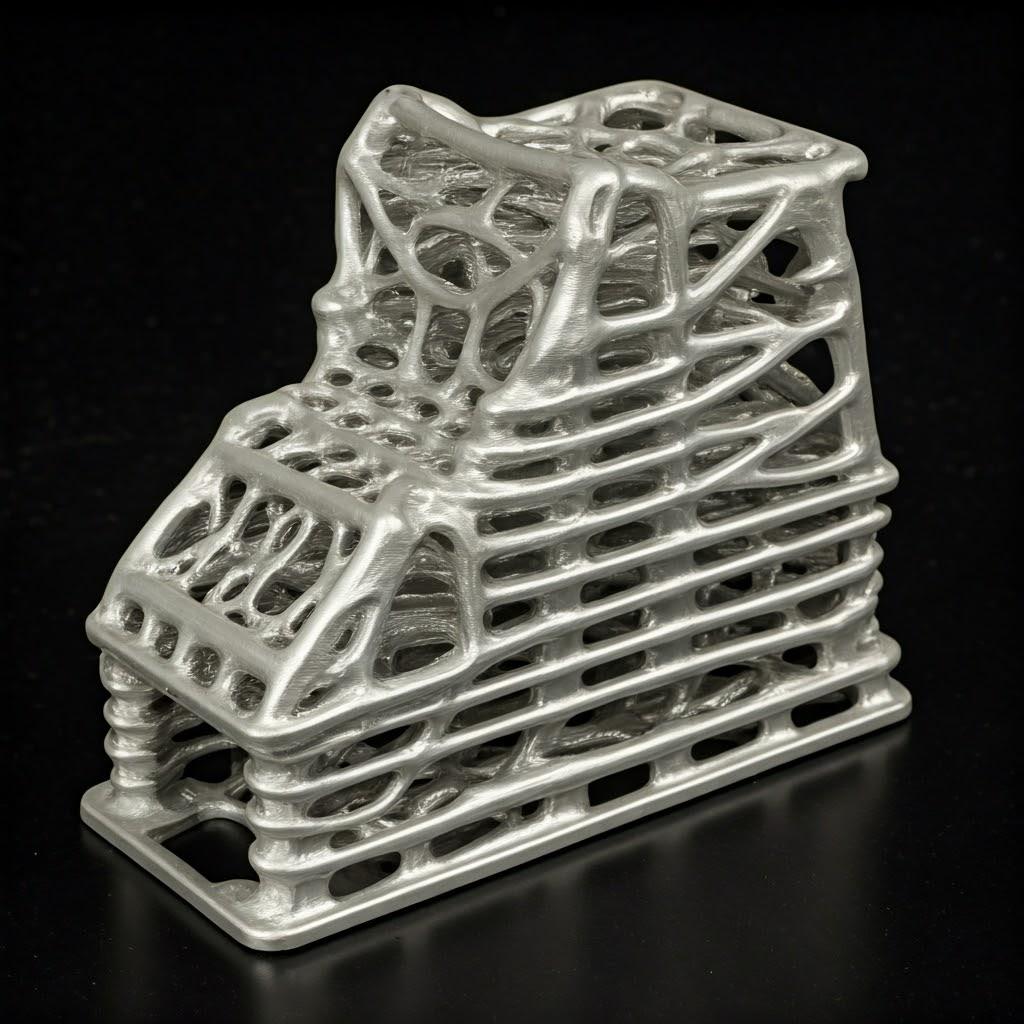

lightweight structural supports using metal 3D printing

İçindekiler

Introduction – The Critical Role of Lightweight Structural Supports in Modern Engineering

In the realm of modern engineering, the demand for lightweight yet robust structural supports is ever-increasing. From the aerospace industry striving for fuel efficiency to the automotive sector aiming for enhanced performance and reduced emissions, and even in medical devices requiring intricate and patient-specific designs, the need for components that offer maximum strength with minimal weight is paramount. Lightweight structural supports are not merely about reducing material usage; they are about enabling innovation, improving functionality, and achieving greater efficiency across a multitude of applications. These critical components serve as the skeletal framework for larger assemblies, bearing loads, maintaining stability, and ensuring the overall integrity of the final product. The evolution of manufacturing technologies has played a crucial role in meeting these demands, with metal 3D baskı emerging as a transformative force in the creation of advanced lightweight structural supports. This blog post will delve into the significance of these supports, explore the advantages of using metal additive manufacturing for their production, discuss suitable materials, and provide insights into the entire process, highlighting how partners like Metal3DP are at the forefront of this revolution, offering cutting-edge solutions with their industry-leading print volume, accuracy, and reliability, as detailed on their Metal 3D Baskı service page.

