GH3625: En omfattande guide till sammansättning, egenskaper och användningsområden

Innehållsförteckning

Välkommen till vår djupgående undersökning av GH3625ett anmärkningsvärt metallpulver som har fått betydande dragkraft i olika branscher. I den här artikeln kommer vi att fördjupa oss i de nitty-gritty detaljerna i GH3625, som täcker allt från dess sammansättning och egenskaper till dess applikationer och fördelar. Oavsett om du är materialingenjör, forskare eller helt enkelt nyfiken på avancerade material, kommer den här guiden att ge dig all information du behöver.

Översikt över GH3625

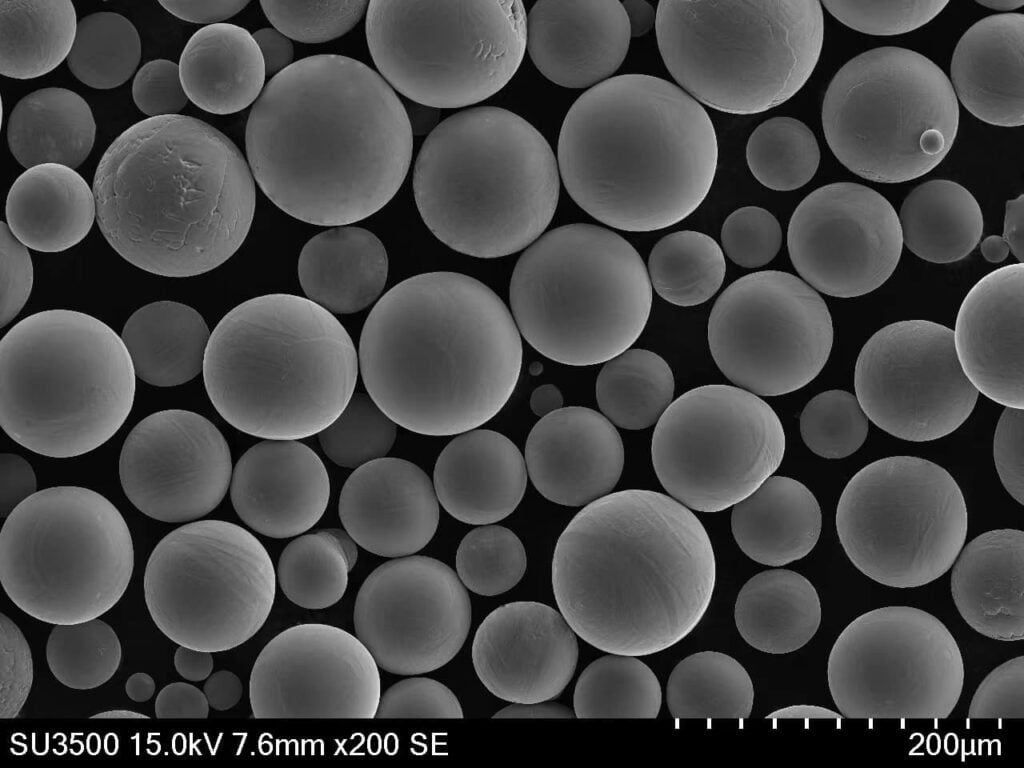

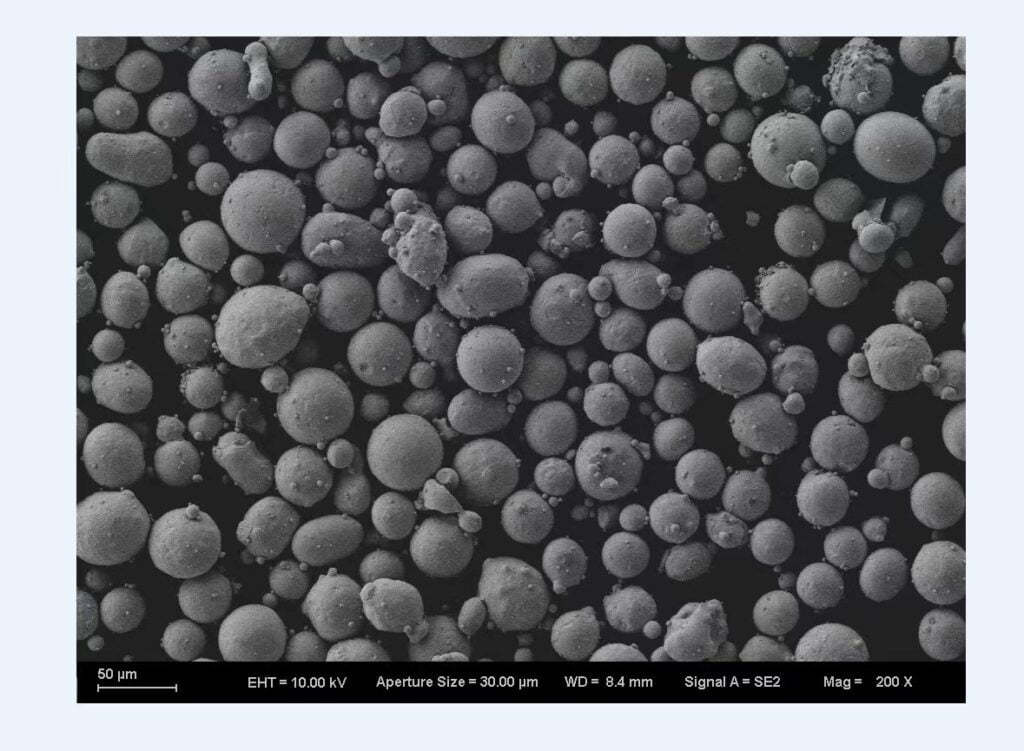

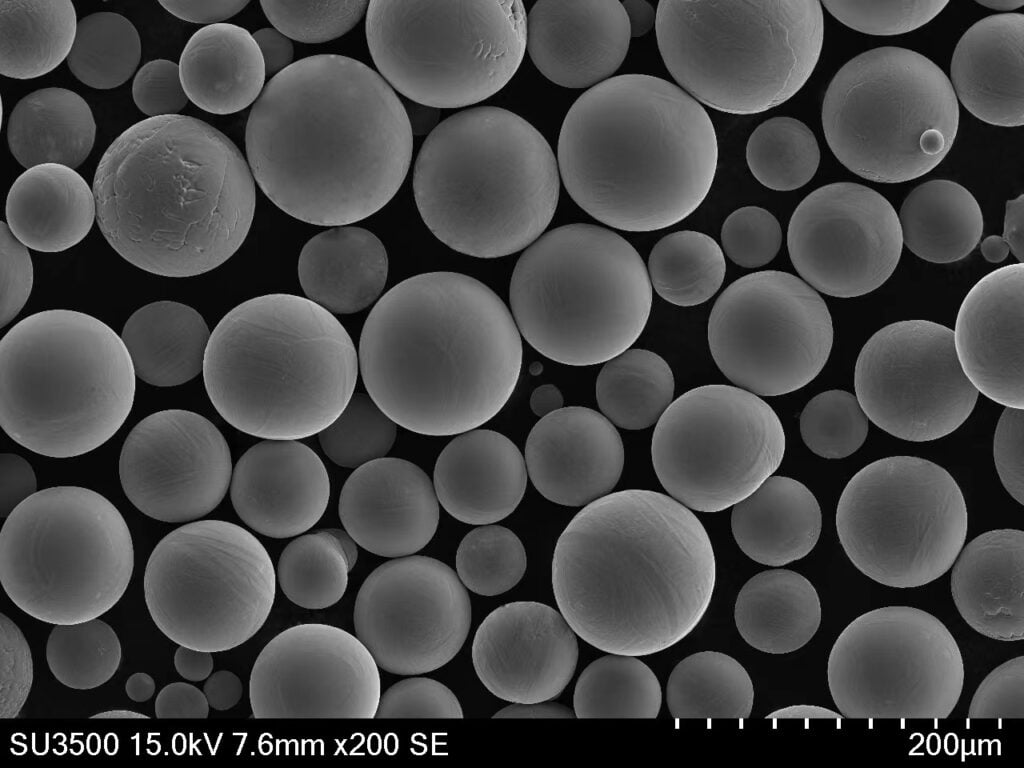

