金属粉末3Dプリントのための水アトマイズ完全ガイド

目次

デジタルアーティストのような正確さで、複雑な金属製のオブジェを何層にも重ね、一から作り上げることを想像してみてほしい。これが 3Dプリンティング金属粉末そして、この革命的な技術の中心には、重要な成分がある: 金属粉.しかし、どうやって固体の金属を3Dプリンティングに必要な微細で流動性のある粉末に変えるのだろうか?参入 水噴霧このガイドの主役は、強力で多彩なテクニックである。

魔法を解き明かす:水の霧化とは何か?

水の霧化とは、溶けた金属を微細な水滴の霧に変える技術だと考えてほしい。一見単純に見えるこのプロセスには、大きな力が秘められている。その仕組みはこうだ:

- 金属を溶かす: その旅は、選ばれた金属が炉の中で溶けた状態にまで熱せられるところから始まる。溶けた金属で光り輝き、変身する準備が整った、燃えるような坩堝を想像してほしい。

- 高圧H2O: 次に、高圧ウォータージェットが溶融金属の流れに放たれる。この強力なジェット噴流は、消防士のホースをステロイドにしたようなもので、液体金属を微細な水滴の飛沫に分解する。

- 急速な凝固: 金属液滴が分散すると、空中で急速に冷えて固化し、個々の金属粉粒子が形成される。小さな金属の雨粒が、地面に落ちる前に固まる様子を思い浮かべてほしい。

- 収集と処理: 新しく形成された金属粉末は回収され、乾燥され、ふるいにかけられて、望ましい粒子径と分布になる。これにより、3Dプリンティング用途での一貫性と最適な性能が保証される。

3Dプリンティング金属粉末:なぜこの方法を選ぶのか?

| 特徴 | ベネフィット | 説明 |

|---|---|---|

| デザインの自由 | 非常に複雑な形状 | 機械加工や鋳造などの減法または成形技術に依存する従来の方法とは異なり、金属粉末を使用した 3D プリントでは、デジタル モデルから直接レイヤーごとに部品を構築します。これにより、他の方法では不可能または非常に非実用的である複雑な内部機能、チャネル、および格子構造を作成できます。 |

| 素材の多様性 | 幅広い金属 | 金属粉末には、チタンやアルミニウムなどの一般的な金属から、インコネルなどの珍しい材料、金などの貴金属まで、さまざまなオプションがあります。これにより、エンジニアは強度、重量、耐腐食性、生体適合性などの要素を考慮して、特定の用途に最適な材料を選択できます。 |

| ラピッドプロトタイピング | より速い設計反復 | 3D プリントのデジタル特性により、設計変更が迅速かつ簡単に行えます。CAD モデルに変更を加え、新しいプロトタイプを短期間で印刷できます。これにより、従来のプロトタイプ作成方法と比較して、開発時間とコストが大幅に削減されます。 |

| 軽量化 | 効率性を重視した設計 | 3D プリント金属粉末を使用して複雑な内部構造を作成できるため、強度を維持しながら部品を軽量化できます。これは、軽量化が燃費と性能の向上につながる航空宇宙や自動車などの用途では非常に重要です。 |

| オンデマンド製造 | 在庫の必要性の削減 | 金属粉末を使用した 3D プリントにより、必要に応じて部品を製造できるため、大量生産や完成品の保管が不要になります。これは、従来のチャネルでは容易に入手できない少量生産やスペアパーツに特に有効です。 |

| 材料の無駄を最小限に抑える | 持続可能な生産 | 金属 3D プリントでは、大量の廃材が発生する従来の方法とは異なり、部品の製造に必要な材料のみを使用します。これにより、廃棄物が削減され、製造プロセスの環境への影響が軽減されます。 |

| カスタマイズ | パーソナライズされた製品 | 3D プリント金属粉末を使用して複雑な形状を作成できるため、高度にカスタマイズされた部品の製造が可能になります。これは、各個人にぴったり合うことが求められる医療用インプラント、補綴物、歯冠などの用途に役立ちます。 |

| 部品の統合 | 組み立ての複雑さを軽減 | 3D プリント金属粉末によって得られる設計の自由度により、複数のコンポーネントの機能を統合した複雑な部品の作成が可能になります。これにより、組み立ての複雑さが軽減され、製造コストが削減され、製品の全体的なパフォーマンスが向上します。 |

