Bästa Hastelloy X-pulver - högtemperaturlegeringspulver för 3D-utskrift

Hastelloy X-pulver har en speciell plats. Det är en nickelbaserad superlegering som har en extraordinär blandning av egenskaper tack vare sin sammansättning som inkluderar krom, järn och molybden. Den höga nickelhalten ger ett exceptionellt motstånd mot oxidation och korrosion.

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

Overview of Hastelloy X Powder

Hastelloy X is a nickel-based superalloy powder known for its excellent high temperature strength, oxidation resistance, and fabricability. It has applications in the aerospace, industrial, and energy industries where parts are exposed to extreme environments.

This article provides a comprehensive guide to Hastelloy X powder. It covers the composition, properties, applications, specifications, suppliers, handling, inspection, comparisons, pros and cons, and frequently asked questions about this versatile alloy powder. Quantitative data is presented in easy-to-read tables for quick reference.

Sammansättning av Hastelloy X-pulver

Hastelloy X has a complex composition optimized for high temperature performance. The main alloying elements are nickel, chromium, iron, and molybdenum.

| Element | Vikt % | Roll |

|---|---|---|

| Nickel | Balans | Matrix element, provides corrosion resistance |

| Krom | 21.5 – 23.5 | Oxidation resistance, formation of protective Cr2O3 |

| Järn | 17 – 20 | Förstärkning av fast lösning |

| Molybden | 8 – 10 | Solid solution strengthening, creep resistance |

| Kobolt | 1 max | Enhances hot workability |

| Mangan | 1 max | Desoxidationsmedel |

| Kisel | 0,5 max | Desoxidationsmedel |

| Kol | 0,15 max | Hårdmetallformare |

Trace additions of boron, zirconium, and carbon are also made to optimize properties like creep resistance. The balance nickel content provides corrosion resistance.

Egenskaper hos Hastelloy X-pulver

Hastelloy X exhibits an excellent combination of properties for high temperature applications:

| Fastighet | Beskrivning |

|---|---|

| Hållfasthet vid höga temperaturer | Excellent creep rupture strength up to 1150°C |

| Oxideringsbeständighet | Resists oxidation in air up to 1200°C |

| Motstånd mot termisk utmattning | Resists cracking during thermal cycling |

| Tillverkningsbarhet | Easy to form and weld compared to other superalloys |

| Korrosionsbeständighet | Resists many oxidizing and reducing environments |

Grain size control and thermomechanical processing modifies properties like tensile strength and ductility.

Applications of Hastelloy X Powder

The unique properties of Hastelloy X enable critical applications including:

| Industri | Tillämpningar |

|---|---|

| Flyg- och rymdindustrin | Jet engine combustion liners, afterburners, exhaust parts |

| Industriell | Reformer tubes, heat treatment equipment |

| Energi | Nuclear & fossil fuel power generation, chemical processing |

| Fordon | Exhaust system components, turbocharger parts |

The oxidation resistance allows thin section capabilities needed for jet engine combustion liners. It also suits the extremes of chemical processing vessels and tubing.

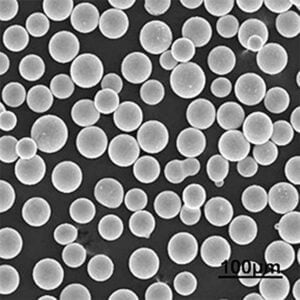

Specifications of Hastelloy X Powder

Hastelloy X powder is commercially available with specifications per alloy grade:

| Parameter | Specifikation |

|---|---|

| Alloy grades | Hastelloy X, B3, BC3, BN |

| Partikelstorlek | 15-45 microns, 45-105 microns |

| Partikelns form | Spherical, irregular morphology |

| Skenbar densitet | 2.5-4.5 g/cc |

| Tappdensitet | 4-6 g/cc |

| Renhet | >99,9% |

| Syrehalt | <1000 ppm |

| Fukthalt | <0,2% |

Other custom size distributions, purity levels, particle shapes and alloy modifications are possible for special applications.

Suppliers of Hastelloy X Powder

Hastelloy X powder is available from the following specialty alloy powder manufacturers:

| Leverantör | Plats |

|---|---|

| Snickeriteknik | USA |

| Sandvik | Sverige |

| Erasteel | Frankrike |

| Aperam | Brazil |

| VDM Metals | Tyskland |

| Nippon Yakin | Japan |

Pricing ranges from $50/kg to $120/kg based on factors like particle size, shape, alloy grade and purchase volume.

