Den omfattande guiden för CuAlNiFe

Innehållsförteckning

Översikt över CuAlNiFe

CuAlNiFe är en avancerad metallegering som är känd för sina anmärkningsvärda egenskaper och breda användningsområden. Denna legering är en kombination av koppar (Cu), aluminium (Al), nickel (Ni) och järn (Fe), som var och en bidrar med unika egenskaper som gör CuAlNiFe till ett idealiskt val för olika industriella applikationer. Den här guiden fördjupar sig i de specifika egenskaperna, användningsområdena och specifikationerna för CuAlNiFe och ger en detaljerad analys för ingenjörer, tillverkare och materialforskare.

Sammansättning av CuAlNiFe

Sammansättningen av CuAlNiFe är avgörande för att förstå dess egenskaper och potentiella tillämpningar. I tabellen nedan beskrivs den typiska sammansättningen av denna legering:

| Element | Procentuell sammansättning |

|---|---|

| Koppar (Cu) | 50-60% |

| Aluminium (Al) | 20-30% |

| Nickel (Ni) | 10-15% |

| Järn (Fe) | 5-10% |

Denna specifika sammansättning resulterar i ett material som har en unik kombination av styrka, korrosionsbeständighet och termisk stabilitet.

Kännetecken för CuAlNiFe

Att förstå egenskaperna hos CuAlNiFe hjälper till att uppskatta dess mångsidighet och prestanda i olika applikationer.

Styrka och hållbarhet

CuAlNiFe är känt för sin höga hållfasthet och hållbarhet. Kombinationen av nickel och järn bidrar väsentligt till dess strukturella integritet, vilket gör den lämplig för tunga applikationer.

Motståndskraft mot korrosion

Aluminiuminnehållet i CuAlNiFe ger utmärkt motståndskraft mot korrosion, särskilt i tuffa miljöer. Det gör det till ett förstahandsval för marina och industriella applikationer där exponering för frätande ämnen är vanligt förekommande.

Termisk stabilitet

CuAlNiFe behåller sina egenskaper över ett brett temperaturintervall. Denna termiska stabilitet är avgörande för applikationer inom flyg- och fordonsindustrin, där materialen ofta utsätts för extrema temperaturvariationer.

Bearbetbarhet

Trots sin styrka och hållbarhet är CuAlNiFe relativt lätt att bearbeta, vilket gör den ännu mer attraktiv för tillverkningsprocesser.

Tillämpningar av CuAlNiFe

CuAlNiFe:s unika egenskaper gör det lämpligt för en mängd olika tillämpningar. Tabellen nedan visar några vanliga användningsområden:

| Tillämpning | Beskrivning |

|---|---|

| Marin teknik | Används inom varvsindustrin och på offshoreplattformar tack vare sin korrosionsbeständighet. |

| Flyg- och rymdindustrin | Komponenter som turbinblad och strukturella delar drar nytta av dess termiska stabilitet. |

| Fordon | Används i högpresterande motorkomponenter och chassidelar. |

| Industriella maskiner | Idealisk för kugghjul, ventiler och andra maskindelar som kräver hög hållfasthet. |

| Elektriska komponenter | Lämplig för kontakter och brytare tack vare sin utmärkta elektriska ledningsförmåga. |

Specifikationer och standarder för CuAlNiFe

För att säkerställa kvalitet och konsekvens måste CuAlNiFe följa specifika standarder och specifikationer. Nedan finns en detaljerad tabell som beskriver dessa parametrar:

| Parameter | Specifikation | Betyg | Standard |

|---|---|---|---|

| Draghållfasthet | 600-800 MPa | A1 | ASTM B150 |

| Utbyteshållfasthet | 400-600 MPa | A2 | ASTM B150 |

| Töjning | 10-20% | A3 | ASTM B150 |

| Hårdhet | 150-200 HB | B1 | DIN 17660 |

| Täthet | 7,5-8,5 g/cm³ | B2 | ISO 9454 |

| Termisk konduktivitet | 100-150 W/m-K | B3 | ISO 9454 |

Leverantörer och prisuppgifter

Att hitta pålitliga leverantörer och förstå prissättningsdetaljerna är avgörande för företag som vill använda CuAlNiFe. Tabellen nedan ger en översikt över några viktiga leverantörer och deras prissättning:

