Nickellegeringspulver för 3d-utskrift

Allt du behöver veta om nickellegeringspulver för 3d-utskrift

Produktkategori

Översikt över nickellegeringspulver för 3D-utskrift

3D-utskrifter, även kända som additiv tillverkning, har revolutionerat produktdesign och tillverkning i branscher som flyg-, bil-, medicin- och konsumentvaror. Till skillnad från traditionell subtraktiv tillverkning som tar bort material, bygger 3D-utskrift upp komponenter lager-för-lager baserat på en digital 3D-modell.

En av de mest populära teknikerna för 3D-utskrift av metaller är pulverbäddfusion, där en termisk energikälla selektivt smälter samman delar av en pulverbädd. Den oöverträffade designfriheten, köp-till-flyg-förhållandet och den ekonomiska produktionen av komplexa delar har drivit fram en enorm användning av pulverbäddsteknologier som selektiv lasersmältning (SLM), direkt metalllasersintring (DMLS), och smältning med elektronstråle (EBM).

Nickellegeringar är en mångsidig klass av material med egenskaper som hög hållfasthet, korrosionsbeständighet och värmebeständighet som gör dem till idealiska kandidater för 3D-utskrift. De vanligaste nickellegeringspulvren som används i pulverbäddsfusion inkluderar Inconel-superlegeringar, rostfria stål, Hastelloys, Nimonics, Kovar, Invar, Monel, nickel-titan-legeringar och nickelbaserade superlegeringar.

Sammansättning av nickellegeringspulver

Nickellegeringar får sina egenskaper från deras elementära sammansättning och mikrostruktur. Nickelhalten varierar från 2% till 99% för olika legeringar. Nickel ger egenskaper som korrosionsbeständighet, oxidationsbeständighet och hög temperaturhållfasthet. Legeringselementen tillsätts för att förbättra specifika egenskaper beroende på applikation.

Nickellegeringspulverkompositioner

| Legeringsfamilj | Nickelinnehåll | Legeringselement |

|---|---|---|

| Inconel | 30-80% | Cr, Mo, Nb, Ta, Al, Ti, Fe |

| Rostfritt stål | 2-20% | Cr, Mo, Mn, Si, C |

| Hastelloy | 35-60% | Mo, Cr, W, Fe, Co |

| Nimonic | Över 50% | Cr, Ti, Al, Mo |

| Kovar | 17% | Fe, Co, Mn, Si |

| Invar | 36% | Fe |

| Monel | Över 67% | Cu, Fe, Mn, Si, C |

| Nickel-titan | 55% Ni, 45% Ti | – |

| Superlegeringar av nickel | Över 50% | Cr, Co, Mo, W, Ta, Al, Ti, Nb |

Kromhalten i rostfria stål och nickelsuperlegeringar förbättrar oxidations- och korrosionsbeständigheten. Molybden, volfram och tantal förbättrar kryphållfastheten och de mekaniska egenskaperna vid hög temperatur. Järn i legeringar som Kovar och Invar kontrollerar termisk expansion. Aluminium, titan och niob tillsätts för fällningshärdning. Mangan förbättrar varm segtilitet medan kol förbättrar styrka och hårdhet. Kisel gynnar smidigheten och svetsbarheten.

Att förstå hur legering påverkar mikrostrukturbildning och egenskaper hjälper till att välja det optimala materialet för en applikation. Korrekt karakterisering och kvalificering av pulversammansättning och kvalitet är avgörande innan man skriver ut uppdragskritiska komponenter.

Egenskaper hos nickellegeringspulver

De unika egenskaperna hos nickellegeringar tryckta av optimerade pulver möjliggör användning av dem över olika applikationer och extrema miljöer. Tabellen nedan sammanfattar de allmänna egenskaperna för vanliga legeringsfamiljer.

