CoCrMo-pulver

CoCrMo är ett pulver av en legering av kobolt-krom-molybden som ofta används vid additiv tillverkning av metaller för biomedicinska, dentala, flyg- och industriella tillämpningar som kräver slitstyrka och biokompatibilitet.

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

Översikt över CoCrMo-pulver

CoCrMo är ett pulver av en legering av kobolt-krom-molybden som ofta används vid additiv tillverkning av metaller för biomedicinska, dentala, flyg- och industriella tillämpningar som kräver slitstyrka och biokompatibilitet.

Den här artikeln ger en detaljerad guide till CoCrMo-pulver som omfattar sammansättning, egenskaper, AM-processparametrar, applikationer, specifikationer, leverantörer, hantering, inspektion, jämförelser, för- och nackdelar och vanliga frågor. Nyckelinformation presenteras i tabeller som är lätta att referera till.

Sammansättning av CoCrMo-pulver

Sammansättningen av CoCrMo legeringspulver är:

| Element | Vikt % | Syfte |

|---|---|---|

| Kobolt | 58-69 | Matriselement, biokompatibilitet |

| Krom | 26-30 | Korrosionsbeständighet, slitstyrka |

| Molybden | 5-7 | Hållfasthet, slitstyrka |

| Kol | 0.05-0.35 | Hårdmetallformare |

| Kisel | 1 max | Desoxidationsmedel |

| Mangan | 1 max | Desoxidationsmedel |

| Järn | 0,75 max | Gränsvärde för kontaminering |

Den höga kobolthalten ger biokompatibilitet medan krom och molybden ger styrka och slitstyrka.

Egenskaper hos CoCrMo-pulver

Viktiga egenskaper hos CoCrMo-pulver inkluderar:

| Fastighet | Beskrivning |

|---|---|

| Biokompatibilitet | Utmärkt kompatibilitet med mänskliga kroppsvävnader |

| Slitstyrka | Hög slitstyrka vid nötning och glidning |

| Korrosionsbeständighet | Motståndskraftig mot kroppsvätskor och många kemikalier |

| Styrka | Draghållfasthet upp till 1310 MPa vid arbetshärdning |

| Hårdhet | Upp till 54 HRC vid åldershärdning |

| Utmattningshållfasthet | Lämplig för cyklisk dynamisk belastning |

Egenskaperna möjliggör användning för lastbärande implantat och anordningar.

Parametrar för AM-process för CoCrMo-pulver

Typiska parametrar för tryckning av CoCrMo-pulver inkluderar:

| Parameter | Typiskt värde | Syfte |

|---|---|---|

| Höjd på lager | 20-50 μm | Upplösning kontra bygghastighet |

| Laserkraft | 150-400 W | Smältningstillstånd utan förångning |

| Skanningshastighet | 400-1200 mm/s | Densitet kontra produktionshastighet |

| Avstånd mellan luckor | 80-120 μm | Mekaniska egenskaper |

| Stöd för | Träd eller gitter | Överhäng, invändiga kanaler |

| Varm isostatisk pressning | 1220°C, 100 MPa, 3 timmar | Eliminerar porositet |

Parametrar skräddarsydda för densitet, mikrostruktur, bygghastighet och krav på efterbearbetning.

Tillämpningar av 3D-tryckta CoCrMo-delar

AM CoCrMo-komponenter används i:

| Industri | Tillämpningar |

|---|---|

| Medicinsk | Knä-/höftimplantat, tandkronor, kirurgiska verktyg |

| Flyg- och rymdindustrin | Turbinblad, motorkomponenter |

| Fordon | Ventilsäten, turboladdarhjul |

| Industriell | Slitstarka verktyg, flänsar, tätningar |

| Olja och gas | Ventildelar, pumpar |

Fördelarna jämfört med smidd CoCrMo är komplexa geometrier, kundanpassade implantat, lägre kostnader och kortare ledtider.

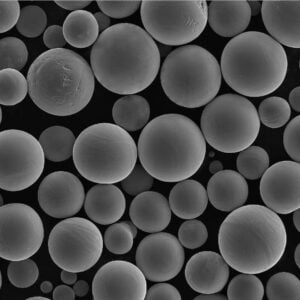

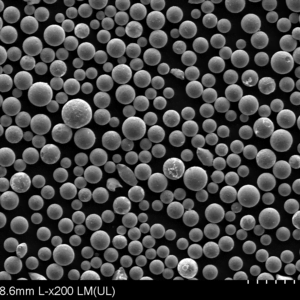

Specifikationer för CoCrMo-pulver för AM

CoCrMo-pulver måste uppfylla strikta specifikationer:

| Parameter | Specifikation |

|---|---|

| Partikelstorleksintervall | 15-45 μm typiskt |

| Partikelns form | Sfärisk morfologi |

| Skenbar densitet | > 4 g/cc |

| Tappdensitet | > 6 g/cc |

| Hall flödeshastighet | > 23 sekunder för 50 g |

| Renhet | >99,9% |

| Syrehalt | <1000 ppm |

Anpassade storleksfördelningar och kontrollerade fuktnivåer tillgängliga.

