Polvos metálicos para semiconductores

Índice

En el mundo de los semiconductores, en constante evolución, el papel de los polvos metálicos es fundamental. Desde la creación de microprocesadores hasta el desarrollo de memorias avanzadas, los polvos metálicos son los héroes anónimos de estas maravillas tecnológicas. Este artículo se sumerge en los entresijos de polvos metálicos para semiconductoressus tipos, composiciones, aplicaciones, especificaciones y mucho más. Embarquémonos en una exploración detallada de este fascinante tema.

Polvo metálico para semiconductores

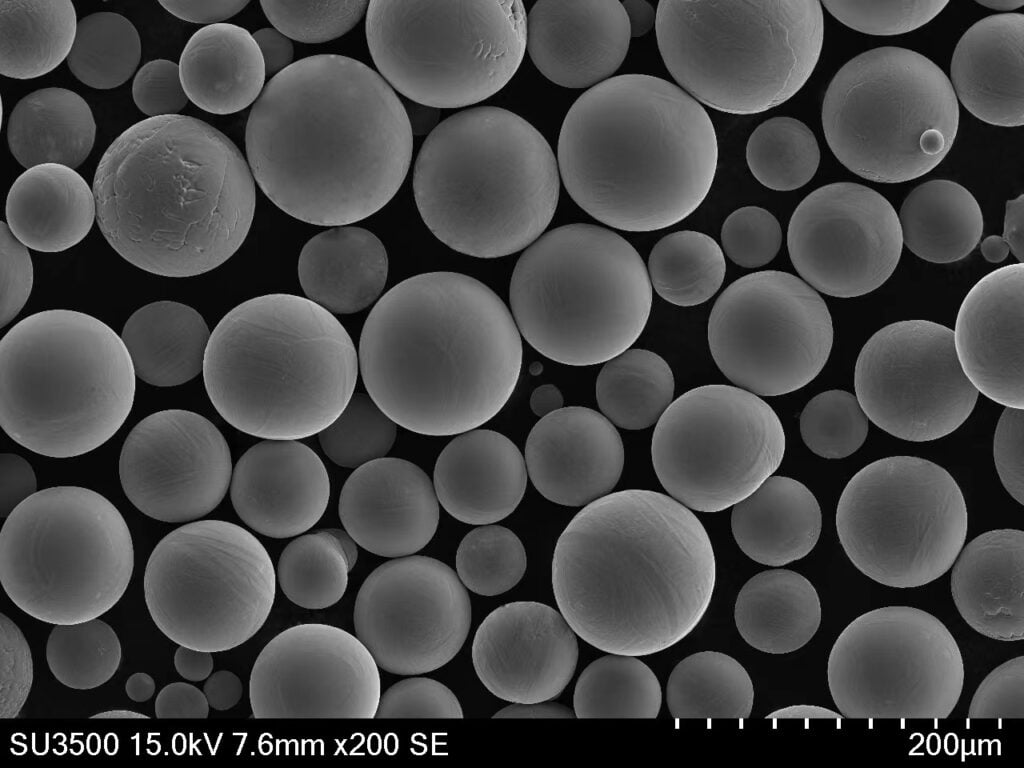

Los polvos metálicos son partículas finamente divididas de metales que se utilizan en diversas aplicaciones, incluida la industria de los semiconductores. Su importancia radica en sus propiedades únicas, como la alta pureza, el tamaño controlado de las partículas y la superficie específica, que los hacen ideales para su uso en la fabricación de dispositivos semiconductores.

Puntos clave:

- Los polvos metálicos son fundamentales en el proceso de fabricación de semiconductores.

- Ofrecen una gran pureza y partículas de tamaño controlado.

- Se utiliza en la creación de microprocesadores, almacenamiento de memoria y otros dispositivos semiconductores.