Egenskaper för familjer med nickellegeringar

| Legeringsfamilj | Täthet | Smältpunkt | Draghållfasthet | Termisk konduktivitet | Termisk expansion | Oxideringsbeständighet | Motståndskraft mot korrosion |

|---|---|---|---|---|---|---|---|

| Inconel | 8,2-8,4 g/cc | 1300-1450°C | 750-1380 MPa | 11-16 W/mK | 12-16 μm/m°C | Utmärkt | Utmärkt |

| Rostfritt stål | 7,5-8,1 g/cc | 1375-1500°C | 450-1100 MPa | 15-30 W/mK | 10-18 μm/m°C | Bra | Bra-Utmärkt |

| Hastelloy | 8,1-9,2 g/cc | 1260-1350°C | 550-1000 MPa | 6-22 W/mK | 12-16 μm/m°C | Bra-Utmärkt | Utmärkt |

| Nimonic | 8,1-8,7 g/cc | 1260-1400°C | 500-1200 MPa | 10-30 W/mK | 12-17 μm/m°C | Bra | Bra |

| Kovar | 8,2 g/cc | 1450°C | 550 MPa | 17 W/mK | 5,9 μm/m°C | Dålig | Dålig |

| Invar | 8 g/cc | 1427°C | 200-450 MPa | 10,5 W/mK | 1,2 μm/m°C | Rättvist | Rättvist |

| Monel | 8,8 g/cc | 1350-1370°C | 550-950 MPa | 21-48 W/mK | 13-17 μm/m°C | Rättvist | Utmärkt |

| Nickel-titan | 6,4 g/cc | 1240-1310°C | 600-900 MPa | 8-18 W/mK | 11 μm/m°C | Rättvist | Utmärkt |

| Superlegeringar av nickel | 8-9 g/cc | 1260-1350°C | 750-1400 MPa | 11-61 W/mK | 12,5-17 μm/m°C | Bra-Utmärkt | Ganska bra |

Den höga smältpunkten för nickellegeringar förhindrar delförvrängning eller deformation under bearbetning. Hållfasthetsnivåer över ett brett temperaturområde möjliggör bärande strukturella tillämpningar. Kontrollerat termisk expansionsbeteende tillåter precisionskomponenter med snäva toleranser. Den utmärkta korrosions- och oxidationsbeständigheten underlättar användning i tuffa miljöer som marin, kemikalier och olja och gas.

Genom att skräddarsy pulversammansättningen och processparametrarna kan materialegenskaper optimeras för designkraven. Emellertid kan den anisotropa naturen hos additiv tillverkning resultera i riktningsberoende egenskaper. Korrekt design och kvalitetssäkring är nyckeln för att uppnå önskad prestanda.

Tillämpningar av nickellegeringspulver

Mångsidigheten hos nickellegeringar gör dem lämpliga för olika applikationer inom flyg, försvar, fordon, marin, olja och gas, kemisk bearbetning, kraftgenerering, medicin, verktyg och andra allmänna tekniska områden.

Industri Tillämpningar av nickellegeringspulver Familjer

| Legeringsfamilj | Industriapplikationer |

|---|---|

| Inconel | Flyg, försvar, fordon, kemisk bearbetning, olja och gas, kraftgenerering, raketer, missiler, kärnkraft |

| Rostfritt stål | Flyg, försvar, fordon, medicin, marin, arkitektur, kemi, livsmedelsförädling, verktyg, formar |

| Hastelloy | Flyg, försvar, kemisk bearbetning, föroreningskontroll, kraftproduktion, olja och gas |

| Nimonic | Flyg, försvar, kraftproduktion, kemisk bearbetning, verktyg |

| Kovar | Elektronik, halvledare, integrerade kretsar, förpackningar |

| Invar | Elektronik, optik, precisionsinstrument, flyg |

| Monel | Marin, olja och gas, kemisk bearbetning, kraftproduktion, massa och papper |

| Nickel-titan | Medicinsk utrustning, ställdon, sensorer, flyg, olja och gas |

| Superlegeringar av nickel | Flyg, försvar, kraftproduktion, olja och gas, fordon, verktyg |

Några exempel på delar av nickellegeringar som produceras med 3D-utskrift inkluderar:

- Flyg: Turbinblad, munstycken, brännkammare, ventiler, konsoler, termofluidkomponenter

- Fordon: Turboladdare, rotorer, grenrör, ventiler, delar till drivlinan

- Medicinsk: Implantat, proteser, kirurgiska instrument, patientspecifika apparater

- Olja och gas: Borrhålsverktyg, ventiler, brunnshuvudkomponenter, rördelar

- Verktyg: Injektionsformar, extruderingsformar, jiggar och fixturer, pressverktyg

- Allmänt: Värmeväxlare, vätskehanteringsdelar, fästelement, höljen, kapslingar

De utmärkta materialegenskaperna, komplexa geometrierna, kortare ledtider, minskade kostnader och designflexibilitet som möjliggörs av 3D-utskrift av nickellegeringar gör dem till ett mycket attraktivt alternativ för många kritiska applikationer.

