Okategoriserade

alla samlingar

Advantages of using DED for manufacturing molds and tools

Imagine a world where complex molds and tools can be built with near-unparalleled freedom of design, reduced lead times, and minimized material waste. This isn’t science fiction; it’s the reality offered by Directed Energy Deposition (DED), a revolutionary additive manufacturing (AM) technology poised to transform the manufacturing landscape. DED, also

Tillämpningen av DED inom det medicinska området

Imagine a world where damaged bones can be repaired with implants perfectly customized to fit your unique anatomy. A world where surgeons wield tools built layer-by-layer to match the intricate needs of complex procedures. This future is rapidly approaching, thanks to the innovative technology known as Directed Energy Deposition (DED).

DED för biltillverkning

The automotive industry is in a constant state of flux, driven by relentless demands for lighter, stronger, and more fuel-efficient vehicles. Enter Directed Energy Deposition (DED), a revolutionary additive manufacturing (AM) technology poised to transform the way cars are built. Imagine a process that builds complex metal parts layer by

Application of DED in the aerospace field

Imagine a world where complex aircraft components can be built layer by layer, on-demand, with minimal waste. This isn’t science fiction; it’s the reality of Directed Energy Deposition (DED), a cutting-edge additive manufacturing (AM) technology rapidly transforming the aerospace industry. DED, also known as Laser Engineered Net Shaping (LENS), utilizes

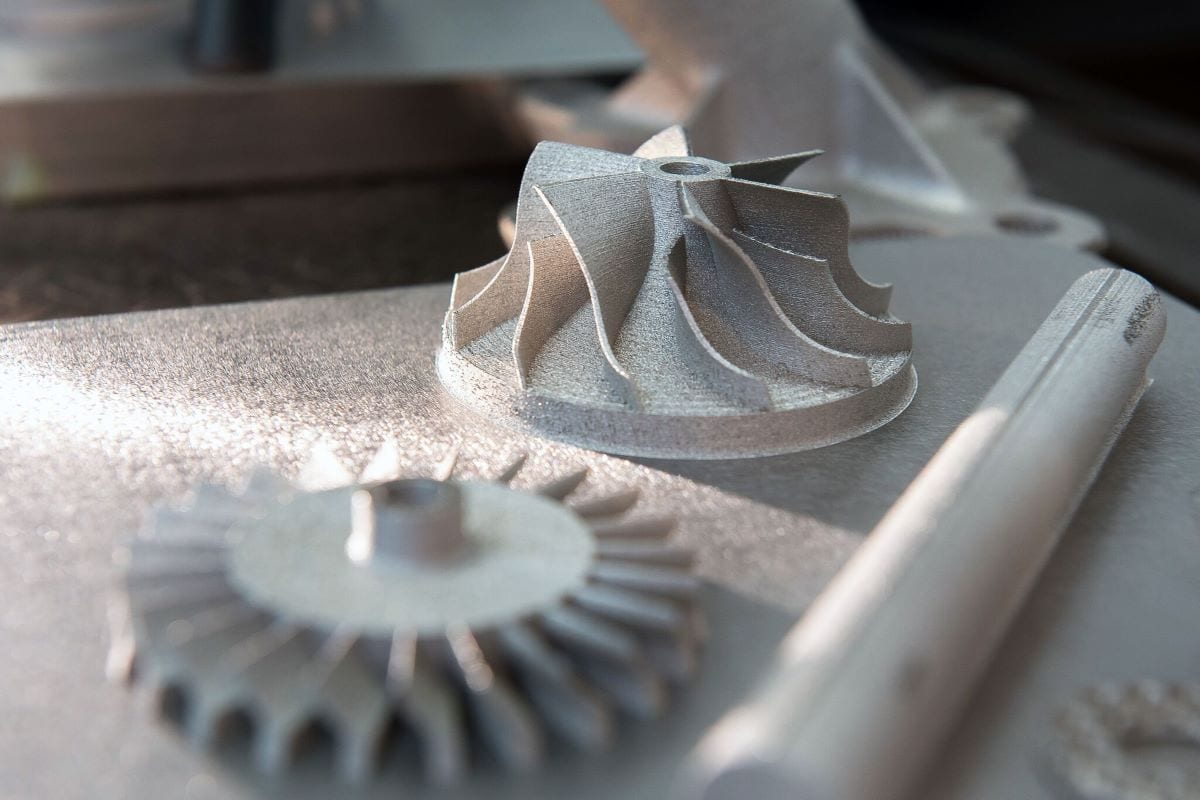

Introduction to Directed Energy Deposition

Imagine building complex metal structures layer by layer, with precise control over material properties and minimal waste. This isn’t science fiction; it’s the reality of Directed Energy Deposition (DED), a revolutionary 3D printing technology that’s transforming the manufacturing landscape. Directed Energy Deposition, also known by terms like Laser Engineered Net