Tipos de polvo metálico para semiconductores

Se utilizan distintos metales en forma de polvo para diversas aplicaciones de semiconductores. Cada polvo metálico tiene propiedades distintas que lo hacen adecuado para usos específicos.

| Polvo metálico | Composición | Propiedades | Características |

|---|---|---|---|

| Cobre (Cu) | Cobre puro | Alta conductividad | Resistencia a la corrosión, ductilidad |

| Aluminio (Al) | Aluminio puro | Ligero, alta conductividad | Reflectividad, maleabilidad |

| Plata (Ag) | Plata pura | Máxima conductividad eléctrica | Resistencia al deslustre, antimicrobiano |

| Oro (Au) | Oro puro | Excelente conductividad | No reactivo, ductilidad |

| Níquel (Ni) | Níquel puro | Resistencia a la corrosión | Magnetismo, alto punto de fusión |

| Titanio (Ti) | Titanio puro | Resistencia, ligereza | Resistencia a la corrosión, biocompatibilidad |

| Tungsteno (W) | Tungsteno puro | Alto punto de fusión | Densidad, dureza |

| Molibdeno (Mo) | Molibdeno puro | Alta resistencia | Alta conductividad térmica, baja dilatación térmica |

| Paladio (Pd) | Paladio puro | Resistencia a la corrosión | Buena conductividad, propiedades catalíticas |

| Cobalto (Co) | Cobalto puro | Propiedades magnéticas | Alto punto de fusión, resistencia |

Aplicaciones del polvo metálico para semiconductores

Los polvos metálicos se utilizan en diversas aplicaciones de la industria de semiconductores. He aquí un desglose de dónde y cómo se utilizan estos polvos.

| Aplicación | Polvos metálicos utilizados | Descripción |

|---|---|---|

| Microprocesadores | Cobre, oro, plata | Vías conductoras e interconexiones |

| Almacenamiento en memoria | Aluminio, níquel | Capas de almacenamiento de datos y grabación magnética |

| Sensores | Paladio, cobalto | Elementos sensibles en los sensores |

| Transistores | Tungsteno, molibdeno | Materiales de compuerta e interconexión |

| Condensadores | Titanio, níquel | Materiales dieléctricos y electrodos |

| LEDs | Aluminio, Oro | Vías conductoras y disipadores de calor |

| Dispositivos de alimentación | Cobre, plata | Componentes de alta intensidad |

| Células solares | Plata, Aluminio | Rejillas y contactos conductores |

Especificaciones, tamaños, calidades y normas

Comprender las especificaciones, tamaños, grados y normas de los polvos metálicos es crucial para su aplicación eficaz en semiconductores.

| Polvo metálico | Tamaños (µm) | Grados | Normas |

|---|---|---|---|

| Cobre (Cu) | 0.1 – 10 | Alta pureza (99,99%) | ASTM B170-99 |

| Aluminio (Al) | 0.5 – 15 | Grado electrónico | ISO 8000 |

| Plata (Ag) | 0.2 – 5 | 99,999% Puro | ASTM B779-99 |

| Oro (Au) | 0.1 – 3 | Grado semiconductor | ISO 9208 |

| Níquel (Ni) | 1 – 20 | 99,98% Puro | ASTM B330-03 |

| Titanio (Ti) | 2 – 30 | Alta pureza (99,6%) | ASTM B348-19 |

| Tungsteno (W) | 0.3 – 15 | Alta pureza | ISO 2768-1 |

| Molibdeno (Mo) | 0.5 – 10 | 99.95% Puro | ASTM B386-03 |

| Paladio (Pd) | 0.1 – 5 | 99,9% Puro | ISO 6284 |

| Cobalto (Co) | 1 – 25 | 99,8% Puro | ASTM B330-03 |

Proveedores y precios

Saber dónde abastecerse de polvos metálicos y conocer sus precios es vital para planificar y presupuestar la fabricación de semiconductores.

| Proveedor | Polvos metálicos disponibles | Precio (por kg) |

|---|---|---|

| Elementos americanos | Cobre, oro, níquel, plata | $300 – $10,000 |

| NanoAmor | Aluminio, tungsteno, titanio | $200 – $8,000 |

| Nanomateriales SkySpring | Paladio, cobalto, molibdeno | $500 – $12,000 |

| Tekna | Aluminio, cobre, níquel | $250 – $9,000 |

| Goodfellow | Oro, plata, titanio | $400 – $15,000 |

Comparación de ventajas e inconvenientes de los polvos metálicos

Cada polvo metálico tiene sus ventajas y limitaciones. He aquí un análisis comparativo para ayudar a comprender cuál puede ser el más adecuado para aplicaciones específicas.

