UAE의 맞춤형 탄탈륨 합금 첨가 제조: B2B 구매자를 위한 종합 가이드

목차

1. Introduction: The Growing Demand for Tantalum Alloy Additive Manufacturing in UAE

What is Tantalum Alloy Additive Manufacturing?

Tantalum alloy additive manufacturing (AM) refers to the 3D printing of high-performance tantalum-based metal powders to create customized industrial parts. Tantalum is a rare, corrosion-resistant metal widely used in industries such as aerospace, medical implants, and electronics.

Why is Tantalum 3D Printing Gaining Popularity in UAE?

The UAE has positioned itself as a hub for advanced manufacturing and industrial innovation. The increasing adoption of tantalum alloy additive manufacturing is driven by:

- The growing aerospace sector, which requires high-performance, heat-resistant materials.

- Medical advancements, where biocompatible tantalum alloys are used for implants.

- Oil & gas industry applications, where corrosion-resistant materials are essential.

With the UAE’s focus on 인더스트리 4.0과 디지털 제조, companies are investing in custom tantalum alloy 3D printing to gain a competitive edge.

2. Market Trends & Growth Potential for Tantalum 3D Printing in UAE

Key Market Drivers for Tantalum Alloy Additive Manufacturing

에 대한 수요 tantalum-based 3D printing materials in the UAE is fueled by several factors:

| 시장 드라이버 | Impact on Tantalum 3D Printing |

|---|---|

| 항공우주 성장 | Increased demand for lightweight, high-strength materials |

| 의료 혁신 | Rising use of biocompatible tantalum implants |

| 석유 및 가스 산업 | Corrosion-resistant materials for extreme environments |

| 정부 지원 | UAE’s investment in additive manufacturing technologies |

Projected Growth of Tantalum Alloy AM in UAE

업계 보고서에 따르면 Middle East’s additive manufacturing market is expected to grow at a CAGR of 15% over the next five years. The UAE is leading this growth, with major investments in industrial 3D printing hubs.

Competitive Advantages of Tantalum 3D Printing

- 재료 낭비 감소 – Traditional machining wastes expensive materials, while AM optimizes usage.

- 복잡한 지오메트리 – Tantalum 3D 프린팅 enables intricate part designs that are impossible with conventional methods.

- 향상된 성능 – Tantalum alloys offer superior corrosion resistance, high-temperature strength및 생체 적합성.

With these advantages, UAE manufacturers are rapidly adopting custom tantalum alloy 3D printing 임무 수행에 중요한 애플리케이션을 위해.

3. Key Factors to Consider When Choosing a Tantalum Alloy Supplier

오른쪽 선택 tantalum alloy supplier is crucial for ensuring high-quality, reliable 3D printing results. Here are the key factors to evaluate:

1. Material Purity & Quality

- 공급자가 제공하는 것을 확인하세요 high-purity tantalum alloy powders 불순물이 최소화됨.

- Look for materials optimized for 레이저 분말 베드 융합(LPBF) 및 전자빔 용융(EBM).

