Blogg

alla samlingar

Vilka metallpulver är lämpliga för WAAM

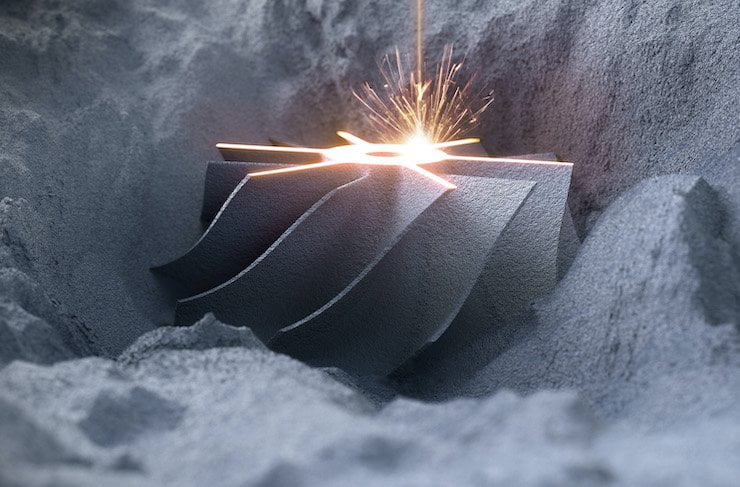

The world of 3D printing continues to evolve at a breakneck pace, pushing the boundaries of what’s possible. Wire Arc Additive Manufacturing (WAAM) stands as a testament to this innovation, offering a robust and efficient method for constructing large-scale metal structures. But just like a master chef requires the finest

Jämförelse mellan DED-teknik och WAAM-teknik

Introduction Hook: Imagine crafting complex metal objects layer by layer, with molten metal meticulously deposited to build anything from towering wind turbine components to intricate medical implants. This captivating realm belongs to Directed Energy Deposition (DED) and Wire Arc Additive Manufacturing (WAAM), two revolutionary metal additive manufacturing (AM) techniques. Problem:

Tillämpningar av WAAM inom flyg- och rymdindustrin

The aerospace industry thrives on innovation. It’s a constant push to create lighter, stronger, and more efficient vehicles that can conquer the skies and beyond. Enter Wire Arc Additive Manufacturing (WAAM), a revolutionary 3D printing technology that’s rapidly transforming how we build aircraft and spacecraft. Imagine building complex, near-net-shape components

The working steps of WAAM

Imagine building complex metal structures layer by layer, like a culinary master crafting a magnificent cake. That’s the essence of Wire Arc Additive Manufacturing (WAAM), a revolutionary 3D printing technology that’s transforming the way we create metal parts. This comprehensive guide will delve into the captivating world of WAAM, taking

introduktion till Wire Arc Additive Manufacturing

Imagine building large, robust metal parts layer by layer, not through subtractive manufacturing techniques like machining, but by adding material meticulously. This transformative technology is Wire Arc Additive Manufacturing (WAAM), poised to reshape how we create critical components across various industries. The Working Principle of Wire Arc Additive Manufacturing WAAM,