| Leverantör | Plats | Prissättning (per kg) | Minsta antal beställningar |

|---|---|---|---|

| ABC Metals | USA | $50 | 100 kg |

| Globala legeringar | Tyskland | €45 | 200 kg |

| MetalWorks Inc. | Kina | $40 | 500 kg |

| Experter på legeringar | STORBRITANNIEN | £35 | 150 kg |

| Högteknologiska material | Japan | ¥5000 | 250 kg |

För- och nackdelar med CuAlNiFe

Varje material har sina fördelar och begränsningar. Här jämför vi för- och nackdelar med CuAlNiFe:

| Proffs | Nackdelar |

|---|---|

| Utmärkt korrosionsbeständighet | Relativt dyr jämfört med andra legeringar |

| Hög hållfasthet och hållbarhet | Kräver specialiserad maskinbearbetningsteknik |

| God termisk stabilitet | Begränsad tillgänglighet i vissa regioner |

| Mångsidiga tillämpningar | Högre densitet jämfört med vissa alternativ |

| Lätt att bearbeta | Potential för oxidation vid höga temperaturer |

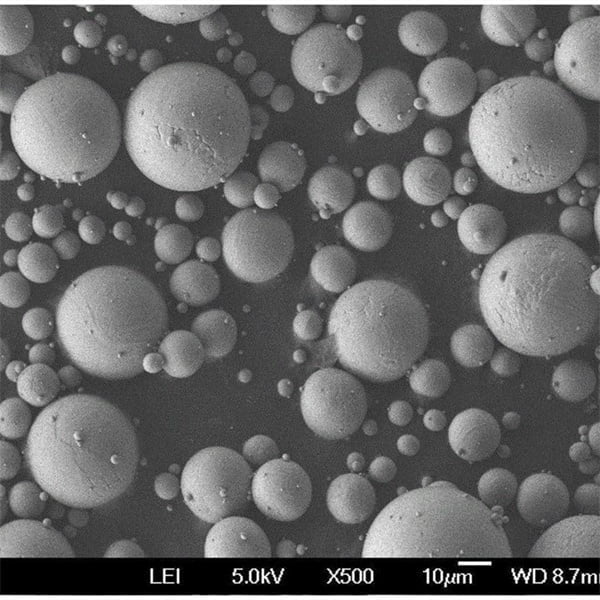

Specifika metallpulvermodeller av CuAlNiFe

När det gäller metallpulver erbjuder CuAlNiFe flera olika modeller som var och en lämpar sig för olika applikationer. Nedan följer beskrivningar av tio specifika modeller:

- CuAlNiFe-101

- Beskrivning: Ett allmänt pulver med balanserade egenskaper som lämpar sig för ett brett spektrum av applikationer.

- Applikationer: Flyg- och rymdindustrin, fordonskomponenter.

- CuAlNiFe-202

- Beskrivning: Förbättrad korrosionsbeständighet, idealisk för marina tillämpningar.

- Applikationer: Skeppsbyggnad, offshoreplattformar.

- CuAlNiFe-303

- Beskrivning: Hög hållfasthet och termisk stabilitet, perfekt för miljöer med höga påfrestningar.

- Applikationer: Turbinblad, industrimaskiner.

- CuAlNiFe-404

- Beskrivning: Förbättrad elektrisk ledningsförmåga för elektroniska komponenter.

- Applikationer: Anslutningar, omkopplare.

- CuAlNiFe-505

- Beskrivning: Optimerad för enkel maskinbearbetning, vilket minskar tillverkningskostnaderna.

- Applikationer: Kugghjul, ventiler.

- CuAlNiFe-606

- Beskrivning: Överlägsen hårdhet, vilket ger extra hållbarhet.

- Applikationer: Slitstarka delar.