2. Production Capabilities

| 팩터 | 중요한 이유 |

|---|---|

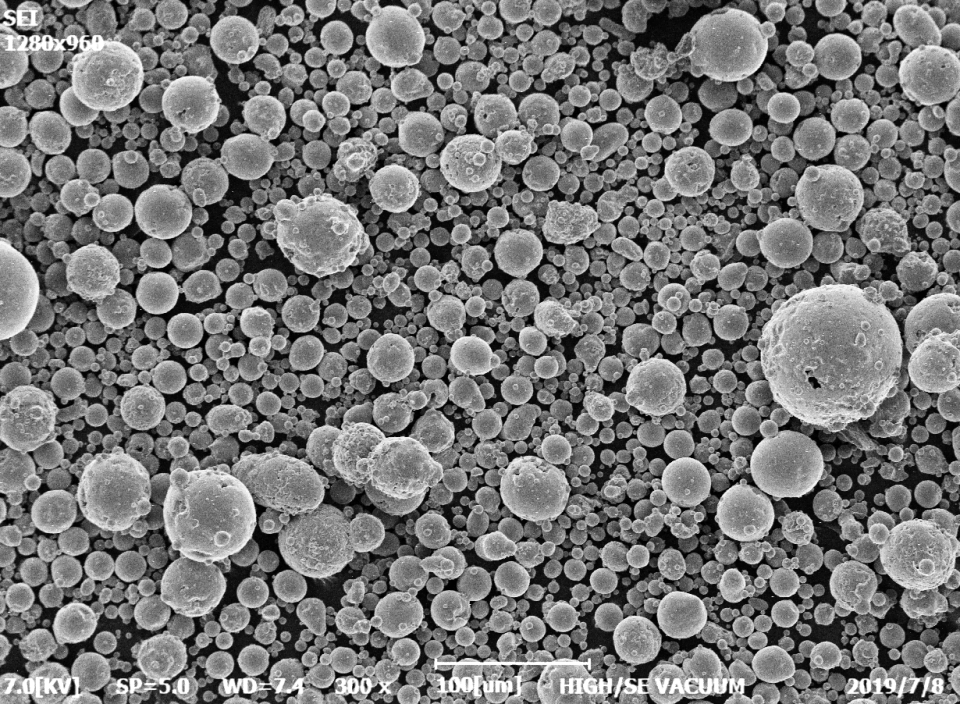

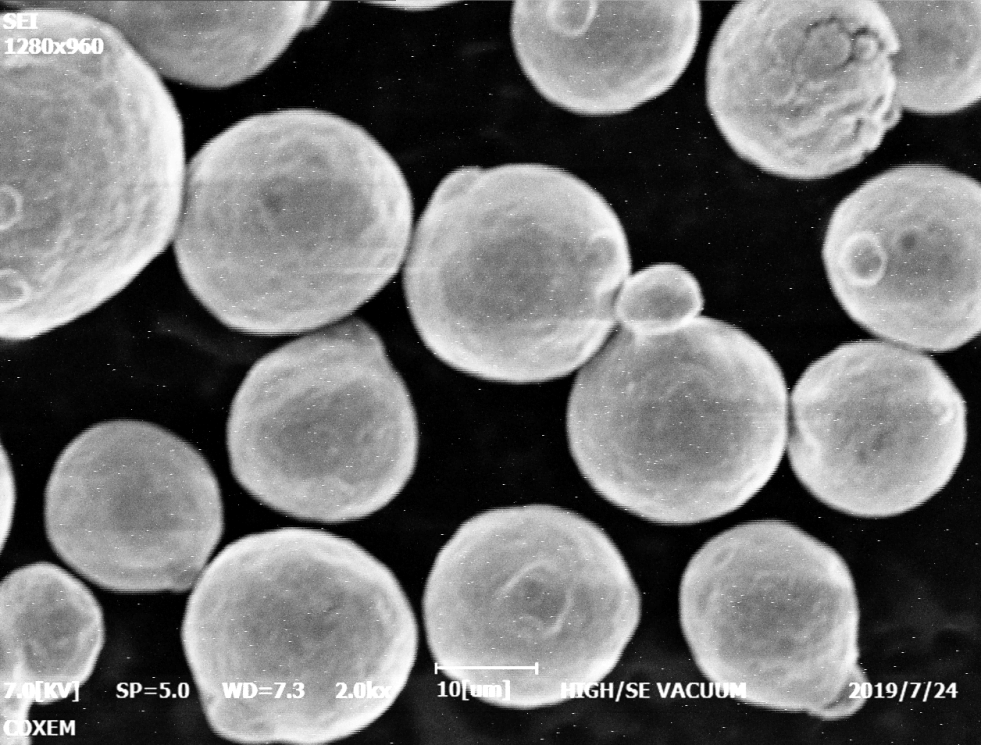

| 분말 제조 방법 | Gas atomization ensures high sphericity and flowability. |

| 합금 맞춤화 | Availability of tailored tantalum alloy compositions. |

| 일관성 | Uniform powder size distribution for optimal printing. |

3. 산업 인증 및 규정 준수

- Ensure the supplier complies with ISO 9001, ASTM 및 항공우주/의료 인증.