What are Lightweight Structural Supports and Their Key Applications?

Lightweight structural supports are integral components designed to provide mechanical stability and load-bearing capacity while minimizing overall weight. Their design often incorporates features such as lattice structures, thin walls, and optimized geometries to achieve this balance. These supports can take various forms, including brackets, trusses, internal reinforcements, and custom-designed frameworks tailored to specific application requirements. The versatility of lightweight structural supports makes them indispensable across a wide range of industries:

- Havacılık ve uzay: In aircraft and spacecraft, reducing weight is critical for fuel efficiency, payload capacity, and overall performance. Lightweight supports are used in airframes, engine mounts, interior structures, and satellite components.

- Otomotiv: The automotive industry utilizes lightweight supports to enhance vehicle performance, improve fuel economy, and reduce emissions. Applications include chassis components, seat frames, and structural reinforcements.

- Tıbbi: Medical devices, particularly those that are implantable or require portability, benefit significantly from lightweight structural supports. Examples include customized implants, surgical instruments, and prosthetic limbs.

- Endüstriyel Üretim: Various industrial applications, such as robotic arms, machinery components, and custom tooling, leverage lightweight supports to improve efficiency, reduce inertia, and enhance operational performance.

The ability to create complex geometries with tailored strength-to-weight ratios makes metal 3D printing an ideal manufacturing method for these applications. Şirketler gibi Metal3DP offer advanced printing methods, as outlined on their Baskı Yöntemleri page, which enable the production of intricate lightweight structures with high precision and material integrity.

Why Metal 3D Printing is Revolutionizing the Production of Lightweight Structural Supports

Traditional manufacturing methods often impose limitations on the complexity and weight optimization of structural supports. Subtractive methods, for instance, can lead to significant material waste when creating intricate designs. Metal 3D printing, on the other hand, offers several key advantages that are revolutionizing the production of lightweight structural supports:

- Tasarım Özgürlüğü: Additive manufacturing allows for the creation of complex geometries, including internal lattices and intricate networks, that are difficult or impossible to achieve with conventional methods. This design freedom enables engineers to optimize the strength-to-weight ratio of supports precisely.

- Malzeme Verimliliği: 3D printing builds parts layer by layer, using only the material needed for the component. This significantly reduces material waste compared to subtractive manufacturing processes.

- Customization and Rapid Prototyping: Metal 3D printing facilitates the rapid creation of prototypes and customized parts. This is particularly beneficial for industries like medical and aerospace, where bespoke solutions are often required. Metal3DP’s application development services can assist organizations in leveraging this capability.

- Integration of Functionality: Additive manufacturing allows for the integration of multiple functionalities into a single component, reducing the need for assembly and further decreasing weight.

- İsteğe Bağlı Üretim: 3D printing enables on-demand production, reducing the need for large inventories and allowing for the creation of parts only when needed.

Metal3DP’s commitment to providing comprehensive additive manufacturing solutions, including their high-performance metal powders and SEBM printers, positions them as a key enabler in the advancement of lightweight structural support production. Their advanced powder making system ensures the quality and performance required for these critical applications.

Recommended Metal Powders for Lightweight Structures: AlSi10Mg and Scalmalloy®

The choice of metal powder is crucial in determining the final properties and performance of 3D printed lightweight structural supports. Metal3DP offers a range of high-quality metal powders optimized for additive manufacturing, including two excellent candidates for lightweight applications: AlSi10Mg and Scalmalloy®.

AlSi10Mg:

- Kompozisyon: An aluminum alloy containing silicon and magnesium.

- Anahtar Özellikler:

- Düşük Yoğunluk: Making it ideal for weight-sensitive applications.

- Yüksek Mukavemet-Ağırlık Oranı: Offers excellent mechanical properties relative to its density.

- Good Thermal Conductivity: Beneficial for applications where heat dissipation is important.

- Mükemmel Basılabilirlik: Well-suited for laser powder bed fusion (LPBF) processes.

- Uygulamalar: Widely used in aerospace, automotive, and general engineering for structural components, brackets, and housings.

Scalmalloy®:

- Kompozisyon: A high-performance aluminum-magnesium-scandium alloy.

- Anahtar Özellikler:

- Ultra Yüksek Mukavemet: Offers significantly higher strength than conventional aluminum alloys.

- Düşük Yoğunluk: Maintains the weight-saving benefits of aluminum.

- Mükemmel Süneklik: Provides good formability and resistance to fracture.

- Superior Fatigue Resistance: Crucial for dynamically loaded structural supports.