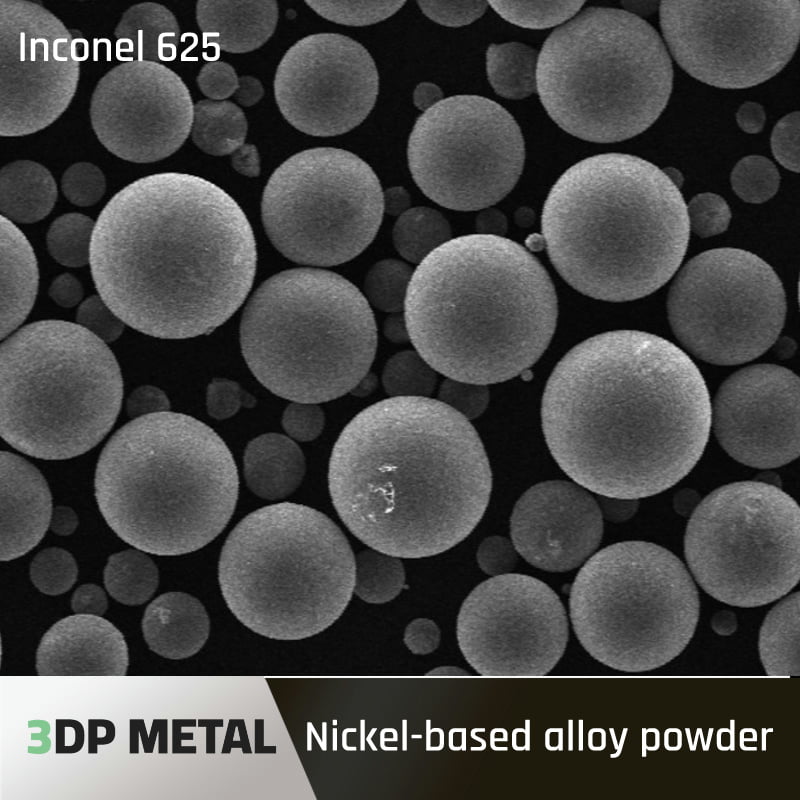

GH3625 är en högpresterande nickel-krombaserad superlegering som är känd för sin exceptionella oxidations- och korrosionsbeständighet, högtemperaturstabilitet och utmärkta mekaniska egenskaper. Denna legering används ofta i krävande miljöer, t.ex. inom flyg- och rymdindustrin, kraftgenerering och kemisk processindustri.

Viktiga detaljer:

- Sammansättning: Nickel-krom-baserad superlegering

- Egenskaper: Hög temperaturstabilitet, korrosions- och oxidationsbeständighet, utmärkt mekanisk hållfasthet

- Applikationer: Flyg- och rymdindustrin, kraftgenerering, kemisk bearbetning m.m.

Sammansättning av GH3625

Att förstå sammansättningen av GH3625 är avgörande för att uppskatta dess unika egenskaper. Denna legering är omsorgsfullt konstruerad med specifika element för att uppnå sin enastående prestanda.

| Element | Innehåll (%) |

|---|---|

| Nickel (Ni) | 58.0 – 63.0 |

| Krom (Cr) | 20.0 – 23.0 |

| Molybden (Mo) | 8.0 – 10.0 |

| Järn (Fe) | 5.0 – 7.0 |

| Niob (Nb) | 3.15 – 4.15 |

| Titan (Ti) | 0.65 – 1.15 |

| Aluminium (Al) | 0.2 – 0.8 |

| Kobolt (Co) | ≤ 1.0 |

| Mangan (Mn) | ≤ 0.35 |

| Kisel (Si) | ≤ 0.35 |

| Kol (C) | ≤ 0.10 |

Egenskaper för GH3625

GH3625 har en rad imponerande egenskaper som gör den lämplig för applikationer med höga påfrestningar:

- Stabilitet vid höga temperaturer: Bibehåller styrka och integritet vid förhöjda temperaturer.

