Blogg

alla samlingar

Fuel Manifolds Designed for Additive Flow Optimization

Introduction: Revolutionizing Fuel Delivery with Custom Metal 3D Printed Manifolds The intricate dance of engineering that powers our modern world often relies on the precise control and distribution of fluids. From the roar of a jet engine piercing the stratosphere to the refined hum of a high-performance automotive engine hugging

High-Precision Instrument Mounting via Metal 3D Printing

In the intricate world of advanced technology, where measurements push the boundaries of physics and devices operate under demanding conditions, the humble mount plays a surprisingly critical role. Precision instruments – whether they are aligning lasers, stabilizing sensors in satellites, holding delicate samples in medical scanners, or ensuring accuracy in

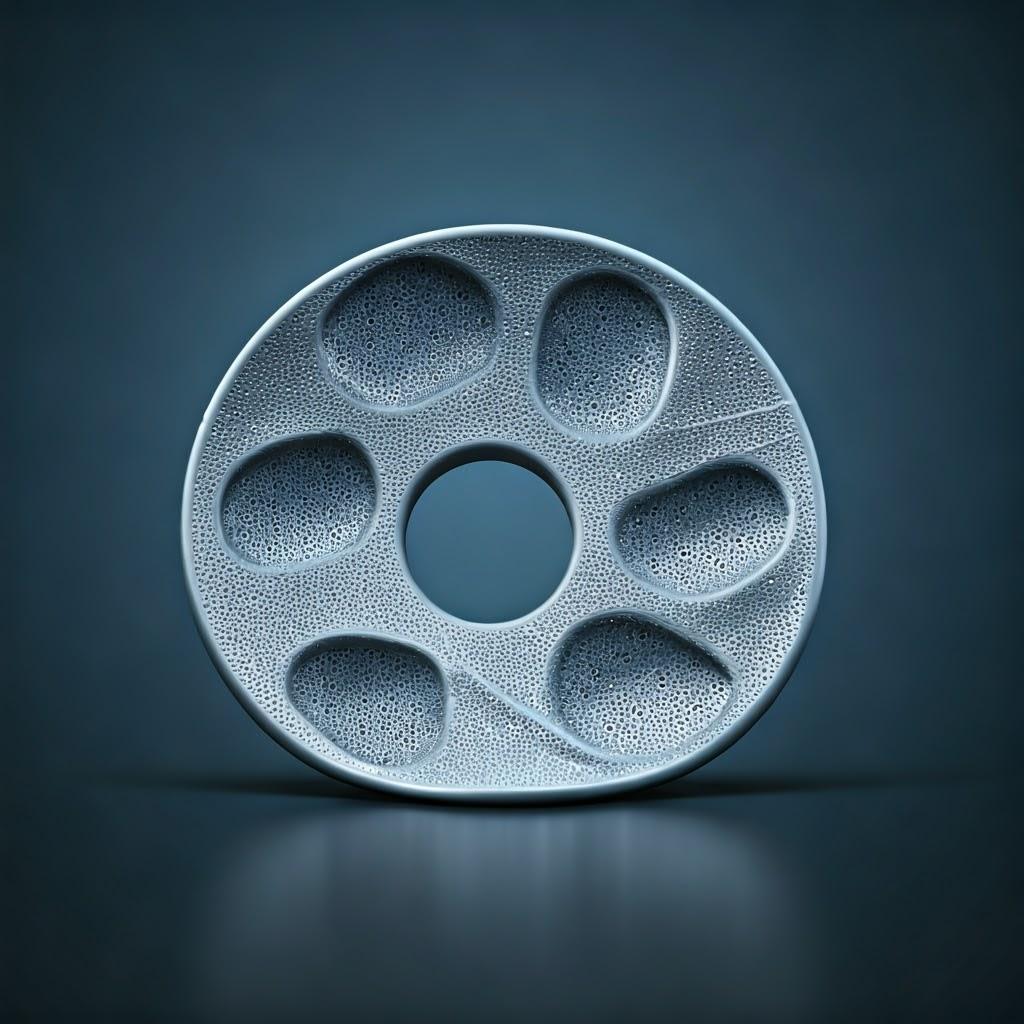

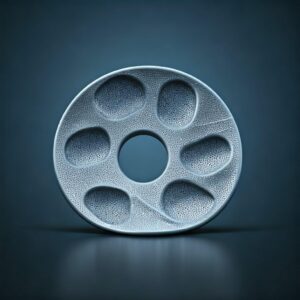

Thermal Insulation Plates for Space Systems via Metal AM

Introduction: The Critical Role of Thermal Insulation in Spacecraft Spacecraft, whether orbiting Earth, traveling to distant planets, or docking with space stations, operate in one of the most extreme environments imaginable. They face a relentless barrage of challenges: the vacuum of space, intense solar radiation, micrometeoroid impacts, and extreme temperature

3D Printed Connection Brackets for Aircraft Winglets

Introduction: The Critical Role of Winglet Connection Brackets in Modern Aviation Look closely at the wingtip of almost any modern commercial airliner or business jet, and you’ll likely see a distinctive upward (or sometimes downward and upward) angled extension: the winglet. While seemingly small relative to the entire aircraft, winglets

Reinforced Lever Arms via Maraging Steel Additive Manufacturing

Introduction: The Critical Role of High-Strength Levers and the Maraging Steel AM Solution Lever arms are fundamental mechanical components found across countless industrial applications, translating input force into amplified output force or motion. From the intricate actuation systems in aerospace landing gear to the robust linkages in heavy industrial machinery,