- Uygulamalar: Ideal for demanding applications in aerospace, motorsports, and robotics where maximum strength and minimum weight are critical.

Metal3DP’s expertise in metal powders ensures that customers can achieve dense, high-quality parts with superior mechanical properties using these and other advanced alloys from their Ürün catalog. Their industry-leading gas atomization and PREP technologies guarantee the high sphericity and flowability of their powders, essential for consistent and reliable 3D printing. Sources and related content

Design Optimization Strategies for Additively Manufactured Lightweight Supports

The unique capabilities of metal 3D printing open up a realm of possibilities for designing lightweight structural supports that go beyond the limitations of traditional manufacturing. Optimizing designs for additive manufacturing involves considering factors such as material distribution, part orientation, and the integration of advanced geometric features. Here are some key strategies:

- Topology Optimization: This computational method helps to identify the most efficient material distribution for a given set of loads and constraints. By removing material from low-stress areas, topology optimization can result in significantly lighter parts without compromising structural integrity.

- Kafes Yapılar: Incorporating lattice or cellular structures within the support’s interior can dramatically reduce weight while maintaining stiffness and strength. Different lattice patterns, such as gyroid, diamond, and cubic, offer varying mechanical properties and can be tailored to specific load requirements.

- Generative Design: Utilizing algorithms to explore a multitude of design options based on predefined parameters and performance goals. This approach can yield innovative and highly optimized geometries that might not be intuitively conceived.

- Thin-Walled Structures with Ribbing: Designing parts with thin walls supported by internal or external ribs can provide a high strength-to-weight ratio. The ribs add stiffness and prevent buckling in thin sections.

- Hollow Structures: For certain applications, creating hollow structures with strategically placed internal supports can significantly reduce material usage and weight.

- Parça Konsolidasyonu: Additive manufacturing allows for the integration of multiple components into a single part, eliminating the need for fasteners and reducing overall weight and assembly time.

When designing for metal 3D printing, it’s also crucial to consider the chosen printing process and material. Metal3DP‘s expertise in both SEBM printers and a wide range of high-quality metal powders ensures that customers can leverage these design freedoms effectively. Their application development services can provide valuable insights into optimizing designs for their specific equipment and materials.

Achieving Precision: Tolerance, Surface Finish, and Dimensional Accuracy in 3D Printed Supports

In structural applications, the tolerance, surface finish, and dimensional accuracy of the supports are critical for proper fit, assembly, and overall performance. Metal 3D printing technologies have made significant advancements in achieving high levels of precision. However, the achievable tolerances and surface finishes can vary depending on the printing process, material, and post-processing techniques.

- Tolerance: The degree of allowable variation in a manufactured part’s dimensions. Metal 3D printing can achieve tight tolerances, often within the range of ±0.1 to ±0.5 mm, depending on the machine and part geometry. Factors influencing tolerance include the printer’s accuracy, material shrinkage during solidification, and the build orientation.

- Yüzey İşlemi: The roughness or texture of the printed surface. As-printed metal parts typically have a rougher surface finish compared to machined parts. The surface roughness is influenced by the powder particle size, layer thickness, and the printing process. For applications requiring smoother surfaces, post-processing methods like polishing or machining are employed.

- Boyutsal Doğruluk: The ability of the printing process to produce parts that closely match the intended design dimensions. Achieving high dimensional accuracy requires careful calibration of the printer, optimized build parameters, and consideration of material-specific shrinkage rates.

Metal3DP‘s commitment to industry-leading print volume, accuracy, and reliability ensures that their customers can produce structural supports with the precision required for demanding applications. Their advanced SEBM printers are engineered to deliver high dimensional accuracy, and their comprehensive solutions include guidance on achieving desired surface finishes through appropriate post-processing techniques.

Post-Processing Techniques for Enhanced Performance of Lightweight Metal Supports

While metal 3D printing offers significant advantages in creating complex geometries, post-processing steps are often necessary to enhance the performance, surface finish, and dimensional accuracy of lightweight structural supports. Common post-processing techniques include:

- Destek Kaldırma: Metal 3D printed parts often require support structures to prevent collapse or distortion during the printing process. These supports need to be carefully removed after printing, which can involve manual breaking, cutting, or machining.

- Isıl İşlem: Applying controlled heating and cooling cycles to the printed parts can relieve internal stresses, improve mechanical properties such as strength and ductility, and achieve desired microstructures.

- CNC İşleme: For applications requiring very tight tolerances or specific surface finishes, CNC machining can be used as a secondary process to achieve the desired level of precision.

