Pulver av metallegeringar

Innehållsförteckning

Pulver av metallegeringar möjliggör tillverkning av högpresterande delar med hjälp av pulvermetallurgiska pressnings- och sintringsmetoder eller additiva tillverkningsmetoder inom transport-, industri-, medicin- och energiindustrin. Den här guiden omfattar olika legeringsalternativ, pulverproduktionsprocesser, viktiga specifikationer, användningsområden, kvalitetshänsyn och inköpsrådgivning.

Olika typer av pulver av metallegeringar

Gemensamma kategorier:

| Typ | Exempel | Viktiga egenskaper |

|---|---|---|

| Nickellegeringar | Inconel, Monel, Hastelloy | Korrosionsbeständighet, värmebeständighet |

| Koboltlegeringar | MP35N, Haynes 25, Stellit | Slitstyrka, biokompatibilitet |

| Titanlegeringar | CP-kvalitet, Ti-6Al-4V, Ti-6Al-7Nb | Hög hållfasthet, låg vikt |

| Rostfria stål | 316, 17-4PH, 15-5PH | Korrosionsbeständighet, hållfasthet |

| Verktygsstål | H13, M2, M4, P20 | Slitstyrka, seghet |

| Kopparlegeringar | Krom koppar, Mässing, Brons | Elektrisk och termisk ledningsförmåga |

Anpassa legeringsmaterialets egenskaper till kritiska krav på detaljens prestanda, t.ex. värmetolerans, hårdhet, utmattningslivslängd etc. genom att välja pulverkvalitet.

Metoder för produktion av metallpulver

Viktiga tillverkningsprocesser i kommersiell skala:

- Atomisering av gas - Inert gas under högt tryck bryter upp smält metallström till fina droppar. Uppnår sfäriska pulver med bra flödes- och packningsegenskaper. Olika munstycken genererar önskade storleksintervall.

- Plasmaatomisering - Plasmabåge med hög energi smälter råmaterialet. Kraftfulla induktionsspolar genererar droppar som stelnar till sfäriska pulver med snäva partikelfördelningar.

- Roterande elektrod - Centrifugalkrafter som verkar på en roterande smält legering som utsätts för inerta gasstrålar orsakar sönderdelning i fina droppar som resulterar i sfäriska pulver.

- Elektrolys - Metalljoner från lösningen plattas ut på katoderna som fina pulverpartiklar. Används för reaktiva material som aluminium, magnesium och titan.

Kontroll av processparametrar som temperatur, atmosfär och kylhastighet resulterar i ett högkvalitativt pulvermaterial för tillverkning av detaljer med additiv tillverkning eller pulvermetallurgisk kompaktering.

Typiska specifikationer

| Parameter | Beskrivning | Testmetod |

|---|---|---|

| Renhet | >99%, minimera föroreningar | ICP-analys |

| Partikelns form | Sfärisk >80% | Mikroskopi |

| Fördelning av partikelstorlek | Snäva intervall enligt behov | Laserdiffraktion |

| Tappdensitet | Materialberoende | Hall-flödesmätare |

| Skenbar densitet | Materialberoende | Pyknometri |

| Flödeshastigheter | Standardiserad för varje nominell storlek | Hall-flödesmätare |

| Oxider på ytan | <3000 ppm; oxidtjocklek | Fusion i inert gas; XRD |

Granska statistiska batchdata från tillverkaren mot dessa mätvärden som är specifika för din målkvalitet och bekräfta kvalitet och konsekvens i förhållande till standarder.

Tillämpningar

Tillämpningar för pulver av metallegeringar:

Flyg- och rymdindustrin - Motorkomponenter som blad, munstycken; flygplansdelar, delar till landningsställ; ombordsystem

Industriell - Pumpar, ventiler, borrkronor för naturgas/petroleum; verktygsinsatser; kärnreaktorer; värmeväxlare

Fordon - Motorkomponenter, turboladdningsrotorer, kugghjul; chassi, drivlinor

Medicinsk - Implantat för knä, höft, tand; kirurgiska verktyg; bildbehandlingsinstrument

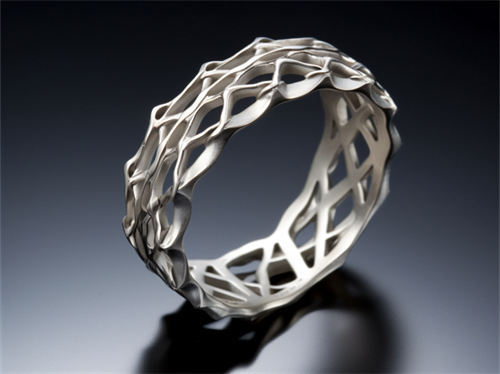

Konsument - Högklassiga klockor, sportutrustning som cyklar, golfklubbor etc. som kräver styrka och estetik

Energi - Solcellskontakter, elektroder; generatorer; batterikomponenter; vindturbiner

Utnyttja materialens varierande egenskaper med designfrihet och precision.

