Järnpulver med hög renhet

Innehållsförteckning

Översikt över Järnpulver med hög renhet

Järnpulver med hög renhet är ett mycket mångsidigt material med tillämpningar inom många olika branscher, från fordonsindustrin till läkemedelsindustrin. Dess unika egenskaper, inklusive dess renhet och specifika partikelstorleksfördelning, gör det oumbärligt i tillverkningsprocesser som kräver precision och konsekvens. Men vad är det egentligen som gör järnpulver med hög renhet så speciellt? Låt oss dyka in i detaljerna och utforska allt som finns att veta om detta fascinerande material.

Vad är järnpulver med hög renhet?

Järnpulver med hög renhet är ett fint metalliskt ämne med en järnhalt som vanligtvis överstiger 99%. Denna höga renhetsgrad uppnås genom noggranna produktionsprocesser som avlägsnar orenheter och säkerställer en enhetlig partikelstorlek. Resultatet är ett pulver som erbjuder exceptionella prestandaegenskaper i en rad olika applikationer.

Olika typer av järnpulver med hög renhet

Järnpulver med hög renhet finns i olika former, var och en skräddarsydd för specifika användningsområden. Här är en närmare titt på några av de vanligaste typerna:

| Typ | Sammansättning | Fastigheter | Tillämpningar |

|---|---|---|---|

| Atomiserat järnpulver | Fe ≥ 99% | Hög kompressibilitet, god flytbarhet | Pulvermetallurgi, magnetiska material |

| Reducerat järnpulver | Fe ≥ 99,5% | Stor yta, oregelbunden form | Svetsning, kemisk reduktion |

| Elektrolytiskt järnpulver | Fe ≥ 99,9% | Mycket hög renhet, dendritisk struktur | Elektronik, delar med hög densitet |

| Karbonyljärnpulver | Fe ≥ 99,5%, C ≤ 0,1% | Sfäriska partiklar, hög renhet | Magnetiska bläck, induktorer, läkemedel |

| Ultrafint järnpulver | Fe ≥ 99,9%, partikelstorlek <1 µm | Extremt fina partiklar, hög ytarea | Katalysatorer, medicinska tillämpningar |

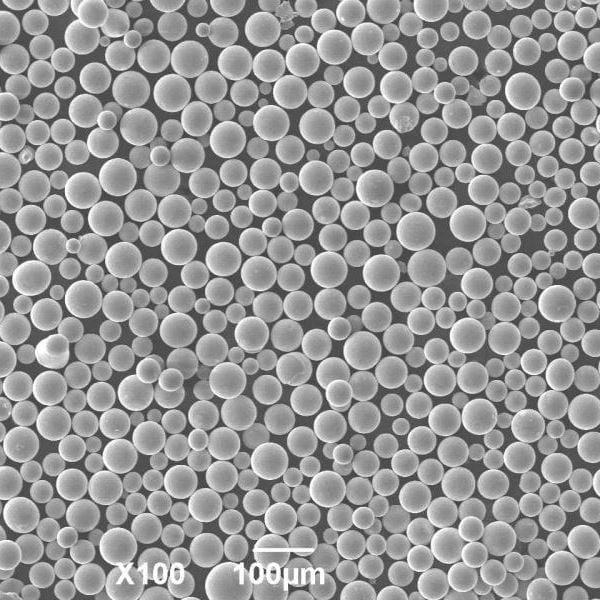

| Sfäriskt järnpulver | Fe ≥ 99,5%, sfärisk form | Utmärkt flytbarhet, enhetliga partiklar | Additiv tillverkning, MIM |

| Sprayformigt järnpulver | Fe ≥ 99,5% | Fina partiklar, jämn fördelning | Ytbeläggningar, sintring |

| Väte-reducerat järnpulver | Fe ≥ 99,8% | Hög renhet, fina partiklar | Pulvermetallurgi, magnetiska tillämpningar |

| Förlegerat järnpulver | Fe legerat med andra metaller | Skräddarsydda egenskaper, mångsidiga | Specialiserade delar, höghållfasta applikationer |

| Järngranulat med hög renhet | Fe ≥ 99,8%, granulär form | Hög bulkdensitet, enkel hantering | Gjutning, tillverkning av täta delar |