- Yüzey İşlemi: Techniques such as polishing, sandblasting, and vibratory finishing can be used to improve the surface finish of the printed parts, which can be important for aesthetics, reducing friction, or enhancing corrosion resistance.

- Coating and Surface Treatment: Applying coatings, such as anodizing or painting, can enhance the corrosion resistance, wear resistance, or other surface properties of the lightweight structural supports.

Metal3DP provides comprehensive solutions that extend beyond printing, offering guidance and support for post-processing requirements to ensure the final parts meet the specific needs of their customers. Understanding these post-processing steps is crucial for achieving the desired performance characteristics of lightweight metal supports.

Overcoming Common Challenges in 3D Printing Lightweight Structural Components

While metal 3D printing offers numerous advantages, there are also common challenges that need to be addressed to ensure successful production of lightweight structural components:

- Çarpıtma ve Bozulma: Thermal stresses during the printing process can lead to warping or distortion of the parts, especially for complex geometries or thin-walled structures. Optimizing build orientation, using support structures effectively, and controlling the printing environment can help mitigate these issues.

- Support Removal Damage: Improper removal of support structures can damage the surface of the printed part. Careful design of support interfaces and the use of appropriate removal techniques are essential.

- Gözeneklilik: Internal voids or porosity within the printed part can compromise its mechanical strength. Optimizing printing parameters, material quality, and powder bed density are crucial for minimizing porosity. Metal3DP’s high-quality metal powders, produced with advanced techniques, help in achieving dense, high-performance parts.

- Yüzey Pürüzlülüğü: As-printed metal surfaces can be rough, which may not be suitable for all applications. Post-processing techniques are often required to achieve smoother surfaces.

- Residual Stresses: The layer-by-layer build process can introduce residual stresses in the printed parts, which can affect their mechanical properties and dimensional stability. Heat treatment is often used to relieve these stresses.

By understanding these potential challenges and implementing appropriate design and process optimization strategies, manufacturers can effectively leverage metal 3D printing to produce high-quality lightweight structural supports. Partnering with experienced providers like Metal3DP, who offer expertise in both equipment and materials, can significantly aid in overcoming these challenges.

Selecting the Right Metal 3D Printing Service Provider for Your Lightweight Support Needs

Choosing the right metal 3D printing service provider is crucial for the successful production of high-quality lightweight structural supports. Several factors should be considered when evaluating potential suppliers:

- Material Capabilities: Ensure the provider offers the specific metal powders required for your application, such as AlSi10Mg or Scalmalloy®, and has experience working with these materials. Metal3DP boasts a wide range of high-quality metal powders, including innovative alloys, optimized for laser and electron beam powder bed fusion.

- Equipment and Technology: Understand the types of 3D printing technologies the provider utilizes. Selective Electron Beam Melting (SEBM) and Laser Powder Bed Fusion (LPBF) are common methods for metal printing. Metal3DP specializes in SEBM printers known for their industry-leading print volume, accuracy, and reliability.

- Quality Assurance and Certifications: Inquire about the provider’s quality control processes and certifications (e.g., ISO 9001, AS9100 for aerospace). This ensures that the manufactured parts meet stringent quality standards.

- Design and Engineering Support: Determine if the provider offers design optimization services for additive manufacturing. Experienced engineers can help refine your designs for optimal printability and performance. Metal3DP provides comprehensive solutions spanning SEBM printers, advanced metal powders, and application development services. 1 1. met3dp.sg met3dp.sg

- Post-Processing Services: Check if the provider offers necessary post-processing services such as support removal, heat treatment, CNC machining, and surface finishing. A comprehensive service offering can streamline the production process.

- Lead Times and Production Capacity: Evaluate the provider’s typical lead times and their capacity to handle your production volumes, especially for ongoing or large-scale projects.

- Cost Structure and Transparency: Understand the pricing model and ensure transparency in cost breakdowns. Request detailed quotes that include material costs, printing fees, and any post-processing charges.

- Communication and Customer Support: Assess the provider’s responsiveness, communication practices, and overall customer support. A reliable partner will offer clear communication and timely assistance throughout the project.

By carefully evaluating these factors, you can select a metal 3D printing service provider that aligns with your specific requirements for lightweight structural supports. Consider reaching out to Metal3DP to explore how their capabilities can power your organization’s additive manufacturing goals, as highlighted on their Hakkımızda sayfa.

Understanding Cost Drivers and Lead Times for Metal 3D Printed Structural Supports

The cost and lead time for metal 3D printed structural supports are influenced by several factors. Understanding these drivers can help in project planning and budgeting:

Maliyet Etkenleri:

- Malzeme Maliyetleri: The type and quantity of metal powder used are significant cost factors. Advanced alloys like Scalmalloy® typically have higher material costs compared to standard alloys like AlSi10Mg.

