SLM para la fabricación aditiva de metales

Índice

Descripción general de la fusión selectiva por láser

Fusión selectiva por láser (SLM) es un proceso de impresión 3D de metal por fusión de lecho de polvo que utiliza un láser para fundir y fusionar selectivamente partículas de polvo metálico capa por capa para construir piezas completamente densas.

Atributos clave de la tecnología SLM:

| Característica | Descripción |

|---|---|

| Materiales | Metales como acero inoxidable, titanio, aluminio, aleaciones de níquel. |

| Tipo láser | Láseres de fibra, CO2 o diodo directo |

| Atmósfera | Atmósfera inerte de argón o nitrógeno |

| Resolución | Capaz de realizar características finas de hasta 150 μm |

| Precisión | Piezas con dimensiones de ±0,2% o mejores |

SLM permite fabricar piezas metálicas complejas y personalizables para aplicaciones aeroespaciales, médicas, automotrices e industriales.

Cómo funciona la fusión selectiva por láser

El proceso de impresión SLM funciona de la siguiente manera:

- Modelo 3D dividido en capas de sección transversal 2D

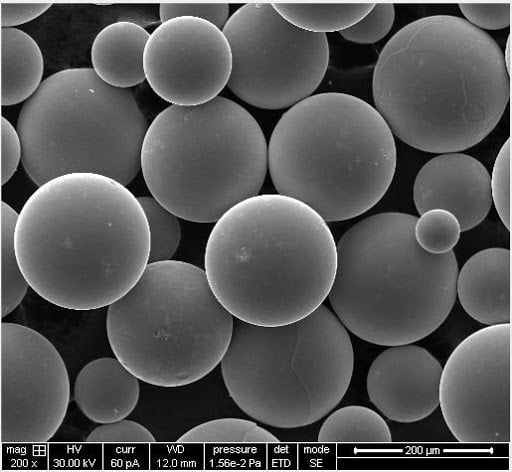

- Polvo esparcido sobre la placa de construcción en una capa fina

- El láser escanea selectivamente la capa y derrite el polvo.

- El polvo derretido se solidifica y se fusiona.

- La placa de construcción se baja y la nueva capa se extiende en la parte superior

- El proceso se repite hasta que se construye toda la pieza.

El polvo sin fundir proporciona soporte durante la construcción del componente. Esto permite geometrías complejas sin estructuras de soporte específicas.

Tipos de sistemas de fusión selectiva por láser

Hay varios SLM configuraciones del sistema:

| Sistema | Detalles |

|---|---|

| Láser único | Un láser de alta potencia para fundir |

| Láser múltiple | Múltiples láseres para aumentar la velocidad de construcción |

| Sistema de escaneo | Espejos galvanométricos u ópticas fijas |

| Manipulación de polvo metálico | Sistemas abiertos o de reciclaje de polvo cerrado |

| Control de la atmósfera | Cámara de construcción sellada llena de argón o nitrógeno |

Los sistemas multiláser ofrecen construcciones más rápidas mientras que el manejo de polvo de circuito cerrado mejora la eficiencia y la reciclabilidad.

Materiales para fusión selectiva por láser

Los materiales metálicos comunes utilizados para SLM incluyen:

| Material | Beneficios |

|---|---|

| Aleaciones de aluminio | Ligero y con buena resistencia. |

| Aleaciones de titanio | Elevada relación resistencia/peso |

| Aceros inoxidables | Resistencia a la corrosión, alta tenacidad |

| Aceros para herramientas | Gran dureza y resistencia al desgaste |

| Aleaciones de níquel | Resistencia a altas temperaturas |

| Cobalto-Cromo | Biocompatible con buen desgaste. |

Una gama de polvos de aleación permite propiedades como resistencia, dureza, resistencia a la temperatura y biocompatibilidad necesarias en todas las aplicaciones.

