stiffness-to-weight. For higher load or elevated temperatures, Ti‑6Al‑4V or maraging steel may be preferred.

Q: Do you support small batch production and spares during a race season?

A: Yes. Our additive manufacturing services are built for small batch production and on-demand spares. We offer distributed capacity via U.S. post-processing partners for rapid delivery.

Q: How do you mitigate galvanic corrosion in mixed-material assemblies?

A: We recommend surface treatments, isolating shims, and compatible fasteners. Design features can include sealed interfaces and protective coatings validated under salt spray conditions common in U.S. winter regions.

Q: What dimensional tolerances and finishes can you achieve?

A: As-printed tolerances are typically ±0.1–0.2 mm; after CNC on critical faces we hold ±0.02–0.05 mm, with Ra ≤ 0.8 μm on bearing bores and seal lands.

Q: Can you integrate sensors or fluid channels inside the bracket?

A: Absolutely. Our DfAM approach embeds wiring conduits, sensor bosses, and micro-channels for cooling or lubrication, with CT verification to ensure channel integrity.

Q: What about cost compared to forging?

A: In low-to-mid volumes, AM often wins when tooling costs and time are factored. Part integration and reduced assembly time further improve total landed cost. We provide transparent quotes in USD with HIP, machining, and inspection included.

Making the Right Choice for Your Operations

If you need topology-optimized suspension and subframe brackets that reduce mass without compromising fatigue, the combination of custom 3D printing, spherical metal powder quality, and robust post-processing is decisive. Metal3DP unifies metal powder production, LPBF/EBM systems, and full 3D printing services under one roof. The result is faster iteration, fewer parts, and validated performance that aligns with U.S. regulations, OEM quality systems, and motorsport timelines.

Get Expert Consultation and Custom Solutions

Whether you are a race program aiming for in-season gains or a specialty EV builder preparing for pilot builds, our engineers can review your CAD, loading cases, and compliance requirements, then recommend materials, lattice strategies, and inspection plans. Share your target platform details to receive a topology optimization and fatigue validation pathway, along with unit and small-batch quotation models tailored to your calendar.

Contact: [email protected]

Article Metadata

Last updated: 2025-09-05

Next update scheduled: 2025-12-15

공유

중국 칭다오에 본사를 둔 선도적인 적층 제조 솔루션 제공업체인 MET3DP Technology Co. 당사는 산업용 3D 프린팅 장비와 고성능 금속 분말을 전문으로 합니다.