Guide complet de l'atomisation à l'eau pour l'impression 3D de poudres métalliques

Table des matières

Imaginez que vous sculptez des objets métalliques complexes couche par couche, en les construisant à partir de la base avec la précision d'un artiste numérique. C'est la magie de Poudres métalliques pour l'impression 3DAu cœur de cette technologie révolutionnaire se trouve un ingrédient essentiel : poudre métallique. Mais comment transformer un métal solide en une poudre fine et fluide nécessaire à l'impression 3D ? Entrer atomisation de l'eauUne technique puissante et polyvalente qui occupe une place centrale dans ce guide.

Dévoiler la magie : Qu'est-ce que l'atomisation de l'eau ?

L'atomisation de l'eau est l'art de transformer le métal en fusion en un fin brouillard de minuscules gouttelettes. Ce processus apparemment simple est pourtant doté d'un immense pouvoir. Voici comment il fonctionne :

- Faire fondre le métal : Le voyage commence avec le métal choisi, chauffé à l'état de fusion dans un four. Imaginez un creuset ardent, rougeoyant de métal en fusion, prêt à être transformé.

- H2O haute pression : Ensuite, un jet d'eau à haute pression est lâché sur le métal en fusion. Ce puissant jet, semblable à une lance de pompier sous stéroïdes, brise le métal liquide en une fine pulvérisation de minuscules gouttelettes.

- Solidification rapide : Lorsque les gouttelettes de métal se dispersent, elles se refroidissent rapidement et se solidifient dans l'air, formant des particules de poudre métallique. Imaginez de minuscules gouttes de pluie métalliques qui se solidifient avant même de toucher le sol.

- Collecte et traitement : La poudre métallique nouvellement formée est recueillie, séchée et tamisée pour obtenir la taille et la distribution des particules souhaitées. Cela garantit une cohérence et des performances optimales pour les applications d'impression 3D.

Poudres métalliques pour l'impression 3D: Pourquoi choisir cette méthode ?

| Fonctionnalité | Bénéfice | Explication |

|---|---|---|

| Liberté de conception | Géométries très complexes | Contrairement aux méthodes traditionnelles telles que l'usinage ou le moulage, qui reposent sur des techniques soustractives ou formatives, l'impression 3D avec des poudres métalliques permet de construire des pièces couche par couche directement à partir d'un modèle numérique. Cela permet de créer des caractéristiques internes complexes, des canaux et des structures en treillis qui seraient impossibles ou très peu pratiques avec d'autres méthodes. |

| Polyvalence des matériaux | Large gamme de métaux | Les poudres métalliques sont disponibles dans une vaste gamme d'options, des métaux courants comme le titane et l'aluminium aux matériaux plus exotiques comme l'Inconel et les métaux précieux comme l'or. Les ingénieurs peuvent ainsi choisir le matériau idéal pour une application spécifique, en tenant compte de facteurs tels que la solidité, le poids, la résistance à la corrosion et la biocompatibilité. |

| Prototypage rapide | Itération plus rapide de la conception | La nature numérique de l'impression 3D permet de modifier rapidement et facilement la conception. Des modifications peuvent être apportées au modèle CAO et un nouveau prototype peut être imprimé dans un délai très court. Cela permet de réduire considérablement les délais et les coûts de développement par rapport aux méthodes de prototypage traditionnelles. |

| Allègement | Conception pour l'efficacité | La capacité de créer des structures internes complexes grâce à l'impression 3D de poudres métalliques permet aux pièces d'être légères tout en conservant leur résistance. Cet aspect est crucial dans des applications telles que l'aérospatiale et l'automobile, où la réduction du poids se traduit par une amélioration de l'efficacité énergétique et des performances. |

| Fabrication à la demande | Réduction des besoins en stocks | L'impression 3D avec des poudres métalliques permet de produire des pièces en fonction des besoins, ce qui élimine la nécessité de produire de grandes séries et de stocker les produits finis. Cela est particulièrement avantageux pour la production de faibles volumes ou pour les pièces de rechange qui ne sont pas toujours disponibles dans les circuits traditionnels. |

| Déchets minimaux de matériaux | Production durable | L'impression 3D de métaux n'utilise que le matériau nécessaire à la fabrication de la pièce, contrairement aux méthodes traditionnelles qui génèrent d'importants rebuts. Cela permet de réduire les déchets et l'impact environnemental du processus de fabrication. |

| Personnalisation | Produits personnalisés | La capacité de créer des géométries complexes avec les poudres métalliques de l'impression 3D permet de produire des pièces hautement personnalisées. Ceci est bénéfique pour des applications telles que les implants médicaux, les prothèses et les couronnes dentaires qui nécessitent un ajustement parfait pour chaque individu. |

| Consolidation des pièces | Complexité d'assemblage réduite | La liberté de conception offerte par l'impression 3D de poudres métalliques permet de créer des pièces complexes qui intègrent les fonctionnalités de plusieurs composants. Cela permet de réduire la complexité de l'assemblage, de diminuer les coûts de production et d'améliorer les performances globales du produit. |

