Fusión por inducción en vacío

Índice

Visión general

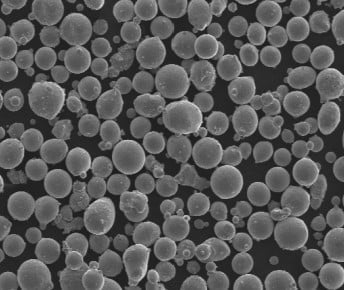

Fusión por inducción en vacío (VIM) es un proceso sofisticado y muy preciso utilizado para producir aleaciones y polvos metálicos de alta calidad. Este método es crucial para aplicaciones que requieren una pureza excepcional y una composición precisa, por lo que resulta esencial en sectores como el aeroespacial, los dispositivos médicos y la ingeniería de alto rendimiento. Profundicemos en los entresijos del VIM, explorando sus procesos, aplicaciones, ventajas, desventajas e información detallada sobre diversos modelos de polvo metálico producidos mediante esta técnica.

¿Qué es la fusión por inducción en vacío?

La fusión por inducción en vacío consiste en fundir metales en un entorno de vacío mediante inducción electromagnética. Esta técnica minimiza la contaminación por gases e impurezas, garantizando la producción de metales con una pureza y homogeneidad superiores. Al fundir los metales al vacío, la VIM evita la oxidación y permite un control preciso de la composición del producto final.

Detalles clave de VIM:

- Proceso: Fundición de metales por inducción electromagnética en el vacío.

- Propósito: Producción de aleaciones y polvos metálicos de gran pureza.

- Aplicaciones: Aeroespacial, dispositivos médicos, ingeniería de alto rendimiento.

Cómo funciona la fusión por inducción en vacío

Imagine una cocina de alta tecnología en la que pueda cocinar su plato favorito en un entorno perfectamente controlado, libre de olores o contaminantes no deseados. Eso es el VIM en pocas palabras, ¡pero para metales! El proceso comienza con la colocación de las materias primas en un crisol dentro de la cámara de vacío. Una bobina de inducción rodea el crisol, generando un campo magnético cuando una corriente eléctrica pasa a través de él. Este campo magnético induce corrientes de Foucault en el metal, que se calienta y acaba fundiéndose.

Una vez que el metal alcanza la temperatura deseada, pueden añadirse elementos de aleación para lograr la composición específica requerida. El entorno de vacío garantiza que no queden gases atrapados en la masa fundida, lo que da como resultado una aleación más limpia y homogénea.

Tipos de metales y aleaciones producidos

VIM es versátil, capaz de producir una amplia gama de metales y aleaciones. He aquí algunos modelos específicos de polvo metálico:

- Superaleaciones a base de níquel (por ejemplo, INCONEL 718)

- Composición: Níquel, cromo, hierro y otros elementos.

- Propiedades: Alta resistencia, resistencia a la corrosión y excelente comportamiento a altas temperaturas.

- Aplicaciones: Álabes de turbina, componentes aeroespaciales.

- Aleaciones de titanio (por ejemplo, Ti-6Al-4V)

- Composición: Titanio, aluminio, vanadio.

- Propiedades: Elevada relación resistencia/peso, excelente resistencia a la corrosión.

- Aplicaciones: Aeroespacial, implantes médicos.

- Aleaciones de cobalto-cromo (por ejemplo, CoCrMo)

- Composición: Cobalto, cromo, molibdeno.

- Propiedades: Alta resistencia al desgaste, biocompatibilidad.

- Aplicaciones: Implantes médicos, dispositivos dentales.

- Aceros inoxidables (por ejemplo, 316L)

- Composición: Hierro, cromo, níquel, molibdeno.

- Propiedades: Resistencia a la corrosión, resistencia mecánica.

- Aplicaciones: Instrumentos quirúrgicos, aplicaciones marinas.

- Aleaciones de aluminio (por ejemplo, AlSi10Mg)

- Composición: Aluminio, silicio, magnesio.

- Propiedades: Ligero, buenas propiedades térmicas.

- Aplicaciones: Piezas de automóvil, componentes aeroespaciales.

- Aleaciones de magnesio (por ejemplo, AZ91D)

- Composición: Magnesio, Aluminio, Zinc.

- Propiedades: Ligero, de gran resistencia.

- Aplicaciones: Automoción, electrónica.

- Aleaciones de cobre (por ejemplo, CuCrZr)

- Composición: Cobre, cromo, circonio.

- Propiedades: Alta conductividad eléctrica, buenas propiedades mecánicas.

- Aplicaciones: Componentes eléctricos, intercambiadores de calor.

- Aceros para herramientas (por ejemplo, acero rápido M2)

- Composición: Hierro, wolframio, molibdeno, cromo.

- Propiedades: Alta dureza, resistencia al desgaste.

- Aplicaciones: Herramientas de corte, moldes.

- Aleaciones de metales preciosos (por ejemplo, PtIr)

- Composición: Platino, Iridio.

- Propiedades: Alta resistencia a la corrosión, buenas propiedades mecánicas.

- Aplicaciones: Joyería, dispositivos médicos.