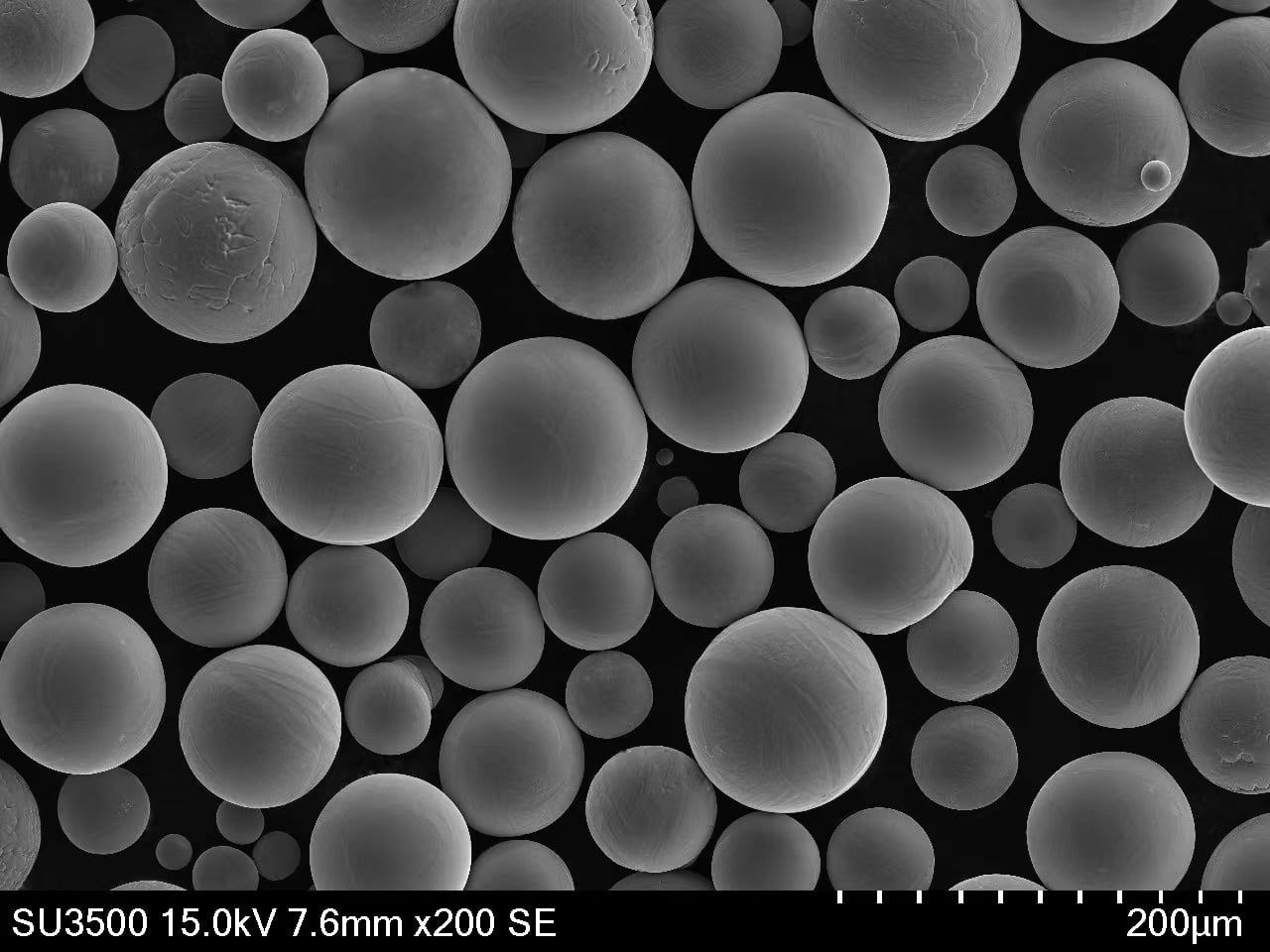

PREP-processen (Plasma Rotating Electrode Process) för högvärdiga metallpulver

Imagine a world where metal components are crafted not through traditional means, but by meticulously building them layer by layer using tiny, perfectly spherical metal particles. This futuristic vision is the cornerstone of Additive Manufacturing (AM), also known as 3D printing. But what about the magic ingredient that brings these

Vilka metallpulver är lämpliga för WAAM

The world of 3D printing continues to evolve at a breakneck pace, pushing the boundaries of what’s possible. Wire Arc Additive Manufacturing (WAAM) stands as

Jämförelse mellan DED-teknik och WAAM-teknik

Introduction Hook: Imagine crafting complex metal objects layer by layer, with molten metal meticulously deposited to build anything from towering wind turbine components to intricate

Tillämpningar av WAAM inom flyg- och rymdindustrin

The aerospace industry thrives on innovation. It’s a constant push to create lighter, stronger, and more efficient vehicles that can conquer the skies and beyond.

The working steps of WAAM

Imagine building complex metal structures layer by layer, like a culinary master crafting a magnificent cake. That’s the essence of Wire Arc Additive Manufacturing (WAAM),

introduktion till Wire Arc Additive Manufacturing

Föreställ dig att bygga stora, robusta metalldelar lager för lager, inte genom subtraktiva tillverkningstekniker som bearbetning, utan genom att lägga till material noggrant. Denna transformerande teknik är

PREP-processen (Plasma Rotating Electrode Process) för högvärdiga metallpulver

Imagine a world where metal components are crafted not through traditional means, but by meticulously building them layer by layer using tiny, perfectly spherical metal

Vår produkt

PRODUKT MED HET FÖRSÄLJNING

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731