Omfattande guide till AM-processen

Innehållsförteckning

Välkommen till den fascinerande världen av AM-process, där gränserna för traditionell tillverkning ständigt tänjs på. I den här guiden kommer vi att dyka djupt in i förvecklingarna med AM och belysa olika aspekter från metallpulvermodeller till deras applikationer, fördelar, nackdelar och mer. Spänn dig för en engagerande och informativ resa genom tillverkningens moderna underverk!

Översikt över additiv tillverkning

Additiv tillverkning, ofta kallad 3D-utskrift, är en process för att skapa tredimensionella objekt genom att lägga till material lager för lager. Till skillnad från traditionella tillverkningsmetoder, som ofta innebär att man subtraherar material från ett större block, bygger AM objekt från grunden, vilket möjliggör komplexa konstruktioner och minskat avfall.

Viktiga detaljer om AM-processen

- Teknik: Materialtillsats lager för lager

- Använda material: Metaller, polymerer, keramer och kompositer

- Tillämpningar: Flyg-, bil-, hälso- och sjukvård, konsumentvaror och mer

- Fördelar: Komplexa geometrier, minskat avfall, anpassning och snabb prototypframställning

- Utmaningar: Materialbegränsningar, ytfinish och höga initialkostnader

Typer av metallpulver som används i AM

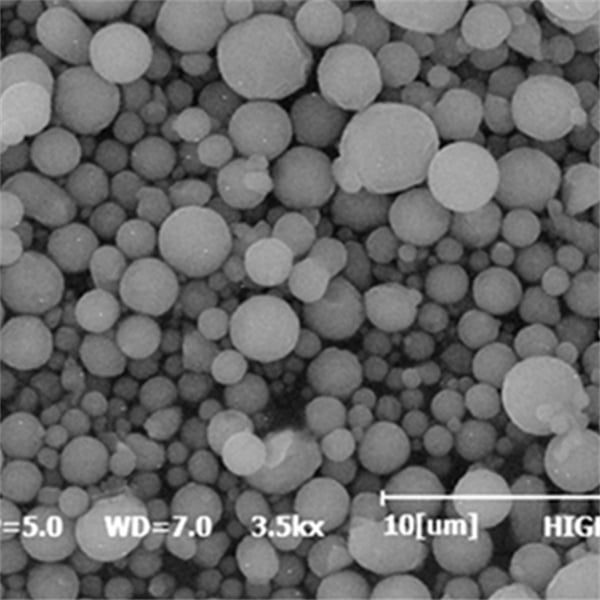

I AM:s rike är metallpulver en kritisk komponent. Låt oss utforska några av de mest använda metallpulvren, deras sammansättning och deras unika egenskaper.

Vanliga metallpulver för AM

| Metallpulver | Sammansättning | Fastigheter | Tillämpningar |

|---|---|---|---|

| Titan (Ti-6Al-4V) | 90% titan, 6% aluminium, 4% vanadin | Hög hållfasthet, låg vikt, korrosionsbeständig | Flyg- och rymdindustrin, medicinska implantat |

| Rostfritt stål (316L) | 16-18% Krom, 10-14% Nickel, 2-3% Molybden | Korrosionsbeständig, hållbar, god svetsbarhet | Medicinska instrument, livsmedelsbearbetning |

| Aluminium (AlSi10Mg) | 89-91% Aluminium, 9-11% Silicon, 0,2-0,4% Magnesium | Lätt, bra värmeledningsförmåga, stark | Fordon, flyg- och rymdindustrin |

| Inconel (IN718) | 50-55% nickel, 17-21% krom, 4,75-5,5% niob | Värmebeständig, hög hållfasthet vid förhöjda temperaturer | Turbiner, flygkomponenter |

| Kobolt-krom (CoCr) | 55-65% kobolt, 27-30% krom, 5-7% molybden | Slitstark, biokompatibel, hög hårdhet | Tandimplantat, ortopedisk utrustning |

| Koppar (Cu) | 99,9% Koppar | Utmärkt termisk och elektrisk ledningsförmåga | Elektriska komponenter, värmeväxlare |

| Verktygsstål (H13) | 0,35-0,45% kol, 5-5,5% krom, 1-1,2% molybden | Hög hårdhet, slitstark, bra bearbetningsförmåga | Gjutformar, matriser, skärverktyg |