| Polvo metálico | Ventajas | Desventajas |

|---|---|---|

| Cobre (Cu) | Alta conductividad, rentable | Susceptible a la oxidación |

| Aluminio (Al) | Ligero, buena conductividad | Punto de fusión más bajo |

| Plata (Ag) | Máxima conductividad, resistente al deslustre | Caro |

| Oro (Au) | No reactivo, excelente conductividad | Muy caro |

| Níquel (Ni) | Resistente a la corrosión, magnético | Conductividad moderada |

| Titanio (Ti) | Resistente, ligero y biocompatible | Caro, reactivo |

| Tungsteno (W) | Alto punto de fusión, duro | Muy denso, difícil de procesar |

| Molibdeno (Mo) | Alta resistencia, conductividad térmica | Quebradizo, caro |

| Paladio (Pd) | Buena conductividad, resistente a la corrosión | Muy caro |

| Cobalto (Co) | Propiedades magnéticas, alto punto de fusión | Caro, puede ser tóxico |

Composición del polvo metálico para semiconductores

La composición de los polvos metálicos desempeña un papel crucial en su eficacia y aplicación en dispositivos semiconductores. A continuación profundizamos en las composiciones y sus repercusiones.

Cobre (Cu) en polvo:

- Composición: Cobre puro (99,99%)

- Impacto: Proporciona una excelente conductividad eléctrica, crucial para interconexiones y vías conductoras en microprocesadores y dispositivos de memoria.

Polvo de aluminio (Al):

- Composición: Aluminio puro (99,98%)

- Impacto: Ligero y reflectante, ideal para rejillas conductoras en células solares y disipadores de calor LED.

Plata (Ag) en polvo:

- Composición: Plata pura (99,999%)

- Impacto: La más alta conductividad eléctrica, utilizada en dispositivos de alta frecuencia y alta potencia para una resistencia mínima.

Oro (Au) en polvo:

- Composición: Oro puro (99,99%)

- Impacto: No reactivo y excelente conductor, se utiliza en aplicaciones críticas donde la fiabilidad y la durabilidad son primordiales.

Níquel (Ni) en polvo:

- Composición: Níquel puro (99,98%)

- Impacto: Resistente a la corrosión y magnético, adecuado para almacenamiento de datos y sensores.

Titanio (Ti) en polvo:

- Composición: Titanio puro (99,6%)

- Impacto: Resistente y ligero, se utiliza en condensadores y dispositivos avanzados de potencia.

Polvo de wolframio (W):

- Composición: Tungsteno puro (99,95%)

- Impacto: Alto punto de fusión y densidad, ideal para transistores y aplicaciones de alta temperatura.

Molibdeno (Mo) en polvo:

- Composición: Molibdeno puro (99,95%)

- Impacto: Alta resistencia y conductividad térmica, utilizado en dispositivos de potencia y gestión térmica.

Paladio (Pd) en polvo:

- Composición: Paladio puro (99,9%)

- Impacto: Excelente conductividad y resistencia a la corrosión, utilizado en sensores de alto rendimiento y aplicaciones catalíticas.

Cobalto (Co) en polvo:

- Composición: Cobalto puro (99,8%)

- Impacto: Propiedades magnéticas y alto punto de fusión, utilizado en aplicaciones de almacenamiento magnético y sensores avanzados.

