Equipos VIGA de un solo hogar

Índice

Bienvenido a la guía definitiva sobre Equipo VIGA (atomización de gas por inducción en vacío) de un solo quemador. Si se está adentrando en el mundo de la metalurgia avanzada y la producción de polvo metálico, está en el lugar adecuado. Vamos a desglosar todo lo que necesita saber sobre los sistemas VIGA de un solo horno, cubriendo su funcionalidad, ventajas, aplicaciones y mucho más.

Visión general de Equipos VIGA de un solo hogar

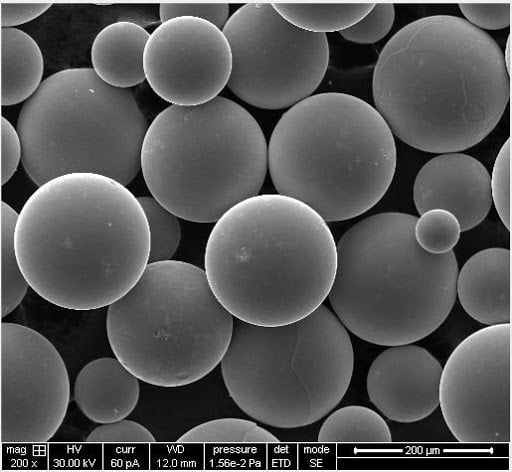

Los equipos VIGA de un solo horno representan un método de vanguardia para producir polvos metálicos de alta calidad. Estos sistemas utilizan la fusión por inducción en vacío combinada con la atomización con gas para crear polvos finos y esféricos con propiedades superiores. Esta técnica es fundamental para las industrias que requieren características precisas de los materiales, como los sectores aeroespacial, automovilístico y biomédico.

Tipos de polvos metálicos producidos por VIGA de un solo horno

Empecemos por algunos modelos específicos de polvo metálico producidos por equipos VIGA de un solo horno. Aquí tiene una lista detallada para familiarizarse:

| Modelo de polvo metálico | Composición | Propiedades clave | Aplicaciones |

|---|---|---|---|

| Acero inoxidable 316L | Fe, Cr, Ni, Mo | Resistencia a la corrosión, alta resistencia | Implantes médicos, equipos marinos |

| Acero inoxidable 17-4 PH | Fe, Cr, Ni, Cu, Nb | Alta resistencia, resistencia a la corrosión | Piezas aeroespaciales, procesamiento químico |

| Aleación de titanio Ti-6Al-4V | Ti, Al, V | Elevada relación resistencia/peso, biocompatibilidad | Componentes aeroespaciales, productos sanitarios |

| Inconel 718 | Ni, Cr, Fe, Nb, Mo | Resistencia al calor, resistencia a la oxidación | Piezas de motores a reacción, reactores nucleares |

| Aleación de cobalto-cromo | Co, Cr, Mo, W | Resistencia al desgaste, gran dureza | Implantes dentales, dispositivos ortopédicos |

| Aleación de aluminio AlSi10Mg | Al, Si, Mg | Ligero, buenas propiedades de fundición | Piezas de automóvil, estructuras aeroespaciales |

| Acero martensítico envejecido | Fe, Ni, Co, Mo | Alta resistencia, excelente tenacidad | Utillaje, estructuras aeroespaciales |

| Haynes 282 | Ni, Cr, Co, Mo, Ti | Resistencia a la fluencia, estabilidad térmica | Turbinas de gas, intercambiadores de calor |

| Aleación de cobre C18150 | Cu, Cr, Zr | Alta conductividad eléctrica, buena resistencia | Componentes eléctricos, electrodos de soldadura |

| Superaleación de níquel Nimonic 90 | Ni, Cr, Co, Ti, Al | Resistencia a la oxidación, resistencia a altas temperaturas | Álabes de turbina, válvulas de escape |