- CuAlNiFe-707

- Beskrivning: Låg vikt med hög hållfasthet, lämplig för fordons- och flygplansindustrin.

- Applikationer: Motorkomponenter, strukturella delar.

- CuAlNiFe-808

- Beskrivning: Hög temperaturbeständighet, bibehåller integriteten under extrema förhållanden.

- Applikationer: Högpresterande motorer, industriugnar.

- CuAlNiFe-909

- Beskrivning: Speciellt framtagen för additiv tillverkning och 3D-printing.

- Applikationer: Prototyptillverkning, specialtillverkade delar.

- CuAlNiFe-1000

- Beskrivning: Premiumkvalitet med maximal korrosionsbeständighet och styrka.

- Applikationer: Kritiska tillämpningar inom flyg, rymd och försvar.

VANLIGA FRÅGOR

Vad är CuAlNiFe?

CuAlNiFe är en legering som består av koppar, aluminium, nickel och järn och som är känd för sin höga hållfasthet, korrosionsbeständighet och termiska stabilitet.

Var används CuAlNiFe?

Tack vare sina mångsidiga egenskaper används denna legering i olika branscher, t.ex. marin-, flyg-, fordons- och industrimaskiner.

Vilka är fördelarna med att använda CuAlNiFe?

CuAlNiFe har utmärkt korrosionsbeständighet, hög hållfasthet, god termisk stabilitet och är lätt att bearbeta.

Finns det några begränsningar för CuAlNiFe?

Ja, CuAlNiFe kan vara relativt dyrt och kan kräva specialiserade bearbetningstekniker. Det har också en högre densitet jämfört med vissa alternativa material.

Hur väljer jag rätt CuAlNiFe-modell för min applikation?

Valet av rätt modell beror på de specifika kraven i din applikation. Tänk på faktorer som korrosionsbeständighet, hållfasthet, termisk stabilitet och enkel maskinbearbetning.

Kan CuAlNiFe användas i additiv tillverkning?

Ja, vissa modeller som CuAlNiFe-909 är speciellt framtagna för additiv tillverkning och 3D-utskrifter.

Vilka är de största leverantörerna av CuAlNiFe?

Bland leverantörerna märks ABC Metals (USA), Global Alloys (Tyskland), MetalWorks Inc (Kina), Alloy Experts (Storbritannien) och HighTech Materials (Japan).

Är CuAlNiFe miljövänligt?

CuAlNiFe är relativt miljövänlig tack vare sin hållbarhet och korrosionsbeständighet, vilket minskar behovet av frekventa byten och reparationer.

Vilka standarder gäller för CuAlNiFe?

CuAlNiFe måste följa standarder som ASTM B150, DIN 17660 och ISO 9454, vilket säkerställer kvalitet och enhetlighet.

Hur är CuAlNiFe prissatt?

Priset på CuAlNiFe kan variera beroende på leverantör, plats och orderkvantitet och varierar vanligtvis från $40 till $50 per kg.

Slutsats

CuAlNiFe är en högpresterande metallegering som erbjuder en unik kombination av egenskaper, vilket gör den lämplig för ett brett spektrum av industriella tillämpningar. Dess sammansättning, egenskaper och mångsidighet är oöverträffade och ger ingenjörer och tillverkare ett tillförlitligt material för krävande miljöer. Oavsett om du letar efter styrka, korrosionsbeständighet eller termisk stabilitet framstår CuAlNiFe som ett förstahandsval i världen av avancerade material.

Dela på

MET3DP Technology Co, LTD är en ledande leverantör av lösningar för additiv tillverkning med huvudkontor i Qingdao, Kina. Vårt företag är specialiserat på 3D-utskriftsutrustning och högpresterande metallpulver för industriella tillämpningar.

Förfrågan för att få bästa pris och anpassad lösning för ditt företag!

Relaterade artiklar

Högpresterande segment för munstycksvingar: Revolutionerande turbineffektivitet med 3D-utskrift i metall

Läs mer "Om Met3DP

Senaste uppdateringen

Vår produkt

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731