3Dプリンティングにおける水アトマイズの応用:金属に命を吹き込む

| プロセス | 説明 | メリット | デメリット |

|---|---|---|---|

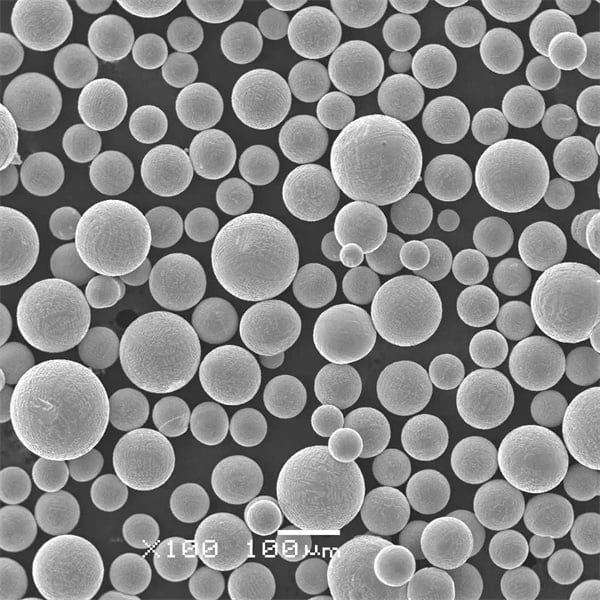

| 水の霧化 | 溶融金属は、複数の段階を経て微粉末に加工されます。まず、金属を炉で溶かします。次に、高圧ノズルで液体金属を細い流れに押し出します。この流れは高速水ジェットで小さな液滴に分解されます。最後に、急速に冷却された液滴は個々の粉末粒子に固まり、集められ、乾燥され、特定のサイズと分布になるようにふるいにかけられます。 | – コスト効率が高い: 水アトマイゼーションは、他の技術と比較して、大量の金属粉末を生産するための比較的低コストの方法を提供します。 – 幅広い材料互換性: この方法は、鋼鉄やアルミニウムなどの一般的な種類から、より特殊なオプションまで、幅広い金属を扱うことができます。 | – 粒子の形状: 水噴霧粉末は、他の方法で製造されたものよりも球形になりにくい傾向があります。これは、粉末の流動性と 3D プリントベッド内の充填密度に影響し、最終的な印刷部品の表面品質に影響を及ぼす可能性があります。 |

| 選択的レーザー溶融(SLM) | 高出力レーザーを使用して金属粉末粒子を層ごとに選択的に溶かして融合する 3D 印刷技術。レーザー ビームはデジタル デザインに沿って進み、目的の 3D オブジェクトを構築します。 | – 高精度と正確性: SLM は、厳しい公差で複雑な形状を作成できるため、複雑な金属部品に最適です。 – 設計の自由度: 従来の製造方法とは異なり、SLM は設計の自由度が非常に高く、内部チャネル、格子、その他の独自の機能を備えた部品の製造が可能になります。 | – 造形体積の制限: 現在の SLM マシンは通常、造形体積が制限されており、印刷可能なオブジェクトのサイズが制限されます。 – 表面粗さ: SLM の層ごとの性質により、印刷された部品の表面仕上げがわずかに粗くなる可能性があり、追加の後処理が必要になる場合があります。 |

| 電子ビーム溶解(EBM) | SLM と同様に、EBM では高出力ビームを使用しますが、この場合、電子ビームは真空環境で動作します。電子ビームは金属粉末粒子を溶かし、融合させて目的の 3D オブジェクトを形成します。 | – 優れた機械的特性: EBM は、高強度、優れた疲労耐性など、優れた機械的特性を持つ部品を生産します。これは、酸化を最小限に抑え、材料特性を向上させる真空環境によるものです。 – より幅広い材料適合性: SLM と比較して、EBM はチタンなどの反応性材料を含む、より幅広い金属との適合性を備えています。 | – コストが高い: EBM システムは一般に SLM マシンよりも高価であり、全体的な生産コストに影響します。 – 真空要件: 真空環境の必要性により EBM プロセスが複雑になり、特定の設定ではアクセスが制限される可能性があります。 |

| バインダージェッティング(BJ) | 液体結合剤を使用して金属粉末粒子を印刷プラットフォーム上に選択的にインクジェットする 3D 印刷方法。その後、層を硬化させて固体構造を作成します。 | – 高い造形体積: バインダー ジェッティングは、SLM や EBM に比べて造形体積が大きいため、より大きな金属部品の製造が可能になります。 – フルカラー印刷の可能性: 色付きバインダーを組み込んだバインダー ジェッティング技術が開発中であり、機能的で見た目にも魅力的な金属部品の作成への道が開かれています。 | – 部品の強度が低い: バインダー ジェッティングで製造された部品は、通常、SLM または EBM で製造された部品に比べて強度が低くなります。このため、望ましい機械的特性を得るには、浸透などの追加の後処理手順が必要になる場合があります。 – 限られた材料オプション: 現在、バインダー ジェッティングでは、他の 3D 印刷方法と比較して、互換性のある金属材料の範囲が限られています。 |