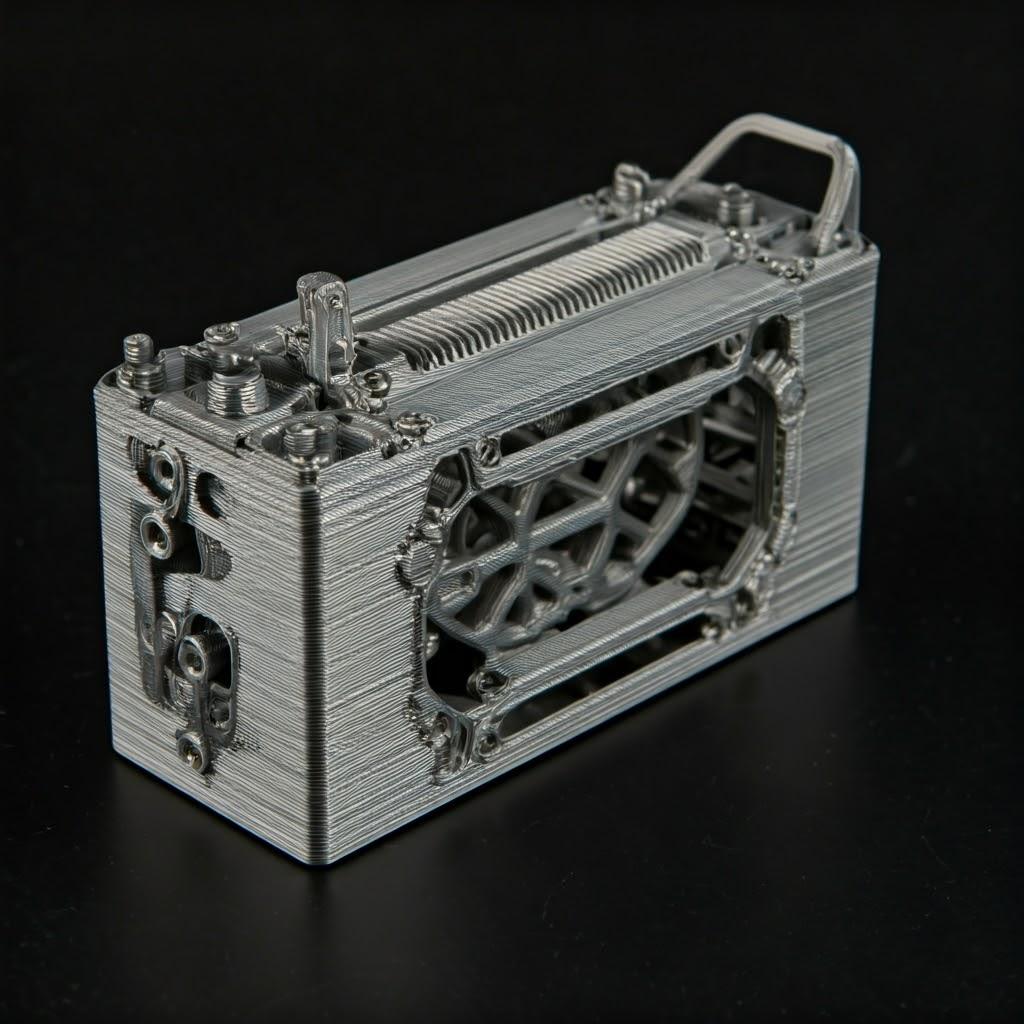

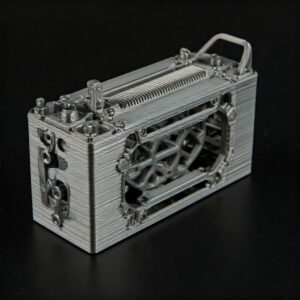

Battery Frame Components for EV Cooling via Metal 3D Printing

Introduction: Revolutionizing EV Thermal Management with Metal 3D Printed Battery Cooling Frames The electric vehicle (EV) revolution is accelerating, driven by advancements in battery technology, powertrain efficiency, and a global push towards sustainable transportation. At the heart of every high-performing EV lies its battery pack – a sophisticated energy storage

Fuel Manifolds Designed for Additive Flow Optimization

Introduction: Revolutionizing Fuel Delivery with Custom Metal 3D Printed Manifolds The intricate dance of engineering that powers our modern world often relies on the precise

High-Precision Instrument Mounting via Metal 3D Printing

In the intricate world of advanced technology, where measurements push the boundaries of physics and devices operate under demanding conditions, the humble mount plays a

Thermal Insulation Plates for Space Systems via Metal AM

Introduction: The Critical Role of Thermal Insulation in Spacecraft Spacecraft, whether orbiting Earth, traveling to distant planets, or docking with space stations, operate in one

3D Printed Connection Brackets for Aircraft Winglets

Introduction: The Critical Role of Winglet Connection Brackets in Modern Aviation Look closely at the wingtip of almost any modern commercial airliner or business jet,

Reinforced Lever Arms via Maraging Steel Additive Manufacturing

Introduction: The Critical Role of High-Strength Levers and the Maraging Steel AM Solution Lever arms are fundamental mechanical components found across countless industrial applications, translating

Battery Frame Components for EV Cooling via Metal 3D Printing

Introduction: Revolutionizing EV Thermal Management with Metal 3D Printed Battery Cooling Frames The electric vehicle (EV) revolution is accelerating, driven by advancements in battery technology,

Vår produkt

PRODUKT MED HET FÖRSÄLJNING

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731