- Oxiderings- och korrosionsbeständighet: Tål tuffa kemiska miljöer.

- Mekanisk hållfasthet: Ger utmärkt draghållfasthet och utmattningshållfasthet.

- Mångsidighet: Lämplig för olika tillverkningsprocesser, t.ex. additiv tillverkning och pulvermetallurgi.

Användningsområden för GH3625

GH3625 används inom många olika branscher tack vare sina robusta egenskaper. Här är en titt på några av de viktigaste tillämpningarna:

| Industri | Tillämpning |

|---|---|

| Flyg- och rymdindustrin | Turbinblad, avgassystem, förbränningskammare |

| Kraftgenerering | Gasturbiner, värmeväxlare |

| Kemisk bearbetning | Reaktorer, rörsystem, utrustning för värmebehandling |

| Marin | Motorkomponenter, ventiler, pumpar |

| Fordon | Rotorer för turboladdare, avgasgrenrör |

Specifikationer, storlekar, kvaliteter och standarder

När du väljer GH3625 för specifika applikationer är det viktigt att ta hänsyn till dess specifikationer, storlekar, kvaliteter och standarder.

| Parameter | Detaljer |

|---|---|

| Standarder | ASTM B443, B444, B446, AMS 5666, DIN 17751 |

| Betyg | GH3625, Inconel 625 |

| Storlekar | Finns i pulverform, stång, plåt och skivor |

| Specifikationer | Pulver: D50 10-45 mikron, Stänger: 1-100 mm diameter |

Specifika metallpulvermodeller

När det gäller metallpulver är det viktigt att ha flera olika modeller för att kunna göra ett exakt val baserat på den avsedda applikationen. Här är tio specifika modeller av GH3625 metallpulver, var och en med unika egenskaper:

- GH3625-P1: Idealisk för additiv tillverkning med en partikelstorlek på 15-45 mikrometer.

- GH3625-P2: Pulver med hög renhet avsett för kritiska komponenter inom flyg- och rymdindustrin.

- GH3625-P3: Optimerad för högtemperaturtillämpningar med förbättrad oxidationsbeständighet.

- GH3625-P4: Fint pulver (10-30 mikrometer) för precisionsdetaljer och komplicerade mönster.

- GH3625-P5: Medelstora partiklar (20-50 mikrometer) som lämpar sig för allmänt bruk.

- GH3625-P6: Pulver med hög flytbarhet för effektiva fusionsprocesser i pulverbädd.

- GH3625-P7: Förbättrad för kemiska processapplikationer med överlägsen korrosionsbeständighet.

- GH3625-P8: Speciellt anpassad för marina miljöer med ökad motståndskraft mot saltvatten.

- GH3625-P9: Utformad för komponenter i fordonsindustrin med utmärkt termisk stabilitet.

- GH3625-P10: Universalpulver med balanserade egenskaper för olika industriella användningsområden.

Leverantörer och prisuppgifter

Att välja rätt leverantör är avgörande för att säkerställa kvaliteten och tillförlitligheten hos GH3625. Här är några framstående leverantörer tillsammans med vägledande prisuppgifter:

| Leverantör | Plats | Pris (per kg) | Kontakt |

|---|---|---|---|

| Metalloy Corp | USA | $80 | www.metalloycorp.com |

| Avancerade legeringar | Tyskland | $85 | www.advancedalloys.de |

| NickelTech | STORBRITANNIEN | $90 | www.nickeltech.co.uk |

| Superlegerade metaller | Kina | $75 | www.superalloymetals.cn |

| TechMet | Japan | $95 | www.techmet.jp |

Jämförelse mellan GH3625 och andra legeringar

När man överväger GH3625 är det bra att jämföra den med andra liknande legeringar för att förstå dess fördelar och begränsningar.

