함부르크의 최고 항공우주 적층 제조: B2B 구매자를 위한 종합 가이드

목차

1. Introduction to Aerospace Additive Manufacturing in Hamburg

Hamburg is a key hub for aerospace manufacturing in Europe, home to leading companies such as Airbus and Lufthansa Technik. With the growing demand for lightweight, high-performance parts, additive manufacturing (AM) in aerospace has gained significant traction in the region.

Aerospace additive manufacturing involves 3D printing metal and polymer components to enhance aircraft performance, reduce material waste, and accelerate production timelines. This technology is widely used for engine components, structural parts, and intricate geometries that are difficult to manufacture using traditional methods.

Key Benefits of Aerospace 3D Printing

✅ 무게 감소 – Optimized part designs reduce overall aircraft weight, improving fuel efficiency.

✅ 비용 절감 – Minimizes material waste and reduces production costs for complex components.

✅ 더 짧은 리드 타임 – Rapid prototyping and on-demand production accelerate time-to-market.

✅ 향상된 성능 – AM enables the creation of high-strength, intricate parts with superior durability.

As aerospace manufacturers in Hamburg increasingly adopt 금속 적층 제조, sourcing the right 3D printing suppliers and materials is crucial for success.

2. Market Trends and Growth Potential in Aerospace 3D Printing

The aerospace additive manufacturing market is experiencing rapid growth, driven by advancements in metal 3D printing technologies, high-performance materials, and automated production processes.

주요 시장 동향

📈 Increased Adoption of Metal 3D Printing – Aerospace companies favor 금속 분말 like titanium, aluminum, and superalloys for critical components.

📈 지속 가능성 이니셔티브 – Additive manufacturing reduces waste and supports greener production practices.

📈 Customization & On-Demand Production – Airlines and manufacturers leverage on-demand 3D printing for spare parts, reducing inventory costs.

📈 Regulatory Approvals & Certifications – Aerospace AM suppliers must meet 엄격한 산업 표준 like AS9100 and Nadcap certification.

| 시장 성장 통계 | Figures |

|---|---|

| Global Aerospace AM Market Size (2023) | $35억 |

| Projected CAGR (2023-2030) | 19.8% |

| Adoption Rate Among Aerospace OEMs | 85% |

| Reduction in Lead Time via AM | 50-70% |

함께 Hamburg’s strong aerospace ecosystem, companies are investing in advanced 첨가 제조 기술 to enhance production efficiency and competitiveness.

3. 항공우주 3D 프린팅 공급업체를 선택할 때 고려해야 할 핵심 요소

오른쪽 선택 aerospace additive manufacturing supplier in Hamburg requires careful evaluation of several critical factors:

1️⃣ Experience & Certifications

Ensure the supplier has aerospace industry experience and meets stringent certifications such as:

✔ AS9100 인증 – Quality management standard for aerospace manufacturers.

✔ Nadcap Accreditation – Ensures compliance with aerospace additive manufacturing processes.

✔ ISO 9001 인증 – Demonstrates quality control and consistency in production.

2️⃣ Material & Technology Capabilities

평가하다 3D 프린팅 기술 및 metal powder materials the supplier offers:

- 레이저 파우더 베드 퓨전(LPBF) – Ideal for high-precision metal components.

- 전자빔 용융(EBM) – Suitable for high-strength aerospace parts.

- 직접 에너지 증착(DED) – Used for repair and refurbishment of aircraft components.

🔹 Common Aerospace 3D Printing Materials:

- 티타늄 합금(Ti6Al4V) – Lightweight and corrosion-resistant.

- Nickel-Based Superalloys (Inconel 718, 625) – High-temperature resistance.

- 알루미늄 합금(AlSi10Mg) – Excellent strength-to-weight ratio.

- 스테인리스 스틸(316L, 17-4PH) – High durability and wear resistance.

3️⃣ Production Capabilities & Lead Times

✔ Can the supplier handle 대량 생산?

✔ What are the lead times for prototyping vs. full-scale production?

✔ Do they offer on-demand production for spare parts?