Specifikationer för nickellegering

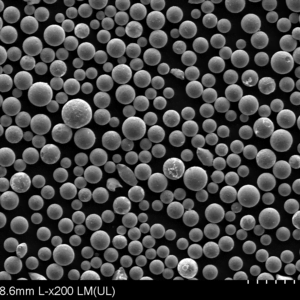

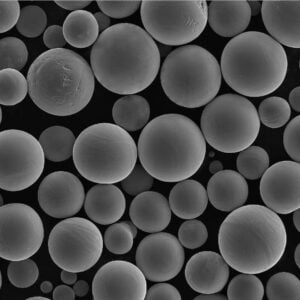

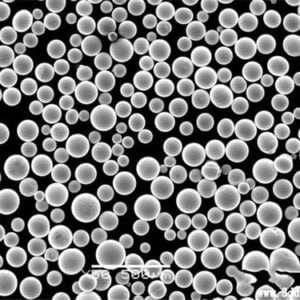

Nickellegeringspulver är kommersiellt tillgängliga i olika storleksfördelningar, morfologier och kvalitetsnivåer skräddarsydda för 3D-utskriftskrav. Vanliga specifikationer ges nedan:

Typiska nickellegeringspulverspecifikationer

| Fastighet | Typiska värden |

|---|---|

| Legeringens sammansättning | Speciallegeringar, klass enligt ASTM/ASME |

| Partikelns form | Sfärisk, nästan sfärisk |

| Partikelstorlek | 10-45 mikrometer |

| Fördelning av partikelstorlek | D10: 15-25 μm, D50: 25-35 μm, D90: 35-45 μm |

| Skenbar densitet | 2,5-5,5 g/cc |

| Tappdensitet | 4-8 g/cc |

| Flytbarhet | Utmärkt per Hall flödesmätare |

| Resterande syre | 100-400 ppm |

| Återstående kväve | 50-150 ppm |

| Återstående kol | 100-300 ppm |

Sfärisk morfologi och snäv partikelstorleksfördelning med D10-, D50- och D90-värden i idealiska intervall för den specifika utskriftsprocessen hjälper till att uppnå god densitet och mekaniska egenskaper. Hög flytbarhet förhindrar pulveragglomerering och spridbarhetsproblem under övermålning. Låg kvarvarande syre, kväve och kol minimerar kontaminering och porositet.

Pulverkvalitet, storleksparametrar och andra egenskaper påverkar avsevärt slutkomponentens egenskaper och måste anpassas till skrivarens och applikationskraven. De flesta leverantörer tillhandahåller anpassade legeringskompositioner och partikeloptimering för att möta användarspecifikationer.

Nickellegeringspulver 3D-utskriftsmetoder

De vanligaste tillsatstillverkningsmetoderna som används för att bearbeta nickellegeringspulver inkluderar:

Utskriftsprocesser för nickellegering

| Metod | Beskrivning |

|---|---|

| Selektiv lasersmältning (SLM) | Pulverbädd smält av fokuserad laserstråle |

| Direkt metallsintring med laser (DMLS) | Liknar SLM men laser med lägre effekt |

| Smältning med elektronstråle (EBM) | Pulverbädd sammansmält med elektronstråle under vakuum |

| Lasermetalldeponering (LMD) | Pulver injiceras i smält pool skapad av laser |

| Deposition med riktad energi (DED) | Liknar LMD med pulver eller trådmatning |

| Binder Jetting | Flytande bindemedel selektivt tryckt på pulverbädd |

SLM och DMLS använder en laser med hög effektdensitet för att helt smälta metallpulvret till täta delar skiktvis. EBM använder en elektronstråle som kraftkälla för att bygga delar under vakuum. Trådmatad LMD smälter den inkommande metalltråden med en fokuserad laser. Binder jetting skriver ut ett flytande bindemedel för att bilda delen följt av sintring.

Den specifika tekniken som väljs beror på faktorer som delstorlek, geometrikomplexitet, ytfinish, funktionsupplösning, produktionshastighet och kostnad. Varje process kräver optimering av skrivarinställningar och parametrar skräddarsydda för pulverlegeringssammansättningen.