Applications de l'atomisation de l'eau dans l'impression 3D : Donner vie au métal

| Processus | Description | Avantages | Inconvénients |

|---|---|---|---|

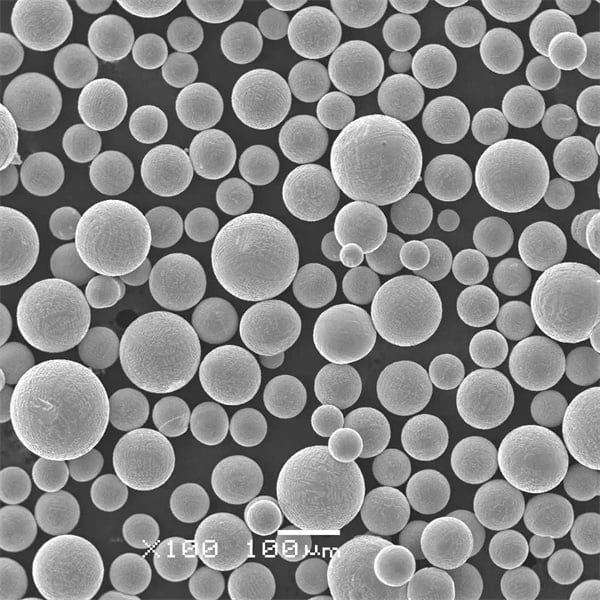

| Atomisation de l'eau | Le métal en fusion est transformé en une fine poudre par un processus en plusieurs étapes. Tout d'abord, le métal est fondu dans un four. Ensuite, une buse à haute pression force le métal liquide à former un mince filet. Ce flux est brisé en minuscules gouttelettes par un jet d'eau à grande vitesse. Enfin, les gouttelettes rapidement refroidies se solidifient en particules de poudre individuelles, qui sont collectées, séchées et tamisées pour obtenir une taille et une distribution spécifiques. | - Rentable : L'atomisation de l'eau est une méthode relativement peu coûteuse pour produire de grandes quantités de poudre métallique par rapport à d'autres techniques. - Large compatibilité avec les matériaux : Cette méthode permet de traiter un large éventail de métaux, depuis les variétés courantes comme l'acier et l'aluminium jusqu'à des options plus spécialisées. | - Forme des particules : Les poudres atomisées à l'eau ont tendance à être moins sphériques que celles produites par d'autres méthodes. Cela peut affecter la fluidité de la poudre et la densité d'empilement dans le lit d'impression 3D, ce qui peut avoir un impact sur la qualité de la surface de la pièce imprimée finale. |

| Fusion sélective par laser (SLM) | Technique d'impression 3D qui utilise un laser de forte puissance pour fondre et fusionner sélectivement des particules de poudre métallique, couche par couche. Le faisceau laser suit un dessin numérique, construisant l'objet 3D souhaité. | - Haute précision et exactitude : le procédé SLM permet de créer des géométries complexes avec des tolérances étroites, ce qui le rend idéal pour les pièces métalliques complexes. - Liberté de conception : Contrairement aux méthodes de fabrication traditionnelles, le SLM offre une grande liberté de conception, permettant la production de pièces avec des canaux internes, des treillis et d'autres caractéristiques uniques. | - Volume de construction limité : Les machines SLM actuelles ont généralement un volume de construction restreint, ce qui limite la taille des objets imprimables. - Rugosité de la surface : La nature couche par couche de la technique SLM peut entraîner une finition de surface légèrement rugueuse sur les pièces imprimées, ce qui peut nécessiter un post-traitement supplémentaire. |