4️⃣ Cost & Scalability

Compare pricing models based on:

💲 재료비 – Metal powders can vary in price depending on composition and purity.

📦 생산 비용 – Evaluate per-part pricing for small vs. large production runs.

🚀 확장성 – Can the supplier scale production based on demand fluctuations?

By carefully considering these factors, aerospace manufacturers in Hamburg can select the best 3D printing partner to support their production needs.

4. Top Aerospace Additive Manufacturing Companies in Hamburg

Hamburg is a major hub for aerospace innovation, home to 선도적인 첨가 제조 회사 전문 분야 metal 3D printing for aircraft and spacecraft components. Below are some of the top aerospace additive manufacturing providers in the region:

🔝 Leading Aerospace 3D Printing Suppliers in Hamburg

| 회사 이름 | 주요 역량 | 인증 | 스페셜티 |

|---|---|---|---|

| Airbus Additive Manufacturing | Metal & polymer 3D printing, prototyping, production | AS9100, Nadcap | 항공기 구조 부품 |

| Lufthansa Technik | Repair & maintenance via metal 3D printing | EASA, FAA, AS9100 | Spare parts & engine components |

| 구체화 | Aerospace-grade metal & polymer printing | ISO 9001, AS9100 | Lightweight aircraft parts |

| FIT 적층 제조 그룹 | High-end metal 3D printing, complex geometries | AS9100, ISO 13485 | Aircraft & space applications |

| Metal3DP | 고성능 SEBM & LPBF metal 3D printing, 고급 금속 분말 | ISO 9001, Industry-leading expertise | Titanium, superalloys, aerospace-grade materials |

Each of these suppliers brings unique strengths to aerospace additive manufacturing. 그러나, Metal3DP stands out with its specialized focus on metal powders and high-precision 3D printing solutions that meet the rigorous demands of aerospace.

5. Why More Aerospace Manufacturers Are Adopting Additive Manufacturing

의 채택 metal 3D printing in aerospace is accelerating as manufacturers recognize its numerous advantages over traditional production methods.

🚀 Key Reasons for Adoption

✅ Lightweight Design for Fuel Efficiency

- 3D printing enables the creation of hollow lattice structures 및 topology-optimized parts, significantly reducing weight.

- Lighter aircraft consume less fuel, improving operational efficiency and sustainability.

✅ Reduced Waste & Sustainability

- 기존 가공 폐기물은 최대 80% of raw material반면 additive manufacturing uses only the necessary material.

- Closed-loop recycling systems allow manufacturers to reuse metal powder, reducing overall waste.

✅ 신속한 프로토타이핑 및 빠른 생산

- Traditional aerospace parts take months to produce due to complex supply chains.

- 함께 적층 제조, production cycles are cut by 50-70%, enabling faster iteration and market readiness.

✅ On-Demand Spare Parts Production

- Airlines and MRO (Maintenance, Repair, Overhaul) providers can 3D print spare parts on demand재고 비용이 감소합니다.

- This is particularly useful for rare, discontinued, or customized aircraft components.

✅ Superior Material Properties

- 금속 3D 프린팅 생산하다 고강도, 부식 방지 부품 that outperform traditionally manufactured parts.

- Advanced alloys such as Ti6Al4V, Inconel 718, and CoCrMo 는 다음 분야에서 널리 사용됩니다. jet engines, landing gear, and structural components.

As the aerospace industry continues to evolve, companies that integrate additive manufacturing into their production workflows gain a competitive edge in cost, speed, and innovation.

6. Why Choose Metal3DP as Your Aerospace 3D Printing Partner?

다음과 같은 경우 high-performance aerospace additive manufacturing, Metal3DP is a trusted partner for OEMs, Tier-1 suppliers, and research institutions.

🔹 What Sets Metal3DP Apart?

1️⃣ Industry-Leading Metal 3D Printing Technologies

- 선택적 전자빔 용융(SEBM) – Ideal for high-precision titanium and superalloy parts.

- 레이저 파우더 베드 퓨전(LPBF) – 보장합니다 tight tolerances and fine surface finishes for aerospace components.