Aplicaciones de la fusión selectiva por láser

Las aplicaciones típicas de la impresión de metal SLM incluyen:

| Industria | Aplicaciones |

|---|---|

| Aeroespacial | Componentes de motor, estructuras ligeras |

| Médico | Implantes, prótesis e instrumentos personalizados |

| Automoción | Piezas ligeras, herramientas personalizadas |

| Industrial | Componentes aligerados, producción para uso final |

| Petróleo y gas | Válvulas resistentes a la corrosión, piezas de cabezal de pozo |

SLM permite fabricar piezas metálicas complejas y personalizadas consolidadas en una sola pieza y optimizadas en cuanto a peso y rendimiento.

Beneficios de la fusión selectiva por láser

Ventajas clave de la tecnología SLM:

| Beneficio | Descripción |

|---|---|

| Geometrías complejas | Libertad de diseño ilimitada para formas orgánicas |

| Consolidación parcial | Conjuntos impresos como un solo componente |

| Personalización | Fácilmente adaptable para producir piezas personalizadas. |

| Aligeramiento | Estructuras reticulares y optimización topológica. |

| Ahorro de material | Reducción de residuos en comparación con los métodos sustractivos |

| Tratamiento posterior | Puede requerir la eliminación del soporte y el acabado de la superficie. |

Estas ventajas permiten fabricar piezas metálicas de uso final de mayor rendimiento con plazos de entrega y costes competitivos y con volúmenes de producción más bajos.

Limitaciones de la fusión selectiva por láser

Las limitaciones del SLM incluyen:

| Limitación | Descripción |

|---|---|

| Tamaño de la pieza | Restringido al volumen de construcción de la impresora, normalmente menos de 1 m3 |

| Productividad | Las tasas de producción relativamente lentas limitan los grandes volúmenes |

| Tratamiento posterior | Puede requerir eliminación de soporte, mecanizado y acabado. |

| Anisotropía | Las propiedades mecánicas varían según la orientación de la construcción. |

| Acabado superficial | La superficie impresa es relativamente rugosa |

| Experiencia del operador | Requiere amplia experiencia en impresión. |

La tecnología es más adecuada para volúmenes de producción bajos a medianos de piezas metálicas complejas.

Proveedores de impresoras SLM

Fabricantes líderes de sistemas SLM:

| Empresa | Sistemas notables |

|---|---|

| EOS | Serie EOS M |

| Sistemas 3D | Serie DMP |

| Aditivos GE | Línea X 2000R |

| trompeta | TruPrint 1000, 3000 |

| Soluciones SLM | SLM 500, SLM 800 |

| Renishaw | AM500, AM400 |

La gama de máquinas va desde volúmenes de construcción más pequeños de alrededor de 250 x 250 x 300 mm hasta sistemas grandes de 800 x 400 x 500 mm para una alta productividad.

Selección de una impresora 3D SLM

Consideraciones clave a la hora de seleccionar un sistema SLM:

| Factor | Prioridad |

|---|---|

| Volumen de construcción | Adaptarse a los tamaños de piezas requeridos |

| Materiales de apoyo | Se necesitan aleaciones como Ti, Al, acero inoxidable y aceros para herramientas. |

| Sistema de gas inerte | Manipulación automatizada y sellada de argón o nitrógeno |

| Tecnología láser | Láseres de fibra, CO2 o diodo directo |

| Método de escaneo | Escaneo por galvanoplastia o espejo fijo |

| Manipulación del polvo | Se prefiere el reciclaje de circuito cerrado |

El sistema SLM óptimo proporciona los materiales, el volumen de construcción, la velocidad y las características de manejo de polvo necesarias para las aplicaciones.

Requisitos de las instalaciones SLM

Para operar una impresora SLM, la instalación debe cumplir:

- Niveles de potencia eléctrica típicos de 20 a 60 kW

- Temperatura estable alrededor de 20-25°C

- Humedad baja por debajo de 70% RH

- Control de partículas y manejo de polvo metálico

- Suministro y ventilación de gas inerte

- Filtración de gases de escape para partículas liberadas

- Sistemas de monitorización de la atmósfera

- Procedimientos estrictos de seguridad del personal

Los sistemas SLM requieren una infraestructura importante para energía, refrigeración, manipulación de polvo y suministro de gas inerte.

