Laser Solid Forming (LSF)

Innehållsförteckning

Laser Solid Forming (LSF) är en revolutionerande teknik inom additiv tillverkning. Den kombinerar principerna för laserbeklädnad och 3D-utskrift för att skapa högprecision, högpresterande metalldelar direkt från digital design. Processen använder en laser för att smälta samman metallpulver till fasta föremål, lager för lager, vilket resulterar i delar med utmärkta mekaniska egenskaper och komplexa geometrier. Låt oss dyka djupt in i LSF:s krångligheter och utforska dess typer, tillämpningar, fördelar, begränsningar och mer.

Översikt över Laser Solid Forming (LSF)

LSF utmärker sig inom additiv tillverkning för sin förmåga att producera delar med överlägsna mekaniska egenskaper och intrikata design. Denna teknik är särskilt fördelaktig för industrier som kräver högpresterande komponenter, såsom flyg-, bil- och medicintekniska produkter. Genom att använda en kraftfull laser smälter LSF metallpulver som deponeras exakt lager för lager och bildar en solid struktur. Denna metod säkerställer hög noggrannhet, minimalt avfall och förmågan att producera komplexa former som skulle vara utmanande eller omöjliga med traditionella tillverkningstekniker.

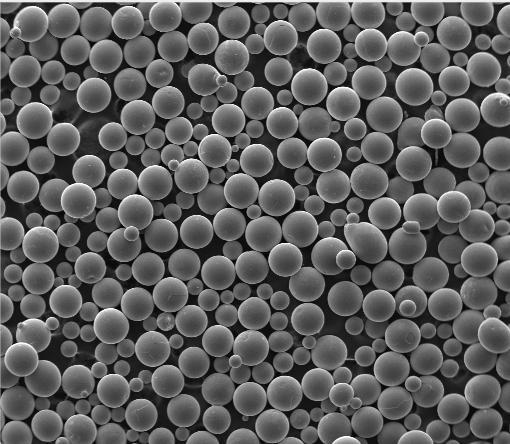

Typer av metallpulver som används i LSF

Olika metallpulver används i LSF för att tillgodose olika applikationsbehov. Här är tio specifika metallpulvermodeller som vanligtvis används i LSF:

| Metallpulver | Sammansättning | Fastigheter | Egenskaper |

|---|---|---|---|

| Inconel 718 | Nickel-krom | Hög hållfasthet, korrosionsbeständighet | Utmärkt svetsbarhet, används inom flyg |

| Ti-6Al-4V | Titanlegering | Högt förhållande mellan styrka och vikt | Biokompatibel, används i medicinska implantat |

| 316L rostfritt stål | Krom-nickel-molybden | Korrosionsbeständighet, goda mekaniska egenskaper | Används ofta i marina applikationer |

| AlSi10Mg | Aluminiumlegering | Låg vikt, god värmeledningsförmåga | Idealisk för bildelar |

| Maråldrat stål | Nickel-kobolt | Ultrahög hållfasthet | Används inom verktygs- och flygindustrin |

| Kobolt-Krom | Kobolt-krom-molybden | Hög slitstyrka och korrosionsbeständighet | Vanligt vid tand- och medicinska implantat |

| H13 Verktygsstål | Krom-molybden | Hög seghet och slitstyrka | Används i formar och stansar |

| Koppar (Cu) | Ren koppar | Utmärkt termisk och elektrisk ledningsförmåga | Används i elektriska komponenter |

| NiTi (nitinol) | Nickel-titan | Formminne och superelasticitet | Används i medicintekniska produkter och ställdon |

| Tantal (Ta) | Ren tantal | Hög korrosionsbeständighet | Används i kemisk bearbetningsutrustning |

Tillämpningar av Laser Solid Forming (LSF)

