Kopparpulver med hög renhet

Innehållsförteckning

Copper is one of the most versatile and widely used metals in the world. When it comes to applications demanding the highest quality, high-purity copper powder stands out. From electronics to aerospace, its uses are myriad and growing. Let’s dive deep into the world of high-purity copper powder, exploring its types, properties, applications, and much more.

Overview of High-Purity Copper Powder

High-purity copper powder is renowned for its exceptional electrical and thermal conductivity, corrosion resistance, and ease of fabrication. These qualities make it indispensable in industries ranging from electronics to manufacturing.

Viktiga detaljer

- Sammansättning: Typically >99.99% pure copper.

- Egenskaper: Excellent conductivity, malleability, and resistance to oxidation.

- Applikationer: Electronics, aerospace, 3D printing, medical devices, and more.

- Manufacturing Methods: Atomization, electrolysis, chemical reduction.

Typer av Kopparpulver med hög renhet

High-purity copper powder comes in various forms, each with specific characteristics suited to different applications. Here are some prominent models:

Elektrolytiskt kopparpulver

- Beskrivning: Produced through electrolytic refining, offering high purity and uniform particle size.

- Applikationer: Electrical and electronic components, batteries, conductive inks.

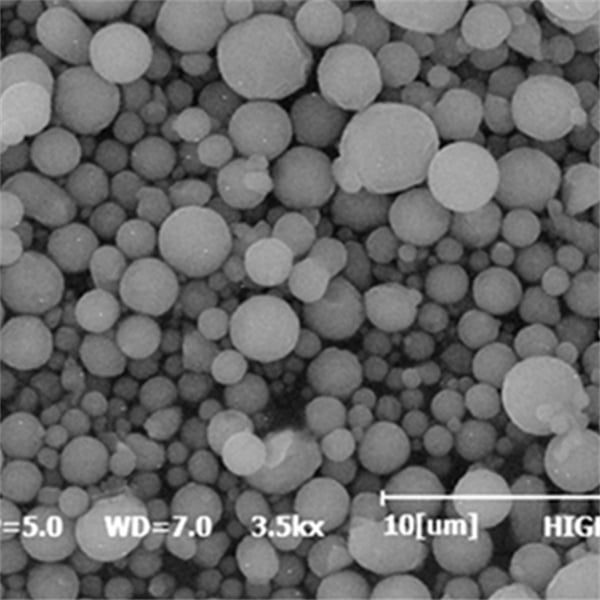

Atomiserat kopparpulver

- Beskrivning: Created by atomizing molten copper, resulting in spherical particles.

- Applikationer: Powder metallurgy, thermal spraying, 3D printing.

Reducerat kopparpulver

- Beskrivning: Obtained via chemical reduction of copper oxide, featuring irregular particle shapes.

- Applikationer: Catalysts, brazing, metal coatings.

Nano Copper Powder

- Beskrivning: Ultra-fine particles produced through physical or chemical methods.

- Applikationer: Conductive inks, nanocomposites, medical applications.

Spray-Dried Copper Powder

- Beskrivning: Fine copper particles dried using a spray process for consistency.

- Applikationer: High-density electronic components, conductive adhesives.

Electroless Copper Powder

- Beskrivning: Deposited through an autocatalytic reaction without electric current.

- Applikationer: Printed circuit boards, RFID tags, electroless plating.

Ultrafine Copper Powder

- Beskrivning: Extremely small particles with high surface area-to-volume ratio.

- Applikationer: Lubricants, sintering aids, high-performance alloys.

Sfäriskt kopparpulver

- Beskrivning: Round particles produced via gas or water atomization.

- Applikationer: Additive manufacturing, powder injection molding, thermal management materials.

Coated Copper Powder

- Beskrivning: Copper particles coated with other metals or compounds for enhanced properties.

- Applikationer: Specialized electronic components, corrosion-resistant coatings.

Granular Copper Powder

- Beskrivning: Larger, granular particles for specific industrial processes.

- Applikationer: Metallurgical processes, filtration, chemical production.

Kännetecken och egenskaper

| Typ | Sammansättning | Fastigheter | Egenskaper |

|---|---|---|---|

| Elektrolytiskt kopparpulver | >99.99% Cu | Hög renhet, enhetlig storlek | Utmärkt elektrisk ledningsförmåga |

| Atomiserat kopparpulver | >99.9% Cu | Sfärisk form, hög flytbarhet | Ideal for powder metallurgy |

| Reducerat kopparpulver | >99.8% Cu | Irregular shape, high surface area | Versatile industrial applications |

| Nano Copper Powder | >99.99% Cu | Ultra-fine particles, high reactivity | Advanced electronics and medical uses |

| Spray-Dried Copper Powder | >99.9% Cu | Consistent particle size, high density | Suitable for dense packing in electronics |

| Electroless Copper Powder | >99.95% Cu | Uniform deposition, high adhesion | Essential for printed circuit boards |

| Ultrafine Copper Powder | >99.99% Cu | Extremely fine, large surface area | Optimal for sintering and high-performance alloys |

| Sfäriskt kopparpulver | >99.9% Cu | Round particles, high packing density | Excellent for 3D printing and thermal management |

| Coated Copper Powder | Varies (Cu core) | Enhanced properties from coating | Specialized applications requiring specific traits |

| Granular Copper Powder | >99.5% Cu | Larger particles, robust | Ideal for metallurgical and chemical processes |

