Uncategorized

tüm kolleksiyonlar

Demir Bazlı Alaşımlar 430L

Metalurji ve malzeme bilimi söz konusu olduğunda, Demir Bazlı Alaşımlar 430L önemli bir yere sahiptir. Genellikle toz metalurjisi ve diğer uygulamalarda kullanılan bu özel alaşım, benzersiz özellikleri nedeniyle ödüllendirilir. İster bir mühendis, ister bir malzeme bilimcisi ya da sadece metalin iç işleyişini merak eden biri olun

Demir Bazlı Alaşımlar HK30

Aşırı ortamlarda kullanılan yüksek performanslı malzemeler söz konusu olduğunda, HK30 gibi demir bazlı alaşımlar en iyi rakiplerdir. Bu alaşımlar, yüksek sıcaklıklara ve korozif ortamlara karşı olağanüstü dirençleriyle bilinir ve bu da onları çeşitli endüstriyel uygulamalarda vazgeçilmez kılar. Ancak HK30 tam olarak nedir ve neden bu kadar saygı görmektedir?

Demir Bazlı Alaşım 904L

Demir bazlı alaşımlar, benzersiz güç, dayanıklılık ve korozyon direnci kombinasyonları sunarak uzun zamandır modern mühendisliğin kalbinde yer almaktadır. Bunlar arasında Demir Bazlı Alaşım 904L, çok çeşitli ortamlarda korozyona karşı olağanüstü direnci ile tanınan yüksek performanslı bir malzeme olarak öne çıkmaktadır. Bu makalede, aşağıdaki konulara değineceğiz

Demir Bazlı Alaşımlar 2209: Kapsamlı Kılavuz

Demir Bazlı Alaşımlara Genel Bakış 2209 Demir Bazlı Alaşımlar 2209, yüksek performans, korozyon direnci ve dayanıklılığın önemli olduğu endüstrilerde çok önemli bir rol oynayan özel bir malzeme grubudur. Genellikle kaynak uygulamalarında bulunan bu alaşım, krom, nikel gibi benzersiz element dengesiyle bilinir,

Demir Bazlı Alaşımlar 2507

Demir Bazlı Alaşımlara Giriş 2507 Demir bazlı alaşımlar, özellikle 2507 çeşidi, modern metalürjinin harikalarıdır. Bu alaşımlar olağanüstü güç, dayanıklılık ve korozyona karşı direnç kombinasyonlarıyla ünlüdür. Peki bu alaşımları bu kadar özel kılan tam olarak nedir? Neden bazı endüstrilerde diğerlerine göre tercih edilirler?

Ti2AlNb Kılavuzu

Genel Bakış Havacılık ve yüksek performanslı mühendislik uygulamaları için gelişmiş malzemeler söz konusu olduğunda, Ti2AlNb çok yönlü ve güçlü bir alaşım olarak öne çıkmaktadır. Bu titanyum alüminit niyobyum alaşımı, çeşitli endüstrilerde önemli bir bileşen haline getiren olağanüstü özellikler sunar. Bu makalede, Ti2AlNb'nin iç ve dış özelliklerini keşfedeceğiz,

TiAl4822: Kapsamlı Bir Kılavuz

TiAl4822'ye Genel Bakış Titanyum-alüminyum alaşımı olan TiAl4822, dikkat çekici özellikleri nedeniyle öne çıkıyor. Hafifliği ve yüksek mukavemet özellikleriyle bilinen bu yüksek performanslı malzeme, havacılık, otomotiv ve güç üretim endüstrilerinde yaygın olarak kullanılıyor. Peki TiAl4822'yi öne çıkaran tam olarak nedir? Gelin bileşimine, özelliklerine ve

Demir Bazlı Alaşımlar 317L

Demir Bazlı Alaşımlar 317L'ye Genel Bakış Demir Bazlı Alaşımlar 317L, olağanüstü korozyon direnci ve yüksek sıcaklık performansıyla bilinen ostenitik paslanmaz çeliktir. Hem mekanik mukavemetin hem de korozyona karşı direncin kritik olduğu zorlu ortamlar için ideal bir seçimdir. Bu alaşım, kimya, petrokimya,

Demir Bazlı Alaşımlar 430

Demir Bazlı Alaşımlara Genel Bakış 430 Demir bazlı alaşımlar, özellikle 430 serisi, mükemmel korozyon direnci, şekillendirilebilirlik ve mekanik özellikleri nedeniyle çeşitli endüstrilerde temel bir unsur olmuştur. Öncelikle paslanmaz çelik uygulamalarında kullanımlarıyla bilinen bu alaşımlar, krom, demir ve diğer alaşımların bir karışımını bir araya getirir.

