Bästa IN939-pulver för 3D-utskrift 2024

IN939 pulver är en nickelbaserad superlegering som uppvisar exceptionella mekaniska egenskaper och hög motståndskraft mot korrosion och oxidation. Den består huvudsakligen av nickel, krom, kobolt, molybden och tantal. Denna sammansättning ger IN939-pulvret dess anmärkningsvärda styrka, värmebeständighet och stabilitet vid förhöjda temperaturer.

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

Översikt över IN939-pulver för 3D-utskrift

IN939 är ett högpresterande nickelbaserat superlegeringspulver som är utformat för additiv tillverkning av kritiska komponenter som behöver exceptionella mekaniska egenskaper vid höga temperaturer. Den här artikeln ger en omfattande guide till IN939-pulver för 3D-utskriftstillämpningar inom flyg-, fordons-, energi- och industrisektorerna.

Viktiga aspekter som behandlas inkluderar IN939 sammansättning, egenskaper, tryckparametrar, applikationer, specifikationer, leverantörer, hantering, inspektion, jämförelser med alternativ, fördelar och begränsningar samt vanliga frågor. Kvantitativa data presenteras i tabeller som är lätta att hänvisa till.

Sammansättning av IN939-pulver

IN939 har en komplex utskiljningshärdande legeringssammansättning:

| Element | Vikt % | Syfte |

|---|---|---|

| Nickel | Balans | Huvudmatriselement |

| Krom | 15 – 18 | Oxideringsbeständighet |

| Aluminium | 3.8 – 4.8 | Härdning genom utfällning |

| Titan | 0.9 – 1.4 | Härdning genom utfällning |

| Kobolt | 12 – 15 | Förstärkning av fast lösning |

| Tantalum | 3.8 – 4.8 | Hårdmetallformare |

| Kol | 0.05 – 0.15 | Hårdmetallformare |

| Bor | 0.006 – 0.012 | Förstärkare av korngränser |

Spårmängder av zirkonium, magnesium och svavel har också tillsatts för att förbättra egenskaperna.

Egenskaper för IN939 Pulver

IN939 har en exceptionell kombination av egenskaper:

| Fastighet | Beskrivning |

|---|---|

| Hög hållfasthet | Utmärkt drag- och krypbrotthållfasthet upp till 1050°C |

| Termisk stabilitet | Hållfastheten bibehålls upp till 1000°C |

| Krypbeständighet | Hög spänningsbrottstid vid höga temperaturer |

| Oxideringsbeständighet | Bildar skyddande Cr2O3-oxidavlagringar |

| Motstånd mot termisk utmattning | Motstår sprickbildning under termisk cykling |

| Fasstabilitet | Mikrostrukturen är stabil efter långvarig exponering |

| Korrosionsbeständighet | Motståndskraftig mot varmkorrosion, oxidation och sulfidation |

Egenskaperna möjliggör användning under extrema termiska och mekaniska belastningar.

Parametrar för 3D-utskrift för IN939-pulver

Typiska AM-bearbetningsparametrar för IN939 inkluderar:

| Parameter | Typiskt värde | Syfte |

|---|---|---|

| Skiktets tjocklek | 20-50 μm | Upplösning kontra bygghastighet |

| Laserkraft | 250-500 W | Tillräcklig smältning utan avdunstning |

| Skanningshastighet | 800-1200 mm/s | Densitet kontra produktionshastighet |

| Avstånd mellan luckor | 100-200 μm | Mekaniska egenskaper |

| Stödstruktur | Minimal | Enkel borttagning |

| Varm isostatisk pressning | 1160°C, 100 MPa, 3h | Eliminerar porositet |

Parametrarna optimeras för attribut som densitet, mikrostruktur, bygghastighet och krav på efterbearbetning.

Användningsområden för 3D-printade IN939-delar

Additivt tillverkade IN939-komponenter används i kritiska applikationer, bland annat

| Industri | Komponenter |

|---|---|

| Flyg- och rymdindustrin | Turbinblad, skovlar, brännkammare |

| Kraftproduktion | Delar till varmgasvägar, värmeväxlare |

| Fordon | Turboladdare hjul, ventiler |

| Kemisk bearbetning | Pumpar, ventiler, reaktionskärl |

Fördelarna jämfört med konventionellt bearbetad IN939 är bland annat komplexa geometrier och kortare ledtider.

Specifikationer för IN939 Pulver för 3D-utskrift

IN939-pulver för AM måste uppfylla exakta specifikationer:

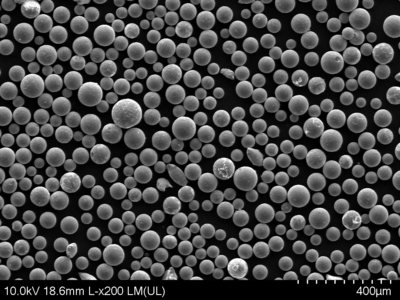

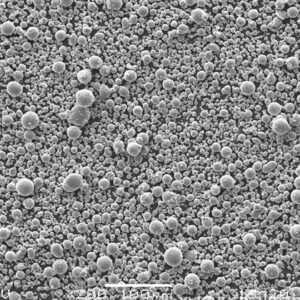

| Parameter | Specifikation |

|---|---|

| Partikelstorlek | 15-45 μm typiskt |

| Partikelns form | Sfärisk morfologi |

| Skenbar densitet | > 4 g/cc |

| Tappdensitet | > 6 g/cc |

| Hall flödeshastighet | > 23 sekunder för 50 g |

| Renhet | >99,9% |

| Syrehalt | <100 ppm |

Snävare toleranser, anpassade storleksfördelningar och kontrollerade föroreningsnivåer finns tillgängliga.

