Blogg

alla samlingar

Complex Wing Ribs via Metal 3D Printing

Introduction: Revolutionizing Aerospace Structures with Metal 3D Printed Wing Ribs The aerospace industry stands at the forefront of technological advancement, constantly pushing the boundaries of performance, efficiency, and safety. Central to this pursuit is the relentless optimization of aircraft structures, where every gram saved and every performance enhancement translates into

3D Printed Heat Sinks for Electric Motor Cooling

Introduction: Revolutionizing Electric Motor Thermal Management with Metal 3D Printing Electric motors are the workhorses of modern industry, powering everything from electric vehicles (EVs) and aerospace actuators to industrial robots and medical devices. However, as performance demands increase – higher power density, faster speeds, and more compact designs – effective

Lightweight Brake Pedal Arms via Metal Additive Manufacturing

Introduction: Revolutionizing Automotive Components with Metal AM In the intricate system that constitutes a modern vehicle, few components are as fundamentally critical to safety and driver control as the brake pedal arms. It’s the direct interface between the driver’s input and the vehicle’s braking system, translating foot pressure into hydraulic

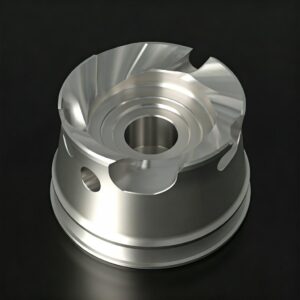

3D Printed Support Rings for Jet Engine Components

Introduction: The Critical Role of Support Rings in Modern Jet Engines Jet engines represent the pinnacle of complex engineering, operating under extreme conditions to generate the immense thrust required for modern flight. Within this intricate assembly of high-performance machinery, numerous components play vital roles, often unseen but absolutely critical. Among

Payload Mounts for Satellites and Aircraft via 3D Printing

Introduction: Revolutionizing Aerospace Componentry with 3D Printed Payload Mounts The aerospace industry operates at the zenith of engineering achievement, demanding components that exhibit extraordinary performance under extreme conditions. From the vacuum of space to the dynamic stresses of atmospheric flight, every part must function flawlessly, often while pushing the boundaries

High-Performance Nozzle Vanes via Additive Manufacturing

Introduction to Turbine Nozzle Guide Vanes (NGVs): The Critical Hot Section Component Turbine Nozzle Guide Vanes (NGVs), often referred to simply as nozzle vanes or stator vanes, are absolutely fundamental components situated within the challenging environment of a gas turbine’s hot section. Positioned typically between the combustor outlet and the

Complex Wing Ribs via Metal 3D Printing

Introduction: Revolutionizing Aerospace Structures with Metal 3D Printed Wing Ribs The aerospace industry stands at the forefront of technological advancement, constantly pushing the boundaries of

3D Printed Heat Sinks for Electric Motor Cooling

Introduction: Revolutionizing Electric Motor Thermal Management with Metal 3D Printing Electric motors are the workhorses of modern industry, powering everything from electric vehicles (EVs) and

Lightweight Brake Pedal Arms via Metal Additive Manufacturing

Introduction: Revolutionizing Automotive Components with Metal AM In the intricate system that constitutes a modern vehicle, few components are as fundamentally critical to safety and

3D Printed Support Rings for Jet Engine Components

Introduction: The Critical Role of Support Rings in Modern Jet Engines Jet engines represent the pinnacle of complex engineering, operating under extreme conditions to generate

Payload Mounts for Satellites and Aircraft via 3D Printing

Introduction: Revolutionizing Aerospace Componentry with 3D Printed Payload Mounts The aerospace industry operates at the zenith of engineering achievement, demanding components that exhibit extraordinary performance

High-Performance Nozzle Vanes via Additive Manufacturing

Introduction to Turbine Nozzle Guide Vanes (NGVs): The Critical Hot Section Component Turbine Nozzle Guide Vanes (NGVs), often referred to simply as nozzle vanes or

Vår produkt

PRODUKT MED HET FÖRSÄLJNING

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731