Leverantörer av CoCrMo-pulver

Välrenommerade leverantörer av CoCrMo-pulver inkluderar:

| Leverantör | Plats |

|---|---|

| Snickare Tillsats | USA |

| Sandvik Osprey | STORBRITANNIEN |

| Erasteel | Sverige |

| AP&C | Kanada |

| LPW-teknik | STORBRITANNIEN |

| Arcam AB | Sverige |

Priserna varierar från $50/kg till $120/kg baserat på kvalitetsaspekter och ordervolym.

Hantering och förvaring av CoCrMo-pulver

Eftersom CoCrMo är ett reaktivt material är det viktigt med noggrann hantering av pulver:

- Förvara förslutna behållare åtskilt från fukt, syror och antändningskällor

- Förhindra exponering för luft och använd inert gas

- Jorda utrustningen för att avleda statiska laddningar

- Undvik ansamling av damm och använd dammutsug

- Lokal avgasventilation rekommenderas

- Följ säkerhetsdatabladets försiktighetsåtgärder

Rätt teknik ger optimalt kruttillstånd.

Inspektion och provning av CoCrMo-pulver

Metoder för kvalitetstestning inkluderar:

| Metod | Testade parametrar |

|---|---|

| Analys av siktar | Fördelning av partikelstorlek |

| SEM-avbildning | Partikelns morfologi |

| EDX | Kemi och sammansättning |

| XRD | Befintliga faser |

| Pyknometri | Täthet |

| Hall flödeshastighet | Flödbarhet för pulver |

Testning enligt ASTM-standarder verifierar pulverkvalitet och batchkonsistens.

Jämförelse mellan CoCrMo och alternativa legeringspulver

CoCrMo kan jämföras med andra legeringar som:

| Legering | Biokompatibilitet | Styrka | Kostnad | Utskriftsmöjlighet |

|---|---|---|---|---|

| CoCrMo | Utmärkt | Medium | Medium | Bra |

| Titan Ti64 | Bra | Låg | Hög | Rättvist |

| Rostfritt stål 316L | Bra | Medium | Medium | Utmärkt |

| Inconel 718 | Dålig | Hög | Hög | Bra |

CoCrMo ger den bästa kombinationen av biokompatibilitet, styrka och tryckbarhet för många tillämpningar.

För- och nackdelar med CoCrMo-pulver för AM

| Proffs | Nackdelar |

|---|---|

| Utmärkt biokompatibilitet och korrosionsbeständighet | Begränsad kapacitet för höga temperaturer |

| Mycket god slitstyrka och nötningsbeständighet | Känslig för porositet under tryckning |

| Lätt att 3D-printa och svetsa | Kräver hantering i kontrollerad atmosfär |

| Kostnadsfördel jämfört med titanlegeringar | Efterbearbetning behövs ofta |

| Kan matcha egenskaper hos smidda material | Lägre brottseghet än rostfritt stål |

CoCrMo möjliggör funktionella implantat och komponenter i metall, om än med kontrollerade bearbetningskrav.

Vanliga frågor om CoCrMo-pulver

F: Vilket partikelstorleksintervall fungerar bäst för 3D-utskrift av CoCrMo-legering?

S: Ett typiskt intervall är 15-45 mikrometer. Det ger god pulverflödbarhet i kombination med hög upplösning och densitet.

Q: Vilka efterbehandlingsmetoder används på CoCrMo AM-delar?

A: Varm isostatisk pressning, värmebehandling, ytbearbetning och polering är vanliga efterbehandlingar för att uppnå full densitet och ytfinish.

F: Vilka 3D-utskriftsprocesser för metall är kompatibla med CoCrMo-legeringen?

A: Selektiv lasersmältning (SLM), direkt metall lasersintring (DMLS) och elektronstrålesmältning (EBM) kan alla bearbeta CoCrMo-pulver.

Q: Vilka industrier använder additivt tillverkade CoCrMo-komponenter?

A: Medicinska, dentala, flyg-, fordons-, olje- och gas- samt industrisektorer drar nytta av 3D-printade CoCrMo-delar.

F: Kräver CoCrMo stödstrukturer under 3D-utskrift?

S: Ja, det behövs stöd för överhäng och invändiga kanaler för att förhindra deformation och göra det lätt att ta bort dem efter tryckningen.

F: Vilka defekter kan uppstå vid tryckning av CoCrMo-pulver?

S: Potentiella defekter är porositet, sprickbildning, distorsion, ofullständig sammansmältning och ytjämnhet. De flesta kan förebyggas med optimerade parametrar.

F: Vilken typ av biokompatibilitetstest görs på CoCrMo-legeringar?

A: Cytotoxicitet, sensibilisering, irritation, systemisk toxicitet, genotoxicitet och implantationstestning enligt standarder som ISO 10993 utförs.

Q: Hur är egenskaperna hos tryckt CoCrMo jämfört med gjuten legering?

A: AM CoCrMo-komponenter kan uppnå mekaniska egenskaper i nivå med eller bättre än gjutna och glödgade motsvarigheter när de optimeras.

Q: Vilka är de största skillnaderna mellan CoCr F75 och SP2 legeringar?

A: F75 har högre kolhalt för bättre bearbetbarhet medan SP2 har lägre kolhalt plus niob för förbättrad smältning av partiklar under tryckning.

F: Vilken densitet kan förväntas med 3D-utskrivna CoCrMo-komponenter?

S: Densitet över 99% kan uppnås för CoCrMo med idealiska parametrar som är skräddarsydda för legeringen och matchar smidda materialegenskaper.

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731