| Nickellegering (Hastelloy X) | 47-52% Nickel, 20,5-23% krom, 17-20% järn | Oxidationsbeständig, hög hållfasthet vid höga temperaturer | Kemisk bearbetning, flyg |

| Magnesium (AZ91D) | 8,5-9,5% aluminium, 0,6-1,4% zink, 0,15% mangan | Lättvikt, bra förhållande mellan styrka och vikt | Fordon, elektronik |

| Volfram (W) | 99.95% Tungsten | Extremt hög smältpunkt, tät, stark | Flyg-, försvarsapplikationer |

Detaljerade metallpulvermodeller

- Titan (Ti-6Al-4V): Denna legering är känd för sitt exceptionella hållfasthet-till-viktförhållande och biokompatibilitet och är en bas inom flyg- och medicinindustrin. Den erbjuder imponerande motståndskraft mot utmattning och korrosion, vilket gör den idealisk för kritiska komponenter.

- Rostfritt stål (316L): En mångsidig legering, 316L rostfritt stål är uppskattad för sin hållbarhet och motståndskraft mot korrosion. Det används i stor utsträckning i miljöer där hygien och livslängd är av största vikt, till exempel i medicinsk utrustning och livsmedelsutrustning.

- Aluminium (AlSi10Mg): Denna legering är känd för sin lätta natur och utmärkta värmeledningsförmåga. Det är ett populärt val inom fordons- och flygsektorn där viktminskning är avgörande utan att kompromissa med styrkan.

- Inconel (IN718): Inconel 718 är känd för sin förmåga att motstå extrema temperaturer och mekanisk påfrestning, och används flitigt inom flygindustrin för turbinmotorer och andra högtemperaturapplikationer.

- Kobolt-krom (CoCr): Denna biokompatibla legering är perfekt för medicinska implantat på grund av sin höga hårdhet och slitstyrka. Det säkerställer lång livslängd och tillförlitlighet i ortopediska och dentala tillämpningar.

- Koppar (Cu): Med oöverträffad termisk och elektrisk ledningsförmåga är koppar avgörande i elektroteknik och värmeväxlartillämpningar, där effektiv värmeöverföring är avgörande.

- Verktygsstål (H13): Idealiskt för att tillverka formar och skärverktyg, H13 verktygsstål erbjuder hög hårdhet och slitstyrka, vilket säkerställer hållbarhet och precision i tillverkningsprocesser.

- Nickellegering (Hastelloy X): Denna legering utmärker sig i högtemperaturmiljöer, motstår oxidation och bibehåller styrkan. Den används i kemisk bearbetning och rymdtillämpningar där tillförlitlighet under extrema förhållanden är avgörande.

- Magnesium (AZ91D): Som en av de lättaste strukturella metallerna används magnesium AZ91D där viktbesparing är avgörande, som i bil- och elektronikindustrin, vilket ger en bra balans mellan styrka och lätthet.

- Volfram (W): Volfram är känt för sin otroligt höga smältpunkt och densitet och är oumbärligt i flyg- och försvarstillämpningar, särskilt där exponering för extrema förhållanden förväntas.

Tillämpningar av AM-processen

Mångsidigheten hos AM återspeglas i dess breda användningsområde. Här fördjupar vi oss i olika branscher som utnyttjar AM för att tänja på gränserna för innovation.

Branscher som använder AM

| Industri | Tillämpningar | Fördelar |

|---|---|---|

| Flyg- och rymdindustrin | Motorkomponenter, strukturella delar, verktyg | Lätta delar, minskade ledtider, komplexa geometrier |

| Fordon | Prototyper, anpassade delar, lättviktskomponenter | Designflexibilitet, snabb prototypframställning, minskad vikt |

| Hälso- och sjukvård | Implantat, proteser, kirurgiska instrument | Anpassning, biokompatibilitet, exakta geometrier |

| Konsumentvaror | Anpassade produkter, bärbar teknologi, hushållsapparater | Personalisering, on-demand-produktion, minskat lager |

| Arkitektur | Skalmodeller, skräddarsydda komponenter, byggverktyg | Anpassad design, snabb produktion, minskat materialspill |

| Utbildning | Läromedel, prototyputveckling, forskning | Praktiskt lärande, innovativ design, kostnadseffektiv prototypframställning |

| Försvar | Lätta rustningar, vapenkomponenter, fältreparationsverktyg | Hållbarhet, anpassning, snabb tillverkning |

| Energi | Turbinkomponenter, värmeväxlare, rörledningar | Hög prestanda, materialeffektivitet, komplexa konstruktioner |

Fördelar med AM Process

- Flexibilitet i designen: AM möjliggör skapandet av komplexa och intrikata konstruktioner som skulle vara omöjliga eller kostsamma med traditionella metoder.