Demir Bazlı Alaşımlar 420: Anlamak, Seçmek ve Kullanmak

Demir Bazlı Alaşımlar 420'ye Genel Bakış 420 demir bazlı alaşımlar, paslanmaz çelik 420 olarak da bilinir, mükemmel sertlikleri ve orta düzeyde korozyon dirençleri nedeniyle çeşitli endüstrilerde popüler bir seçimdir. Martensitik paslanmaz çelik ailesinin bir parçası olan bu alaşımlar, öncelikle yüksek mukavemet ve

Demir Bazlı Alaşımlar 430L

Metalurji ve malzeme bilimi söz konusu olduğunda, Demir Bazlı Alaşımlar 430L önemli bir yere sahiptir. Bu özel alaşım, genellikle toz metalurjisinde ve

Demir Bazlı Alaşımlar HK30

Aşırı ortamlarda kullanılan yüksek performanslı malzemeler söz konusu olduğunda, HK30 gibi demir bazlı alaşımlar en iyi rakiplerdir. Bu alaşımlar olağanüstü performanslarıyla bilinir.

Demir Bazlı Alaşım 904L

Demir bazlı alaşımlar, benzersiz güç, dayanıklılık ve korozyon direnci kombinasyonları sunarak uzun zamandır modern mühendisliğin kalbinde yer almaktadır. Bunlar arasında Demir Bazlı Alaşım

Demir Bazlı Alaşımlar 2209: Kapsamlı Kılavuz

Demir Bazlı Alaşımlar 2209'a Genel Bakış Demir Bazlı Alaşımlar 2209, yüksek kaliteli malzemelerin kullanıldığı endüstrilerde çok önemli bir rol oynayan özel bir malzeme grubudur.

Demir Bazlı Alaşımlar 2507

Demir Bazlı Alaşımlara Giriş 2507 Demir bazlı alaşımlar, özellikle 2507 çeşidi, modern metalürjinin harikalarıdır. Bu alaşımlar olağanüstü özellikleri ile ünlüdür

Ti2AlNb Kılavuzu

Genel Bakış Havacılık ve yüksek performanslı mühendislik uygulamaları için gelişmiş malzemeler söz konusu olduğunda, Ti2AlNb çok yönlü ve güçlü bir alaşım olarak öne çıkmaktadır. Bu titanyum alüminit

TiAl4822: Kapsamlı Bir Kılavuz

TiAl4822'ye Genel Bakış Titanyum-alüminyum alaşımı olan TiAl4822, dikkat çekici özellikleri nedeniyle öne çıkmaktadır. Hafifliği ve yüksek mukavemetiyle bilinen bu yüksek performanslı malzeme,

Demir Bazlı Alaşımlar 317L

Demir Bazlı Alaşımlar 317L'ye Genel Bakış Demir Bazlı Alaşımlar 317L, olağanüstü korozyon direnci ve yüksek sıcaklık performansıyla bilinen ostenitik paslanmaz çeliktir. Bunlar

Demir Bazlı Alaşımlar 430

Demir Bazlı Alaşımlara Genel Bakış 430 Demir bazlı alaşımlar, özellikle 430 serisi, mükemmel korozyon dayanımları nedeniyle çeşitli endüstrilerde temel bir unsur olmuştur.

Demir Bazlı Alaşımlar 420: Anlamak, Seçmek ve Kullanmak

Demir Bazlı Alaşımlar 420'ye Genel Bakış 420 demir bazlı alaşımlar, paslanmaz çelik 420 olarak da bilinir, çeşitli endüstrilerde popüler bir seçimdir.

Bizim Ürünümüz

SICAK SATIŞ ÜRÜNÜ

BİZE ULAŞIN

Herhangi bir sorunuz var mı? Bize şimdi mesaj gönderin! Mesajınızı aldıktan sonra tüm ekibimizle talebinize hizmet edeceğiz.

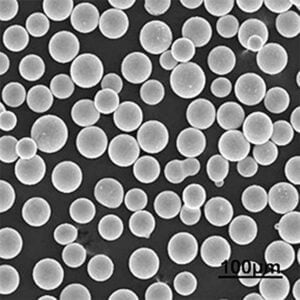

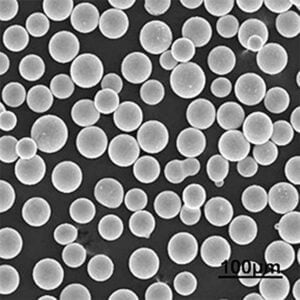

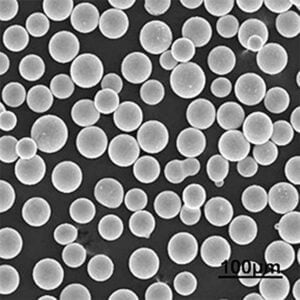

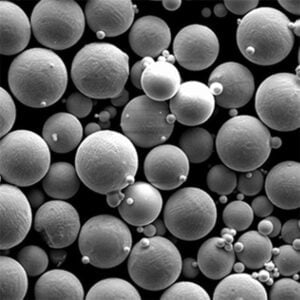

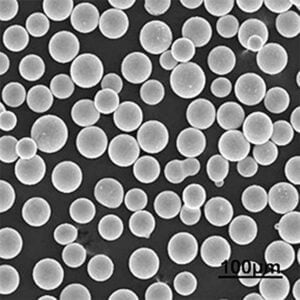

3D Baskı ve Katmanlı Üretim için Metal Tozları

ÜRÜN

cONTACT BİLGİLERİ

- Qingdao Şehri, Shandong, Çin

- [email protected]

- [email protected]

- +86 19116340731