Parámetros del proceso de impresión SLM

Parámetros típicos de impresión SLM:

| Parámetro | Alcance típico |

|---|---|

| Potencia del láser | 100-400 W |

| Velocidad de escaneo | 100-2000 mm/s |

| Grosor de la capa | 20-100 μm |

| Distancia entre escotillas | 50-200 μm |

| Tamaño del punto | 50-100 micras |

| Patrón de escaneo | Alternando, rotando para cada capa |

Se requiere un ajuste preciso de estos parámetros para lograr piezas completamente densas para cada polvo de aleación.

SLM Directrices de diseño y limitaciones

Las pautas clave de diseño de SLM incluyen:

| Directriz | Razón |

|---|---|

| Espesor mínimo de pared | Evite la acumulación de calor y la deformación. |

| Voladizos soportados | Prevenir el colapso sin apoyos |

| Evite los rasgos delgados | Prevenir la fusión o vaporización |

| Orientar para la fuerza | Optimizar para la dirección de carga |

| Minimizar el uso del soporte | Simplificar el posprocesamiento |

El proceso SLM impone requisitos geométricos como ángulos de voladizo y tamaños mínimos de características que deben tenerse en cuenta.

Requisitos de posprocesamiento de SLM

Pasos comunes de posprocesamiento para piezas SLM:

| Proceso | Propósito |

|---|---|

| Eliminación de soportes | Eliminar los soportes generados automáticamente del software |

| Eliminación de polvo | Limpie el polvo restante de los conductos internos |

| Acabado de superficies | Mejorar el acabado superficial y la rugosidad mediante el mecanizado. |

| Alivio del estrés | Reducir las tensiones residuales mediante tratamiento térmico |

| Prensado isostático en caliente | Mejorar la densidad y reducir los huecos internos |

El nivel de posprocesamiento depende de los requisitos de la aplicación en cuanto a tolerancias, acabados superficiales y propiedades del material.

Pruebas de calificación para piezas SLM

Pruebas de calificación típicas para componentes SLM:

| Tipo de prueba | Descripción |

|---|---|

| Análisis de densidad | Medir la densidad en comparación con los materiales forjados |

| Pruebas mecánicas | Ensayos de tracción, fatiga y tenacidad a la fractura |

| Metalografía | Imágenes de microestructura y análisis de defectos |

| Análisis químicos | Comprobar que la composición coincida con las especificaciones |

| No destructivo | Tomografía computarizada o inspección por rayos X para detectar huecos |

Pruebas exhaustivas garantizan que las piezas SLM cumplan con los requisitos antes de incorporarlas a aplicaciones de producción.

Beneficios de SLM Tecnología

La fusión selectiva por láser ofrece ventajas clave:

- Geometrías orgánicas complejas que no son posibles con fundición o CNC

- Estructuras más ligeras mediante optimización topológica

- Consolidación de piezas en componentes impresos individuales

- Reducción de residuos en comparación con los métodos sustractivos

- Personalización e iteraciones rápidas de diseño

- Producción justo a tiempo de piezas metálicas

- Alta resistencia y dureza próxima a la de los materiales forjados.

Estos beneficios hacen que SLM sea adecuado para producir piezas de alto valor y bajo volumen según demanda en todas las industrias.

Desafíos de la adopción de la impresión SLM

Las barreras para la adopción de SLM incluyen:

| Desafío | Estrategias de mitigación |

|---|---|

| Alto costo de la impresora | Aprovechar las agencias de servicios y validar el ROI |

| Opciones de material | Nuevas aleaciones en desarrollo, proveedores especializados |

| Conocimiento del proceso | Programas de formación, curva de aprendizaje |

| Normas | Protocolos de calificación de piezas en desarrollo |

| Tratamiento posterior | Procesos automatizados en desarrollo |

A medida que la tecnología madura, estas barreras se reducen mediante mejores materiales, equipos, capacitación y esfuerzos de estandarización en toda la industria.

