Blogg

alla samlingar

3D Printed Industrial Robot Joints for Automation

Introduction – Revolutionizing Automation with 3D Printed Robot Joints The landscape of industrial automation is constantly evolving, driven by the need for increased efficiency, flexibility, and customization. At the forefront of this revolution lies metal additive manufacturing, commonly known as metal 3D printing. This cutting-edge technology is transforming how critical

3D Printing Hydraulic Valve Blocks for Fluid Control

Introduction to 3D Printed Hydraulic Valve Blocks In the realm of fluid power, hydraulic valve blocks serve as critical components, orchestrating the flow of hydraulic fluid to control the movement and force of machinery. Traditionally manufactured through subtractive methods like machining, these blocks are now undergoing a transformative shift with

Igniter Housings for Rocket Engines via Superalloy AM

Revolutionizing Rocketry: Metal 3D Printed Igniter Housings in IN718 & Haynes 282 The quest for more efficient, powerful, and reliable access to space demands constant innovation in rocket propulsion technology. At the very heart of initiating the immense power of a rocket engine lies a critical, often underappreciated component: the

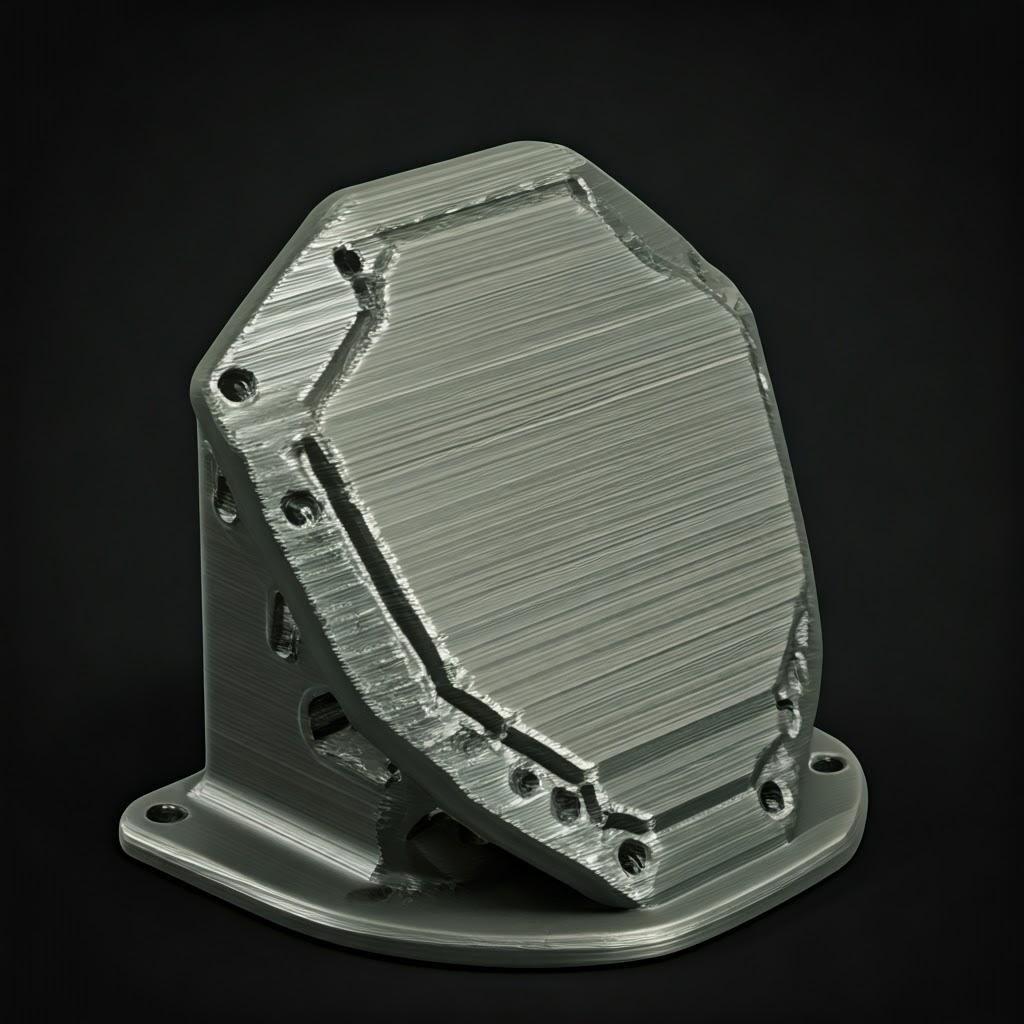

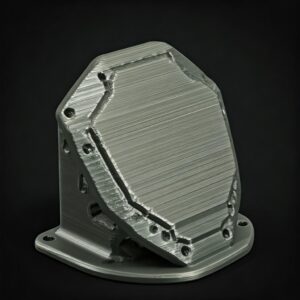

Heat Shield Brackets via 3D Printed Aluminum

Introduction: Revolutionizing Automotive Heat Shield Brackets with Aluminum 3D Printing The modern automotive landscape is defined by relentless innovation, driven by demands for greater fuel efficiency, enhanced performance, stringent safety regulations, and reduced environmental impact. Central to achieving these goals is the optimization of every vehicle component, no matter how

Lightweight Enclosures for UAV Payload Systems

Lightweight Enclosures for UAV Payload Systems: The Metal 3D Printing Advantage Unmanned Aerial Vehicles (UAVs), commonly known as drones, have transcended their military origins to become indispensable tools across a vast spectrum of industries. From precision agriculture and infrastructure inspection to defense surveillance and commercial delivery, UAVs are performing tasks

Guide Rails for Aerospace Assemblies

Revolutionizing Aerospace Assemblies: The Power of Metal 3D Printed Guide Rails The aerospace industry perpetually seeks innovation – lighter components, stronger materials, faster production cycles, and enhanced performance under extreme conditions. Every gram saved translates to fuel efficiency or increased payload capacity. Every improvement in component reliability enhances safety and

3D Printed Industrial Robot Joints for Automation

Introduction – Revolutionizing Automation with 3D Printed Robot Joints The landscape of industrial automation is constantly evolving, driven by the need for increased efficiency, flexibility,

3D Printing Hydraulic Valve Blocks for Fluid Control

Introduction to 3D Printed Hydraulic Valve Blocks In the realm of fluid power, hydraulic valve blocks serve as critical components, orchestrating the flow of hydraulic

Igniter Housings for Rocket Engines via Superalloy AM

Revolutionizing Rocketry: Metal 3D Printed Igniter Housings in IN718 & Haynes 282 The quest for more efficient, powerful, and reliable access to space demands constant

Heat Shield Brackets via 3D Printed Aluminum

Introduction: Revolutionizing Automotive Heat Shield Brackets with Aluminum 3D Printing The modern automotive landscape is defined by relentless innovation, driven by demands for greater fuel

Lightweight Enclosures for UAV Payload Systems

Lightweight Enclosures for UAV Payload Systems: The Metal 3D Printing Advantage Unmanned Aerial Vehicles (UAVs), commonly known as drones, have transcended their military origins to

Guide Rails for Aerospace Assemblies

Revolutionizing Aerospace Assemblies: The Power of Metal 3D Printed Guide Rails The aerospace industry perpetually seeks innovation – lighter components, stronger materials, faster production cycles,

Vår produkt

PRODUKT MED HET FÖRSÄLJNING

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731