På upptäcktsfärd i Ni4Ti3:s värld

Innehållsförteckning

Översikt

Har du någonsin undrat vad som gör modern teknik mer hållbar, flexibel och effektiv? En nyckelkomponent är avancerade material som Ni4Ti3, en intermetallisk förening inom den bredare familjen av nickeltitanlegeringar (ofta kallad Nitinol). Denna förening har unika egenskaper som gör den oumbärlig i olika högteknologiska tillämpningar. I den här artikeln kommer vi att dyka djupt in i den fascinerande världen av Ni4Ti3, utforska dess typer, sammansättning, egenskaper, tillämpningar och mer. Gör dig redo för en engagerande resa genom de intrikata detaljerna i detta enastående material.

Vad är Ni4Ti3?

Ni4Ti3 är en specifik intermetallisk fas av nickel titan (Nitinol), känd för sina exceptionella mekaniska egenskaper och unika fasomvandlingar. Men vad gör att det sticker ut? Det är den exakta sammansättningen och hur atomerna är ordnade som ger den unika egenskaper. Denna fas är avgörande för att kontrollera formminneseffekten och superelasticiteten i Nitinol-legeringar.

Varför är Ni4Ti3 viktigt?

I en värld av avancerade material är det att ha kontroll över materialegenskaper som att ha en superkraft. Ni4Ti3 tillåter ingenjörer och forskare att finjustera egenskaperna hos Nitinol-legeringar, vilket gör dem lämpliga för ett brett spektrum av applikationer – från medicinsk utrustning till flygkomponenter. Denna förmåga att manipulera och förbättra materialegenskaper platser Ni4Ti3 i hjärtat av tekniska innovationer.

Sammansättning och egenskaper hos Ni4Ti3

Förstå sammansättningen och egenskaperna hos Ni4Ti3 är som att lära känna en superatlets DNA. Låt oss bryta ner dessa aspekter i detalj.

Sammansättning

De primära komponenterna i Ni4Ti3 är nickel (Ni) och titan (Ti). Men magin ligger i det specifika atomförhållandet och den resulterande kristallstrukturen. Här är en detaljerad tabell som sammanfattar sammansättningen:

| Element | Symbol | Atomprocent |

|---|---|---|

| Nickel | Ni | 57.14% |

| Titan | Ti | 42.86% |

Fastigheter

Vad sätter Ni4Ti3 förutom andra material är dess anmärkningsvärda egenskaper. Dessa inkluderar:

- Shape Memory-effekt: Möjligheten att återgå till en fördefinierad form vid uppvärmning.

- Superelasticitet: Förmågan att utsättas för stora påfrestningar och återställa sin ursprungliga form vid lossning.

- Hög korrosionsbeständighet: Utmärkt motståndskraft mot korrosion, vilket gör den lämplig för medicinska och marina tillämpningar.

- Biokompatibilitet: Säker för användning i medicinska implantat på grund av dess kompatibilitet med mänsklig vävnad.

Egenskaper

För att få en heltäckande förståelse, låt oss titta på de detaljerade egenskaperna hos Ni4Ti3:

| Karaktäristisk | Beskrivning |

|---|---|

| Kristallstruktur | Beställd intermetallisk fas med ett specifikt Ni:Ti-förhållande. |

| Fasomvandling | Uppvisar martensitiska transformationer som är avgörande för formminne och superelasticitet. |

| Termisk stabilitet | Stabil över ett intervall av temperaturer, vilket säkerställer tillförlitlighet i olika applikationer. |

| Mekanisk styrka | Hög draghållfasthet och utmattningsbeständighet. |

| Elektrisk konduktivitet | Måttlig elektrisk ledningsförmåga, användbar i vissa elektroniska tillämpningar. |

Tillämpningar av Ni4Ti3

Mångsidigheten hos Ni4Ti3 gör det till ett valbart material inom olika områden. Här är en närmare titt på var den används:

Medicintekniska produkter

En av de viktigaste tillämpningarna av Ni4Ti3 är inom det medicinska området. Dess biokompatibilitet och unika mekaniska egenskaper gör den idealisk för medicinska implantat och apparater.

- Stentar: Används i kardiovaskulära behandlingar för att hålla artärerna öppna.

- Ortodontiska bågtrådar: Används i hängslen för deras superelastiska egenskaper.

- Benplattor och skruvar: Används vid ortopediska operationer för benfixering.

Komponenter för flyg- och rymdindustrin

Inom flygindustrin är material som tål extrema förhållanden avgörande. Ni4Ti3 passar räkningen perfekt.