- Check if they provide material traceability and quality assurance reports.

4. Supply Chain & Logistics

- Choose suppliers with a strong distribution network in UAE 적시 배송을 보장하기 위해.

- Consider suppliers with local warehousing or production facilities 를 사용하여 리드 타임을 단축할 수 있습니다.

5. 비용 및 확장성

- Compare pricing for bulk orders and 맞춤형 합금 제형.

- Evaluate their ability to 규모 생산 for large manufacturing projects.

One trusted provider for high-purity tantalum alloy powders 는 Metal3DP, which specializes in advanced metal powders and additive manufacturing solutions. 그들의 가스 분무 기술 ensures superior powder quality for industrial applications.

결론

UAE’s adoption of tantalum alloy additive manufacturing is driven by aerospace, medical, and oil & gas industries. The market is growing rapidly, and businesses must carefully evaluate suppliers based on material quality, production capabilities, and logistics.

4. Top 5 Reliable Suppliers of Tantalum Alloy for 3D Printing in UAE

공급업체를 선택할 때 tantalum alloy additive manufacturing, businesses must consider material purity, customization options, and local availability. Below are five suppliers offering high-quality tantalum alloy powders 아랍에미리트에서.

1. 메탈3DP (Metal3DP 방문)

✅ 왜 Metal3DP를 선택하시나요?

- 첨단 가스 분무 기술 for high-purity tantalum powders.

- Customizable tantalum-based alloys for 항공우주, 의료 및 산업 애플리케이션.

- 업계를 선도하는 powder flowability and sphericity를 사용하여 우수한 인쇄 품질을 보장합니다.

- 강력한 전문성 selective electron beam melting (SEBM) and laser powder bed fusion (LPBF).

2. AM Metals UAE

✅ Key Offerings:

- 공급업체 tantalum and refractory metal powders for industrial 3D printing.

- 다음 사항에 중점을 둡니다. 항공우주 및 방위 애플리케이션.

- 제공 custom powder sizing based on customer needs.

3. Emirates Advanced Additive Manufacturing (EAAM)

✅ Key Offerings:

- 전문 분야 고성능 금속 분말, including tantalum.

- Strong distribution network across the UAE.

- 오퍼 on-demand manufacturing services.

4. Dubai Industrial Metals

✅ Key Offerings:

- 소모품 tantalum and superalloy powders 에 대한 oil & gas and medical applications.

- 제공 bulk supply contracts for large-scale projects.

5. Middle East AM Technologies

✅ Key Offerings:

- 다음 사항에 중점을 둡니다. customized metal powder formulations, including tantalum-based solutions.

- 와 함께 작동 research institutes and manufacturers for R&D collaborations.

| 공급업체 | 주요 강점 | 산업 포커스 |

|---|---|---|

| Metal3DP | High-purity tantalum powders, advanced production | 항공우주, 의료, 산업 |

| AM Metals UAE | Custom powder sizing, aerospace applications | 항공우주, 방위 |

| EAAM | Strong UAE distribution, on-demand services | 일반 제조 |

| Dubai Industrial Metals | Large-scale bulk supply | Oil & Gas, Medical |

| Middle East AM Technologies | 맞춤형 합금 개발 | R&D, Specialized Manufacturing |

For UAE manufacturers seeking premium tantalum alloy powders, Metal3DP stands out due to cutting-edge production technologies and customization capabilities.