Tillämpningar av Kopparpulver med hög renhet

High-purity copper powder is indispensable across various industries. Here are some of the most prominent applications:

| Industri | Tillämpningar |

|---|---|

| Elektronik | Conductive inks, printed circuit boards, batteries |

| Flyg- och rymdindustrin | Structural components, thermal management |

| Medicintekniska produkter | Antimicrobial coatings, conductive adhesives |

| 3D-utskrift | Additive manufacturing, prototyping |

| Katalys | Catalysts for chemical reactions, environmental applications |

| Metallurgi | Alloy production, sintering aids |

| Fordon | Brake pads, friction materials, sensors |

| Förnybar energi | Solar cells, wind turbine components |

| Konstruktion | Roofing materials, architectural elements |

| Konsumentvaror | High-end audio equipment, jewelry |

Specifikationer, storlekar, kvaliteter och standarder

| Specifikation | Detalj |

|---|---|

| Renhet | >99.99% for high-purity copper powder |

| Partikelstorlek | Nano to granular, typically in microns (0.1-100 µm) |

| Form | Spherical, irregular, coated |

| Tillverkningsmetod | Atomization, electrolysis, chemical reduction |

| Branschstandarder | ASTM B748, ISO 4499, JIS H 2125 |

Leverantörer och prisuppgifter

| Leverantör | Produkt | Pris (per kg) | Anteckningar |

|---|---|---|---|

| ABC Metals | Elektrolytiskt kopparpulver | $75 | Hög renhet, jämn kvalitet |

| XYZ Materials | Nano Copper Powder | $1500 | Specialized for high-tech applications |

| CopperTech | Atomiserat kopparpulver | $60 | Excellent for powder metallurgy |

| PureCopper Co. | Reducerat kopparpulver | $55 | Versatile industrial use |

| NanoCopper Innovations | Ultrafine Copper Powder | $1200 | Suitable for advanced electronics |

Fördelar och nackdelar

| Fördelar | Nackdelar |

|---|---|

| Exceptionell elektrisk ledningsförmåga | Higher cost compared to lower-purity copper |

| Superior thermal conductivity | Oxidizes easily in air |

| High malleability and ductility | Requires careful handling and storage |

| Korrosionsbeständighet | Limited availability of certain types |

| Versatility in various applications | Complex manufacturing processes |

In-Depth Comparisons

Electrolytic vs. Atomized Copper Powder

Elektrolytiskt kopparpulver offers unmatched purity and is ideal for electronic applications due to its uniform particle size. Atomiserat kopparpulver, on the other hand, is perfect for powder metallurgy and additive manufacturing because of its spherical shape and high flowability.

Nano vs. Ultrafine Copper Powder

Nano Copper Powder excels in applications requiring high reactivity and surface area, such as advanced electronics and medical devices. Ultrafine Copper Powder also has a high surface area but is better suited for sintering and high-performance alloys due to its slightly larger particle size.

Reduced vs. Spray-Dried Copper Powder

Reducerat kopparpulver is versatile and widely used in industrial applications, thanks to its irregular particle shape. Spray-Dried Copper Powder is preferred in electronics for its consistent particle size and high density, making it ideal for dense packing.

Detailed Insights and Examples

Use in Electronics

Imagine the delicate circuit boards in your smartphone. They rely on the superior conductivity of high-purity copper powder to function flawlessly. The tiny copper pathways, crafted using electrolytic copper powder, ensure your device operates at lightning speed without overheating.

Tillämpningar inom flyg- och rymdindustrin

Consider the rigorous demands of aerospace components. High-purity copper powder, with its excellent thermal management properties, is used to manufacture parts that withstand extreme conditions, ensuring safety and efficiency in high-altitude flights.

Medicinska innovationer

In the medical field, the antimicrobial properties of copper are harnessed in devices and coatings. High-purity copper powder is used to create conductive adhesives and coatings for medical instruments, enhancing both functionality and hygiene.

Vanliga frågor

| Fråga | Svar |

|---|---|

| What is high-purity copper powder? | Copper powder with a purity of >99.99%, used for high-performance applications. |

| How is high-purity copper powder made? | Through methods like atomization, electrolysis, and chemical reduction. |

| Vilka är de viktigaste tillämpningarna? | Electronics, aerospace, medical devices, 3D printing, automotive components, and more. |

| Is high-purity copper powder expensive? | Yes, it tends to be pricier due to the cost of achieving high purity and specialized manufacturing processes. |

| How does high-purity copper powder compare to other metals? | It excels in conductivity and malleability compared to most metals but can oxidize more easily. |

Slutsats

High-purity copper powder is not just a material; it’s a cornerstone of modern technology. From enhancing the efficiency of electronics to pushing the boundaries of aerospace innovation, its versatility and performance are unmatched. Whether in the form of electrolytic, atomized, or nano powder, its applications continue to grow, driven by advancements in materials science and industrial demand.

As industries evolve, so does the role of high-purity copper powder, promising even greater feats in conductivity, durability, and environmental sustainability. Embrace its potential, and you’ll find yourself at the forefront of technological progress.

In conclusion, high-purity copper powder is more than just a substance; it’s a conduit for innovation and progress, powering the world forward one particle at a time.

Dela på

MET3DP Technology Co, LTD är en ledande leverantör av lösningar för additiv tillverkning med huvudkontor i Qingdao, Kina. Vårt företag är specialiserat på 3D-utskriftsutrustning och högpresterande metallpulver för industriella tillämpningar.

Förfrågan för att få bästa pris och anpassad lösning för ditt företag!

Relaterade artiklar

Högpresterande segment för munstycksvingar: Revolutionerande turbineffektivitet med 3D-utskrift i metall

Läs mer "Om Met3DP

Senaste uppdateringen

Vår produkt

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731