Industriella standarder

Viktiga specifikationer som gäller för Pulver av metallegeringar:

| Standard | Beskrivning |

|---|---|

| ASTM B213 | Standardiserat klassificeringssystem för metallpulver |

| ISO 4490 | Kemisk analys, provtagningsförfaranden |

| ASTM B822 | Mätning av skenbar densitet och flödeshastighet |

| MPIF 04 | Statistiska metoder för analys av metallpulver |

Granska statistiskt validerade intyg som visar överensstämmelse med gränser för kvalitetssammansättning och produktionskvalitet i förhållande till tillämpliga standarder.

Vanliga metallpulverkvaliteter

| Legering | Handelsnamn | Specifikationer | |

|---|---|---|---|

| Nickellegeringar | Inconel 718, 625; Hastelloy X; Monel K500 | AMS 5662, 5663 etc. | |

| Koboltlegeringar | MP35N, Haynes 25, Stellit 21 | ASTM F90, F1537 etc. | |

| Titanlegeringar | Ti-6Al-4V klass 5; Ti-6Al-7Nb ; CP Ti klass 2 | AMS 4911, ASTM B348 etc. | |

| Rostfria stål | SS 316L; 17-4PH; 15-5 PH; | ASTM A240, B945 etc. | |

| Verktygsstål | H13; M2; M4; P20+Ni | AISI-typer | ASTM A681 |

| Kopparlegeringar | C18150, C19500, C95810 | UNS nr, ASTM B194 etc. |

Matcha målkvalitet med tillämpliga legeringsspecifikationer som överensstämmer med funktionskraven för den färdiga detaljen när det gäller parametrar för styrka, ledningsförmåga och korrosionsbeständighet.

Överväganden om kvalitet

| Metrisk | Syfte | Testmetod |

|---|---|---|

| Sammansättning | Verifiera kvalitetens renhet | ICP-analys |

| Fördelning av partikelstorlek | AM-kompatibilitet, sintringsrespons | Laserdiffraktion |

| Hall flödeshastighet | Pulverpackningens densitet, skiktets enhetlighet | Hall-flödesmätare |

| Tappdensitet | Indikerar den slutliga deldensiteten | Väg uppmätt volym |

| Skenbar densitet | Pulversystemets densitet | Pyknometri för gas |

| Partikelns form | Sfäriskhet optimerar egenskaper | Mikroskopi |

| Oxider på ytan | Påverkar återanvändning av pulver | Fusionsanalysator för inert gas |

Konsekvent kvalitet enligt dessa mått är direkt korrelerad med konsekvent prestanda för slutprodukten som uppfyller specifikationerna.

Överväganden om inköp

| Parameter | Betydelse |

|---|---|

| Batch-datablad | Hög |

| Stöd för provtagning | Hög |

| Ledtid | Medium |

| Anpassning | Låg |

| Prisfaktorer | Låg |

Prova pulverprover innan du gör ett större inköp för att kontrollera tryck- eller kompressionsrespons i förhållande till applikationsbehoven.

Vanliga frågor

F: Vad är skillnaden mellan förlegerade och blandade elementpulver?

S: Förlegerade pulver har en enhetlig sammansättning genom varje sfärisk partikel. Blandade elementblandningar kan ha små skillnader i sammansättningen mellan partiklarna som kan skapa inhomogeniteter i de slutliga delarna.

F: Bör metallpulver förvaras under särskilda förhållanden?

A: Förvaras förseglat med torkmedel på avstånd från fukt och syre som orsakar försämring. Begränsa temperaturvariationen till 10-30°C. Kassera vid kraftig missfärgning, kakbildning eller betydande flödesförlust. Hållbarheten är normalt över ett år vid korrekt förvaring.

F: Vilka är de vanligaste blandningarna av metallpulver?

S: Pulverblandningar av kobolt-krom, rostfritt stål-17-4PH och nickellegering-rostfritt stål erbjuder sätt att skräddarsy materialegenskaper för slutdelen, t.ex. styrka, slitstyrka eller korrosionsbeständighet, till lägre kostnader än högrena kvaliteter.

F: Vilka försiktighetsåtgärder krävs vid hantering av metallpulver?

A: Använd lämplig personlig skyddsutrustning och undvik hudkontakt eller inandning vid pulverhantering. Passiverade pulver utgör mindre hälsorisker jämfört med finfördelade pulver som kan vara mer reaktiva. Läs igenom säkerhetsdatabladen om brandfarlighet, reaktivitet och exponeringsprotokoll.

Dela på

MET3DP Technology Co, LTD är en ledande leverantör av lösningar för additiv tillverkning med huvudkontor i Qingdao, Kina. Vårt företag är specialiserat på 3D-utskriftsutrustning och högpresterande metallpulver för industriella tillämpningar.

Förfrågan för att få bästa pris och anpassad lösning för ditt företag!

Relaterade artiklar

Högpresterande segment för munstycksvingar: Revolutionerande turbineffektivitet med 3D-utskrift i metall

Läs mer "Om Met3DP

Senaste uppdateringen

Vår produkt

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731