- Aleaciones de alta entropía (por ejemplo, CoCrFeNiMn)

- Composición: Cobalto, Cromo, Hierro, Níquel, Manganeso.

- Propiedades: Excelentes propiedades mecánicas, alta resistencia a la corrosión.

- Aplicaciones: Aplicaciones avanzadas de ingeniería.

Ventajas de Fusión por inducción en vacío

¿Por qué está tan bien considerado el VIM en el mundo de la metalurgia? He aquí algunas de sus principales ventajas:

- Alta pureza: El entorno de vacío elimina la contaminación por gas, lo que da como resultado metales con una pureza excepcional.

- Composición precisa: Permite un control exacto de los elementos de aleación, produciendo materiales con propiedades a medida.

- Propiedades mecánicas mejoradas: Los metales producidos mediante VIM presentan características mecánicas superiores.

- Homogeneidad: Garantiza una distribución uniforme de los elementos de aleación en todo el metal.

- Versatilidad: Capaz de fundir una amplia gama de metales y aleaciones.

Desventajas de la fusión por inducción en vacío

Como cualquier proceso, el VIM tiene sus inconvenientes. He aquí algunos:

- Costo: Los costes de equipamiento y funcionamiento del VIM son relativamente elevados.

- Complejidad: El proceso requiere tecnología y conocimientos sofisticados.

- Escala: Adecuado para lotes más pequeños que otros métodos de fusión.

Aplicaciones de Fusión por inducción en vacío

El VIM cambia las reglas del juego en muchos sectores. Exploremos sus principales aplicaciones:

Aeroespacial:

- Componentes: Álabes de turbina, piezas de motor.

- Ventajas: Rendimiento a altas temperaturas, durabilidad.

Productos sanitarios:

- Componentes: Implantes, instrumental quirúrgico.

- Ventajas: Biocompatibilidad, resistencia a la corrosión.

Ingeniería de alto rendimiento:

- Componentes: Componentes sometidos a grandes esfuerzos, herramientas especializadas.

- Ventajas: Solidez, resistencia al desgaste.

Tipos de metales y aleaciones producidos por VIM

| Metal/aleación | Composición | Propiedades | Aplicaciones |

|---|---|---|---|

| INCONEL 718 | Níquel, cromo, hierro | Alta resistencia, resistencia a la corrosión | Álabes de turbina, componentes aeroespaciales |

| Ti-6Al-4V | Titanio, Aluminio, Vanadio | Alta relación resistencia-peso, resistencia a la corrosión | Aeroespacial, implantes médicos |

| CoCrMo | Cobalto, cromo, molibdeno | Alta resistencia al desgaste, biocompatibilidad | Implantes médicos, dispositivos dentales |

| Acero inoxidable 316L | Hierro, cromo, níquel, molibdeno | Resistencia a la corrosión, resistencia mecánica | Instrumental quirúrgico, aplicaciones marinas |

| AlSi10Mg | Aluminio, silicio, magnesio | Ligero, buenas propiedades térmicas | Piezas de automóvil, componentes aeroespaciales |

| AZ91D | Magnesio, Aluminio, Zinc | Ligero, de gran resistencia | Automoción, electrónica |

| CuCrZr | Cobre, cromo, circonio | Alta conductividad eléctrica, buenas propiedades mecánicas | Componentes eléctricos, intercambiadores de calor |

| Acero rápido M2 | Hierro, wolframio, molibdeno, cromo | Gran dureza, resistencia al desgaste | Herramientas de corte, moldes |

| PtIr | Platino, Iridio | Alta resistencia a la corrosión, buenas propiedades mecánicas | Joyería, productos sanitarios |

| CoCrFeNiMn | Cobalto, Cromo, Hierro, Níquel, Manganeso | Excelentes propiedades mecánicas, alta resistencia a la corrosión | Aplicaciones avanzadas de ingeniería |

Aplicaciones de los metales producidos por VIM

| Industria | Componentes | Beneficios |

|---|---|---|

| Aeroespacial | Álabes de turbina, piezas de motor | Rendimiento a altas temperaturas, durabilidad |

| Productos sanitarios | Implantes, instrumental quirúrgico | Biocompatibilidad, resistencia a la corrosión |

| Ingeniería de alto rendimiento | Componentes sometidos a grandes esfuerzos, herramientas especializadas | Fuerza, resistencia al desgaste |

Especificaciones y normas

| Metal/aleación | Estándar | Grado | Especificación |

|---|---|---|---|

| INCONEL 718 | ASTM B637 | Grado 1 | Alta resistencia a temperaturas elevadas |

| Ti-6Al-4V | ASTM B348 | 5º curso | Elevada relación resistencia/peso |

| CoCrMo | ASTM F1537 | Grado 1 | Gran resistencia al desgaste |

| Acero inoxidable 316L | ASTM A240 | Grado 316L | Resistencia a la corrosión |

| AlSi10Mg | ASTM B928 | Grado 1 | Ligero, buenas propiedades térmicas |

| AZ91D | ASTM B93 | Grado AZ91D | Ligero, de gran resistencia |

| CuCrZr | ASTM B224 | Grado 1 | Alta conductividad eléctrica |

| Acero rápido M2 | ASTM A600 | Grado M2 | Gran dureza, resistencia al desgaste |