5. Why More UAE Manufacturers Are Turning to Custom Tantalum Alloy Solutions

수요가 증가함에 따라 high-performance metal materials, UAE manufacturers are shifting towards custom tantalum alloys for additive manufacturing. Here’s why:

1. Unique Material Properties for Specialized Applications

Tantalum alloys are known for:

- 탁월한 내식성 – 이상적 oil & gas pipelines and chemical processing.

- 고온 안정성 – 적합한 항공우주 터빈 부품.

- 생체 적합성 – Critical for 의료용 임플란트 및 보철물.

Customizing tantalum alloys allows manufacturers to enhance performance based on industry-specific requirements.

2. Cost and Material Efficiency

- Traditional manufacturing methods waste raw materials when machining complex parts.

- 적층 제조 with customized tantalum alloys minimizes waste and lowers production costs.

3. Demand for Lightweight and High-Strength Components

- The aerospace and defense sectors in the UAE require 경량, 고강도 소재.

- Custom tantalum alloys can be optimized for weight reduction while maintaining superior mechanical properties.

4. Faster Product Development and Prototyping

- Custom tantalum 3D printing enables rapid prototyping.

- Manufacturers can test and refine designs faster compared to traditional casting or machining methods.

5. Supporting UAE’s Vision for Advanced Manufacturing

- The UAE government’s investment in Industry 4.0 encourages the adoption of 맞춤형 금속 첨가 제조.

- Companies that integrate customized tantalum alloys gain a competitive advantage in the growing 3D printing ecosystem.

6. Why Choose Metal3DP as Your Tantalum Alloy Additive Manufacturing Partner?

✅ Industry-Leading Expertise in Additive Manufacturing

Metal3DP 글로벌 리더입니다 금속 적층 제조, 제공:

- Cutting-edge SEBM and LPBF printing technologies.

- Decades of expertise in advanced metal powders.

- Partnerships with aerospace, medical, and industrial manufacturers.

✅ High-Quality Tantalum Alloy Powders

Metal3DP는 다음을 생성합니다. premium tantalum alloy powders 와 함께:

- 높은 구형도 및 우수한 유동성 for superior 3D printing results.

- 맞춤형 합금 배합 tailored for specific applications.

- 첨단 가스 분무 기술 for enhanced powder purity.

✅ Custom Alloy Development for UAE Manufacturers

Key benefits of Metal3DP’s custom tantalum alloy solutions:

- Optimized powder sizes and compositions for different printing methods.

- 연구개발 협력 개발하다 new material properties.

- 확장 가능한 생산 둘 다 프로토타입 제작 및 대량 생산.

✅ Competitive Supply Chain & Logistics in UAE

- Fast delivery of tantalum powders across the UAE.

- Reliable supply contracts for industrial-scale projects.

- 엔드투엔드 적층 제조 솔루션, from powder supply to printed component production.

✅ Proven Success in Aerospace, Medical, and Industrial Sectors

Metal3DP has successfully supplied tantalum alloy solutions 을 위한:

- 항공우주 엔진 부품 requiring high-temperature resistance.

- 의료용 임플란트 및 보철물 using biocompatible tantalum alloys.

- 부식 방지 부품 에 대한 석유 및 가스 애플리케이션 아랍에미리트에서.

| 왜 Metal3DP를 선택하시나요? | 주요 이점 |

|---|---|

| 첨단 파우더 제조 시스템 | 업계를 선도하는 가스 분무 및 PREP 기술 |

| 맞춤형 합금 개발 | Tailored tantalum alloys for 특정 애플리케이션 |

| 고성능 파우더 | Superior flowability and optimized particle size |

| Trusted by Aerospace & Medical Sectors | Proven success in 중요 산업 |

| Efficient UAE Supply Chain | Fast delivery and large-scale production capacity |

For manufacturers in the UAE looking for a trusted tantalum alloy additive manufacturing partner, Metal3DP 제공 industry-leading expertise and high-quality materials.

결론

In this section, we explored:

✅ The 상위 5개 공급업체 of tantalum alloy in the UAE.