適切な水アトマイズ金属粉末の選択

| ファクター | 説明 | 積層造形プロセスと最終部品への影響 |

|---|---|---|

| 材料特性 | 選択された特定の金属または合金によって、3D プリントされた部品の最終的な特性が決まります。 | • 強度と耐久性: 航空宇宙部品のように高い強度対重量比を必要とする用途を検討してください。ニッケル合金またはチタン粉末はここで優れています。 • 耐食性: 過酷な環境にさらされる部品には、ステンレス鋼や銅合金が効果的です。 • 熱伝導率と電気伝導率: ヒートシンクや電気導体では、最適なパフォーマンスを得るためにアルミニウムや銅の粉末が使用される場合があります。 |

| 粒子径と分布 | 粉末粒子のサイズとばらつきは、印刷性および最終部品の特性に大きな影響を与えます。 | • 流動性: 均一な球状粒子は流れやすくなり、印刷中に一貫した層形成が実現します。 • 梱包密度: 理想的な粉末充填密度により、材料を最大限に活用しながら、層間の適切な融合が可能になります。 • 表面仕上げ: 一般的に、粉末が細かいほど、最終部品の表面仕上げは滑らかになります。 • 機械的特性: 粒子のサイズと分布は、最終部品の強度、多孔性、延性に影響を与える可能性があります。 |

| 粒子の形態学 | 粉末粒子の形状は、その充填挙動と流動性に影響を与えます。 | • 真球度: 高度に球状の粒子は優れた流動性と充填密度を提供し、印刷性が向上します。 • 衛星と衛星粒子: これらは、より大きな粒子に付着した小さな粒子です。サテライトが多すぎると流動性が損なわれ、印刷された部品に不均一性が生じる可能性があります。 • 中空粒子: 中空粒子は軽量化の利点がある一方で、最終部品に内部空洞を作り、機械的強度に影響を与える可能性があります。 |

| 化学組成と粉末純度 | 不純物の存在や望ましい化学組成からの逸脱は、印刷プロセスと最終的な部品の品質に影響を及ぼす可能性があります。 | • 酸素含有量: 酸素が多すぎると多孔性が高まり、機械的特性も低下する可能性があります。 • 水分含有量: 湿気は印刷プロセス中に飛び散りを引き起こし、表面欠陥につながる可能性があります。 • 微量元素: 意図しない要素が存在すると、材料の特性と印刷性に影響する可能性があります。信頼できるサプライヤーは、材料仕様の遵守を保証するために詳細な化学分析レポートを提供します。 |

| 粉体の流動性 | 粉末の流れやすさは、積層造形プロセスにおける一貫した層形成にとって非常に重要です。 | 流動性が悪いと、次のような問題が発生する可能性があります。 • 層の厚さが一定でない • 粉末層内の粒子の分離 • 材料拡散機構の難しさ これらの問題はすべて、最終部品の品質と寸法精度に悪影響を及ぼす可能性があります。 |

水噴霧に関する高度な考察

| ファクター | 説明 | プロセスへの影響 | 緩和戦略 |

|---|---|---|---|

| 多成分原料 | 複数の成分を含む合金またはスラリーを噴霧する場合、粒度分布や組成の均一性などの要素が重要になります。 | 霧化中に成分の分離が発生し、最終製品の特性が変化する可能性があります。 | – 制御された混合: 高せん断ミキサーまたはインラインホモジナイザーを使用すると、原料内の成分の均一な分散を確保できます。 – 共噴霧: 個々の要素を同時に霧化することで、最終的な組成を正確に制御できます。 – 監視およびフィードバックシステム: 粒子のサイズと組成をリアルタイムで監視することで、噴霧パラメータを調整し、一貫した製品品質を実現できます。 |

| 粒子の形態学 | 霧化粒子の形状と表面特性は、粉末処理、焼結、最終製品の性能などの下流プロセスに大きな影響を与えます。 | 粒子の形状が不規則だと、充填密度、流動性、焼結挙動に問題が生じる可能性があります。 | – 噴霧圧力とノズル設計: これらのパラメータを最適化すると、液滴の分解と凝固の程度に影響を与え、より球形の粒子が生成されます。 – 界面活性剤の選択: 特定の界面活性剤を水流に導入することで、表面張力を変更し、粒子の形態をより均一にすることができます。 – 急速な凝固: 高圧噴霧や急速冷却などの技術により、粒子の成長を最小限に抑え、より球形にすることができます。 |