Aplicaciones de Equipos VIGA de un solo hogar

La versatilidad de los equipos VIGA de un solo horno queda patente en su amplia gama de aplicaciones. He aquí algunos usos específicos:

| Industria | Aplicación | Beneficios |

|---|---|---|

| Aeroespacial | Palas de turbina, componentes estructurales | Elevada relación resistencia/peso, resistencia a altas temperaturas |

| Automoción | Piezas de motor, estructuras ligeras | Mayor eficiencia de combustible y durabilidad |

| Biomédica | Implantes, instrumental quirúrgico | Biocompatibilidad, precisión |

| Energía | Componentes de reactores nucleares, intercambiadores de calor | Resistencia a la corrosión y a las altas temperaturas |

| Herramientas | Moldes, matrices | Resistencia al desgaste, longevidad |

| Electrónica | Componentes conductores | Alta conductividad eléctrica, fiabilidad |

Especificaciones detalladas, tamaños y normas

Comprender las especificaciones y normas de los polvos metálicos producidos por los equipos VIGA es crucial para seleccionar el material adecuado a sus necesidades. He aquí un desglose:

| Modelo de polvo metálico | Gama de tamaños de partículas | Normas | Aplicaciones típicas |

|---|---|---|---|

| Acero inoxidable 316L | 15-45 µm | ASTM F138, ISO 5832-1 | Medicina, marina |

| Acero inoxidable 17-4 PH | 20-63 µm | AMS 5643, ASTM A693 | Aeroespacial, química |

| Aleación de titanio Ti-6Al-4V | 15-45 µm | ASTM F1472, ISO 5832-3 | Aeroespacial, médica |

| Inconel 718 | 20-53 µm | AMS 5662, ASTM B637 | Motores a reacción, nucleares |

| Aleación de cobalto-cromo | 10-50 µm | ASTM F1537, ISO 5832-12 | Odontología, ortopedia |

| Aleación de aluminio AlSi10Mg | 20-60 µm | ISO 3522, ASTM B85 | Automoción, aeroespacial |

| Acero martensítico envejecido | 10-45 µm | AMS 6514, ASTM A538 | Utillaje, aeroespacial |

| Haynes 282 | 20-53 µm | AMS 5918, ASTM B637 | Turbinas de gas, intercambiadores de calor |

| Aleación de cobre C18150 | 15-45 µm | ASTM B820, AMS 4596 | Electricidad, soldadura |

| Superaleación de níquel Nimonic 90 | 20-53 µm | AMS 5829, ASTM B637 | Álabes de turbina, válvulas de escape |

Proveedores y precios

Cuando se trata de comprar polvos metálicos producidos mediante equipos VIGA de un solo hornoconocer a sus proveedores y sus precios es fundamental. Aquí tienes una lista de algunos proveedores destacados y sus precios aproximados:

| Proveedor | Modelos de polvo metálico | Precio (por kg) | Servicios adicionales |

|---|---|---|---|

| Höganäs | 316L, Ti-6Al-4V, Inconel 718 | $50-$200 | Tallaje a medida, asistencia técnica |

| Tecnología Carpenter | 17-4 PH, acero martensítico envejecido | $60-$250 | Consultoría metalúrgica, aleaciones a medida |

| Sandvik | Cromo-cobalto, Haynes 282 | $80-$300 | Pruebas de calidad, apoyo a I+D |

| Tecnología LPW | AlSi10Mg, aleación de cobre C18150 | $40-$150 | Gestión del ciclo de vida del polvo, trazabilidad |

| AP&C (Aditivo GE) | 316L, Ti-6Al-4V, Inconel 718 | $55-$220 | Caracterización avanzada, servicios de reciclado |

| Tecnologías de superficie Praxair | Inconel 718, Nimonic 90 | $70-$280 | Ingeniería de aplicaciones, soluciones de revestimiento |