✅ The growing shift towards custom tantalum alloy solutions.

✅ Why Metal3DP 는 최고의 선택 에 대한 탄탈럼 첨가 제조.

7. How to Order Custom Tantalum Alloy for Additive Manufacturing in UAE

조달을 원하는 기업을 위해 custom tantalum alloy powders 에 대한 적층 제조, it’s crucial to follow a structured process to ensure high-quality materials and seamless transactions.

1단계: 자료 요구 사항 정의

주문하기 전에 다음 사항을 확인하세요.

✅ Type of Tantalum Alloy Needed: Pure tantalum or a specific alloy (e.g., Ta-Nb, Ta-Ti).

✅ Powder Size Distribution: 다음 대상에 최적화 레이저 파우더 베드 융합(LPBF), 전자빔 용융(EBM)또는 직접 에너지 증착(DED).

✅ Application-Specific Requirements: Aerospace, medical, or industrial needs.

✅ Batch Size & Quantity: Small-scale prototyping or bulk production.

Step 2: Select a Reliable Supplier

For high-quality tantalum alloy powders, it’s essential to work with a 신뢰할 수 있는 공급업체.

- Metal3DP 제공 고급 금속 분말 with superior purity and consistency.

- 공급자가 제공하는 것을 확인하세요 material traceability and certifications 다음과 같은 ISO 9001 및 ASTM 표준.

Step 3: Request a Quote & Technical Consultation

Once you’ve identified your supplier:

- Contact their sales team and request a quote based on your specifications.

- 요청하다 기술 컨설팅 to ensure the selected alloy meets your application needs.

- 논의하다 bulk order pricing and logistics for UAE-based delivery.

Step 4: Sample Testing (Optional)

For large-scale projects, it’s recommended to test a sample batch before full production.

- Evaluate powder flowability, particle size consistency, and printability.

- 지휘하다 mechanical property testing on printed samples.

Step 5: Finalize Order & Arrange Logistics

- Confirm the production timeline and delivery schedule.

- 공급자가 제공하는지 확인하십시오 proper packaging and storage conditions to prevent contamination.

- 준비하다 customs clearance and UAE import compliance, if applicable.

6단계: 후처리 및 품질 관리

After receiving your tantalum alloy powder:

- 지휘하다 품질 검사 to ensure the material meets specifications.

- Store the powder in controlled environments to maintain print quality.

- Proceed with additive manufacturing and post-processing as needed.

| 주문 프로세스 단계 | Key Actions |

|---|---|

| 요구사항 정의 | Choose alloy type, particle size, and application |

| 공급업체 선택 | Ensure reliability, certifications, and traceability |

| 견적요청 | Get pricing, technical consultation, and delivery details |

| Sample Testing | Evaluate powder characteristics and printability |

| 주문 완료 | Confirm logistics, packaging, and customs compliance |

| 포스트 프로세싱 | Conduct quality control and proceed with AM |

대상 custom tantalum alloy procurement, Metal3DP 는 streamlined ordering process and expert support.

8. Future of Tantalum Alloy Additive Manufacturing in the UAE

The UAE has been at the forefront of 첨단 제조 및 산업 4.0, making additive manufacturing a key pillar of industrial growth. The future of tantalum alloy 3D printing in the UAE looks promising, driven by several factors:

1. Expansion of Aerospace & Defense Applications

- UAE’s aerospace industry is investing heavily in high-performance metal materials.

- Tantalum alloys offer heat resistance and strength 다음에 필요합니다. aircraft engines, satellites, and defense components.

- The UAE Space Agency is exploring 3D-printed tantalum parts for space applications.

2. Growth in Medical Implant Manufacturing

- Tantalum’s biocompatibility 에 이상적인 소재입니다. orthopedic implants, dental prosthetics, and spinal cages.

- 3D printing enables personalized implants, reducing surgery risks and improving patient outcomes.

- The UAE’s healthcare sector is rapidly adopting 맞춤형 적층 제조 솔루션.