| Fusion par faisceau d'électrons (EBM) | Comme le SLM, l'EBM utilise un faisceau de forte puissance, mais dans ce cas, un faisceau d'électrons fonctionnant dans un environnement sous vide. Le faisceau d'électrons fait fondre les particules de poudre métallique et les fusionne pour former l'objet 3D souhaité. | - Propriétés mécaniques supérieures : EBM produit des pièces présentant d'excellentes propriétés mécaniques, notamment une grande solidité et une bonne résistance à la fatigue. Cela est dû à l'environnement sous vide, qui minimise l'oxydation et améliore les propriétés des matériaux. - Compatibilité plus large avec les matériaux : Par rapport à la technique SLM, la technique EBM est compatible avec une plus large gamme de métaux, y compris des matériaux réactifs comme le titane. | - Coût plus élevé : Les systèmes EBM sont généralement plus coûteux que les machines SLM, ce qui a un impact sur le coût global de production. - Exigence de vide : La nécessité d'un environnement sous vide ajoute de la complexité au processus EBM et peut limiter son accessibilité dans certains contextes. |

| Jets de liant (BJ) | Une méthode d'impression 3D qui utilise un agent liant liquide pour projeter sélectivement des particules de poudre métallique sur une plate-forme d'impression. Les couches sont ensuite durcies pour créer une structure solide. | - Volume de fabrication élevé : Le jet de liant offre un volume de fabrication plus important que le SLM et l'EBM, ce qui permet de produire des pièces métalliques plus grandes. - Possibilité d'impression en quadrichromie : Des techniques de projection de liant incorporant des liants colorés sont en cours de développement. Elles ouvrent la voie à la création de pièces métalliques fonctionnelles et visuellement attrayantes. | - Résistance moindre des pièces : Les pièces produites par projection de liant présentent généralement une résistance plus faible que celles fabriquées par SLM ou EBM. Cela peut nécessiter des étapes de post-traitement supplémentaires, telles que l'infiltration, pour obtenir les propriétés mécaniques souhaitées. - Options de matériaux limitées : À l'heure actuelle, la projection de liant offre une gamme plus limitée de matériaux métalliques compatibles que d'autres méthodes d'impression 3D. |

Choisir la bonne poudre métallique atomisée à l'eau

| Facteur | Description | Impact sur le processus de fabrication additive et la pièce finale |

|---|---|---|

| Propriétés des matériaux | Le métal ou l'alliage choisi dictera les propriétés finales de la pièce imprimée en 3D. | - Solidité et durabilité : Pensez aux applications nécessitant un rapport résistance/poids élevé, comme les composants aérospatiaux. Les alliages de nickel ou les poudres de titane excellent dans ce domaine. - Résistance à la corrosion : Les pièces exposées à des environnements difficiles peuvent être fabriquées en acier inoxydable ou en alliages de cuivre. - Conductivité thermique et électrique : Les dissipateurs thermiques ou les conducteurs électriques peuvent utiliser des poudres d'aluminium ou de cuivre pour des performances optimales. |

| Taille et distribution des particules | La taille et les variations de taille des particules de poudre affectent de manière significative l'imprimabilité et les caractéristiques de la pièce finale. | - Fluidité : Les particules uniformes et sphériques s'écoulent plus facilement, ce qui permet de former des couches homogènes pendant l'impression. - Densité de l'emballage : La densité idéale d'empaquetage de la poudre permet une utilisation maximale du matériau tout en permettant une fusion correcte entre les couches. - Finition de la surface : Les poudres plus fines permettent généralement d'obtenir des finitions de surface plus lisses sur la pièce finale. - Propriétés mécaniques : La taille et la distribution des particules peuvent influencer la résistance, la porosité et la ductilité de la pièce finale. |

| Morphologie des particules | La forme des particules de poudre influe sur leur comportement d'emballage et leur fluidité. | - Sphéricité : Les particules hautement sphériques offrent une fluidité et une densité de tassement supérieures, ce qui améliore l'imprimabilité. - Satellites et particules satellisées : Il s'agit de particules plus petites attachées à des particules plus grandes. Un excès de satellites peut entraver la fluidité et entraîner des incohérences dans la pièce imprimée. - Particules creuses : Tout en offrant des avantages en termes de réduction de poids, les particules creuses peuvent créer des vides internes dans la pièce finale, ce qui a un impact sur sa résistance mécanique. |

| Composition chimique et pureté de la poudre | La présence d'impuretés ou d'écarts par rapport à la composition chimique souhaitée peut affecter le processus d'impression et la qualité de la pièce finale. | - Teneur en oxygène : Un excès d'oxygène peut entraîner une plus grande porosité et une réduction des propriétés mécaniques. - Teneur en eau : L'humidité peut provoquer des éclaboussures pendant le processus d'impression et entraîner des défauts de surface. - Oligo-éléments : La présence d'éléments indésirables peut influencer les propriétés et l'imprimabilité du matériau. Les fournisseurs réputés fournissent des rapports d'analyse chimique détaillés pour garantir le respect des spécifications du matériau. |

| Fluidité des poudres | La facilité avec laquelle la poudre s'écoule est cruciale pour la formation de couches homogènes dans les processus de fabrication additive. | Une mauvaise fluidité peut entraîner : - Épaisseur de la couche incohérente - Ségrégation des particules dans le lit de poudre - Difficultés liées aux mécanismes de diffusion des matériaux Ces problèmes peuvent tous avoir un impact négatif sur la qualité et la précision dimensionnelle de la pièce finale. |