Tillämpningar av Järnpulver med hög renhet

Järnpulvers mångsidighet gör det till en värdefull komponent i en mängd olika branscher. Här är några viktiga tillämpningar:

| Industri | Tillämpning |

|---|---|

| Fordon | Pulvermetallurgiska delar, bromsbelägg, kopplingar |

| Elektronik | Magnetkärnor, induktorer, EMI-skärmning |

| Läkemedel | Järntillskott, magnetisk läkemedelstillförsel |

| Kemisk | Katalysatorer, reduktionsmedel |

| Additiv tillverkning | 3D-printing, formsprutning av metall (MIM) |

| Svetsning | Svetselektroder, rörtrådar |

| Ytbeläggningar | Skyddsbeläggningar, slitstarka skikt |

| Miljö | Vattenrening, marksanering |

| Berikning av livsmedel | Näringsmässiga järntillsatser |

| Flyg- och rymdindustrin | Lättviktiga strukturella komponenter |

Fordonsindustrin

Inom fordonssektorn är järnpulver med hög renhet oumbärligt för att skapa pulvermetallurgiska delar som erbjuder hög hållfasthet och slitstyrka. Dessa komponenter är viktiga för att tillverka hållbara och effektiva motorer, växellådor och bromssystem.

Elektronik

De unika magnetiska egenskaperna hos järnpulver med hög renhet gör det idealiskt för tillverkning av magnetkärnor och induktorer. Dessa komponenter är avgörande för att olika elektroniska enheter ska fungera effektivt, från transformatorer till sensorer.

Läkemedel

Inom läkemedelsindustrin används järnpulver med hög renhet för att skapa järntillskott som lätt absorberas av kroppen. Dessutom utnyttjas dess magnetiska egenskaper i innovativa system för läkemedelstillförsel, där magnetfält styr läkemedlet till dess målplats.

Kemisk industri

Som reduktionsmedel och katalysator spelar järnpulver med hög renhet en avgörande roll i olika kemiska processer. Dess höga ytarea och reaktivitet gör det lämpligt för att producera kemikalier på ett effektivt och säkert sätt.

Additiv tillverkning

Ökningen av 3D-utskrifter och formsprutning av metall (MIM) har öppnat nya möjligheter för järnpulver med hög renhet. Dess enhetliga partikelstorlek och utmärkta flytbarhet säkerställer exakt och repeterbar produktion av komplexa delar, vilket gör det till en stapelvara i modern tillverkning.

Fördelar med Järnpulver med hög renhet

Järnpulver med hög renhet erbjuder flera fördelar som gör det till ett förstahandsval i många applikationer. Här är en närmare titt:

| Fördel | Beskrivning |

|---|---|

| Hög renhet | Minimerar kontaminering, vilket ger jämn kvalitet och prestanda. |

| Utmärkt kompressibilitet | Underlättar tillverkningen av täta och starka detaljer i pulvermetallurgi. |

| Överlägsen flytbarhet | Förbättrar processeffektiviteten inom additiv tillverkning och MIM. |

| Hög ytarea | Ökar reaktiviteten i kemiska tillämpningar och katalys. |

| Skräddarsydd fördelning av partikelstorlek | Möjliggör anpassning till specifika applikationer och prestandabehov. |

| Mångsidighet | Lämplig för ett brett spektrum av industrier och användningsområden. |

Hög renhet

En av de utmärkande egenskaperna hos järnpulver med hög renhet är dess extremt låga nivå av föroreningar. Denna höga renhetsnivå säkerställer att pulvret kan användas i känsliga applikationer utan att kompromissa med prestanda eller kvalitet.

Utmärkt kompressibilitet

Järnpulvrets utmärkta kompressibilitet är avgörande inom pulvermetallurgi, där det pressas till komplexa former. Denna egenskap gör det möjligt att skapa starka, hållbara delar som tål rigorös användning.

Överlägsen flytbarhet

Pulvrets överlägsna flytbarhet är en betydande fördel vid additiv tillverkning och formsprutning av metall. Det säkerställer en jämn och konsekvent matning av pulvret till formar eller skrivare, vilket resulterar i högkvalitativa, felfria delar.

Nackdelar med järnpulver med hög renhet

Trots sina många fördelar har järnpulver med hög renhet också vissa nackdelar som måste beaktas:

| Nackdel | Beskrivning |

|---|---|

| Kostnad | Järnpulver med hög renhet är dyrare än alternativ med lägre renhet. |

| Känslighet för kontaminering | Kräver noggrann hantering och förvaring för att bibehålla renhetsgraden. |

| Begränsad tillgänglighet | Är kanske inte lika lättillgängligt som andra typer av järnpulver. |

| Specifika krav på bearbetning | Kräver specialutrustning och processer för optimal prestanda. |

Kostnad

Den primära nackdelen med järnpulver med hög renhet är dess kostnad. På grund av de omfattande reningsprocesser som krävs är det dyrare än standardjärnpulver, vilket kan vara en begränsande faktor för vissa applikationer.