3. Role in Oil & Gas Industry Innovations

- The oil & gas sector in the UAE requires 부식 방지 소재 극한 환경에 적합합니다.

- Tantalum alloys 우수한 내화학성 에 대한 downhole tools, valves, and heat exchangers.

- On-demand 3D printing of replacement parts reduces downtime and maintenance costs.

4. UAE Government’s Focus on Additive Manufacturing

- The UAE has launched multiple initiatives to promote 3D printing를 포함합니다:

- 두바이 3D 프린팅 전략, aiming for 25% of construction materials to be 3D printed by 2030.

- Investment in industrial 3D printing hubs 금속 적층 제조에 사용됩니다.

- Support for research & development in advanced materials like tantalum alloys.

5. Advancements in Tantalum 3D Printing Technologies

- Innovations in powder production (e.g., gas atomization, PREP) are improving tantalum powder quality.

- Next-generation 3D printing systems offer higher precision, faster production, and improved material efficiency.

- 다음과 같은 회사 Metal3DP are leading the way in 최첨단 적층 제조 솔루션 for tantalum alloys.

| Future Trend | Impact on UAE Manufacturing |

|---|---|

| 항공우주 및 방위 산업 성장 | Increased demand for heat-resistant tantalum parts |

| Medical Implant Innovations | More custom, biocompatible implants |

| Oil & Gas Industry Applications | Corrosion-resistant tantalum components |

| Government 3D Printing Initiatives | Investment in industrial AM hubs |

| Technology Advancements | Higher efficiency and precision in tantalum AM |

아랍에미리트의 첨단 제조에 대한 투자 will continue to drive the growth of tantalum alloy additive manufacturing.

9. FAQs: Common Questions About Buying Tantalum Alloy for 3D Printing

Q1: Why is tantalum alloy used in additive manufacturing?

A: Tantalum alloys offer high-temperature resistance, corrosion protection, and biocompatibility에 이상적입니다. 항공우주, 의료 및 산업 애플리케이션.

Q2: What printing technologies are compatible with tantalum alloy powders?

A: Tantalum alloy powders are optimized for:

- 레이저 파우더 베드 퓨전(LPBF)

- 전자빔 용융(EBM)

- 직접 에너지 증착(DED)

Q3: How do I choose the right tantalum alloy for my application?

A: Consider:

- Pure Tantalum (Ta) 에 대한 medical and chemical processing.

- Tantalum-Niobium (Ta-Nb) Alloy 에 대한 항공우주 및 방위산업.

- Tantalum-Titanium (Ta-Ti) Alloy 에 대한 lightweight, high-strength applications.

Q4: Where can I buy high-quality tantalum alloy powders in the UAE?

A: Metal3DP 오퍼 premium tantalum powders 와 함께 customizable compositions 첨단 제조를 위해

Q5: How long does it take to receive a bulk order of tantalum alloy in UAE?

A: Delivery timelines depend on order size, customization, and shipping logistics. Metal3DP 제공 fast supply chain solutions for UAE-based customers.

결론 및 행동 촉구

Tantalum alloy additive manufacturing is rapidly growing in the UAE와 함께 applications in aerospace, medical, and industrial sectors. Businesses looking to leverage tantalum 3D printing should partner with a 신뢰할 수 있는 공급업체 보장하기 위해 high-quality materials and reliable supply chains.

대상 premium tantalum alloy powders and expert support, contact Metal3DP 오늘!

공유

중국 칭다오에 본사를 둔 선도적인 적층 제조 솔루션 제공업체인 MET3DP Technology Co. 당사는 산업용 3D 프린팅 장비와 고성능 금속 분말을 전문으로 합니다.

관련 기사

Met3DP 소개

최근 업데이트

제품

3D 프린팅 및 적층 제조용 금속 분말

문의 정보

- 칭다오시, 산둥성, 중국

- [email protected]

- [email protected]

- +86 19116340731