Máquinas VIGA

Índice

Cuando hablamos de Máquinas VIGANos adentramos en el mundo de la tecnología avanzada de producción de polvo metálico que ha revolucionado diversas industrias. En este artículo, exploraremos todo lo que necesita saber sobre las máquinas VIGA, desde una descripción general hasta especificaciones detalladas, aplicaciones e incluso una sección de preguntas frecuentes. ¡Comencemos!

Descripción general de las máquinas VIGA

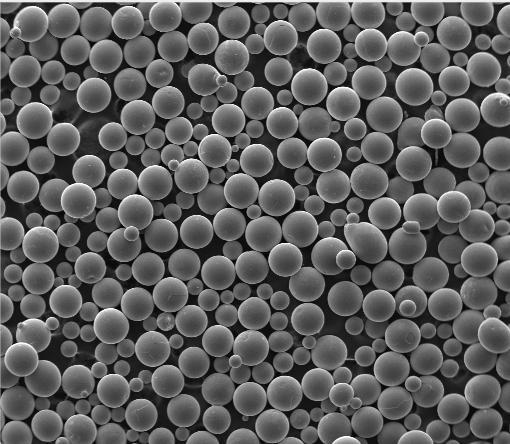

Las máquinas VIGA (Atomización por Gas Inerte al Vacío) son equipos de vanguardia que se utilizan para producir polvos metálicos de alta calidad. Estos polvos son esenciales para aplicaciones en las industrias aeroespacial, automotriz, biomédica y de fabricación aditiva. La tecnología VIGA destaca por su capacidad para producir polvos con excelente fluidez, forma esférica y distribución controlada del tamaño de partícula.

Características principales de las máquinas VIGA

- Polvos metálicos de alta pureza: Las máquinas VIGA funcionan en un entorno de vacío o de gas inerte, minimizando la contaminación.

- Partículas esféricas: Garantiza una excelente fluidez y densidad de empaque.

- Tamaño de partícula controlado: Parámetros de atomización ajustables para características de polvo personalizadas.

- Amplia gama de materiales: Adecuado para diversos metales y aleaciones, incluidos titanio, acero inoxidable y superaleaciones.

Tipos y modelos de polvos metálicos producidos por Máquinas VIGA

A continuación se muestran modelos específicos de polvo metálico producidos por las máquinas VIGA, junto con sus descripciones:

| Modelo de polvo metálico | Composición | Propiedades | Aplicaciones |

|---|---|---|---|

| Ti-6Al-4V | Aleación de titanio | Alta resistencia, resistente a la corrosión, biocompatible | Aeroespacial, implantes médicos |

| Acero inoxidable 316L | Aleación de Fe-Cr-Ni-Mo | Excelente resistencia a la corrosión, buenas propiedades mecánicas | Dispositivos biomédicos, aplicaciones marinas |

| IN718 | Superaleación a base de níquel | Resistencia a altas temperaturas y a la oxidación. | Álabes de turbina, componentes aeroespaciales |

| AlSi10Mg | Aleación de aluminio | Ligero, buenas propiedades térmicas | Automoción, aeroespacial |

| CoCrMo | Aleación de cobalto, cromo y molibdeno | Alta resistencia al desgaste, biocompatible | Implantes médicos, prótesis dentales |

| CuCrZr | Aleación de cobre, cromo y circonio | Alta conductividad eléctrica, buena resistencia mecánica. | Componentes eléctricos, electrodos de soldadura |

| Acero martensítico envejecido (18Ni300) | Aleación de Fe-Ni-Co-Mo-Ti | Resistencia ultra alta, buena tenacidad | Herramientas, engranajes de alto rendimiento |

| FeNiCo | Aleación de hierro, níquel y cobalto | Propiedades magnéticas, buena resistencia mecánica. | Componentes magnéticos, aeroespacial |

| NiTi (Nitinol) | Aleación de níquel y titanio | Memoria de forma, superelasticidad. | Dispositivos médicos, actuadores |

| Hastelloy X | Aleación de níquel-cromo-molibdeno | Resistencia a altas temperaturas y a la corrosión. | Componentes de turbinas de gas, procesamiento químico |

Aplicaciones de las máquinas VIGA

Las máquinas VIGA se utilizan en diversas industrias gracias a su capacidad para producir polvos metálicos de alta calidad. A continuación, se detallan sus aplicaciones:

| Industria | Aplicaciones |

|---|---|

| Aeroespacial | Álabes de turbina, componentes estructurales, elementos de fijación |

| Automoción | Componentes ligeros, piezas de motor |

| Biomédica | Implantes, prótesis, instrumental quirúrgico |

| Fabricación aditiva | Polvos de impresión 3D, prototipado, geometrías complejas |

| Energía | Componentes de turbinas, piezas de reactores nucleares |

| Electrónica | Pastas conductoras, componentes magnéticos |

Ventajas de las máquinas VIGA

- Alta pureza y limpieza: Operar en un entorno de vacío o de gas inerte reduce la contaminación, lo que da lugar a polvos metálicos de alta pureza.

