진공 유도 용융

목차

개요

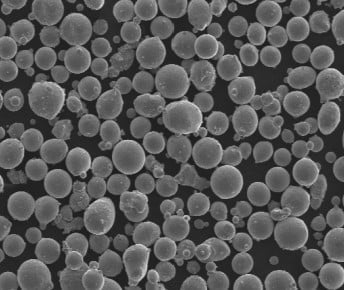

진공 유도 용융 (VIM) is a sophisticated and highly precise process used to produce high-quality metal alloys and powders. This method is crucial for applications requiring exceptional purity and precise composition, making it essential in industries like aerospace, medical devices, and high-performance engineering. Let’s delve into the intricacies of VIM, exploring its processes, applications, advantages, disadvantages, and detailed information on various metal powder models produced through this technique.

진공 유도 용융이란 무엇인가요?

Vacuum Induction Melting involves melting metals in a vacuum environment using electromagnetic induction. This technique minimizes contamination from gases and impurities, ensuring the production of metals with superior purity and homogeneity. By melting metals under vacuum, VIM prevents oxidation and enables precise control over the composition of the final product.

Key Details of VIM:

- 프로세스: Melting metals using electromagnetic induction in a vacuum.

- 목적: Producing high-purity metal alloys and powders.

- 애플리케이션: Aerospace, medical devices, high-performance engineering.

How Vacuum Induction Melting Works

Imagine a high-tech kitchen where you cook your favorite dish in a perfectly controlled environment, free from any unwanted odors or contaminants. That’s VIM in a nutshell, but for metals! The process begins with placing raw materials into a crucible within the vacuum chamber. An induction coil surrounds the crucible, generating a magnetic field when an electric current passes through it. This magnetic field induces eddy currents in the metal, causing it to heat up and eventually melt.

Once the metal reaches the desired temperature, alloying elements can be added to achieve the specific composition required. The vacuum environment ensures that no gases are trapped in the melt, resulting in a cleaner and more homogeneous alloy.

Types of Metals and Alloys Produced

VIM is versatile, capable of producing a wide range of metals and alloys. Here are some specific metal powder models:

- Nickel-Based Superalloys (e.g., INCONEL 718)

- 구성: Nickel, Chromium, Iron, and other elements.

- 속성: High strength, corrosion resistance, and excellent high-temperature performance.

- 애플리케이션: Turbine blades, aerospace components.

- Titanium Alloys (e.g., Ti-6Al-4V)

- 구성: Titanium, Aluminum, Vanadium.

- 속성: 높은 중량 대비 강도, 우수한 내식성.

- 애플리케이션: Aerospace, medical implants.

- Cobalt-Chromium Alloys (e.g., CoCrMo)

- 구성: Cobalt, Chromium, Molybdenum.

- 속성: High wear resistance, biocompatibility.

- 애플리케이션: Medical implants, dental devices.

- Stainless Steels (e.g., 316L)

- 구성: Iron, Chromium, Nickel, Molybdenum.

- 속성: Corrosion resistance, mechanical strength.

- 애플리케이션: Surgical instruments, marine applications.

- Aluminum Alloys (e.g., AlSi10Mg)

- 구성: Aluminum, Silicon, Magnesium.

- 속성: Lightweight, good thermal properties.

- 애플리케이션: Automotive parts, aerospace components.

- Magnesium Alloys (e.g., AZ91D)

- 구성: Magnesium, Aluminum, Zinc.

- 속성: Lightweight, high strength.

- 애플리케이션: Automotive, electronics.

- Copper Alloys (e.g., CuCrZr)

- 구성: Copper, Chromium, Zirconium.

- 속성: High electrical conductivity, good mechanical properties.

- 애플리케이션: 전기 부품, 열교환기.

- Tool Steels (e.g., M2 High-Speed Steel)

- 구성: Iron, Tungsten, Molybdenum, Chromium.

- 속성: High hardness, wear resistance.

- 애플리케이션: 절단 도구, 금형.

- Precious Metal Alloys (e.g., PtIr)

- 구성: Platinum, Iridium.

- 속성: High corrosion resistance, good mechanical properties.

- 애플리케이션: Jewelry, medical devices.