Handling and Storage of Hastelloy X Powder

As a reactive metal powder, Hastelloy X requires controlled handling and storage:

- Förvaras i slutna behållare i en sval och torr miljö

- Avoid contact with moisture, acids, halogen compounds

- Ground containers and transfer equipment to prevent static buildup

- Använd gnistsäkra verktyg och minimera dammbildningen

- Prevent accumulation of dusts to reduce explosion risk

- Wear appropriate PPE and avoid inhalation of powders

Proper precautions during handling, storage and processing are critical for safety and quality.

Inspection and Testing of Hastelloy X Powder

Hastelloy X powder batches are tested to ensure they meet specifications:

| Testmetod | Parameters Checked |

|---|---|

| Analys av siktar | Fördelning av partikelstorlek |

| Skenbar densitet | Flödbarhet för pulver |

| Tappdensitet | Packed density |

| Skannande elektronmikroskopi | Partikelns morfologi |

| Energy dispersive X-ray | Chemistry, alloy composition |

| Röntgendiffraktion | Befintliga faser |

| Inductively coupled plasma | Trace element analysis |

Sampling and testing as per ASTM standards ensures batch-to-batch consistency and quality.

Comparing Hastelloy X to Alternatives

Hastelloy X has advantages and limitations compared to other superalloys:

| Legering | Oxideringsbeständighet | Tillverkningsbarhet | Kostnad |

|---|---|---|---|

| Hastelloy X | Utmärkt | Bra | Hög |

| Inconel 625 | Bra | Utmärkt | Medium |

| Haynes 230 | Utmärkt | Dålig | Mycket hög |

| Inconel 718 | Medium | Rättvist | Medium |

Hastelloy X provides the best combination of oxidation resistance, fabricability, and cost for many high temperature applications.

Pros and Cons of Hastelloy X Powder

| Proffs | Nackdelar |

|---|---|

| Utmärkt hållfasthet vid höga temperaturer | Expensive compared to stainless steels |

| Outstanding oxidation resistance | Lower fabricability than Inconel 625 |

| Motstånd mot termisk utmattning | Susceptible to embrittlement at lower temperatures |

| Ease of welding and machining | Requires controlled handling and processing |

| Resists many corrosive environments | Limited data available compared to popular alloys |

Hastelloy X enables exceptional performance but requires care in processing and has high material cost.

Frequently Asked Questions about Hastelloy X Powder

Here are answers to some common questions about Hastelloy X powder:

Q: What is Hastelloy X used for?

A: Hastelloy X is used in aircraft engines, industrial furnaces, chemical processing, and power generation applications where strength and oxidation resistance at extreme temperatures are required.

Q: What is the difference between Hastelloy X and Hastelloy C?

A: Hastelloy X has addition of iron and higher molybdenum content. This gives better fabricability and high temperature strength compared to Hastelloy C which relies only on chromium for oxidation resistance.

Q: Is Hastelloy X weldable?

A: Yes, Hastelloy X has good weldability compared to other nickel superalloys, making it suitable for fabrication of complex components. Proper welding process and parameters must be used to avoid cracking.

Q: What is the temperature range of Hastelloy X?

A: It maintains good strength and oxidation resistance up to 1100°C for prolonged service. Shorter exposures up to 1200°C are possible. Lower temperatures can cause embrittlement.

Q: Is Hastelloy X magnetic?

A: No, Hastelloy X is non-magnetic, with magnetic permeability close to 1. This makes it useful for certain electronic and high temperature applications.

Q: What corrosion environments can Hastelloy X withstand?

A: It exhibits excellent corrosion resistance to oxidizing acids, halogens, sulfidation, and stress corrosion cracking environments found in chemical processing.

Q: Does Hastelloy X contain cobalt?

A: Most grades of Hastelloy X contain 1% or less cobalt. Cobalt-free variants are also available for biomedical applications where cobalt can cause negative health effects.

Q: What are the contents of a Hastelloy X powder MSDS?

A: It provides composition data, health and reactivity hazards, handling guidance, storage requirements, spill and firefighting procedures, transport information and disposal guidelines that are essential to review before use.

Q: Can Hastelloy X powder be 3D printed?

A: Yes, Hastelloy X alloy powders can be used in laser and electron beam powder bed fusion additive manufacturing processes. Parameters are optimized to provide dense, crack-free parts.

Q: How is Hastelloy X powder made?

A: Gas atomization is the common production method where the alloy melt is broken into fine droplets and rapidly solidified into powder. Water atomization is also used either by itself or with gas atomization.

Q: What are the alternatives to Hastelloy X?

A: Alternatives include Inconel 617, Haynes 230, Inconel 625, and stainless steels like 310 and 330. They offer lower cost but cannot match the oxidation resistance of Hastelloy X in extreme environments.

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731