Vakum İndüksiyon Ergitme

İçindekiler

Genel Bakış

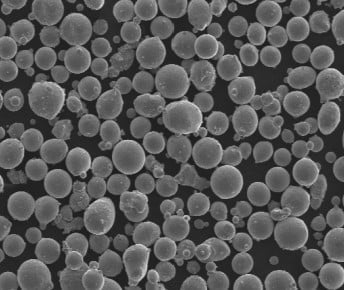

Vakum İndüksiyon Ergitme (VIM) is a sophisticated and highly precise process used to produce high-quality metal alloys and powders. This method is crucial for applications requiring exceptional purity and precise composition, making it essential in industries like aerospace, medical devices, and high-performance engineering. Let’s delve into the intricacies of VIM, exploring its processes, applications, advantages, disadvantages, and detailed information on various metal powder models produced through this technique.

Vakum İndüksiyon Ergitme Nedir?

Vacuum Induction Melting involves melting metals in a vacuum environment using electromagnetic induction. This technique minimizes contamination from gases and impurities, ensuring the production of metals with superior purity and homogeneity. By melting metals under vacuum, VIM prevents oxidation and enables precise control over the composition of the final product.

Key Details of VIM:

- Süreç: Melting metals using electromagnetic induction in a vacuum.

- Amacımız: Producing high-purity metal alloys and powders.

- Uygulamalar: Aerospace, medical devices, high-performance engineering.

How Vacuum Induction Melting Works

Imagine a high-tech kitchen where you cook your favorite dish in a perfectly controlled environment, free from any unwanted odors or contaminants. That’s VIM in a nutshell, but for metals! The process begins with placing raw materials into a crucible within the vacuum chamber. An induction coil surrounds the crucible, generating a magnetic field when an electric current passes through it. This magnetic field induces eddy currents in the metal, causing it to heat up and eventually melt.

Once the metal reaches the desired temperature, alloying elements can be added to achieve the specific composition required. The vacuum environment ensures that no gases are trapped in the melt, resulting in a cleaner and more homogeneous alloy.

Types of Metals and Alloys Produced

VIM is versatile, capable of producing a wide range of metals and alloys. Here are some specific metal powder models:

- Nickel-Based Superalloys (e.g., INCONEL 718)

- Kompozisyon: Nickel, Chromium, Iron, and other elements.

- Özellikler: High strength, corrosion resistance, and excellent high-temperature performance.

- Uygulamalar: Turbine blades, aerospace components.

- Titanium Alloys (e.g., Ti-6Al-4V)

- Kompozisyon: Titanium, Aluminum, Vanadium.

- Özellikler: Yüksek mukavemet/ağırlık oranı, mükemmel korozyon direnci.

- Uygulamalar: Aerospace, medical implants.

- Cobalt-Chromium Alloys (e.g., CoCrMo)

- Kompozisyon: Cobalt, Chromium, Molybdenum.

- Özellikler: High wear resistance, biocompatibility.

- Uygulamalar: Medical implants, dental devices.

- Stainless Steels (e.g., 316L)

- Kompozisyon: Iron, Chromium, Nickel, Molybdenum.

- Özellikler: Corrosion resistance, mechanical strength.

- Uygulamalar: Surgical instruments, marine applications.

- Aluminum Alloys (e.g., AlSi10Mg)

- Kompozisyon: Aluminum, Silicon, Magnesium.

- Özellikler: Lightweight, good thermal properties.

- Uygulamalar: Automotive parts, aerospace components.

- Magnesium Alloys (e.g., AZ91D)

- Kompozisyon: Magnesium, Aluminum, Zinc.

- Özellikler: Lightweight, high strength.

- Uygulamalar: Automotive, electronics.

- Copper Alloys (e.g., CuCrZr)

- Kompozisyon: Copper, Chromium, Zirconium.

- Özellikler: High electrical conductivity, good mechanical properties.

- Uygulamalar: Elektrikli bileşenler, ısı eşanjörleri.

- Tool Steels (e.g., M2 High-Speed Steel)

- Kompozisyon: Iron, Tungsten, Molybdenum, Chromium.

- Özellikler: High hardness, wear resistance.

- Uygulamalar: Kesici aletler, kalıplar.

- Precious Metal Alloys (e.g., PtIr)

- Kompozisyon: Platinum, Iridium.

- Özellikler: High corrosion resistance, good mechanical properties.

- Uygulamalar: Jewelry, medical devices.

- High-Entropy Alloys (e.g., CoCrFeNiMn)

- Kompozisyon: Cobalt, Chromium, Iron, Nickel, Manganese.

- Özellikler: Excellent mechanical properties, high corrosion resistance.

- Uygulamalar: Advanced engineering applications.