- High-Entropy Alloys (e.g., CoCrFeNiMn)

- 구성: Cobalt, Chromium, Iron, Nickel, Manganese.

- 속성: Excellent mechanical properties, high corrosion resistance.

- 애플리케이션: Advanced engineering applications.

장점 진공 유도 용융

Why is VIM so highly regarded in the metallurgy world? Here are some key benefits:

- 고순도: The vacuum environment eliminates gas contamination, resulting in metals with exceptional purity.

- Precise Composition: Allows for exact control over alloying elements, producing materials with tailored properties.

- 향상된 기계적 특성: Metals produced through VIM exhibit superior mechanical characteristics.

- 동질성: Ensures uniform distribution of alloying elements throughout the metal.

- 다용도성: Capable of melting a wide range of metals and alloys.

Disadvantages of Vacuum Induction Melting

Like any process, VIM has its drawbacks. Here are a few:

- 비용: The equipment and operational costs for VIM are relatively high.

- 복잡성: The process requires sophisticated technology and expertise.

- Scale: Typically suitable for smaller batch sizes compared to other melting methods.

응용 진공 유도 용융

VIM is a game-changer in many industries. Let’s explore its key applications:

항공우주:

- Components: Turbine blades, engine parts.

- 혜택: High-temperature performance, durability.

의료 기기:

- Components: 임플란트, 수술 기구.

- 혜택: Biocompatibility, corrosion resistance.

High-Performance Engineering:

- Components: High-stress components, specialized tools.

- 혜택: Strength, wear resistance.

Types of Metals and Alloys Produced by VIM

| 금속/합금 | 구성 | 속성 | 애플리케이션 |

|---|---|---|---|

| INCONEL 718 | 니켈, 크롬, 철 | 고강도, 내식성 | 터빈 블레이드, 항공우주 부품 |

| Ti-6Al-4V | 티타늄, 알루미늄, 바나듐 | 높은 강도 대 중량비, 내식성 | 항공우주, 의료용 임플란트 |

| CoCrMo | 코발트, 크롬, 몰리브덴 | 높은 내마모성, 생체 적합성 | Medical implants, dental devices |

| 316L 스테인리스 스틸 | 철, 크롬, 니켈, 몰리브덴 | Corrosion resistance, mechanical strength | Surgical instruments, marine applications |

| AlSi10Mg | 알루미늄, 실리콘, 마그네슘 | 가볍고 우수한 열적 특성 | 자동차 부품, 항공우주 부품 |

| AZ91D | 마그네슘, 알루미늄, 아연 | 경량, 고강도 | 자동차, 전자 |

| CuCrZr | 구리, 크롬, 지르코늄 | High electrical conductivity, good mechanical properties | 전기 부품, 열교환기 |

| M2 고속 강철 | 철, 텅스텐, 몰리브덴, 크롬 | 높은 경도, 내마모성 | 절삭 공구, 금형 |

| PtIr | Platinum, Iridium | 높은 내식성, 우수한 기계적 특성 | Jewelry, medical devices |

| CoCrFeNiMn | Cobalt, Chromium, Iron, Nickel, Manganese | Excellent mechanical properties, high corrosion resistance | 고급 엔지니어링 애플리케이션 |

Applications of VIM-Produced Metals

| 산업 | 구성 요소 | 혜택 |

|---|---|---|

| 항공우주 | Turbine blades, engine parts | High-temperature performance, durability |

| 의료 기기 | 임플란트, 수술 기구 | 생체 적합성, 내식성 |

| High-Performance Engineering | High-stress components, specialized tools | 강도, 내마모성 |