Känslighet för kontaminering

För att bibehålla järnpulvrets höga renhet krävs strikta hanterings- och lagringsrutiner. Även mindre föroreningar kan påverka dess prestanda avsevärt, vilket gör att noggrann hantering är avgörande.

Begränsad tillgänglighet

Järnpulver med hög renhet är inte lika allmänt tillgängligt som varianter med lägre renhet. Detta kan innebära utmaningar för leveranskedjan, särskilt för industrier som kräver stora volymer av materialet.

Specifika krav på bearbetning

För att utnyttja järnpulver med hög renhet till sin fulla potential krävs ofta specialutrustning och processer. Detta kan medföra ytterligare investeringar och expertis, vilket kanske inte är genomförbart för alla användare.

Jämförelse av modeller för järnpulver med hög renhet

När du väljer järnpulver med hög renhet är det viktigt att jämföra olika modeller baserat på specifika parametrar. Här är en detaljerad jämförelse:

| Modell | Partikelstorlek | Renhet (%) | Form | Tillämpningar | Fördelar | Nackdelar |

|---|---|---|---|---|---|---|

| Atomiserat järnpulver | 10-150 µm | ≥ 99% | Sfärisk | Pulvermetallurgi, magnetiska material | God flytbarhet, kompressibilitet | Högre kostnad jämfört med reducerat pulver |

| Reducerat järnpulver | 45-150 µm | ≥ 99,5% | Oregelbunden | Svetsning, kemisk reduktion | Hög ytarea | Oregelbunden form påverkar flytbarheten |

| Elektrolytiskt järnpulver | 2-50 µm | ≥ 99,9% | Dendritisk | Elektronik, delar med hög densitet | Mycket hög renhet | Kostsamt, känsligt för kontaminering |

| Karbonyljärnpulver | 1-10 µm | ≥ 99,5% | Sfärisk | Magnetiska bläck, läkemedel | Hög renhet, sfärisk form | Dyr produktionsprocess |

| Ultrafint järnpulver | <1 µm | ≥ 99,9% | Sfärisk | Katalysatorer, medicinska tillämpningar | Extremt fina partiklar | Utmaningar vid hantering och förvaring |

| Sfäriskt järnpulver | 10-150 µm | ≥ 99,5% | Sfärisk | Additiv tillverkning, MIM | Utmärkt flytbarhet | Högre produktionskostnad |

| Sprayformigt järnpulver | 5-50 µm | ≥ 99,5% | Oregelbunden | Ytbeläggningar, sintring | Fina partiklar, jämn fördelning | Oregelbunden form påverkar flytbarheten |

| Väte-reducerat järnpulver | 20-100 µm | ≥ 99,8% | Oregelbunden | Pulvermetallurgi, magnetiska tillämpningar | Hög renhet, fina partiklar | Oregelbunden form påverkar flytbarheten |

| Förlegerat järnpulver | 10-150 µm | Fe-legerad | Variabel | Specialiserade delar | Skräddarsydda fastigheter | Komplexitet i produktionen |

| Järngranulat med hög renhet | 100-500 µm | ≥ 99,8% | Granulärt | Gjutning, tillverkning av täta delar | Enkel hantering, hög bulkdensitet | Begränsad till specifika tillämpningar |

Specifikationer och standarder

Att förstå specifikationerna och standarderna för järnpulver med hög renhet är avgörande för att säkerställa att det uppfyller kraven i din applikation. Här är en detaljerad titt på specifikationerna:

| Specifikation | Beskrivning |

|---|---|

| Fördelning av partikelstorlek | Olika partikelstorlekar inom pulvret |

| Renhetsgrad | Procentuell andel av järninnehållet |

| Form | Partiklarnas morfologi (sfäriska, oregelbundna, dendritiska) |

| Bulkdensitet | Vikt per volymenhet av pulvret |

| Flödeshastighet | Hastighet med vilken pulvret flödar |

| Kompressibilitet | Förmåga att komprimeras till en fast form |

| Skenbar densitet | Pulvrets densitet när det är löst packat |

| Grön styrka | Styrkan hos det kompakta pulvret före sintring |

Detaljerade specifikationer

| Fastighet | Värdeintervall |

|---|---|

| Partikelstorlek | 1 µm till 150 µm |

| Renhet | 99% till 99.99% |

| Bulkdensitet | 2,5 g/cm³ till 5,0 g/cm³ |

| Flödeshastighet | 30 s/50 g till 120 s/50 g |

| Kompressibilitet | 6 g/cm³ till 7,5 g/cm³ |

| Skenbar densitet | 2,8 g/cm³ till 4,5 g/cm³ |

| Grön styrka | 15 MPa till 60 MPa |

Standarder

Järnpulver med hög renhet följer olika industristandarder för att säkerställa kvalitet och prestanda. Några viktiga standarder inkluderar:

- ASTM B213: Standardprovningsmetoder för flödeshastighet hos metallpulver

- ASTM B328: Standardprovningsmetod för metallpulvers densitet

- ISO 4490: Metallpulver - Bestämning av flödeshastigheten med hjälp av en kalibrerad tratt (Hall-flödesmätare)

- ISO 3923-1: Metallpulver - Bestämning av skrymdensitet - Del 1: Trattmetoden

Leverantörer och prissättning

Tillgängligheten och kostnaden för järnpulver med hög renhet kan variera avsevärt beroende på leverantör och specifik modell. Här är en titt på några av de ledande leverantörerna och deras prissättningsdetaljer:

| Leverantör | Modell | Pris (USD/kg) | Anteckningar |

|---|---|---|---|

| Höganäs AB | Atomiserat järnpulver | $15 – $30 | Hög kvalitet, pålitlig leverantör |

| BASF | Karbonyljärnpulver | $80 – $120 | Mycket hög renhet, specialtillämpningar |

| Rio Tinto Metallpulver | Reducerat järnpulver | $10 – $25 | Konkurrenskraftiga priser, god tillgänglighet |

| JFE Steel Corporation | Elektrolytiskt järnpulver | $100 – $150 | Premiumkvalitet, hög renhet |

| GKN Hoeganaes | Sfäriskt järnpulver | $20 – $40 | Utmärkt flytbarhet, mångsidiga användningsområden |

| Sandvik Osprey | Sprayformigt järnpulver | $50 – $90 | Hög enhetlighet, fina partiklar |

| Shanghai CNPC Pulvermaterial | Ultrafint järnpulver | $200 – $300 | Specialapplikationer, hög ytarea |

| NIPPON STÅL & SUMITOMO METALL | Förlegerat järnpulver | $25 – $60 | Anpassade egenskaper |

| Erasteel Kloster AB | Järngranulat med hög renhet | $10 – $20 | Enkel hantering, stora användningsområden |

| Carpenter Technology Corporation | Väte-reducerat järnpulver | $30 – $50 | Hög renhet, fokus på pulvermetallurgi |

Jämförelse av fördelar och begränsningar

Att förstå för- och nackdelarna med järnpulver med hög renhet hjälper till att fatta ett välgrundat beslut. Här är en jämförande översikt:

| Fördel | Begränsning |

|---|---|

| Hög renhet | Högre kostnad |

| Utmärkt kompressibilitet | Känslighet för kontaminering |

| Överlägsen flytbarhet | Specifika krav på bearbetning |

| Hög ytarea | Begränsad tillgänglighet |

| Mångsidiga tillämpningar | Utmaningar vid hantering och förvaring |

Fördelar

Järnpulvrets höga renhet garanterar minimal kontaminering och konsekvent prestanda, vilket gör det lämpligt för kritiska applikationer inom branscher som läkemedel och elektronik. Dess utmärkta kompressibilitet och överlägsna flytbarhet förbättrar tillverkningseffektiviteten och produktkvaliteten.

Begränsningar

Dessa fördelar har dock ett pris. Järnpulver med hög renhet är dyrare än sina motsvarigheter med lägre renhet och kräver noggrann hantering för att undvika kontaminering. Dessutom kan dess specifika bearbetningskrav och begränsade tillgänglighet utgöra utmaningar för vissa användare.

Vanliga frågor

Varför är det viktigt med hög renhet i järnpulver?

Hög renhet i järnpulver minimerar risken för kontaminering, vilket säkerställer jämn kvalitet och prestanda i känsliga applikationer. Detta är särskilt viktigt i branscher som läkemedelsindustrin, där även mindre föroreningar kan ha en betydande inverkan på produkternas säkerhet och effektivitet.

Hur mäts renheten hos järnpulver?

Renheten hos järnpulver mäts med hjälp av tekniker som t.ex:

- Röntgenfluorescens (XRF): Bestämmer grundämnessammansättningen.

- Induktivt kopplad plasma (ICP): Analyserar spårämnen.