- Ställdon: Används i adaptiva styrsystem för deras formminnesegenskaper.

- Fästelement och kopplingar: Ger pålitlig prestanda under förhållanden med hög stress.

- Tätningar och packningar: Säkerställ lufttäta och flexibla tätningslösningar.

Konsumentelektronik

Även i vardagselektronik, Ni4Ti3 finner sin plats tack vare sin hållbarhet och unika egenskaper.

- Flexibla skärmar: Används i skärmar som kan böjas och böjas utan att gå sönder.

- Smarta wearables: Inbyggd i enheter som kräver flexibilitet och hållbarhet.

- Anslutningsstift: Tillhandahåll pålitliga elektriska anslutningar i olika prylar.

Industriella tillämpningar

Utöver de högteknologiska och medicinska områdena, Ni4Ti3 är också värdefullt i flera industriella tillämpningar.

- Robotteknik: Används i robotleder och ställdon för deras flexibilitet och styrka.

- Fordon: Används i olika komponenter för att förbättra prestanda och hållbarhet.

- Energisektorn: Implementerad i system som kräver hög utmattningsmotstånd och tillförlitlighet.

Tabell: Detaljerade tillämpningar av Ni4Ti3

| Industri | Tillämpning | Fördelen med Ni4Ti3 |

|---|---|---|

| Medicintekniska produkter | Stentar | Biokompatibilitet, flexibilitet |

| Ortodontiska bågtrådar | Superelasticitet | |

| Benplattor och skruvar | Hög hållfasthet, korrosionsbeständighet | |

| Komponenter för flyg- och rymdindustrin | Ställdon | Formminnesegenskaper, tillförlitlighet |

| Fästelement och kopplingar | Prestanda under hög stress | |

| Tätningar och packningar | Lufttäta och flexibla tätningslösningar | |

| Konsumentelektronik | Flexibla skärmar | Hållbarhet, flexibilitet |

| Smarta wearables | Flexibilitet, hållbarhet | |

| Anslutningsstift | Tillförlitliga elektriska anslutningar | |

| Industriella tillämpningar | Robotteknik | Flexibilitet, styrka |

| Fordon | Förbättrad prestanda, hållbarhet | |

| Energisektorn | Hög utmattningsmotstånd, tillförlitlighet |

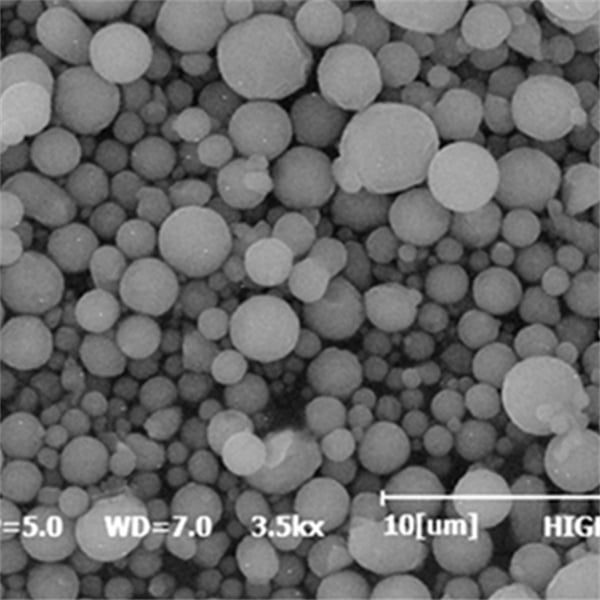

Typer av Ni4Ti3 Modeller av metallpulver

När det kommer till att jobba med Ni4Ti3, olika metallpulvermodeller finns tillgängliga, var och en skräddarsydd för specifika applikationer och krav. Här är en lista över några framstående modeller med deras beskrivningar:

1. Ni4Ti3-100

Ni4Ti3-100 är en standardmodell känd för sin fina partikelstorlek och höga renhet, vilket gör den idealisk för precisionsapplikationer inom det medicinska området.

- Partikelstorlek: 10-50 mikron

- Renhet: 99.9%

- Tillämpningar: Medicinska implantat, precisionsinstrument

2. Ni4Ti3-200

Ni4Ti3-200 är designad för flygtillämpningar där styrka och tillförlitlighet är av största vikt.

- Partikelstorlek: 20-60 mikron

- Renhet: 99.8%

- Tillämpningar: Flyg- och rymdkomponenter, ställdon

3. Ni4Ti3-300

Denna modell erbjuder förbättrade mekaniska egenskaper, lämplig för industriella tillämpningar med hög belastning.