| Fastighet | GH3625 | Inconel 718 | Hastelloy X |

|---|---|---|---|

| Temperaturstabilitet | Utmärkt | Mycket bra | Bra |

| Motståndskraft mot korrosion | Hög | Hög | Måttlig |

| Oxideringsbeständighet | Hög | Måttlig | Hög |

| Mekanisk styrka | Utmärkt | Mycket bra | Bra |

| Kostnad | Måttlig | Hög | Måttlig |

| Tillämpningar | Flyg- och rymdindustrin, Kraft | Flyg- och rymdindustrin, marinindustrin | Kemisk bearbetning |

Fördelar och nackdelar med GH3625

Fördelar:

- Prestanda vid höga temperaturer: GH3625 bibehåller sina mekaniska egenskaper vid förhöjda temperaturer, vilket gör den idealisk för tillämpningar inom flyg och kraftgenerering.

- Motståndskraft mot korrosion och oxidation: Dess robusta motståndskraft mot korrosiva och oxidativa miljöer säkerställer långvarig prestanda, särskilt i kemisk bearbetning och marina applikationer.

- Mångsidighet: Legeringens anpassningsförmåga till olika tillverkningsprocesser, inklusive additiv tillverkning, breddar dess användningsområde.

Nackdelar:

- Kostnad: Även om priset är måttligt kan GH3625 vara dyrare jämfört med vissa andra legeringar, vilket kan påverka budgetmedvetna projekt.

- Tillgänglighet: Beroende på leverantör och region kan tillgängligheten variera, vilket ibland leder till längre ledtider.

VANLIGA FRÅGOR

Låt oss avslutningsvis ta upp några vanliga frågor om GH3625:

| Fråga | Svar |

|---|---|

| Vad används GH3625 främst för? | GH3625 används främst inom flyg- och rymdindustrin, kraftproduktion, kemisk bearbetning, marin- och fordonstillämpningar. |

| Hur är GH3625 jämfört med Inconel 718? | GH3625 ger bättre oxidationsbeständighet och stabilitet vid höga temperaturer jämfört med Inconel 718, men kan vara dyrare. |

| Kan GH3625 användas vid additiv tillverkning? | Ja, GH3625 är lämplig för additiv tillverkning, särskilt när man använder finpulvermodeller som GH3625-P1 och GH3625-P4. |

| Vilka är de viktigaste elementen i GH3625:s komposition? | Viktiga beståndsdelar är nickel, krom, molybden, niob och titan. |

| Är GH3625 motståndskraftig mot korrosion? | Ja, GH3625 har utmärkt korrosionsbeständighet, vilket gör den idealisk för tuffa kemiska miljöer. |

| Vilka standarder överensstämmer GH3625 med? | GH3625 överensstämmer med standarder som ASTM B443, B444, B446, AMS 5666 och DIN 17751. |

Slutsats

GH3625 är en kraftfull legering som kombinerar hög temperaturstabilitet, korrosionsbeständighet och mekanisk styrka, vilket gör den till ett oumbärligt material i applikationer med hög belastning. Genom att förstå dess sammansättning, egenskaper och olika tillämpningar kan industrier utnyttja dess fulla potential för att driva innovation och effektivitet. Oavsett om du är verksam inom flyg, kraftproduktion eller kemisk bearbetning erbjuder GH3625 en tillförlitlig lösning för dina materialbehov.

Denna omfattande guide syftar till att förse dig med all viktig information om GH3625. Om du har några fler frågor eller behöver ytterligare information är du välkommen att kontakta de leverantörer som anges eller konsultera ytterligare resurser.

Dela på

MET3DP Technology Co, LTD är en ledande leverantör av lösningar för additiv tillverkning med huvudkontor i Qingdao, Kina. Vårt företag är specialiserat på 3D-utskriftsutrustning och högpresterande metallpulver för industriella tillämpningar.

Förfrågan för att få bästa pris och anpassad lösning för ditt företag!

Relaterade artiklar

Högpresterande segment för munstycksvingar: Revolutionerande turbineffektivitet med 3D-utskrift i metall

Läs mer "Om Met3DP

Senaste uppdateringen

Vår produkt

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731