LSF:s mångsidighet gör att den kan användas inom ett brett spektrum av industrier. Här är några applikationer:

| Industri | Tillämpning | Fördelar |

|---|---|---|

| Flyg- och rymdindustrin | Turbinblad, strukturella komponenter | Lättvikt, hög hållfasthet, komplexa geometrier |

| Fordon | Motordelar, anpassade komponenter | Minskad vikt, förbättrad prestanda |

| Medicinsk | Implantat, kirurgiska verktyg | Biokompatibilitet, anpassning |

| Energi | Turbiner, värmeväxlare | Hög effektivitet, korrosionsbeständighet |

| Verktyg | Gjutformar, matriser | Hög slitstyrka, precision |

| Försvar | Vapenkomponenter, rustning | Hållbarhet, komplexa konstruktioner |

| Elektronik | Kontaktdon, kylflänsar | Utmärkt värmeledningsförmåga |

| Smycken | Anpassad design, invecklade mönster | Hög precision, unik estetik |

| Marin | Propellrar, skrovkomponenter | Korrosionsbeständighet, hållfasthet |

| Konstruktion | Konstruktionsdelar, reparationsarbete | Hållbarhet, tillverkning på plats |

Specifikationer, storlekar, betyg och standarder i LSF

Olika branscher kräver delar med specifika standarder och specifikationer. Här är en tabell som sammanfattar några viktiga specifikationer:

| Specifikation | Detaljer |

|---|---|

| Laserkraft | 200W till 10kW |

| Skiktets tjocklek | 20-100 mikrometer |

| Byggvolym | Upp till 1m³ |

| Upplösning | ±0,05 mm |

| Ytfinish | Så lågt som Ra 1,6 µm |

| Standarder | ISO/ASTM 52900, ASME BPVC, AMS 4999 |

| Materialkvaliteter | Inconel 718, Ti-6Al-4V Grade 23, 316L, AlSi10Mg |

Leverantörer och prisuppgifter för LSF-metallpulver

När du väljer metallpulver för LSF är det avgörande att ta hänsyn till leverantörer och prissättning. Här är en översikt:

| Leverantör | Metallpulver | Pris (per kg) | Kommentarer |

|---|---|---|---|

| Höganäs | Inconel 718 | $150-$200 | Hög renhet, jämn kvalitet |

| Sandvik | Ti-6Al-4V | $250-$350 | Medicinsk kvalitet, utmärkta egenskaper |

| Snickeriteknik | 316L rostfritt stål | $50-$80 | Allmänt tillgänglig, kostnadseffektiv |

| LPW-teknik | AlSi10Mg | $70-$100 | Högkvalitativ, pålitlig leverantör |

| GKN Additiv | Maråldrat stål | $200-$300 | Ultrahög styrka, premiumkvalitet |

| HC Starck | Kobolt-Krom | $150-$250 | Idealisk för medicinska tillämpningar |

| Arcam AB | H13 Verktygsstål | $100-$150 | Hög seghet, slitstyrka |

| Oerlikon Metco | Koppar | $60-$90 | Utmärkt ledningsförmåga, ren kvalitet |

| ATI speciallegeringar | NiTi (nitinol) | $300-$450 | Premiumkvalitet, formminne |

| Globala avancerade metaller | Tantalum | $400-$600 | Hög korrosionsbeständighet, ren |

Fördelar med Laser Solid Forming (LSF)

LSF erbjuder många fördelar jämfört med traditionella tillverkningsmetoder:

- Hög precision och noggrannhet: LSF möjliggör skapandet av mycket detaljerade delar med snäva toleranser.

- Materialeffektivitet: Minimalt avfall genereras, eftersom processen endast använder det material som behövs för delen.

- Komplexa geometrier: Kan producera intrikata mönster som är omöjliga med konventionella metoder.

- Anpassning: Delar kan skräddarsys efter specifika krav, perfekt för skräddarsydda applikationer.

- Kortare ledtid: Snabbare produktion jämfört med traditionell tillverkning, speciellt för komplexa delar.