- Partikelstorlek: 15-55 mikron

- Renhet: 99.7%

- Tillämpningar: Industriell robotik, fordonskomponenter

4. Ni4Ti3-400

Ni4Ti3-400 har ultrafina partiklar som ger exceptionella detaljer och prestanda inom hemelektronik.

- Partikelstorlek: 5-30 mikron

- Renhet: 99.9%

- Tillämpningar: Flexibla displayer, smarta wearables

5. Ni4Ti3-500

Denna modell är skräddarsydd för högpresterande energitillämpningar och erbjuder överlägsen utmattningsmotstånd.

- Partikelstorlek: 10-40 mikron

- Renhet: 99.85%

- Tillämpningar: Komponenter i energisektorn, applikationer med hög utmattning

6. Ni4Ti3-600

Ni4Ti3-600 är optimerad för additiv tillverkning, vilket säkerställer högkvalitativa 3D-utskrivna komponenter.

- Partikelstorlek: 20-50 mikrometer

- Renhet: 99.9%

- Tillämpningar: 3D-utskrift, specialtillverkning

7. Ni4Ti3-700

Designad för applikationer som kräver extrem precision, Ni4Ti3-700 erbjuder den finaste partikelstorleken i serien.

- Partikelstorlek: 2-20 mikron

- Renhet: 99.95%

- Tillämpningar: Mikroelektronik, precisionsinstrument

8. Ni4Ti3-800

Denna modell är perfekt för marina applikationer och ger utmärkt korrosionsbeständighet.

- Partikelstorlek: 10-60 mikron

- Renhet: 99.8%

- Tillämpningar: Marina komponenter, undervattensutrustning

9. Ni4Ti3-900

Ni4Ti3-900 erbjuder en balanserad kombination av styrka och flexibilitet, vilket gör den mångsidig för olika användningsområden.

- Partikelstorlek: 15-45 mikrometer

- Renhet: 99.85%

- Tillämpningar: Allmän industriell användning, flexibla komponenter

10. Ni4Ti3-1000

Den mest avancerade modellen, Ni4Ti3-1000, är konstruerad för banbrytande forsknings- och utvecklingsprojekt.

- Partikelstorlek: 5-25 mikron

- Renhet: 99.95%

- Tillämpningar: FoU, experimentella tillämpningar

Fördelar och nackdelar med Ni4Ti3

Som alla material har Ni4Ti3 sin egen uppsättning fördelar och nackdelar. Att förstå dessa kan hjälpa till att fatta välgrundade beslut om användningen.

Fördelar

- Hög hållfasthet: Utmärkt mekanisk hållfasthet, vilket gör den lämplig för applikationer med hög belastning.

- Flexibilitet: Överlägsen superelasticitet och formminnesegenskaper.

- Motståndskraft mot korrosion: Hög motståndskraft mot korrosion, förbättrar livslängden i tuffa miljöer.

- Biokompatibilitet: Säker för användning i medicinska tillämpningar, vilket minskar risken för biverkningar.

- Termisk stabilitet: Stabil över ett brett temperaturområde, vilket säkerställer tillförlitlighet.

Nackdelar

- Kostnad: Högre kostnad jämfört med konventionella material på grund av komplexa tillverkningsprocesser.

- Bearbetbarhet: Svårt att bearbeta, kräver specialiserad utrustning och teknik.

- Tillgänglighet: Begränsad tillgänglighet, vilket gör det utmanande att köpa för vissa applikationer.

- Komplexitet: Kräver exakt kontroll under tillverkningen för att uppnå önskade egenskaper.

- Förslitning: Även om den är hållbar, kan den utsättas för slitage i mycket slitande miljöer.

Tabell: Fördelar och nackdelar med Ni4Ti3

| Aspekt | Fördelar | Nackdelar |

|---|---|---|

| Styrka | Hög mekanisk hållfasthet | Hög kostnad |

| Flexibilitet | Överlägsen superelasticitet och formminnesegenskaper | Svårt att bearbeta |

| Motståndskraft mot korrosion | Hög motståndskraft mot korrosion | Begränsad tillgänglighet |

| Biokompatibilitet | Säker för medicinska tillämpningar | Kräver exakt tillverkningskontroll |

| Termisk stabilitet | Stabil över ett brett temperaturområde | Kan utsättas för slitage i mycket nötande miljöer |