Avantajları Vakum İndüksiyon Ergitme

Why is VIM so highly regarded in the metallurgy world? Here are some key benefits:

- Yüksek Saflıkta: The vacuum environment eliminates gas contamination, resulting in metals with exceptional purity.

- Precise Composition: Allows for exact control over alloying elements, producing materials with tailored properties.

- Geliştirilmiş Mekanik Özellikler: Metals produced through VIM exhibit superior mechanical characteristics.

- Homojenlik: Ensures uniform distribution of alloying elements throughout the metal.

- Çok yönlülük: Capable of melting a wide range of metals and alloys.

Disadvantages of Vacuum Induction Melting

Like any process, VIM has its drawbacks. Here are a few:

- Maliyet: The equipment and operational costs for VIM are relatively high.

- Karmaşıklık: The process requires sophisticated technology and expertise.

- Scale: Typically suitable for smaller batch sizes compared to other melting methods.

Uygulamaları Vakum İndüksiyon Ergitme

VIM is a game-changer in many industries. Let’s explore its key applications:

Havacılık ve uzay:

- Components: Turbine blades, engine parts.

- Avantajlar: High-temperature performance, durability.

Tıbbi Cihazlar:

- Components: İmplantlar, cerrahi aletler.

- Avantajlar: Biocompatibility, corrosion resistance.

High-Performance Engineering:

- Components: High-stress components, specialized tools.

- Avantajlar: Strength, wear resistance.

Types of Metals and Alloys Produced by VIM

| Metal/Alaşım | Kompozisyon | Özellikler | Uygulamalar |

|---|---|---|---|

| INCONEL 718 | Nikel, Krom, Demir | Yüksek mukavemet, korozyon direnci | Türbin kanatları, havacılık bileşenleri |

| Ti-6Al-4V | Titanyum, Alüminyum, Vanadyum | Yüksek mukavemet/ağırlık oranı, korozyon direnci | Havacılık ve uzay, tıbbi implantlar |

| CoCrMo | Kobalt, Krom, Molibden | Yüksek aşınma direnci, biyouyumluluk | Medical implants, dental devices |

| 316L Paslanmaz Çelik | Demir, Krom, Nikel, Molibden | Corrosion resistance, mechanical strength | Surgical instruments, marine applications |

| AlSi10Mg | Alüminyum, Silikon, Magnezyum | Hafif, iyi termal özellikler | Otomotiv parçaları, havacılık ve uzay bileşenleri |

| AZ91D | Magnezyum, Alüminyum, Çinko | Hafif, yüksek mukavemetli | Otomotiv, elektronik |

| CuCrZr | Bakır, Krom, Zirkonyum | High electrical conductivity, good mechanical properties | Elektrikli bileşenler, ısı eşanjörleri |

| M2 Yüksek Hız Çeliği | Demir, Tungsten, Molibden, Krom | Yüksek sertlik, aşınma direnci | Kesici takımlar, kalıplar |

| PtIr | Platinum, Iridium | Yüksek korozyon direnci, iyi mekanik özellikler | Jewelry, medical devices |

| CoCrFeNiMn | Cobalt, Chromium, Iron, Nickel, Manganese | Excellent mechanical properties, high corrosion resistance | İleri mühendislik uygulamaları |

Applications of VIM-Produced Metals

| Endüstri | Bileşenler | Avantajlar |

|---|---|---|

| Havacılık ve Uzay | Turbine blades, engine parts | High-temperature performance, durability |

| Tıbbi Cihazlar | İmplantlar, cerrahi aletler | Biyouyumluluk, korozyon direnci |

| High-Performance Engineering | High-stress components, specialized tools | Mukavemet, aşınma direnci |

Teknik Özellikler ve Standartlar

| Metal/Alaşım | Standart | Sınıf | Şartname |

|---|---|---|---|

| INCONEL 718 | ASTM B637 | 1. Sınıf | Yüksek sıcaklıklarda yüksek mukavemet |

| Ti-6Al-4V | ASTM B348 | 5. Sınıf | Yüksek mukavemet/ağırlık oranı |

| CoCrMo | ASTM F1537 | 1. Sınıf | Yüksek aşınma direnci |

| 316L Paslanmaz Çelik | ASTM A240 | 316L Sınıfı | Korozyon direnci |

| AlSi10Mg | ASTM B928 | 1. Sınıf | Hafif, iyi termal özellikler |

| AZ91D | ASTM B93 | AZ91D Sınıfı | Hafif, yüksek mukavemetli |

| CuCrZr | ASTM B224 | 1. Sınıf | Yüksek elektrik iletkenliği |

| M2 Yüksek Hız Çeliği | ASTM A600 | Grade M2 | Yüksek sertlik, aşınma direnci |

| PtIr | ASTM B563 | 1. Sınıf | Yüksek korozyon direnci |

| CoCrFeNiMn | ASTM E2209 | 1. Sınıf | Mükemmel mekanik özellikler |

Artıları ve Eksileri Vakum İndüksiyon Ergitme

Avantajlar

| Avantaj | Açıklama |

|---|---|

| Yüksek Saflık | Eliminates gas contamination for superior purity. |

| Precise Composition | Exact control over alloying elements for tailored properties. |