Processparametrar för nickellegering

Kritiska skrivarparametrar för nickellegeringar som kräver optimering för densitet, styrka, precision och ytfinish inkluderar:

Typiska SLM/DMLS-processparametrar

| Parameter | Typiskt intervall |

|---|---|

| Skiktets tjocklek | 20-60 μm |

| Laserkraft | 100-400 W |

| Skanningshastighet | 400-1200 mm/s |

| Avstånd mellan luckor | 80-200 μm |

| Strålens storlek | 50-200 μm |

| Skanningsstrategi | Schack, rand, kontur |

| Stödstruktur | Regelbunden, fragmenterad, hybrid |

Typiska EBM-processparametrar

| Parameter | Typiskt intervall |

|---|---|

| Skiktets tjocklek | 50-200 μm |

| Elektronstråleeffekt | 3-15 kW |

| Hastighetsfunktion | 20-200 mm/s |

| Linjeförskjutning | 0,1-0,3 mm |

| Fokusförskjutning | 15-35 mA |

| Skanningsstrategi | Enkelriktad, dubbelriktad |

| Stödstruktur | Vanlig, tung |

Lägre lagertjocklek och strålstorlek i kombination med högre skanningshastigheter ökar upplösningen, noggrannheten och ytfinishen. Skanningsmönster för schack eller remsor används ofta. Omkretskonturer förbättrar kantkvaliteten. Optimerade stödstrukturer förhindrar deformation men är lättare att ta bort. Förvärmning och återvinning av pulver kan underlätta densitet och materialkvalitet.

Fördelar med 3D-utskrift av nickellegeringar

Additiv tillverkning med optimerade nickellegeringspulver erbjuder många fördelar jämfört med traditionell tillverkning:

- Designfrihet: Komplexa geometrier inte möjliga genom bearbetning

- Viktminskning: Lättare komponenter genom topologioptimering

- Konsolidering av delar: Minskad montering genom tryckta komplexa former

- Anpassning: Patientanpassad medicinsk utrustning, verktyg

- Minskat avfall: Endast erforderlig volym av material som används

- Kortare ledtid: Veckor kontra månader för produktionsverktyg

- Processflexibilitet: Enkla designiterationer och optimering

- Prestandafördelar: Anisotropa styrkor, inbäddade egenskaper

- Kostnadsminskning: Eliminera verktygskostnader, låg volymproduktion

- Köp-till-flyg-förhållande: Skriv ut endast slutdel kontra bearbetning från block

3D-utskrift utökar designen och möjliggör nya nickellegeringsdelar som inte är genomförbara eller ekonomiska med konventionella tekniker. Det revolutionerar produktionen inom flyg-, medicin-, fordons- och andra industrier.

Leverantörer av nickellegeringar

De flesta stora metallpulvertillverkare erbjuder nu en rad nickellegeringspulver optimerade för additiv tillverkning. Några ledande leverantörer inkluderar:

Nyckelleverantörer av nickellegeringar

| Leverantör | Nyckellegeringar |

|---|---|

| Met3DP | Inconel 625, 718, Hastelloy X, rostfritt stål |

| Sandvik | Osprey rostfria stål, superlegeringar, titanlegeringar |

| Praxair | Inconel 718, 625, Hastelloy X, rostfritt stål |

| AP&C | Inconel 718, 625, rostfritt stål |

| LPW-teknik | Inconel 718, rostfria stål, nickel superlegeringar |

| SLM-lösningar | Rostfritt stål 316L, 17-4PH, nickel superlegeringar |

| GE Additiv | Rostfritt stål 316L, Inconel 718, 625, Hastelloy |

Leverantörer erbjuder olika storleksfördelningar, utmärkt pulverflytbarhet, låg syre- och fukthalt, partispårbarhet och anpassade legeringar skräddarsydda för process- och applikationskrav. De flesta tillhandahåller specialiserad karaktärisering för att säkerställa konsekvent högkvalitativt pulver.

Nickellegeringspulver Kostnad

Den genomsnittliga kostnaden för vanliga nickellegeringspulver sammanfattas nedan:

Kostnader för nickellegering

| Material | Kostnad per kg |

|---|---|

| Inconel 718 | $75-150 |

| Inconel 625 | $60-120 |

| Rostfritt stål 316L | $35-70 |

| Rostfritt stål 17-4PH | $45-90 |

| Hastelloy X | $85-170 |

| Superlegeringar av nickel | $90-200 |

Högpresterande legeringar som Inconel 718 och Hastelloy X har en premium medan rostfria stål tenderar att vara det billigaste alternativet. Materialkostnaden är dock bara en komponent av den totala delkostnaden. Mervärde från designflexibilitet, prestandafördelar och minskad ledtid kompenserar ofta högre pulverpriser för lågvolymproduktion.