- Distribución controlada del tamaño de las partículas: Permite la personalización para aplicaciones específicas, mejorando el rendimiento.

- Partículas esféricas: Mejora la fluidez y la densidad de empaque, crucial para la fabricación aditiva.

- Gama de materiales versátiles: Puede procesar una variedad de metales y aleaciones, lo que los hace adecuados para diversas industrias.

Desventajas de Máquinas VIGA

- Alto costo inicial: Las máquinas VIGA son costosas de adquirir e instalar.

- Operación compleja: Requiere operadores calificados y mantenimiento regular.

- Intensivo en energía: El proceso demanda una cantidad considerable de energía, lo que aumenta los costes operativos.

Especificaciones detalladas de las máquinas VIGA

| Especificación | Detalles |

|---|---|

| Capacidad material | Titanio, acero inoxidable, aleaciones de níquel, aleaciones de aluminio, aleaciones de cobalto-cromo, etc. |

| Gas de atomización | Argón, nitrógeno, helio |

| Presión de funcionamiento | Hasta 150 bar |

| Gama de tamaños de partículas | 10 – 200 micras |

| Tasa de producción | Hasta 500 kg/hora |

| Nivel de vacío | Hasta 10^-5 mbar |

| Consumo de energía | 100 – 500 kW |

| Sistema de refrigeración | refrigerado por agua |

Comparación de pros y contras de Máquinas VIGA

| Ventajas | Desventajas |

|---|---|

| Polvos metálicos de alta pureza | Alto costo inicial |

| Partículas esféricas | Operación compleja |

| Tamaño controlado de las partículas | Consumo intensivo de energía |

| Gama de materiales versátiles | Requiere operarios cualificados |

| Excelente fluidez | Se necesita mantenimiento regular |

PREGUNTAS FRECUENTES

| Pregunta | Respuesta |

|---|---|

| ¿Para qué se utilizan las máquinas VIGA? | Producción de polvos metálicos de alta calidad para diversas industrias, incluidas la aeroespacial, la automotriz y la biomédica. |

| ¿Cómo funcionan las máquinas VIGA? | Utilizan vacío o gas inerte para atomizar el metal fundido en polvos finos con partículas esféricas. |

| ¿Qué metales pueden procesar las máquinas VIGA? | Titanio, acero inoxidable, aleaciones de níquel, aleaciones de aluminio y más. |

| ¿Cuál es el rango de tamaño de partícula de los polvos producidos? | Generalmente entre 10 y 200 micrones. |

| ¿Son caras las máquinas VIGA? | Si, tienen un costo inicial elevado, que va desde $900.000 hasta más de $2.500.000. |

| ¿Cuáles son los beneficios de utilizar máquinas VIGA? | Alta pureza, tamaño de partícula controlado, excelente fluidez y versatilidad en el procesamiento de materiales. |

| ¿Qué industrias se benefician de los polvos VIGA? | Aeroespacial, automotriz, biomédico, fabricación aditiva, energía y electrónica. |

| ¿Pueden las máquinas VIGA producir polvos para impresión 3D? | Sí, son ideales para producir polvos de alta calidad para fabricación aditiva. |

| ¿Las máquinas VIGA requieren un mantenimiento especial? | Sí, requieren un mantenimiento regular y operadores capacitados para garantizar un rendimiento óptimo. |

| ¿Cuáles son los gases de atomización más comunes que se utilizan? | El argón, el nitrógeno y el helio se utilizan comúnmente para la atomización. |

Conclusión

Las máquinas VIGA representan la cumbre de la tecnología de producción de polvos metálicos, proporcionando polvos de alta calidad esenciales para las industrias modernas. Su capacidad para producir polvos esféricos, de alta pureza y con un control preciso las hace invaluables para aplicaciones que abarcan desde la industria aeroespacial hasta dispositivos biomédicos. A pesar de su alto costo inicial y complejidad, las ventajas que ofrecen en cuanto a propiedades y rendimiento de los materiales son inigualables. Si desea profundizar en la producción de polvos metálicos de alta calidad, comprender y utilizar las máquinas VIGA puede ser un punto de inflexión.

Compartir

MET3DP Technology Co., LTD es un proveedor líder de soluciones de fabricación aditiva con sede en Qingdao, China. Nuestra empresa está especializada en equipos de impresión 3D y polvos metálicos de alto rendimiento para aplicaciones industriales.

Solicite información para obtener el mejor precio y una solución personalizada para su empresa.

Artículos relacionados

Segmentos de álabe de tobera de alto rendimiento: Revolucionando la eficiencia de las turbinas con la impresión metálica en 3D

Leer Más "Acerca de Met3DP

Actualización reciente

Nuestro producto

CONTACTO

¿Tiene alguna pregunta? ¡Envíenos un mensaje ahora! Atenderemos su solicitud con todo un equipo tras recibir su mensaje.

Polvos metálicos para impresión 3D y fabricación aditiva

PRODUCTO

cONTACT INFO

- Ciudad de Qingdao, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731