| Geliştirilmiş Mekanik Özellikler | Superior mechanical characteristics in final products. |

| Homogeneity | Uniform distribution of alloying elements. |

| Çok Yönlülük | Çok çeşitli metaller ve alaşımlar için uygundur. |

Dezavantajlar

| Dezavantaj | Açıklama |

|---|---|

| Maliyet | High equipment and operational costs. |

| Karmaşıklık | Requires sophisticated technology and expertise. |

| Ölçek | Typically limited to smaller batch sizes compared to other methods. |

Tedarikçiler ve Fiyatlandırma Detayları

Leading Suppliers of VIM Equipment

| Tedarikçi | Ürün Yelpazesi | Fiyatlandırma | Bölge |

|---|---|---|---|

| Inductotherm Group | VIM furnaces, accessories | $100,000 – $1,000,000 | Küresel |

| ALD Vakum Teknolojileri | VIM systems, custom solutions | $150,000 – $2,000,000 | Küresel |

| Seco/Warwick | VIM furnaces, after-sales services | $120,000 – $900,000 | Kuzey Amerika, Avrupa |

| Consarc | VIM and VAR furnaces | $200,000 – $1,500,000 | Küresel |

| ECM Technologies | VIM systems | $100,000 – $850,000 | Avrupa, Asya |

Comparison of VIM vs. Other Melting Methods

| Aspect | Vakum İndüksiyon Eritme (VIM) | Arc Melting | Electroslag Remelting (ESR) |

|---|---|---|---|

| Saflık | High due to vacuum environment | Orta düzeyde | Yüksek |

| Maliyet | Yüksek | Daha düşük | Yüksek |

| Karmaşıklık | Yüksek | Orta düzeyde | Yüksek |

| Parti Büyüklüğü | Küçük ila orta | Orta ila büyük | Orta |

| Uygulama | Yüksek performanslı alaşımlar | General purpose | Yüksek saflıkta uygulamalar |

SSS

| Soru | Cevap |

|---|---|

| What is Vacuum Induction Melting (VIM)? | VIM is a process that melts metals using electromagnetic induction in a vacuum to produce high-purity alloys. |

| Why use VIM over other melting methods? | VIM offers superior purity, precise composition control, and improved mechanical properties. |

| What metals can be produced using VIM? | VIM can produce a wide range of metals, including nickel-based superalloys, titanium alloys, and more. |

| What are the key applications of VIM? | Key applications include aerospace components, medical devices, and high-performance engineering parts. |

| What are the disadvantages of VIM? | Disadvantages include high cost, complexity, and typically smaller batch sizes. |

| Who are the leading suppliers of VIM equipment? | Leading suppliers include Inductotherm Group, ALD Vacuum Technologies, and Seco/Warwick. |

| How does VIM compare to Arc Melting? | VIM provides higher purity but at a higher cost and complexity compared to Arc Melting. |

Sonuç

Vacuum Induction Melting is a pinnacle of modern metallurgy, providing unmatched purity and precision in metal production. Its applications span critical industries where performance and reliability are non-negotiable. While it comes with higher costs and complexity, the benefits often outweigh these challenges, making VIM an invaluable process in advanced material manufacturing.

Paylaş

MET3DP Technology Co, LTD, merkezi Qingdao, Çin'de bulunan lider bir katmanlı üretim çözümleri sağlayıcısıdır. Şirketimiz, endüstriyel uygulamalar için 3D baskı ekipmanları ve yüksek performanslı metal tozları konusunda uzmanlaşmıştır.

İşletmeniz için en iyi fiyatı ve özelleştirilmiş Çözümü almak için sorgulayın!

İlgili Makaleler

Yüksek Performanslı Nozul Kanat Segmentleri: Metal 3D Baskı ile Türbin Verimliliğinde Devrim

Daha Fazla Oku "Met3DP Hakkında

Son Güncelleme

Bizim Ürünümüz

BİZE ULAŞIN

Herhangi bir sorunuz var mı? Bize şimdi mesaj gönderin! Mesajınızı aldıktan sonra tüm ekibimizle talebinize hizmet edeceğiz.

3D Baskı ve Katmanlı Üretim için Metal Tozları

ÜRÜN

cONTACT BİLGİLERİ

- Qingdao Şehri, Shandong, Çin

- [email protected]

- [email protected]

- +86 19116340731