2️⃣ High-Quality Metal Powders for Aerospace Applications

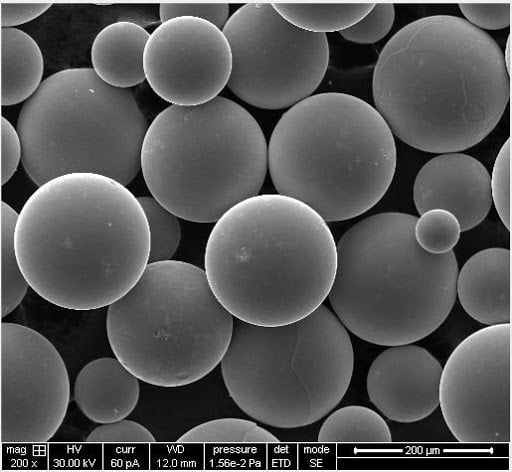

- Our company manufactures aerospace-grade metal powders 사용 가스 분무 및 PREP 기술.

- Available materials:

✔ 티타늄 합금(Ti6Al4V, TiAl, TiNbZr) – 에서 사용됨 airframes, engine parts, and landing gear.

✔ Superalloys (Inconel 718, CoCrMo, Ni-based alloys) – 이상적 high-temperature jet engine components.

✔ 스테인리스 스틸(316L, 17-4PH) – Corrosion-resistant and durable for aircraft interiors and structural parts.

3️⃣ Certified & Reliable Aerospace Manufacturing

- ISO 9001-certified production facility ensures the highest quality standards.

- 사내 powder characterization and quality control guarantee consistent particle size, flowability, and purity.

4️⃣ Expertise in Aerospace Applications

- 수십 년의 경험 aerospace additive manufacturing.

- Close collaboration with 선도적인 항공우주 기업 to develop cutting-edge 3D 프린팅 부품.

📌 Explore Our Metal Powders & 3D Printing Solutions:

🔗 Learn More About Metal3DP’s Metal 3D Printing Capabilities

By partnering with Metal3DP, aerospace manufacturers gain access to top-tier additive manufacturing expertise, high-performance materials, and cutting-edge printing technologies to enhance their production efficiency and competitiveness.

7. How to Source High-Quality Metal Powders for Aerospace 3D Printing

소싱 고품질 금속 분말 is crucial for achieving precision, durability, and performance in aerospace additive manufacturing. The right metal powder ensures optimal printability, mechanical properties, and safety compliance. Here’s how aerospace manufacturers can source the best materials for their 3D 프린팅 필요로 합니다.

🔹 Key Factors to Consider When Choosing Metal Powders

| 팩터 | 중요한 이유 |

|---|---|

| 입자 크기 분포(PSD) | Affects powder flowability and layer uniformity in AM processes. |

| Powder Morphology (Shape and Surface Quality) | Spherical powders improve packing density and reduce defects. |

| Purity and Contamination Levels | High-purity powders ensure stronger, defect-free components. |

| Oxidation and Moisture Sensitivity | Oxidized powders can degrade mechanical properties. |

| Printability & Compatibility | The powder must be optimized for LPBF, SEBM, or DED processes. |

🔹 Recommended Metal Powders for Aerospace 3D Printing

| 재질 | 항공우주 분야의 응용 |

|---|---|

| 티타늄 합금(Ti6Al4V, TiAl, TiNbZr) | Lightweight & corrosion-resistant – used in airframes, engine parts. |

| 니켈 기반 초합금(Inconel 718, Inconel 625) | High-temperature resistance – ideal for 제트 엔진 부품. |

| 코발트-크롬(CoCrMo) | High wear resistance – used in turbine blades, exhaust systems. |

| 스테인리스 스틸(316L, 17-4PH) | Strong & corrosion-resistant – used in aircraft interiors, structural parts. |

🔹 Why Choose Metal3DP’s Metal Powders?

✅ Industry-Leading Purity & Quality – 다음을 사용하여 제조됨 가스 분무 및 PREP 기술 우수한 구형도 및 유동성.

✅ 항공우주 등급 인증 – Compliant with ISO 9001 standards을 사용하여 high-performance, defect-free prints.