Specifikationer, storlekar, kvaliteter och standarder för Ni4Ti3

Att förstå specifikationer, storlekar, kvaliteter och standarder är avgörande för att välja rätt Ni4Ti3 modell för dina behov. Här är en detaljerad tabell som sammanfattar dessa aspekter:

| Specifikation | Detalj |

|---|---|

| Partikelstorleksintervall | 2-60 mikron |

| Renhetsnivåer | 99.7% till 99.95% |

| Standardklasser | ASTM F2063, ISO 5832-11 |

| Tillgängliga formulär | Pulver, trådar, stavar, ark |

| Tillverkningsmetoder | Gasatomisering, Plasmaatomisering, Mekanisk legering |

| Certifiering | ISO 9001, ISO 13485 (för medicinska tillämpningar) |

Tabell: Specifikationer, storlekar, kvaliteter och standarder för Ni4Ti3

| Parameter | Beskrivning |

|---|---|

| Partikelstorleksintervall | 2-60 mikron |

| Renhetsnivåer | 99.7% till 99.95% |

| Standardklasser | ASTM F2063, ISO 5832-11 |

| Tillgängliga formulär | Pulver, trådar, stavar, ark |

| Tillverkningsmetoder | Gasatomisering, Plasmaatomisering, Mekanisk legering |

| Certifiering | ISO 9001, ISO 13485 (för medicinska tillämpningar) |

Leverantörer och prisuppgifter för Ni4Ti3

Att hitta pålitliga leverantörer och förstå prisdetaljerna är avgörande för inköp Ni4Ti3. Här är en detaljerad tabell över några framstående leverantörer och deras prisinformation:

| Leverantör | Plats | Produktsortiment | Prissättning (per kg) | Kontaktuppgifter |

|---|---|---|---|---|

| Johnson Matthey | USA | Ni4Ti3-100, Ni4Ti3-200 | $500 – $700 | www.matthey.com |

| ATI speciallegeringar | USA | Ni4Ti3-300, Ni4Ti3-400 | $600 – $800 | www.atimetals.com |

| Daido Steel Co., Ltd. | Japan | Ni4Ti3-500, Ni4Ti3-600 | $550 – $750 | www.daido.co.jp |

| Avancerade pulver och ytbeläggningar | Kanada | Ni4Ti3-700, Ni4Ti3-800 | $580 – $780 | www.advancedpowders.com |

| Snickeriteknik | USA | Ni4Ti3-900, Ni4Ti3-1000 | $600 – $800 | www.cartech.com |

| Sandvik Materialteknik | Sverige | Olika kvaliteter | $550 – $770 | www.materials.sandvik |

Tabell: Leverantörer och prisuppgifter för Ni4Ti3

| Leverantör | Plats | Produktsortiment | Prissättning (per kg) | Kontaktuppgifter |

|---|---|---|---|---|

| Johnson Matthey | USA | Ni4Ti3-100, Ni4Ti3-200 | $500 – $700 | www.matthey.com |

| ATI speciallegeringar | USA | Ni4Ti3-300, Ni4Ti3-400 | $600 – $800 | www.atimetals.com |

| Daido Steel Co., Ltd. | Japan | Ni4Ti3-500, Ni4Ti3-600 | $550 – $750 | www.daido.co.jp |

| Avancerade pulver och ytbeläggningar | Kanada | Ni4Ti3-700, Ni4Ti3-800 | $580 – $780 | www.advancedpowders.com |

| Snickeriteknik | USA | Ni4Ti3-900, Ni4Ti3-1000 | $600 – $800 | www.cartech.com |

| Sandvik Materialteknik | Sverige | Olika kvaliteter | $550 – $770 | www.materials.sandvik |

Jämförelse Ni4Ti3 Modeller: För- och nackdelar

För att hjälpa dig att välja rätt Ni4Ti3 modell för din applikation, här är en jämförande analys av de olika modellerna som belyser deras för- och nackdelar:

| Modell | Proffs | Nackdelar |

|---|---|---|

| Ni4Ti3-100 | Hög renhet, fin partikelstorlek | Högre kostnad |

| Ni4Ti3-200 | Idealisk för flyg, goda mekaniska egenskaper | Måttlig tillgänglighet |

| Ni4Ti3-300 | Förbättrad styrka, lämplig för industriell användning | Svårt att bearbeta |

| Ni4Ti3-400 | Ultrafina partiklar, utmärkt för elektronik | Begränsad till specifika tillämpningar |

| Ni4Ti3-500 | Överlägsen utmattningsmotstånd, energitillämpningar | Högre tillverkningskomplexitet |

| Ni4Ti3-600 | Optimerad för 3D-utskrift, utskrift av hög kvalitet | Kräver avancerad utrustning |

| Ni4Ti3-700 | Extrem precision, finaste partikelstorlek | Mycket hög kostnad |

| Ni4Ti3-800 | Utmärkt korrosionsbeständighet, marin användning | Tillgängligheten kan vara begränsad |

| Ni4Ti3-900 | Balanserade egenskaper, mångsidig användning | Inte den bästa i någon enskild fastighet |

| Ni4Ti3-1000 | Banbrytande forskningsapplikationer, högsta renhet | Extremt hög kostnad, begränsad till FoU |

