Порошок AM

все коллекции

Порошок IN625: руководство для 2025 года

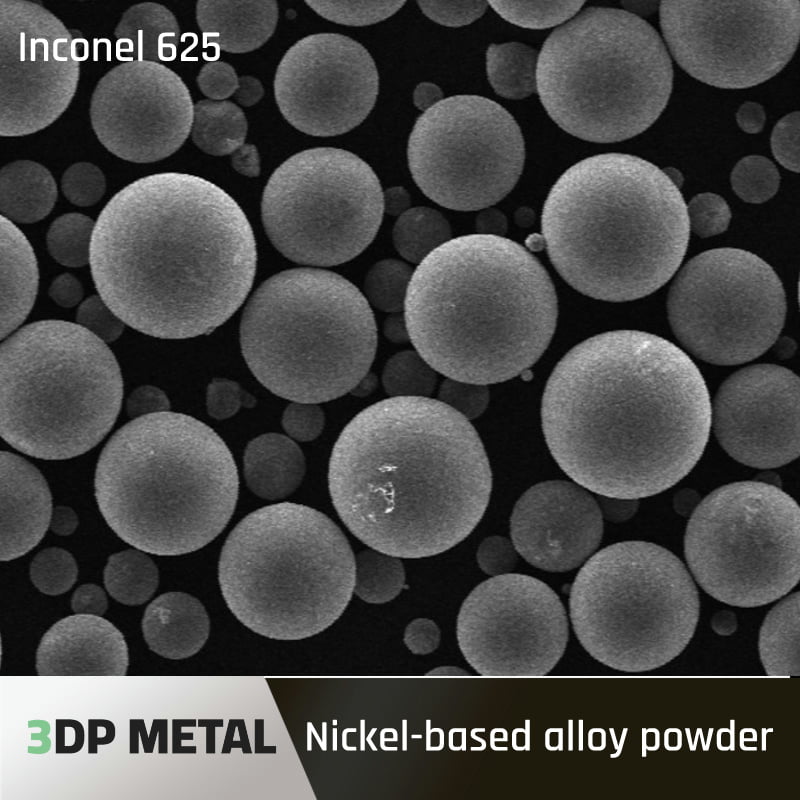

Обзор Порошок IN625, также известный как Inconel 625, представляет собой суперсплав на основе никеля, известный своей исключительной коррозионной стойкостью, прочностью при высоких температурах и превосходной свариваемостью. Он широко используется в аэрокосмической, морской, химической обработке и аддитивном производстве (3D-печати) для высокопроизводительных компонентов, требующих долговечности в экстремальных условиях. В этом руководстве мы рассмотрим

Порошок NiCrAlY: окончательное руководство для 2025 года

Обзор Порошок NiCrAlY - это сплав никель-хром-алюминий-иттрий (NiCrAlY), широко используемый в термобарьерных покрытиях (TBC), аэрокосмической промышленности, газовых турбинах и аддитивном производстве (3D-печать). Этот передовой сплав обеспечивает исключительную стойкость к окислению, термическую стабильность и превосходные адгезионные свойства, что делает его идеальным для защитных покрытий в экстремальных условиях. Ключевые свойства ✔ Выдающаяся стойкость к окислению

Порошок Monel 400: руководство для 2025 года

Обзор Порошок Monel 400 - это никель-медный сплав, известный своей исключительной коррозионной стойкостью, высокой прочностью и отличной теплопроводностью. Он широко используется в морской среде, химической промышленности, аэрокосмической отрасли и аддитивном производстве (3D-печать). Благодаря своей превосходной устойчивости к морской воде, кислотам и щелочам, Monel 400 является

Порошок Hastelloy C-22: окончательное руководство на 2025 год

Обзор Порошок Hastelloy C-22 - это суперсплав на основе никеля, известный своей исключительной коррозионной стойкостью, особенно в кислой, окислительной и восстановительной средах. Этот сплав широко используется в химической промышленности, аэрокосмической отрасли, морской технике, медицинских имплантатах и аддитивном производстве (3D-печать) благодаря своей высокой прочности, отличной свариваемости и превосходной устойчивости к

Порошок IN738LC: окончательное руководство для 2025 года

Обзор Порошок IN738LC, суперсплав на основе никеля, специально разработан для высокотемпературных применений, требующих превосходной стойкости к окислению, прочности при ползучести и сопротивления термической усталости. Этот сплав широко используется в газовых турбинах, аэрокосмических компонентах и промышленной энергетике благодаря своим исключительным механическим свойствам при температурах до 980°C. В этом руководстве,

Порошок из инколоя 800: окончательное руководство для 2025 года

Обзор Порошок Incoloy 800 - это никель-железо-хромовый сплав, известный своей превосходной прочностью, стойкостью к окислению и высокотемпературной стабильностью. Он широко используется в аэрокосмической отрасли, химической промышленности, энергетике и передовом производстве, в частности в аддитивном производстве (3D-печать) для изготовления высокопроизводительных компонентов. В этом руководстве мы рассмотрим: Лучший порошок Incoloy 800 для