- Anpassning: Produkter kan skräddarsys efter individuella behov, vilket gör den idealisk för medicinska implantat och specialanpassade delar.

- Minskat avfall: Material läggs till lager för lager, vilket minimerar spill jämfört med subtraktiva tillverkningsprocesser.

- Snabb prototyptillverkning: AM möjliggör snabb iteration och testning av design, vilket påskyndar utvecklingscykeln.

- Lättviktskonstruktioner: AM kan producera lättviktskomponenter, avgörande inom flyg- och fordonsindustrin.

Nackdelar med AM Process

- Materiella begränsningar: Alla material är inte lämpliga för AM, vilket begränsar utbudet av möjliga applikationer.

- Ytfinish: Delar som tillverkas av AM kräver ofta efterbearbetning för att uppnå önskad ytkvalitet.

- Initiala kostnader: Den initiala investeringen i AM-teknik och material kan vara hög, vilket gör den mindre tillgänglig för småskalig verksamhet.

- Produktionshastighet: Även om AM utmärker sig i komplexitet och anpassning, kan det vara långsammare än traditionella massproduktionsmetoder för stora kvantiteter.

Jämföra AM Metal Powders

Låt oss ta en närmare titt på hur dessa metallpulver står sig mot varandra över olika parametrar.

| Metallpulver | Styrka | Vikt | Motståndskraft mot korrosion | Värmebeständighet | Kostnad |

|---|---|---|---|---|---|

| Titan (Ti-6Al-4V) | Hög | Ljus | Utmärkt | Bra | Hög |

| Rostfritt stål (316L) | Måttlig | Tung | Utmärkt | Måttlig | Måttlig |

| Aluminium (AlSi10Mg) | Måttlig | Mycket lätt | Bra | Måttlig | Låg |

| Inconel (IN718) | Mycket hög | Tung | Bra | Utmärkt | Mycket hög |

| Kobolt-krom (CoCr) | Hög | Tung | Utmärkt | Bra | Hög |

| Koppar (Cu) | Låg | Tung | Dålig | Dålig | Låg |

| Verktygsstål (H13) | Hög | Tung | Måttlig | Måttlig | Måttlig |

| Nickellegering (Hastelloy X) | Hög | Tung | Bra | Utmärkt | Mycket hög |

| Magnesium (AZ91D) | Låg | Mycket lätt | Dålig | Dålig | Låg |

| Volfram (W) | Mycket hög | Mycket tung | Utmärkt | Utmärkt | Mycket hög |

Leverantörer och prisuppgifter

När det gäller att köpa metallpulver för AM är det viktigt att känna till de ledande leverantörerna och deras prissättning. Här är en uppdelning:

| Leverantör | Metallpulver | Pris (per kg) | Kontaktuppgifter |

|---|---|---|---|

| Höganäs AB | Titan (Ti-6Al-4V) | $300 | www.hoganas.com |

| Sandvik | Rostfritt stål (316L) | $150 | www.materials.sandvik |

| EOS GmbH | Aluminium (AlSi10Mg) | $100 | www.eos.info |

| Snickeriteknik | Inconel (IN718) | $400 | www.carpentertechnology.com |

| Arcam AB | Kobolt-krom (CoCr) | $350 | www.arcam.com |

| GKN Hoeganaes | Koppar (Cu) | $50 | www.gknpm.com |

| Böhler Uddeholm | Verktygsstål (H13) | $120 | www.bohler-uddeholm.com |

| Haynes International | Nickellegering (Hastelloy X) | $450 | www.haynesintl.com |

| Avancerade pulver och ytbeläggningar (AP&C) | Magnesium (AZ91D) | $80 | www.advancedpowders.com |