- Överlägsna mekaniska egenskaper: Den skiktade strukturen kan förbättra den sista delens mekaniska egenskaper.

Nackdelar med Laser Solid Forming (LSF)

Även om LSF har många fördelar, finns det också några begränsningar:

- Hög initialkostnad: Installationskostnaden för LSF-utrustning och material kan vara hög.

- Begränsat materialutbud: Alla material är inte lämpliga för LSF, vilket begränsar dess användningsområde.

- Krav på efterbearbetning: Vissa delar kan kräva ytterligare efterbehandlingsprocesser för att uppnå önskad ytkvalitet.

- Teknisk expertis: Kräver skickliga operatörer och avancerad kunskap för att optimera processen.

- Byggstorleksbegränsningar: Större delar kan begränsas av storleken på byggkammaren.

Jämförelse av metallpulver för LSF

Att förstå fördelarna och nackdelarna med olika metallpulver är avgörande för att välja rätt material:

| Metallpulver | Fördelar | Nackdelar |

|---|---|---|

| Inconel 718 | Hög hållfasthet, korrosionsbeständighet | Hög kostnad |

| Ti-6Al-4V | Lätt, biokompatibel | Svårt att bearbeta |

| 316L rostfritt stål | Korrosionsbeständighet, prisvärd | Lägre hållfasthet jämfört med legeringar |

| AlSi10Mg | Låg vikt, god ledningsförmåga | Lägre mekanisk hållfasthet |

| Maråldrat stål | Ultrahög hållfasthet | Dyrt |

| Kobolt-Krom | Slitstyrka, biokompatibel | Hög kostnad, svår att bearbeta |

| H13 Verktygsstål | Seghet, slitstyrka | Kräver efterbearbetning |

| Koppar (Cu) | Utmärkt ledningsförmåga | Oxiderar lätt |

| NiTi (nitinol) | Formminne, superelasticitet | Mycket hög kostnad |

| Tantal (Ta) | Korrosionsbeständighet | Extremt dyr |

VANLIGA FRÅGOR

| Fråga | Svar |

|---|---|

| Vad är Laser Solid Forming (LSF)? | LSF är en additiv tillverkningsprocess som använder en laser för att smälta samman metallpulver till fasta föremål lager för lager. |

| Vilka branscher använder LSF? | Flyg, bil, medicin, energi, verktyg, försvar, elektronik, smycken, marin och konstruktion. |

| Vilka är fördelarna med LSF? | Hög precision, materialeffektivitet, förmåga att skapa komplexa geometrier, anpassning, minskad ledtid och överlägsna mekaniska egenskaper. |

| Vilka är begränsningarna för LSF? | Hög initial kostnad, begränsad materialutbud, krav på efterbearbetning, behov av teknisk expertis och byggstorleksbegränsningar. |

| Vilka metallpulver används vanligtvis i LSF? | Inconel 718, Ti-6Al-4V, 316L rostfritt stål, AlSi10Mg, Maraging Steel, Cobalt-Chrome, H13 Tool Steel, Koppar, NiTi (Nitinol) och Tantal. |

| Hur står sig LSF i jämförelse med traditionell tillverkning? | LSF erbjuder högre precision, materialeffektivitet och förmågan att skapa komplexa konstruktioner, men det kan vara dyrare och kräver avancerad teknisk kunskap. |

Dela på

MET3DP Technology Co, LTD är en ledande leverantör av lösningar för additiv tillverkning med huvudkontor i Qingdao, Kina. Vårt företag är specialiserat på 3D-utskriftsutrustning och högpresterande metallpulver för industriella tillämpningar.

Förfrågan för att få bästa pris och anpassad lösning för ditt företag!

Relaterade artiklar

Högpresterande segment för munstycksvingar: Revolutionerande turbineffektivitet med 3D-utskrift i metall

Läs mer "Om Met3DP

Senaste uppdateringen

Vår produkt

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731