✅ 적층 제조에 최적화됨 – Powders tailored for LPBF, SEBM, and DED 프로세스.

📌 Explore Metal3DP’s Full Range of Metal Powders:

🔗 View Our Metal Powder Products

8. How to Order Aerospace 3D Printing Services in Hamburg

For aerospace manufacturers looking to integrate 적층 제조 into their production workflows, partnering with the right supplier is essential. Here’s how to order aerospace 3D printing services with a streamlined process.

Step-by-Step Guide to Ordering Aerospace 3D Printing Services

1단계: 요구 사항 정의

📌 Determine the part specifications:

- Material type (e.g., Ti6Al4V, 인코넬 718)

- Print technology (LPBF, SEBM, or DED)

- Tolerance requirements

- Mechanical performance needs

Step 2: Select a Trusted Supplier

- 선택 Metal3DP 에 대한 high-precision aerospace printing and advanced metal powders.

- Ensure supplier 인증 (AS9100, ISO 9001) align with industry standards.

Step 3: Request a Quote & Feasibility Analysis

📩 Provide a 3D CAD 파일 (STEP/STL format) to Metal3DP for evaluation.

📊 Receive a technical feasibility assessment & cost estimate.

Step 4: Prototype & Testing Phase

🔬 Prototype production for functional testing and validation.

📏 Material characterization to ensure compliance with aerospace standards.

5단계: 본격적인 생산 및 배송

🚀 Batch production of aerospace components using high-precision 3D printing.

📦 Quality inspection & certification before final delivery.

📌 Get Started with Aerospace Additive Manufacturing:

🔗 Contact Metal3DP for Ordering

9. FAQs: Common Questions About Aerospace Additive Manufacturing

Q1: What are the main advantages of additive manufacturing in aerospace?

Aerospace 3D printing provides:

✔ 무게 감소 연료 효율 향상을 위해

✔ 비용 절감 by minimizing material waste

✔ 신속한 프로토 타입 for faster product development

✔ On-demand spare parts production

Q2: Which metal powders are best for aerospace 3D printing?

🔹 티타늄 합금(Ti6Al4V, TiAl, TiNbZr) – Lightweight, high strength

🔹 니켈 기반 초합금(Inconel 718, 625) – Heat-resistant, durable

🔹 코발트크롬(CoCrMo) – High wear resistance for turbine blades

Q3: How does Metal3DP ensure metal powder quality?

✅ Gas atomization & PREP production 보장 high sphericity, minimal impurities

✅ ISO-certified quality control 에 대한 consistent particle size and flowability

Q4: How long does it take to produce aerospace 3D printed parts?

⏳ Lead times vary based on complexity and production volume:

- 프로토타입: 1-2주

- Full production: 4~8주

Q5: How can I request a custom aerospace 3D printing project?

📩 Submit your CAD file & material requirements 를 Metal3DP로 변경합니다.

📊 Receive a customized production plan & pricing estimate.

📌 Learn More About Metal3DP’s Aerospace 3D Printing Solutions:

🔗 Explore Our Metal 3D Printing Capabilities

마지막 생각과 다음 단계

Aerospace additive manufacturing is revolutionizing the industry, offering lighter, stronger, and more efficient parts for modern aircraft. With Hamburg’s growing 3D printing ecosystem, manufacturers can leverage high-performance metal powders and advanced printing technologies to gain a competitive edge.

🚀 왜 Metal3DP를 선택하시나요?

✅ Industry-leading aerospace 3D printing solutions

✅ High-purity, aerospace-grade metal powders

✅ Precision manufacturing for mission-critical components

📌 Get Started with Metal3DP Today:

🔗 Contact Us for Aerospace 3D Printing Services

By following this guide, aerospace manufacturers in Hamburg can successfully integrate additive manufacturing into their supply chain을 사용하여 high-quality, cost-effective production of critical aircraft components.

공유

중국 칭다오에 본사를 둔 선도적인 적층 제조 솔루션 제공업체인 MET3DP Technology Co. 당사는 산업용 3D 프린팅 장비와 고성능 금속 분말을 전문으로 합니다.

관련 기사