Leverantörer av IN939-pulver

Välrenommerade leverantörer av IN939-pulver inkluderar:

| Leverantör | Plats |

|---|---|

| Met3DP | Kina |

| Snickare Tillsats | USA |

| Praxair | USA |

| AP&C | Kanada |

| Erasteel | Sverige |

| AMETEK | USA |

Priset för IN939-pulver varierar från $110/kg till över $220/kg baserat på kvalitet och ordervolym.

Hantering och förvaring av IN939-pulver

Eftersom IN939 är ett reaktivt pulver måste det hanteras försiktigt:

- Förvara förslutna behållare i en sval, inert atmosfär

- Förhindra kontakt med fukt, syre och syror

- Använd korrekt jordad utrustning

- Undvik ansamling av damm för att minimera explosionsrisken

- Lokal avgasventilation rekommenderas

- Använd lämplig personlig skyddsutrustning vid hantering

Korrekta tekniker och kontroller förhindrar oxidation eller kontaminering av IN939-pulver.

Inspektion och provning av IN939-pulver

IN939 pulver valideras med:

| Metod | Testade parametrar |

|---|---|

| Analys av siktar | Fördelning av partikelstorlek |

| SEM-avbildning | Partikelns morfologi |

| EDX | Kemi och sammansättning |

| XRD | Befintliga faser |

| Pyknometri | Täthet |

| Hall flödeshastighet | Flödbarhet för pulver |

Testning enligt tillämpliga ASTM-standarder säkerställer enhetliga satser.

Jämförelse av IN939 med alternativa legeringspulver

IN939 jämförs med andra Ni-baserade superlegeringar som:

| Legering | Hållfasthet vid höga temperaturer | Kostnad | Utskriftsmöjlighet | Duktilitet |

|---|---|---|---|---|

| IN939 | Utmärkt | Hög | Utmärkt | Låg |

| IN738 | Bra | Medium | Utmärkt | Medium |

| IN718 | Rättvist | Låg | Bra | Utmärkt |

| Hastelloy X | Utmärkt | Hög | Rättvist | Medium |

För balanserade egenskaper och processbarhet överträffar IN939 alternativ som IN718 Pulver eller Hastelloy X Pulver.

För- och nackdelar med IN939-pulver för 3D-utskrift

| Proffs | Nackdelar |

|---|---|

| Exceptionell hållfasthet vid höga temperaturer | Dyrt jämfört med IN718 |

| Utmärkt oxidations- och krypbeständighet | Betydande parameteroptimering krävs |

| Komplexa geometrier genomförbara | Begränsad duktilitet vid rumstemperatur |

| Snabbare bearbetning än gjuten/smidd | Kontrollerad lagrings- och hanteringsmiljö |

| Jämförbara egenskaper med gjuten legering | Svårt att bearbeta efter tryckning |

IN939 möjliggör högpresterande tryckta komponenter, men med högre kostnader och kontrollerade bearbetningsbehov.

Vanliga frågor om IN939-pulver för 3D-utskrift

F: Vilket partikelstorleksintervall fungerar bäst för tryckning av IN939?

A: Ett partikelstorleksintervall på 15-45 mikrometer ger god flytbarhet i kombination med hög upplösning och densitet. Finare partiklar under 10 mikrometer kan förbättra densiteten och ytfinishen.

F: Kräver IN939 någon efterbearbetning efter 3D-utskrift?

S: Efterprocesser som varm isostatisk pressning, värmebehandling och maskinbearbetning behövs vanligtvis för att eliminera porositet, lindra spänningar och uppnå slutliga toleranser och ytfinish.

F: Vilken precision kan uppnås med IN939-tryckta delar?

S: Efter efterbearbetning kan dimensionsnoggrannhet och ytfinhet som är jämförbar med CNC-bearbetade delar uppnås med IN939 AM-komponenter.

F: Behövs det stödstrukturer för att skriva ut IN939-pulver?

S: Minimala stöd rekommenderas för komplexa kanaler och överhäng för att förhindra deformation och underlätta enkel borttagning. IN939-pulvret har god flytbarhet.

F: Vilket legeringspulver är det närmaste alternativet till IN939 för AM?

S: IN738 är det närmaste alternativet när det gäller balanserade egenskaper och mognad för additiv tillverkning. Andra legeringar som IN718 eller Hastelloy X har vissa kompromisser.

F: Är IN939 kompatibel med direkt metall-lasersintring (DMLS)?

S: Ja, IN939 kan lätt bearbetas med de vanligaste pulverbäddsfusionsteknikerna, inklusive DMLS tillsammans med selektiv lasersmältning (SLM) och elektronstrålesmältning (EBM).

F: Vilken densitet kan uppnås med 3D-printade IN939-komponenter?

A: Med optimerade parametrar kan densiteter över 99% uppnås, vilket matchar egenskaperna hos traditionellt bearbetade IN939-produkter.

F: Hur är egenskaperna hos tryckt IN939 jämfört med gjuten legering?

A: Additivt tillverkad IN939 uppvisar jämförbara eller bättre mekaniska egenskaper och mikrostruktur jämfört med konventionella gjutna och smidda former.

F: Vilka defekter kan uppstå vid utskrift med IN939-pulver?

S: Potentiella defekter är sprickbildning, distorsion, porositet, ytjämnhet, ofullständig sammansmältning etc. De flesta kan förebyggas genom korrekt parameteroptimering och pulverkvalitet.

F: Är varm isostatisk pressning (HIP) obligatorisk för IN939 AM-delar?

Svar: HIP eliminerar inre hålrum och förbättrar utmattningshållfastheten. För mindre krävande applikationer kan det räcka med enbart värmebehandling istället för HIP.

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731