Vanliga frågor

1. Vad används Ni4Ti3 till?

Ni4Ti3 används i en mängd olika applikationer inklusive medicinsk utrustning, flygkomponenter, konsumentelektronik, industriell robotik, bildelar och komponenter i energisektorn. Dess unika egenskaper som formminneseffekt, superelasticitet och biokompatibilitet gör den lämplig för dessa högteknologiska applikationer.

2. Hur tillverkas Ni4Ti3?

Ni4Ti3 tillverkas vanligtvis genom processer som gasförstoftning, plasmaförstoftning och mekanisk legering. Dessa metoder säkerställer hög renhet och exakt kontroll över partikelstorlek, vilket är avgörande för att uppnå de önskade egenskaperna hos materialet.

3. Vilka är fördelarna med att använda Ni4Ti3 i medicinsk utrustning?

Fördelarna med att använda Ni4Ti3 i medicinsk utrustning inkluderar dess höga biokompatibilitet, flexibilitet och korrosionsbeständighet. Dessa egenskaper gör den idealisk för implantat och enheter som interagerar med mänsklig vävnad, såsom stentar och ortodontiska bågtrådar.

4. Kan Ni4Ti3 användas i 3D-utskrift?

Ja, vissa modeller av Ni4Ti3, som Ni4Ti3-600, är optimerade för additiv tillverkning eller 3D-utskrift. Dessa modeller ger högkvalitativ, exakt utdata som lämpar sig för specialtillverkning och komplexa komponenter.

5. Vilka är begränsningarna för Ni4Ti3?

Medan Ni4Ti3 erbjuder många fördelar, den har också begränsningar som högre kostnad, svårighet att bearbeta och begränsad tillgänglighet. Dessutom kräver det exakt kontroll under tillverkningen för att uppnå de önskade egenskaperna, vilket kan öka produktionskomplexiteten och kostnaden.

6. Hur jämför Ni4Ti3 med andra nickeltitanlegeringar?

Jämfört med andra nickeltitanlegeringar, Ni4Ti3 ger överlägsen kontroll över formminne och superelastiska egenskaper på grund av dess specifika sammansättning och fasstruktur. Detta gör den särskilt värdefull för applikationer som kräver exakta prestanda, såsom medicin- och flygindustrin.

7. Finns det några miljöproblem med att använda Ni4Ti3?

Ni4Ti3 anses allmänt säkert för användning i olika applikationer, inklusive medicinska och industriella områden. Liksom alla material bör dock korrekt hantering och avfallshantering följas för att minimera miljöpåverkan.

8. Vilka är de bästa metoderna för att köpa Ni4Ti3?

Till källa Ni4Ti3 i praktiken är det viktigt att arbeta med välrenommerade leverantörer som tillhandahåller material av hög kvalitet och följer branschstandarder. Att kontrollera certifieringar som ISO 9001 och ISO 13485 kan också säkerställa att materialet uppfyller de krav som krävs för din applikation.

Avslutningsvis, Ni4Ti3 framstår som ett kritiskt material inom området för avancerad teknik, och erbjuder oöverträffade egenskaper och mångsidighet. Från medicinsk utrustning till flyg- och rymdkomponenter, dess unika egenskaper driver innovation och prestanda. Att förstå dess sammansättning, egenskaper och tillämpningar, tillsammans med fördelarna och nackdelarna, kan hjälpa till att fatta välgrundade beslut om dess användning. Oavsett om du är inom medicin-, flyg- eller industrisektorn, Ni4Ti3 öppnar upp för nya möjligheter för att skapa mer effektiva, hållbara och pålitliga produkter.

Dela på

MET3DP Technology Co, LTD är en ledande leverantör av lösningar för additiv tillverkning med huvudkontor i Qingdao, Kina. Vårt företag är specialiserat på 3D-utskriftsutrustning och högpresterande metallpulver för industriella tillämpningar.

Förfrågan för att få bästa pris och anpassad lösning för ditt företag!

Relaterade artiklar

Högpresterande segment för munstycksvingar: Revolutionerande turbineffektivitet med 3D-utskrift i metall

Läs mer "Om Met3DP

Senaste uppdateringen

Vår produkt

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731