Características del polvo metálico para semiconductores

Las características únicas de cada polvo metálico los hacen adecuados para diferentes aplicaciones de semiconductores. He aquí un desglose de estas características.

| Polvo metálico | Característica | Descripción |

|---|---|---|

| Cobre (Cu) | Conductividad | Alta conductividad eléctrica, esencial para microprocesadores. |

| Aluminio (Al) | Ligero | Reduce el peso total del dispositivo, lo que resulta beneficioso para los dispositivos electrónicos portátiles. |

| Plata (Ag) | Conductividad | Máxima conductividad eléctrica, óptima para dispositivos de alta frecuencia. |

| Oro (Au) | No reactivo | No se empaña ni corroe, ideal para conexiones críticas. |

| Níquel (Ni) | Magnetismo | Propiedades magnéticas, útiles para el almacenamiento de datos. |

| Titanio (Ti) | Fuerza | Elevada relación resistencia/peso, utilizada en componentes duraderos. |

| Tungsteno (W) | Alto punto de fusión | Adecuado para aplicaciones de alta temperatura como transistores. |

| Molibdeno (Mo) | Conductividad térmica | Excelente para la gestión térmica en dispositivos de potencia. |

| Paladio (Pd) | Resistencia a la corrosión | Resistente a la corrosión, se utiliza en sensores y dispositivos de alto rendimiento. |

| Cobalto (Co) | Propiedades magnéticas | Alto punto de fusión y magnetismo, útil para aplicaciones de almacenamiento. |

Calidades de polvo metálico para semiconductores

Las calidades de los polvos metálicos indican su pureza e idoneidad para diversas aplicaciones. A continuación se detallan los grados disponibles para los distintos polvos metálicos.

| Polvo metálico | Grado | Pureza | Aplicación |

|---|---|---|---|

| Cobre (Cu) | Alta pureza | 99.99% | Interconexiones, vías conductoras |

| Aluminio (Al) | Grado electrónico | 99.98% | Células solares, LED |

| Plata (Ag) | 99,999% Puro | 99.999% | Dispositivos de alta frecuencia |

| Oro (Au) | Grado semiconductor | 99.99% | Conexiones críticas |

| Níquel (Ni) | 99,98% Puro | 99.98% | Almacenamiento de datos, sensores |

| Titanio (Ti) | Alta pureza | 99.6% | Condensadores, dispositivos de potencia |

| Tungsteno (W) | Alta pureza | 99.95% | Transistores, aplicaciones de alta temperatura |

| Molibdeno (Mo) | 99.95% Puro | 99.95% | Gestión térmica |

| Paladio (Pd) | 99,9% Puro | 99.9% | Sensores de alto rendimiento |

| Cobalto (Co) | 99,8% Puro | 99.8% | Almacenamiento magnético, sensores |

Proveedores y precios del polvo metálico para semiconductores

Saber dónde abastecerse de polvos metálicos y sus precios es crucial para la fabricación de semiconductores.

| Proveedor | Polvos metálicos disponibles | Precio (por kg) |

|---|---|---|

| Elementos americanos | Cobre, oro, níquel, plata | $300 – $10,000 |

| NanoAmor | Aluminio, tungsteno, titanio | $200 – $8,000 |

| Nanomateriales SkySpring | Paladio, cobalto, molibdeno | $500 – $12,000 |

| Tekna | Aluminio, cobre, níquel | $250 – $9,000 |

| Goodfellow | Oro, plata, titanio | $400 – $15,000 |

Comparación de Polvos metálicos para semiconductores: Ventajas y limitaciones

Cada polvo metálico tiene sus propias ventajas y limitaciones. He aquí un análisis comparativo para ayudarle a decidir qué polvo metálico se adapta mejor a sus necesidades.

| Polvo metálico | Ventajas | Desventajas |

|---|---|---|

| Cobre (Cu) | Alta conductividad, rentable | Susceptible a la oxidación |

| Aluminio (Al) | Ligero, buena conductividad | Punto de fusión más bajo |

| Plata (Ag) | Máxima conductividad, resistente al deslustre | Caro |

| Oro (Au) | No reactivo, excelente conductividad | Muy caro |

| Níquel (Ni) | Resistente a la corrosión, magnético | Conductividad moderada |

| Titanio (Ti) | Resistente, ligero y biocompatible | Caro, reactivo |

| Tungsteno (W) | Alto punto de fusión, duro | Muy denso, difícil de procesar |

| Molibdeno (Mo) | Alta resistencia, conductividad térmica | Quebradizo, caro |

| Paladio (Pd) | Buena conductividad, resistente a la corrosión | Muy caro |

| Cobalto (Co) | Propiedades magnéticas, alto punto de fusión | Caro, puede ser tóxico |

Preguntas frecuentes

P1: ¿Cuáles son los polvos metálicos más utilizados en la fabricación de semiconductores?