- Build Volume and Complexity: Larger parts that occupy more build volume and intricate designs that require extensive support structures will generally incur higher printing costs.

- Baskı Süresi: The duration of the printing process directly impacts the cost. Longer print times consume more machine time and energy.

- İşlem Sonrası Gereksinimler: The extent and complexity of post-processing steps, such as extensive machining or specialized coatings, will add to the overall cost.

- Machine and Labor Costs: The service provider’s operational costs, including machine maintenance, energy consumption, and skilled labor, are factored into the pricing.

- Sipariş Hacmi: Higher production volumes may lead to economies of scale and potentially lower per-part costs.

Teslim Süreleri:

- Part Complexity and Size: More complex and larger parts typically require longer printing times, extending the overall lead time.

- Malzeme Durumu: The availability of the specific metal powder can influence the start of production. Metal3DP manufactures a wide range of high-quality metal powders, potentially reducing lead times associated with material sourcing.

- Machine Availability and Scheduling: The service provider’s current workload and machine availability will affect the production timeline.

- Post-Processing Duration: The time required for post-processing steps can add to the overall lead time.

- Shipping and Logistics: The time taken for shipping the finished parts to the destination needs to be considered.

It’s essential to discuss these factors with your chosen metal 3D printing service provider to get accurate cost estimates and lead times for your lightweight structural support projects.

Sıkça Sorulan Sorular (SSS)

- What are the typical weight savings achievable with metal 3D printed structural supports compared to traditionally manufactured parts? Weight savings can vary significantly depending on the design optimization and the specific application. However, reductions of 20-50% or even more are often achievable by utilizing topology optimization and lattice structures, which are readily enabled by metal 3D printing.

- Are metal 3D printed lightweight supports strong enough for demanding structural applications? Yes, when the appropriate materials and printing parameters are used, metal 3D printed parts can exhibit excellent mechanical properties, often comparable to or even exceeding those of traditionally manufactured parts. Alloys like Scalmalloy® offer ultra-high strength for demanding applications.

- What is the typical surface finish of an as-printed metal 3D support, and can it be improved? The as-printed surface finish is typically rougher than that of machined parts, with a surface roughness (Ra) value that can range from 5 to 20 µm depending on the process and material. Post-processing techniques like polishing, sandblasting, and machining can significantly improve the surface finish to meet specific requirements.

Conclusion – Embracing Metal 3D Printing for Advanced Lightweight Structural Supports

The demand for lightweight structural supports with high performance characteristics is continuously growing across various industries. Metal 3D printing stands out as a transformative manufacturing technology capable of meeting these demands by offering unprecedented design freedom, material efficiency, and customization possibilities. By leveraging advanced materials like AlSi10Mg and Scalmalloy® and employing design optimization strategies tailored for additive manufacturing, engineers and procurement managers can create innovative, lightweight supports that enhance product performance and efficiency.

Şirketler gibi Metal3DP are at the forefront of this revolution, providing industry-leading SEBM printers, a comprehensive range of high-quality metal powders, and extensive application development expertise. Their commitment to accuracy, reliability, and customer support makes them a trusted partner for organizations looking to embrace the benefits of metal additive manufacturing. As industries continue to push the boundaries of engineering and design, metal 3D printing will undoubtedly play an increasingly critical role in the creation of advanced lightweight structural supports, driving innovation and enabling next-generation manufacturing. Contact Metal3DP today to explore how their capabilities can power your organization’s additive manufacturing goals and accelerate your digital manufacturing transformation.

Paylaş

MET3DP Technology Co, LTD, merkezi Qingdao, Çin'de bulunan lider bir katmanlı üretim çözümleri sağlayıcısıdır. Şirketimiz, endüstriyel uygulamalar için 3D baskı ekipmanları ve yüksek performanslı metal tozları konusunda uzmanlaşmıştır.

İşletmeniz için en iyi fiyatı ve özelleştirilmiş Çözümü almak için sorgulayın!

İlgili Makaleler

Metal 3D Printed Subframe Connection Mounts and Blocks for EV and Motorsport Chassis

Daha Fazla Oku "

Metal 3D Printing for U.S. Automotive Lightweight Structural Brackets and Suspension Components

Daha Fazla Oku "Met3DP Hakkında

Son Güncelleme

Bizim Ürünümüz

BİZE ULAŞIN

Herhangi bir sorunuz var mı? Bize şimdi mesaj gönderin! Mesajınızı aldıktan sonra tüm ekibimizle talebinize hizmet edeceğiz.