El futuro de la fusión selectiva por láser

Tendencias emergentes en la tecnología SLM:

- Volúmenes de construcción mayores de 500 x 500 x 500 mm

- Sistemas multiláser para velocidades de construcción más rápidas

- Aleaciones expandidas, incluidas superaleaciones de alta temperatura

- Mejora de la reciclabilidad y la manipulación del polvo

- Eliminación automática de soportes y postprocesamiento

- Fabricación híbrida que combina AM y CNC

- Software especializado para la optimización del diseño

- Estandarización de parámetros de proceso y calificación de piezas

Los sistemas SLM seguirán avanzando en términos de tamaño de construcción, velocidad, materiales y confiabilidad para satisfacer las necesidades de producción en más aplicaciones industriales.

Resumen de puntos clave

- SLM fusiona selectivamente polvo metálico con un láser para lograr una impresión 3D de densidad completa

- Proceso de fusión de lecho de polvo capaz de lograr detalles finos y geometrías complejas

- Adecuado para aplicaciones aeroespaciales, médicas, automotrices e industriales.

- Utiliza metales como acero inoxidable, titanio, aluminio y aleaciones de níquel.

- Proporciona beneficios de consolidación de piezas, personalización y aligeramiento.

- Requiere atmósfera controlada y sistemas robustos de manipulación de polvo.

- Es posible que sea necesario un posprocesamiento significativo en las piezas impresas

- Tecnología líder para aplicaciones de producción de volumen bajo a medio

- Mejoras continuas en materiales, tamaño de construcción, velocidad y calidad.

- Permite componentes metálicos impresos de alto rendimiento

La fusión selectiva por láser seguirá creciendo como solución de fabricación industrial para piezas metálicas personalizadas bajo demanda.

PREGUNTAS FRECUENTES

| Pregunta | Respuesta |

|---|---|

| ¿Qué materiales son compatibles con SLM? | La mayoría de las aleaciones soldables como acero inoxidable, titanio, aluminio, acero para herramientas, aleaciones de níquel y cobalto-cromo. |

| ¿Cuál es la precisión típica de las piezas SLM? | Se puede lograr una precisión dimensional de alrededor de ±0,2% para la mayoría de las geometrías. |

| ¿Qué tratamiento posterior es necesario? | Son habituales la eliminación de soporte, la eliminación de polvo, el acabado de superficies, el alivio de tensiones y el prensado isostático en caliente. |

| ¿Cuáles son los defectos más comunes del SLM? | Porosidad, agrietamiento, delaminación de capas, deformación, mal acabado superficial, partículas no fundidas. |

| ¿Qué tipos de láseres se utilizan en SLM? | Se utilizan habitualmente láseres de fibra, láseres de CO2 o diodos de alta potencia. |

Compartir

MET3DP Technology Co., LTD es un proveedor líder de soluciones de fabricación aditiva con sede en Qingdao, China. Nuestra empresa está especializada en equipos de impresión 3D y polvos metálicos de alto rendimiento para aplicaciones industriales.

Solicite información para obtener el mejor precio y una solución personalizada para su empresa.

Artículos relacionados

Segmentos de álabe de tobera de alto rendimiento: Revolucionando la eficiencia de las turbinas con la impresión metálica en 3D

Leer Más "Acerca de Met3DP

Actualización reciente

Nuestro producto

CONTACTO

¿Tiene alguna pregunta? ¡Envíenos un mensaje ahora! Atenderemos su solicitud con todo un equipo tras recibir su mensaje.

Polvos metálicos para impresión 3D y fabricación aditiva

PRODUCTO

cONTACT INFO

- Ciudad de Qingdao, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731