| Buffalo Tungsten Inc. | Volfram (W) | $500 | www.buffalotungsten.com |

För- och nackdelar med AM Process

Varje teknik har sina styrkor och svagheter. Här är en detaljerad jämförelse av för- och nackdelar med AM-processen:

| Aspekt | Fördelar | Begränsningar |

|---|---|---|

| Design | Tillåter komplexa geometrier, anpassning | Begränsad av materialegenskaper |

| Materialanvändning | Minskat avfall, effektiv användning | Begränsat utbud av användbara material |

| Produktion | Snabb prototypframställning, produktion på begäran | Långsammare för stora mängder |

| Kostnad | Minskade verktygskostnader, mindre materialavfall | Hög initial investering |

| Flexibilitet | Enkla designändringar, mångsidiga applikationer | Efterbearbetning krävs ofta |

VANLIGA FRÅGOR

Låt oss ta upp några vanliga frågor om AM-processen för att reda ut eventuella kvardröjande tvivel.

| Fråga | Svar |

|---|---|

| Vad är Additive Manufacturing (AM)? | AM, eller 3D-utskrift, är en process för att skapa objekt genom att lägga till material lager för lager, vilket möjliggör komplexa mönster och minskat avfall. |

| Vilka material kan användas i AM? | En mängd olika material kan användas, inklusive metaller, polymerer, keramer och kompositer. |

| Vilka är de främsta fördelarna med AM? | AM erbjuder designflexibilitet, anpassning, minskat slöseri, snabb prototypframställning och möjligheten att skapa lätta strukturer. |

| Finns det några begränsningar för AM? | Ja, begränsningarna inkluderar materialbegränsningar, problem med ytfinish, höga initialkostnader och lägre produktionshastigheter för stora kvantiteter. |

| Vilka branscher drar mest nytta av AM? | Flyg-, fordons-, hälso- och sjukvård, konsumentvaror, arkitektur, utbildning, försvar och energiindustrin drar stor nytta av AM. |

| Hur står sig AM jämfört med traditionell tillverkning? | AM utmärker sig i att skapa komplexa, skräddarsydda delar med mindre avfall men kan vara långsammare och dyrare initialt jämfört med traditionella massproduktionsmetoder. |

| Vilka är några vanliga metallpulver som används i AM? | Vanliga metallpulver inkluderar titan (Ti-6Al-4V), rostfritt stål (316L), aluminium (AlSi10Mg), Inconel (IN718), kobolt-krom (CoCr) och mer. |

| Kan AM användas för massproduktion? | Även om AM är idealiskt för prototyper och anpassade delar, är det i allmänhet långsammare och mindre kostnadseffektivt för massproduktion jämfört med traditionella metoder. |

| Vilken efterbearbetning krävs för AM-delar? | Efterbearbetning kan innefatta ytbehandling, värmebehandling, bearbetning och beläggning för att uppnå önskad kvalitet och egenskaper. |

| Hur är kostnaden för AM-material jämfört med traditionella material? | AM-material kan vara dyrare på grund av sin specialiserade natur, men kostnadsbesparingar kan uppnås genom minskade kostnader för avfall och verktyg. |

Slutsats

Additive Manufacturing revolutionerar hur vi närmar oss design och produktion, och erbjuder oöverträffad flexibilitet och effektivitet. Från flyg till sjukvård, tillämpningarna av AM är enorma och varierande. Även om det finns utmaningar att övervinna, är fördelarna med denna innovativa teknik tydliga. När området fortsätter att utvecklas kan vi förvänta oss ännu mer spännande utveckling och bredare användning inom olika branscher.

Dela på

MET3DP Technology Co, LTD är en ledande leverantör av lösningar för additiv tillverkning med huvudkontor i Qingdao, Kina. Vårt företag är specialiserat på 3D-utskriftsutrustning och högpresterande metallpulver för industriella tillämpningar.

Förfrågan för att få bästa pris och anpassad lösning för ditt företag!

Relaterade artiklar

Högpresterande segment för munstycksvingar: Revolutionerande turbineffektivitet med 3D-utskrift i metall

Läs mer "Om Met3DP

Senaste uppdateringen

Vår produkt

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731