| 環境への影響 | 水噴霧プロセスでは金属粒子を含む廃水が発生する可能性があり、大量の水の消費が必要になります。 | 未処理の廃水処理は環境への危険をもたらします。水の使用量が多いと資源に負担がかかります。 | – 水リサイクルシステム: 閉ループ システムを実装して霧化水を捕捉および処理し、廃棄物と水の消費を最小限に抑えることができます。 – 凝集と沈殿: これらの技術は、処理および廃棄の前に廃水から金属粒子を分離するために使用できます。 – 高度な濾過システム: 膜ろ過またはイオン交換プロセスは、廃水から汚染物質を高効率で除去するために使用できます。 |

| プロセスの自動化と制御 | 自動化とリアルタイムのプロセス制御を統合することで、一貫性と効率性が大幅に向上します。 | 手動操作では人為的ミスが発生し、製品品質にばらつきが生じる可能性があります。 | – 自動制御システム: センサーデータに基づくフィードバック ループと自動調整を実装することで、一貫した製品品質が保証されます。 – 高度な監視システム: 流量、圧力、粒子特性などの重要なパラメータをリアルタイムで監視することで、積極的な調整と最適化が可能になります。 – 機械学習の統合: 機械学習アルゴリズムは、履歴データとセンサーの読み取り値を分析して潜在的な問題を予測し、プロセスパラメータを最適化して効率と歩留まりを向上させることができます。 |

| 安全への配慮 | 水噴霧プロセスには、高圧、可動部品、および金属粒子への潜在的な曝露が伴います。 | 不適切な安全手順は事故や怪我につながる可能性があります。 | – 適切なトレーニングと個人用保護具(PPE): 安全な取り扱い手順と適切な個人用保護具の使用についてオペレーターに徹底したトレーニングを行うことが重要です。 – 定期的なメンテナンスと点検: 予防保守スケジュールと安全検査を実施することで、機器の故障や潜在的な危険を最小限に抑えることができます。 – 筐体設計と換気システム: 高圧エリアを囲み、適切な換気システムを利用することで、空気中の金属粒子への曝露を軽減します。 |

よくあるご質問

| 質問 | 答え |

|---|---|

| 3Dプリンティング用の水アトマイズ金属粉末の一般的な粒子径は? | 粒子径の範囲は、通常 10~150マイクロメートル(µm)その具体的な範囲は、選択した金属と希望する用途によって異なる。 |

| 水アトマイズした金属粉はリサイクル可能か? | そう、水アトマイズした金属粉は リサイクル など、さまざまなテクニックを駆使している。 再溶解と再原子化.これにより、次のことが促進される。 持続可能性と廃棄物の削減. |

| 水アトマイズは他の金属粉末製造法と比べてどうですか? | 水噴霧は、以下の点で有利である。 費用対効果と生産率のような方法もある。 ガス霧化 かもしれない より球状の粒子 に適している。 反応性金属.最終的な選択は、特定の用途と希望する特性によって決まる。 |

結論水アトマイズの可能性

3Dプリンティングの世界が進化を続ける中、水アトマイズは依然として基幹技術であり、次のようなものを提供している。 信頼性と費用対効果 様々な用途の金属粉末を製造する手段より 複雑な航空宇宙部品 への 複雑な医療用インプラント水アトマイズされたパウダーは、多様で機能的な3Dプリントパーツの作成に威力を発揮する。

この先、水噴霧の未来は可能性に満ちている。 技術の絶え間ない進歩は約束される:

- 粒子形状の強化: を通して 霧化技術の改良 そして 革新的素材の探求その 球形度 水アトマイズされた粉体は、さらに改善される可能性がある。 品質に見合う ガスアトマイゼーションのような、より高価な方法で達成される。

- 素材の互換性を拡大: 研究者たちは、水霧化の可能性を積極的に探っている。 より幅広い金属を含む。 高反応性材料 従来の方法では困難であったこれは、次のような要求の厳しい産業における3Dプリンティング・アプリケーションの新たな道を開く可能性がある。 航空宇宙と医学.

- 持続可能な進歩: に焦点を当てている。 環境責任 の開発を推進している。 環境に優しい水噴霧プロセス.これには以下が含まれる。 閉ループシステム 水の使用量と廃棄物の発生を最小限に抑え、より効率的な生産に貢献する。 持続可能な未来 3Dプリンティング金属粉末製造用。

水アトマイズの可能性を受け入れ、その限界に挑戦し続けることで、金属を3Dプリンティングすることがさらに容易になる未来を切り開くことができる。 強力で汎用性の高いテクノロジー革新的で変革的な方法で、私たちを取り巻く世界を形作る。

シェアする

フェイスブック

ツイッター

LinkedIn

WhatsApp

電子メール

MET3DP Technology Co., LTDは、中国青島に本社を置く積層造形ソリューションのリーディングプロバイダーです。弊社は3Dプリンティング装置と工業用途の高性能金属粉末を専門としています。

関連記事

Met3DPについて

最新情報

製品

3Dプリンティングと積層造形用金属粉末