Ventajas y desventajas de Equipos VIGA de un solo hogar

Profundicemos en los pros y los contras del uso de sistemas VIGA de un solo horno para la producción de polvo metálico:

| Ventajas | Desventajas |

|---|---|

| Alta pureza: El entorno de vacío minimiza la contaminación. | Coste: Inversión inicial y costes operativos elevados. |

| Tamaño uniforme de las partículas: Calidad constante del polvo. | Complejidad: Requiere operarios cualificados y mantenimiento. |

| Versatilidad: Adecuado para una amplia gama de aleaciones metálicas. | Consumo de energía: Uso significativo de energía. |

| Propiedades mejoradas de los materiales: Mejora de las propiedades mecánicas de los polvos. | Capacidad limitada: Un solo horno limita el volumen de producción en comparación con las instalaciones de varios hornos. |

Preguntas frecuentes

| Pregunta | Respuesta |

|---|---|

| ¿Para qué sirven los equipos VIGA de un solo hogar? | Se utiliza para producir polvos metálicos de alta calidad para diversas industrias como la aeroespacial, la automovilística y la biomédica. |

| ¿Cómo funcionan los equipos VIGA de un solo hogar? | Utiliza la fusión por inducción en vacío combinada con la atomización con gas para producir polvos metálicos finos y esféricos. |

| ¿Cuáles son las ventajas de utilizar VIGA para la producción de polvo metálico? | Entre sus ventajas se incluyen la alta pureza, el tamaño uniforme de las partículas y la mejora de las propiedades del material. |

| ¿Qué metales pueden procesarse con los equipos VIGA? | Una amplia gama que incluye aceros inoxidables, aleaciones de titanio, superaleaciones de níquel, etc. |

| ¿Existen limitaciones a la hora de utilizar equipos VIGA de un solo horno? | Sí, incluido el elevado coste, la complejidad y la limitada capacidad de producción. |

| ¿Qué industrias se benefician más de los polvos producidos por VIGA? | Industrias aeroespacial, automovilística, biomédica, energética, de herramientas y electrónica. |

| ¿Cuáles son los tamaños típicos de las partículas de los polvos producidos por VIGA? | El tamaño de las partículas suele oscilar entre 10 y 63 micras, en función de la aleación y los requisitos específicos. |

| ¿Cómo se compara VIGA con otros métodos de producción de polvo? | La VIGA ofrece una mayor pureza y un mejor control del tamaño de las partículas, pero puede resultar más cara y compleja que otros métodos como la atomización con agua. |

Conclusión

Los equipos VIGA de un solo horno cambian las reglas del juego en el campo de la producción de polvo metálico, ofreciendo una pureza, consistencia y versatilidad sin precedentes. Tanto si trabaja en los sectores aeroespacial, automovilístico o biomédico, conocer los entresijos de la tecnología VIGA puede ayudarle a tomar decisiones informadas y aprovechar las ventajas de los polvos metálicos de alta calidad.

Si tiene más preguntas o necesita información específica, no dude en ponerse en contacto con nosotros. Sumérjase en el mundo de la metalurgia avanzada con los equipos VIGA de un solo horno y eleve sus capacidades de materiales a nuevas cotas.

Compartir

MET3DP Technology Co., LTD es un proveedor líder de soluciones de fabricación aditiva con sede en Qingdao, China. Nuestra empresa está especializada en equipos de impresión 3D y polvos metálicos de alto rendimiento para aplicaciones industriales.

Solicite información para obtener el mejor precio y una solución personalizada para su empresa.

Artículos relacionados

Segmentos de álabe de tobera de alto rendimiento: Revolucionando la eficiencia de las turbinas con la impresión metálica en 3D

Leer Más "Acerca de Met3DP

Actualización reciente

Nuestro producto

CONTACTO

¿Tiene alguna pregunta? ¡Envíenos un mensaje ahora! Atenderemos su solicitud con todo un equipo tras recibir su mensaje.

Polvos metálicos para impresión 3D y fabricación aditiva

PRODUCTO

cONTACT INFO

- Ciudad de Qingdao, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731