- Kol-svavel-analys: Mäter kol- och svavelinnehåll.

Vilka är lagringskraven för järnpulver med hög renhet?

För att bibehålla sin höga renhet bör järnpulver förvaras i:

- Förseglade behållare: För att förhindra kontaminering.

- Torra miljöer: För att undvika oxidation och fuktabsorption.

- Temperaturkontrollerade områden: För att upprätthålla stabilitet och förhindra nedbrytning.

Kan järnpulver med hög renhet användas i 3D-utskrifter?

Ja, järnpulver med hög renhet används ofta vid 3D-utskrift, särskilt för att tillverka höghållfasta, komplexa delar. Dess utmärkta flytbarhet och enhetliga partikelstorleksfördelning gör det idealiskt för additiva tillverkningsprocesser.

Vilka är miljöeffekterna av att producera järnpulver med hög renhetsgrad?

Produktionen av järnpulver med hög renhet omfattar energiintensiva processer och kan generera utsläpp. Framsteg inom tillverkningstekniken bidrar dock till att minska miljöavtrycket, med fokus på att förbättra energieffektiviteten och implementera hållbara metoder.

Är järnpulver med hög renhet återvinningsbart?

Ja, järnpulver med hög renhet kan återvinnas. Återvunnet järnpulver kan upparbetas och återanvändas i olika applikationer, vilket bidrar till resursbevarande och hållbarhetsinsatser i branschen.

Hur påverkar partikelstorleken prestandan hos järnpulver med hög renhet?

Partikelstorleken har en betydande inverkan på prestandan hos järnpulver med hög renhet. Finare partiklar ger en större yta, vilket ökar reaktiviteten i kemiska processer. Omvänt ger större partiklar bättre flytbarhet och kompressibilitet, vilket är avgörande för pulvermetallurgi och additiv tillverkning.

Vilka är några vanliga kvalitetskontrollåtgärder för järnpulver med hög renhet?

Vanliga åtgärder för kvalitetskontroll inkluderar:

- Regelbunden analys av renheten: Säkerställa att pulvret uppfyller de renhetsnivåer som krävs.

- Test av partikelstorleksfördelning: Bekräftar enhetlighet och konsekvens.

- Test av flytbarhet och kompressibilitet: Verifiering av pulvrets lämplighet för specifika applikationer.

Hur är järnpulver med hög renhet jämfört med andra metallpulver?

Järnpulver med hög renhet jämförs ofta med andra metallpulver som aluminium, koppar och titan. Var och en har unika egenskaper och applikationer:

| Fastighet | Järnpulver med hög renhet | Aluminiumpulver | Kopparpulver | Titanpulver |

|---|---|---|---|---|

| Renhet | ≥ 99% | ≥ 99% | ≥ 99% | ≥ 99% |

| Täthet | 7,87 g/cm³ | 2,70 g/cm³ | 8,96 g/cm³ | 4,50 g/cm³ |

| Elektrisk konduktivitet | Måttlig | Hög | Mycket hög | Låg |

| Motståndskraft mot korrosion | Måttlig | Hög | Måttlig | Mycket hög |

| Tillämpningar | Pulvermetallurgi, elektronik, läkemedel | Lättviktsdelar, pyroteknik | Ledande bläck, metallurgi | Flyg- och rymdindustrin, medicinska implantat |

Slutsats

Järnpulver med hög renhet är ett anmärkningsvärt material med ett brett spektrum av tillämpningar och fördelar. Dess exceptionella renhet, utmärkta kompressibilitet och överlägsna flytbarhet gör det till en oumbärlig komponent i olika industrier. Dess högre kostnad, känslighet för föroreningar och specifika bearbetningskrav visar dock att det krävs noggranna överväganden vid val och användning av detta material. Genom att förstå dess egenskaper, tillämpningar, fördelar och begränsningar kan du fatta välgrundade beslut för att utnyttja den fulla potentialen hos järnpulver med hög renhet i dina projekt.

Dela på

MET3DP Technology Co, LTD är en ledande leverantör av lösningar för additiv tillverkning med huvudkontor i Qingdao, Kina. Vårt företag är specialiserat på 3D-utskriftsutrustning och högpresterande metallpulver för industriella tillämpningar.

Förfrågan för att få bästa pris och anpassad lösning för ditt företag!

Relaterade artiklar

Högpresterande segment för munstycksvingar: Revolutionerande turbineffektivitet med 3D-utskrift i metall

Läs mer "Om Met3DP

Senaste uppdateringen

Vår produkt

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731