A1: Los polvos metálicos más utilizados en la fabricación de semiconductores son el cobre (Cu), el aluminio (Al), la plata (Ag), el oro (Au), el níquel (Ni), el titanio (Ti), el wolframio (W), el molibdeno (Mo), el paladio (Pd) y el cobalto (Co).

P2: ¿Por qué es importante la pureza en polvos metálicos para semiconductores?

A2: La pureza es crucial porque las impurezas pueden afectar a las propiedades eléctricas, el rendimiento y la fiabilidad de los dispositivos semiconductores. Los polvos metálicos de gran pureza garantizan una conductividad óptima y minimizan los defectos.

P3: ¿Cómo se utilizan los polvos metálicos en los microprocesadores?

A3: Los polvos metálicos como el cobre y el oro se utilizan para crear vías conductoras e interconexiones dentro de los microprocesadores, garantizando conexiones eléctricas eficientes entre los distintos componentes.

P4: ¿Cuáles son las ventajas de utilizar polvo de oro en los semiconductores?

A4: El polvo de oro ofrece una excelente conductividad, no es reactivo y no se empaña ni corroe, por lo que es ideal para conexiones críticas en las que la fiabilidad y la longevidad son esenciales.

P5: ¿Puede explicar la función del polvo de wolframio en los dispositivos semiconductores?

A5: El polvo de wolframio se utiliza en dispositivos semiconductores debido a su elevado punto de fusión y densidad, que lo hacen adecuado para aplicaciones de alta temperatura como transistores y dispositivos de potencia.

P6: ¿Qué factores influyen en la elección del polvo metálico para una aplicación específica de semiconductores?

A6: Entre los factores a tener en cuenta figuran la conductividad eléctrica y térmica requerida, el punto de fusión, la solidez, la resistencia a la corrosión y las necesidades específicas de la aplicación, como el peso y las propiedades magnéticas.

P7: ¿Existe algún problema medioambiental por el uso de polvos metálicos en semiconductores?

A7: Sí, la producción y eliminación de polvos metálicos puede tener repercusiones medioambientales. Es esencial seguir prácticas sostenibles y medidas de reciclaje para minimizar estos efectos.

P8: ¿Cómo afecta el tamaño de las partículas de los polvos metálicos a su aplicación en semiconductores?

A8: El tamaño de las partículas afecta al área superficial, la densidad de empaquetamiento y las propiedades eléctricas de los polvos metálicos, lo que influye en su rendimiento en aplicaciones de semiconductores.

P9: ¿Qué retos plantea el procesamiento de polvos metálicos para semiconductores?

A9: Entre los retos que se plantean están conseguir una distribución uniforme del tamaño de las partículas, mantener un alto grado de pureza, evitar la oxidación y garantizar una calidad constante durante la producción y el procesamiento.

Q10: ¿Dónde puedo comprar polvos metálicos de alta calidad para aplicaciones de semiconductores?

A10: Los polvos metálicos de alta calidad pueden obtenerse de proveedores como American Elements, NanoAmor, SkySpring Nanomaterials, Tekna y Goodfellow.

Compartir

MET3DP Technology Co., LTD es un proveedor líder de soluciones de fabricación aditiva con sede en Qingdao, China. Nuestra empresa está especializada en equipos de impresión 3D y polvos metálicos de alto rendimiento para aplicaciones industriales.

Solicite información para obtener el mejor precio y una solución personalizada para su empresa.

Artículos relacionados

Segmentos de álabe de tobera de alto rendimiento: Revolucionando la eficiencia de las turbinas con la impresión metálica en 3D

Leer Más "Acerca de Met3DP

Actualización reciente

Nuestro producto

CONTACTO

¿Tiene alguna pregunta? ¡Envíenos un mensaje ahora! Atenderemos su solicitud con todo un equipo tras recibir su mensaje.

Polvos metálicos para impresión 3D y fabricación aditiva

PRODUCTO

cONTACT INFO

- Ciudad de Qingdao, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731