| PtIr | ASTM B563 | Grado 1 | Alta resistencia a la corrosión |

| CoCrFeNiMn | ASTM E2209 | Grado 1 | Excelentes propiedades mecánicas |

Pros y contras de Fusión por inducción en vacío

Ventajas

| Ventaja | Descripción |

|---|---|

| Alta pureza | Elimina la contaminación por gas para una pureza superior. |

| Composición precisa | Control exacto de los elementos de aleación para obtener propiedades a medida. |

| Propiedades mecánicas mejoradas | Características mecánicas superiores en los productos finales. |

| Homogeneidad | Distribución uniforme de los elementos de aleación. |

| Versatilidad | Adecuado para una amplia gama de metales y aleaciones. |

Desventajas

| Desventaja | Descripción |

|---|---|

| Coste | Costes operativos y de equipamiento elevados. |

| Complejidad | Requiere tecnología y conocimientos sofisticados. |

| Escala | Normalmente se limita a lotes más pequeños que otros métodos. |

Proveedores y precios

Principales proveedores de equipos VIM

| Proveedor | Gama de productos | Precios | Región |

|---|---|---|---|

| Grupo Inductotherm | Hornos VIM, accesorios | $100,000 – $1,000,000 | Global |

| Tecnologías de vacío ALD | Sistemas VIM, soluciones a medida | $150,000 – $2,000,000 | Global |

| Seco/Warwick | Hornos VIM, servicios posventa | $120,000 – $900,000 | Norteamérica, Europa |

| Consarc | Hornos VIM y VAR | $200,000 – $1,500,000 | Global |

| Tecnologías ECM | Sistemas VIM | $100,000 – $850,000 | Europa, Asia |

Comparación del VIM con otros métodos de fusión

| Aspecto | Fusión por inducción en vacío (VIM) | Fundición por arco | Refusión por electroescoria (ESR) |

|---|---|---|---|

| Pureza | Alto debido al entorno de vacío | Moderado | Alta |

| Coste | Alta | Baja | Alta |

| Complejidad | Alta | Moderado | Alta |

| Tamaño del lote | Pequeña a mediana | Mediana a grande | Medio |

| Aplicación | Aleaciones de alto rendimiento | Uso general | Aplicaciones de alta pureza |

Preguntas frecuentes

| Pregunta | Respuesta |

|---|---|

| ¿Qué es la fusión por inducción en vacío (VIM)? | El VIM es un proceso que funde metales mediante inducción electromagnética en el vacío para producir aleaciones de gran pureza. |

| ¿Por qué utilizar el VIM en lugar de otros métodos de fusión? | El VIM ofrece una pureza superior, un control preciso de la composición y mejores propiedades mecánicas. |

| ¿Qué metales pueden fabricarse con VIM? | VIM puede producir una amplia gama de metales, como superaleaciones a base de níquel y aleaciones de titanio, entre otros. |

| ¿Cuáles son las principales aplicaciones del VIM? | Entre sus principales aplicaciones se encuentran los componentes aeroespaciales, los dispositivos médicos y las piezas de ingeniería de alto rendimiento. |

| ¿Cuáles son las desventajas del VIM? | Las desventajas son su elevado coste, su complejidad y el hecho de que los lotes suelen ser más pequeños. |

| ¿Quiénes son los principales proveedores de equipos VIM? | Entre los principales proveedores figuran Inductotherm Group, ALD Vacuum Technologies y Seco/Warwick. |

| ¿En qué se diferencia el VIM de la fusión por arco? | El VIM proporciona una mayor pureza, pero con un coste y una complejidad mayores en comparación con la fusión por arco. |

Conclusión

La fusión por inducción en vacío es la cumbre de la metalurgia moderna, ya que proporciona una pureza y precisión inigualables en la producción de metales. Sus aplicaciones abarcan industrias críticas en las que el rendimiento y la fiabilidad no son negociables. Aunque conlleva unos costes y una complejidad mayores, las ventajas a menudo superan estos retos, lo que convierte al VIM en un proceso inestimable en la fabricación de materiales avanzados.

Compartir

MET3DP Technology Co., LTD es un proveedor líder de soluciones de fabricación aditiva con sede en Qingdao, China. Nuestra empresa está especializada en equipos de impresión 3D y polvos metálicos de alto rendimiento para aplicaciones industriales.

Solicite información para obtener el mejor precio y una solución personalizada para su empresa.

Artículos relacionados

Segmentos de álabe de tobera de alto rendimiento: Revolucionando la eficiencia de las turbinas con la impresión metálica en 3D

Leer Más "Acerca de Met3DP

Actualización reciente

Nuestro producto

CONTACTO

¿Tiene alguna pregunta? ¡Envíenos un mensaje ahora! Atenderemos su solicitud con todo un equipo tras recibir su mensaje.

Polvos metálicos para impresión 3D y fabricación aditiva

PRODUCTO

cONTACT INFO

- Ciudad de Qingdao, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731