사양 및 표준

| 금속/합금 | 표준 | 등급 | 사양 |

|---|---|---|---|

| INCONEL 718 | ASTM B637 | 1등급 | 고온에서 높은 강도 |

| Ti-6Al-4V | ASTM B348 | 5학년 | 높은 중량 대비 강도 비율 |

| CoCrMo | ASTM F1537 | 1등급 | 높은 내마모성 |

| 316L 스테인리스 스틸 | ASTM A240 | 316L 등급 | 내식성 |

| AlSi10Mg | ASTM B928 | 1등급 | 가볍고 우수한 열적 특성 |

| AZ91D | ASTM B93 | AZ91D 등급 | 경량, 고강도 |

| CuCrZr | ASTM B224 | 1등급 | 높은 전기 전도성 |

| M2 고속 강철 | ASTM A600 | Grade M2 | 높은 경도, 내마모성 |

| PtIr | ASTM B563 | 1등급 | 높은 내식성 |

| CoCrFeNiMn | ASTM E2209 | 1등급 | 우수한 기계적 성질 |

장점과 단점 진공 유도 용융

장점

| 이점 | 설명 |

|---|---|

| 고순도 | Eliminates gas contamination for superior purity. |

| Precise Composition | Exact control over alloying elements for tailored properties. |

| 향상된 기계적 특성 | Superior mechanical characteristics in final products. |

| Homogeneity | Uniform distribution of alloying elements. |

| 다용도성 | 다양한 금속 및 합금에 적합합니다. |

단점

| 단점 | 설명 |

|---|---|

| 비용 | High equipment and operational costs. |

| 복잡성 | Requires sophisticated technology and expertise. |

| 규모 | Typically limited to smaller batch sizes compared to other methods. |

공급업체 및 가격 세부 정보

Leading Suppliers of VIM Equipment

| 공급업체 | 제품 범위 | 가격 책정 | 지역 |

|---|---|---|---|

| Inductotherm Group | VIM furnaces, accessories | $100,000 – $1,000,000 | 글로벌 |

| ALD 진공 기술 | VIM systems, custom solutions | $150,000 – $2,000,000 | 글로벌 |

| Seco/Warwick | VIM furnaces, after-sales services | $120,000 – $900,000 | 북미, 유럽 |

| Consarc | VIM and VAR furnaces | $200,000 – $1,500,000 | 글로벌 |

| ECM 기술 | VIM systems | $100,000 – $850,000 | 유럽, 아시아 |

Comparison of VIM vs. Other Melting Methods

| 측면 | 진공 유도 용융(VIM) | Arc Melting | Electroslag Remelting (ESR) |

|---|---|---|---|

| 순도 | High due to vacuum environment | 보통 | 높음 |

| 비용 | 높음 | Lower | 높음 |

| 복잡성 | 높음 | 보통 | 높음 |

| 배치 크기 | 중소형 | 중대형 | Medium |

| 애플리케이션 | 고성능 합금 | General purpose | 고순도 애플리케이션 |

자주 묻는 질문

| 질문 | 답변 |

|---|---|

| What is Vacuum Induction Melting (VIM)? | VIM is a process that melts metals using electromagnetic induction in a vacuum to produce high-purity alloys. |

| Why use VIM over other melting methods? | VIM offers superior purity, precise composition control, and improved mechanical properties. |

| What metals can be produced using VIM? | VIM can produce a wide range of metals, including nickel-based superalloys, titanium alloys, and more. |

| What are the key applications of VIM? | Key applications include aerospace components, medical devices, and high-performance engineering parts. |

| What are the disadvantages of VIM? | Disadvantages include high cost, complexity, and typically smaller batch sizes. |

| Who are the leading suppliers of VIM equipment? | Leading suppliers include Inductotherm Group, ALD Vacuum Technologies, and Seco/Warwick. |

| How does VIM compare to Arc Melting? | VIM provides higher purity but at a higher cost and complexity compared to Arc Melting. |

결론

Vacuum Induction Melting is a pinnacle of modern metallurgy, providing unmatched purity and precision in metal production. Its applications span critical industries where performance and reliability are non-negotiable. While it comes with higher costs and complexity, the benefits often outweigh these challenges, making VIM an invaluable process in advanced material manufacturing.

공유

중국 칭다오에 본사를 둔 선도적인 적층 제조 솔루션 제공업체인 MET3DP Technology Co. 당사는 산업용 3D 프린팅 장비와 고성능 금속 분말을 전문으로 합니다.

관련 기사

Met3DP 소개

최근 업데이트

제품

3D 프린팅 및 적층 제조용 금속 분말

문의 정보

- 칭다오시, 산둥성, 중국

- [email protected]

- [email protected]

- +86 19116340731