Considérations avancées pour l'atomisation de l'eau

| Facteur | Description | Impact sur le processus | Stratégies d'atténuation |

|---|---|---|---|

| Matières premières à composants multiples | Lors de l'atomisation d'alliages ou de boues contenant plusieurs composants, des facteurs tels que la distribution de la taille des particules et l'uniformité de la composition deviennent critiques. | La ségrégation des composants peut se produire pendant l'atomisation, entraînant des variations dans les propriétés du produit final. | – Mélange contrôlé : L'utilisation de mélangeurs à haut cisaillement ou d'homogénéisateurs en ligne peut garantir une distribution uniforme des composants dans la matière première. – Co-Atomisation : L'atomisation simultanée d'éléments individuels peut être utilisée pour obtenir un contrôle précis de la composition finale. – Systèmes de suivi et de retour d'information : Le contrôle en temps réel de la taille et de la composition des particules permet d'ajuster les paramètres d'atomisation pour obtenir une qualité de produit constante. |

| Morphologie des particules | La forme et les caractéristiques de surface des particules atomisées influencent considérablement les processus en aval, tels que la manipulation des poudres, le frittage et les performances du produit final. | Les formes irrégulières des particules peuvent poser des problèmes de densité de tassement, de fluidité et de comportement au frittage. | – Pression d'atomisation et conception de la buse : L'optimisation de ces paramètres peut influencer le degré de rupture et de solidification des gouttelettes, ce qui permet d'obtenir des particules plus sphériques. – Sélection des agents tensioactifs : Des agents tensioactifs spécifiques peuvent être introduits dans le flux d'eau pour modifier la tension superficielle et favoriser une morphologie plus uniforme des particules. – Solidification rapide : Des techniques telles que l'atomisation à haute pression ou la trempe rapide peuvent minimiser la croissance des particules et favoriser des formes plus sphériques. |

| Impact sur l'environnement | Les processus d'atomisation de l'eau peuvent générer des eaux usées contenant des particules métalliques et nécessitent une consommation d'eau importante. | L'élimination des eaux usées non traitées présente des risques pour l'environnement. La consommation élevée d'eau peut peser sur les ressources. | – Systèmes de recyclage de l'eau : Des systèmes en circuit fermé peuvent être mis en place pour capter et traiter l'eau de pulvérisation, minimisant ainsi les déchets et la consommation d'eau. – Floculation et décantation : Ces techniques peuvent être utilisées pour séparer les particules métalliques des eaux usées avant leur traitement et leur élimination. – Systèmes de filtration avancés : Les procédés de filtration membranaire ou d'échange d'ions peuvent être utilisés pour éliminer efficacement les contaminants des eaux usées. |

| Automatisation et contrôle des processus | L'intégration de l'automatisation et du contrôle des processus en temps réel peut améliorer considérablement la cohérence et l'efficacité. | Les opérations manuelles peuvent entraîner des erreurs humaines et des incohérences dans la qualité des produits. | – Systèmes de contrôle automatisés : La mise en œuvre de boucles de rétroaction et d'ajustements automatisés basés sur les données des capteurs garantit une qualité constante des produits. – Systèmes de surveillance avancés : La surveillance en temps réel des paramètres critiques tels que les débits, les pressions et les caractéristiques des particules permet des ajustements et une optimisation proactifs. – Intégration de l'apprentissage automatique : Les algorithmes d'apprentissage automatique peuvent analyser les données historiques et les relevés des capteurs afin de prévoir les problèmes potentiels et d'optimiser les paramètres du processus pour améliorer l'efficacité et le rendement. |

| Considérations de sécurité | Les processus d'atomisation de l'eau impliquent des pressions élevées, des pièces mobiles et une exposition potentielle à des particules métalliques. | Des procédures de sécurité inappropriées peuvent entraîner des accidents et des blessures. | – Formation adéquate et équipement de protection individuelle (EPI) : Il est essentiel que les opérateurs reçoivent une formation approfondie sur les procédures de manipulation en toute sécurité et sur l'utilisation des EPI appropriés. – Entretien et inspection réguliers : La mise en œuvre de programmes d'entretien préventif et d'inspections de sécurité permet de minimiser les pannes d'équipement et les risques potentiels. – Conception des enceintes et systèmes de ventilation : L'encoffrement des zones à haute pression et l'utilisation de systèmes de ventilation appropriés réduisent l'exposition aux particules métalliques en suspension dans l'air. |