Порошок NiCr 80/20: окончательное руководство для 2025 года

Обзор Порошок NiCr 80/20 - это никель-хромовый сплав, состоящий из никеля 80% и хрома 20%, широко известный своей исключительной стойкостью к окислению, высокотемпературной стабильностью и превосходной коррозионной стойкостью. Этот сплав широко используется в покрытиях для термического напыления, электрических нагревательных элементах, аэрокосмической промышленности и аддитивном производстве (3D-печать). Основные свойства ✔ Выдающиеся

Пудра Rene 125: руководство для 2025 года

Обзор Порошок Rene 125 — это высокопроизводительный суперсплав на основе никеля, специально разработанный для экстремально высоких температур, в частности, в газовых турбинах, аэрокосмической и оборонной промышленности. Известный своей исключительной прочностью, стойкостью к окислению и сопротивлением ползучести, этот сплав широко используется в компонентах реактивных двигателей, лопатках турбин и в аддитивном производстве (3D-печати). Ключ

Порошок хастеллоя N: окончательное руководство для 2025 года

Обзор Порошок Hastelloy N — это сплав на основе никеля, специально разработанный для высокотемпературных и коррозионно-стойких применений, в частности, в реакторах на расплавленных солях (MSR), аэрокосмической промышленности, химической обработке и аддитивном производстве (3D-печати). Этот материал обеспечивает исключительную стойкость к окислению, термическую стабильность и отличную механическую прочность, что делает его предпочтительным выбором для отраслей, требующих

Порошок IN939: руководство для 2025 года

Обзор Порошок IN939, также известный как Inconel 939, представляет собой высокопрочный суперсплав на основе никеля, разработанный для экстремально высоких температур. Он обеспечивает отличную стойкость к окислению, превосходную прочность на ползучесть и исключительную коррозионную стойкость, что делает его идеальным для газовых турбин, аэрокосмической и энергетической промышленности. В этом руководстве мы рассмотрим: Лучший порошок IN939 для 3D

Порошок IN625: руководство для 2025 года

Обзор Порошок IN625, также известный как Inconel 625, представляет собой суперсплав на основе никеля, известный своей исключительной коррозионной стойкостью, прочностью при высоких температурах и превосходной свариваемостью. Он

Порошок NiCrAlY: окончательное руководство для 2025 года

Обзор Порошок NiCrAlY - это сплав никель-хром-алюминий-иттрий (NiCrAlY), широко используемый в термобарьерных покрытиях (TBC), аэрокосмической промышленности, газовых турбинах и аддитивном производстве (3D-печать). Этот передовой

Порошок Monel 400: руководство для 2025 года

Обзор Порошок Monel 400 - это никель-медный сплав, известный своей исключительной коррозионной стойкостью, высокой прочностью и отличной теплопроводностью. Он широко используется в

Порошок Hastelloy C-22: окончательное руководство на 2025 год

Обзор Порошок Hastelloy C-22 - это суперсплав на основе никеля, известный своей исключительной коррозионной стойкостью, особенно в кислой, окислительной и восстановительной средах. Этот сплав широко

Порошок IN738LC: окончательное руководство для 2025 года

Обзор Порошок IN738LC, суперсплав на основе никеля, специально разработан для высокотемпературных применений, требующих превосходного сопротивления окислению, прочности при ползучести и сопротивления термической усталости. Этот сплав

Порошок из инколоя 800: окончательное руководство для 2025 года

Обзор Порошок Incoloy 800 - это никель-железо-хромовый сплав, известный своей превосходной прочностью, стойкостью к окислению и высокотемпературной стабильностью. Он широко используется в аэрокосмической и химической промышленности.

Порошок NiCr 80/20: окончательное руководство для 2025 года

Обзор Порошок NiCr 80/20 - это никель-хромовый сплав, состоящий из никеля 80% и хрома 20%, широко известный своей исключительной стойкостью к окислению, высокотемпературной стабильностью и

Пудра Rene 125: руководство для 2025 года

Обзор Порошок Rene 125 — это высокопроизводительный суперсплав на основе никеля, специально разработанный для экстремально высоких температур, в частности, в газовых турбинах, аэрокосмической и оборонной промышленности. Известный

Порошок хастеллоя N: окончательное руководство для 2025 года

Обзор Порошок Hastelloy N — это сплав на основе никеля, специально разработанный для высокотемпературных и коррозионно-стойких применений, в частности, в реакторах на расплавленных солях (MSR), аэрокосмической промышленности, химической обработке и т. д.

Порошок IN939: руководство для 2025 года

Обзор Порошок IN939, также известный как Inconel 939, представляет собой высокопрочный суперсплав на основе никеля, предназначенный для экстремально высоких температур. Он обеспечивает отличную стойкость к окислению, превосходную ползучесть

Наш продукт

ПРОДУКТ ГОРЯЧЕЙ ПРОДАЖИ

CONTACT US

Есть вопросы? Отправьте нам сообщение прямо сейчас! После получения Вашего сообщения мы всей командой выполним Ваш запрос.

Металлические порошки для 3D-печати и аддитивного производства

КОМПАНИЯ

ПРОДУКТ

ИНФОРМАЦИЯ О КОНТАКТЕ

- Город Циндао, Шаньдун, Китай

- [email protected]

- [email protected]

- +86 19116340731