Tillämpningar av materialstrålning vid snabb prototyptillverkning

Imagine a world where crafting intricate prototypes is as seamless as printing a document. Material jetting, a revolutionary 3D printing technology, transforms this vision into reality. By meticulously depositing droplets of photopolymer resin layer by layer, material jetting unlocks a treasure trove of possibilities for rapid prototyping. Buckle up, as

The process flow of Material Jetting

Imagine a printer that doesn’t just lay down ink on paper, but builds intricate objects layer by layer, like a tiny sculptor wielding liquid building blocks. That’s the essence of material jetting, a revolutionary 3D printing technology that’s transforming design and manufacturing across industries. Material Jetting: A Miniature Inkjet Revolution

Which metal powder is suitable for Material Jetting

Material jetting, a revolutionary 3D printing technique, has opened doors to creating intricate and functional metal parts. But just like a master chef requires the finest ingredients, achieving optimal results in material jetting hinges on the right metal powder. With a plethora of options available, selecting the most suitable powder

Introduction to Material Jetting

Imagine a 3D printer that works like a high-tech inkjet, meticulously building objects layer-by-layer with incredible detail and precision. That’s the magic of material jetting, a revolutionary additive manufacturing (AM) process taking the prototyping and production world by storm. Buckle up, because we’re diving deep into this fascinating technology, exploring

Tillämpning av Binder Jetting inom konsumentelektronik

Föreställ dig en värld där ditt mobilskal perfekt återspeglar din unika stil, med intrikata mönster och anpassade graveringar. Eller föreställ dig eleganta, lätta hörlursfodral som sömlöst integreras med dina befintliga enheter. Det här är inte science fiction, utan den spännande verklighet som binder jetting inom konsumentelektronik innebär. Binder Jetting: En revolution inom tillverkningen

Advantages of using DED for manufacturing molds and tools

Imagine a world where complex molds and tools can be built with near-unparalleled freedom of design, reduced lead times, and minimized material waste. This isn’t

Tillämpningen av DED inom det medicinska området

Imagine a world where damaged bones can be repaired with implants perfectly customized to fit your unique anatomy. A world where surgeons wield tools built

DED för biltillverkning

The automotive industry is in a constant state of flux, driven by relentless demands for lighter, stronger, and more fuel-efficient vehicles. Enter Directed Energy Deposition

Application of DED in the aerospace field

Imagine a world where complex aircraft components can be built layer by layer, on-demand, with minimal waste. This isn’t science fiction; it’s the reality of

Introduction to Directed Energy Deposition

Imagine building complex metal structures layer by layer, with precise control over material properties and minimal waste. This isn’t science fiction; it’s the reality of

Tillämpningar av materialstrålning vid snabb prototyptillverkning

Imagine a world where crafting intricate prototypes is as seamless as printing a document. Material jetting, a revolutionary 3D printing technology, transforms this vision into

The process flow of Material Jetting

Imagine a printer that doesn’t just lay down ink on paper, but builds intricate objects layer by layer, like a tiny sculptor wielding liquid building

Which metal powder is suitable for Material Jetting

Material jetting, a revolutionary 3D printing technique, has opened doors to creating intricate and functional metal parts. But just like a master chef requires the

Introduction to Material Jetting

Imagine a 3D printer that works like a high-tech inkjet, meticulously building objects layer-by-layer with incredible detail and precision. That’s the magic of material jetting,

Tillämpning av Binder Jetting inom konsumentelektronik

Föreställ dig en värld där ditt mobilskal perfekt återspeglar din unika stil, med intrikata mönster och anpassade graveringar. Eller föreställ dig eleganta, lätta hörlursfodral som

Vår produkt

PRODUKT MED HET FÖRSÄLJNING

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731