FAQ

| Question | Répondre |

|---|---|

| Quelles sont les tailles de particules typiques des poudres métalliques atomisées à l'eau pour l'impression 3D ? | La taille des particules est généralement comprise entre entre 10 et 150 micromètres (µm)La gamme spécifique varie en fonction du métal choisi et de l'application souhaitée. |

| Les poudres métalliques atomisées à l'eau peuvent-elles être recyclées ? | Oui, les poudres métalliques atomisées à l'eau peuvent être recyclé par le biais de différentes techniques, telles que refonte et réatomisation. Cela favorise la durabilité et la réduction des déchets. |

| Comment la pulvérisation d'eau se compare-t-elle aux autres méthodes de production de poudres métalliques ? | Si l'atomisation de l'eau présente des avantages en termes de rentabilité et taux de productiond'autres méthodes comme atomisation du gaz pourrait produire particules plus sphériques et conviennent pour métaux réactifs. Le choix dépend en fin de compte de l'application spécifique et des propriétés souhaitées. |

Conclusion : Exploiter le potentiel de l'atomisation de l'eau

Alors que le monde de l'impression 3D continue d'évoluer, l'atomisation de l'eau reste une technologie de base, offrant un large éventail de possibilités. fiable et rentable pour produire des poudres métalliques destinées à diverses applications. A partir de composants aérospatiaux complexes à implants médicaux complexesLes poudres atomisées à l'eau permettent de créer des pièces imprimées en 3D diverses et fonctionnelles.

L'avenir de l'atomisation de l'eau est plein de potentiel. Les progrès constants de la technologie promettent :

- Amélioration de la forme des particules : A travers perfectionnement des techniques d'atomisation et le l'exploration de matériaux innovants, le sphéricité des poudres atomisées à l'eau peut être encore améliorée, potentiellement une qualité à la hauteur par des méthodes plus coûteuses telles que l'atomisation du gaz.

- Compatibilité élargie avec les matériaux : Les chercheurs explorent activement le potentiel de l'atomisation de l'eau pour une application à l'échelle mondiale. une gamme plus large de métaux, y compris matériaux hautement réactifs qui posent des problèmes avec les méthodes conventionnelles. Cela pourrait ouvrir de nouvelles voies pour les applications d'impression 3D dans des secteurs exigeants tels que l'aérospatiale et la médecine.

- Des progrès durables : L'accent mis sur responsabilité environnementale est à l'origine du développement de des procédés de pulvérisation d'eau respectueux de l'environnement. Il peut s'agir les systèmes en boucle fermée qui minimisent l'utilisation de l'eau et la production de déchets, contribuant ainsi à un environnement plus sain. un avenir durable pour la production de poudres métalliques pour l'impression 3D.

En exploitant le potentiel de l'atomisation de l'eau et en repoussant sans cesse ses limites, nous pouvons ouvrir la voie à un avenir où l'impression 3D de métaux deviendra une activité encore plus importante que par le passé. une technologie puissante et polyvalenteL'Union européenne a pour mission de façonner le monde qui nous entoure de manière innovante et transformatrice.

Partager sur

MET3DP Technology Co. est un fournisseur de premier plan de solutions de fabrication additive dont le siège se trouve à Qingdao, en Chine. Notre société est spécialisée dans les équipements d'impression 3D et les poudres métalliques de haute performance pour les applications industrielles.

Articles connexes

Supports imprimés en 3D pour les capteurs radar automobiles : Précision et performance

Lire la suite "À propos de Met3DP

Mise à jour récente

Notre produit

CONTACTEZ-NOUS

Vous avez des questions ? Envoyez-nous un message dès maintenant ! Nous répondrons à votre demande avec toute une équipe dès réception de votre message.

Obtenir les informations de Metal3DP

Brochure du produit

Obtenir les derniers produits et la liste des prix

Poudres métalliques pour l'impression 3D et la fabrication additive

PRODUIT

cONTACT INFO

- Ville de Qingdao, Shandong, Chine

- [email protected]

- [email protected]

- +86 19116340731