Att köpa pulver i bulkvantiteter kan minska kostnaderna. Många leverantörer erbjuder även tjänster för återanvändning och återvinning av pulver. Totalt sett måste köparen utvärdera den totala kostnaden inklusive arbete, efterbearbetning, materialanvändning, mekaniska egenskaper och andra faktorer när han väljer ett lämpligt nickellegeringspulver.

Grossistpris: $20/Kg-$200/Kg

Visar 1–15 av 17 resultat

-

GH3536 Legeringspulver

-

Pulver av legering K465

-

GH3230 Pulver

-

GH5188 Pulver

-

GH3625 pulver Inconel 625 pulver

-

GH4169 pulver för metall 3d-utskrift

-

GH3230 Pulver

-

GH 3625 Pulver

-

Legeringsserie för höga temperaturer

-

GH4169 Pulver för additiv tillverkning

-

Nickelbaserat K403-pulver

-

Bästa IN939-pulver för 3D-utskrift 2024

-

Bästa IN738LC-pulver för 3D-utskrift 2025

-

Bästa in718-pulver inconel 718-pulver för 3D-utskrift av metall

-

Bästa Hastelloy X-pulver - högtemperaturlegeringspulver för 3D-utskrift

Vanliga frågor om 3D-utskrift av metallpulver

Hur kontaktar jag Metal3DP:s kundtjänst?

Vi erbjuder kundsupport dygnet runt. Du hittar våra kontaktuppgifter på sidan Kontakta oss, inklusive telefon, e-post och onlinechatt.

Vilka metallpulvermaterial erbjuder Metal3DP?

Vi erbjuder olika högkvalitativa metallpulver, inklusive rostfritt stål och högtemperaturlegeringar, som lämpar sig för processer som laser- och elektronstrålepulverbäddsfusion.

Hur säkerställer Metal3DP kvaliteten på metallpulver för 3D-utskrift?

Med vår omfattande expertis inom additiv tillverkning av metall använder vi avancerade processer och sträng kvalitetskontroll för att säkerställa detaljernas mekaniska egenskaper och ytkvalitet.

Inom vilka branscher används Metal3DP:s 3D-printing-enheter?

Våra enheter har ett brett utbud av tillämpningar inom branscher som flyg, medicin, fordonsindustri m.m. och erbjuder lösningar för högpresterande metallkomponenter i tillverkningen.

Erbjuder Metal3DP anpassade legeringsalternativ?

Ja, vi tillhandahåller anpassade legeringstjänster för att uppfylla specifika materialkrav från kunder.

Vilka är fördelarna med Metal3DP:s SEBM-system?

Våra SEBM-system är utmärkta för tillverkning av komplexa metalldelar med exceptionella mekaniska egenskaper. Bland nyckelfunktionerna finns branschledande byggvolym, precision och tillförlitlighet.

Kan jag hitta applikationsfall på Metal3DP:s webbplats?

Ja, på vår webbplats finns ett brett utbud av tillämpningsfall som visar framgångsrika implementeringar av Metal3DP-tekniken i olika branscher.

Hur kan jag börja samarbeta med Metal3DP?

Kontakta oss så kommer vårt team att erbjuda dig skräddarsydda lösningar och samarbetsplaner utifrån dina behov.

Vad är leveranstiden för Metal3DP:s kundanpassade tjänster?

Handläggningstiden för anpassade tjänster varierar beroende på projektets komplexitet. Vi kommer att tillhandahålla exakta leveranstider baserat på dina krav.

Vilka 3D-utskriftstekniker erbjuder Metal3DP?

Vi är specialiserade på SLS (Selective Laser Sintering), SLM (Selective Laser Melting) och SEBM (Selective Electron Beam Melting) bland andra 3D-utskriftstekniker.

SÄND OSS

Fråga efter annan fråga?

Om du inte hittar svaret på din fråga i vår FAQ kan du alltid lämna ett meddelande till oss. Vi kommer att svara dig inom kort.

VÄNTA PÅ OSS

Nästa steg

01. Vi kommer att utarbeta ett förslag

Nödvändig omfattning, tidslinje och APR. Priset kommer att inkluderas om du ger oss detaljerad information om ett projekt.

02. Diskutera det tillsammans

Låt oss bekanta oss med varandra och diskutera alla möjliga varianter och alternativ

03. Låt oss börja bygga

När kontraktet är undertecknat och alla mål är fastställda kan vi starta den första sprinten.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731