D2-pulver

D2-pulver är ett kallbearbetat verktygsstålspulver som erbjuder en utmärkt kombination av hög hårdhet, slitstyrka och seghet. Det är en mångsidig krom-molybden-vanadinlegering som ofta används för pressning till skärverktyg, matriser, precisionsdetaljer och slitdelar inom olika industrisektorer.

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

Översikt över D2-pulver

D2-pulver är ett kallbearbetat verktygsstålspulver som erbjuder en utmärkt kombination av hög hårdhet, slitstyrka och seghet. Det är en mångsidig krom-molybden-vanadinlegering som ofta används för pressning till skärverktyg, matriser, precisionsdetaljer och slitdelar inom olika industrisektorer.

Viktiga egenskaper och fördelar med D2-pulver är bl.a:

D2 Pulvers egenskaper och kännetecken

| Fastigheter | Detaljer |

|---|---|

| Sammansättning | Legering Fe-1,5Cr-0,3C-0,4V-1Mo |

| Täthet | 7,7 g/cc |

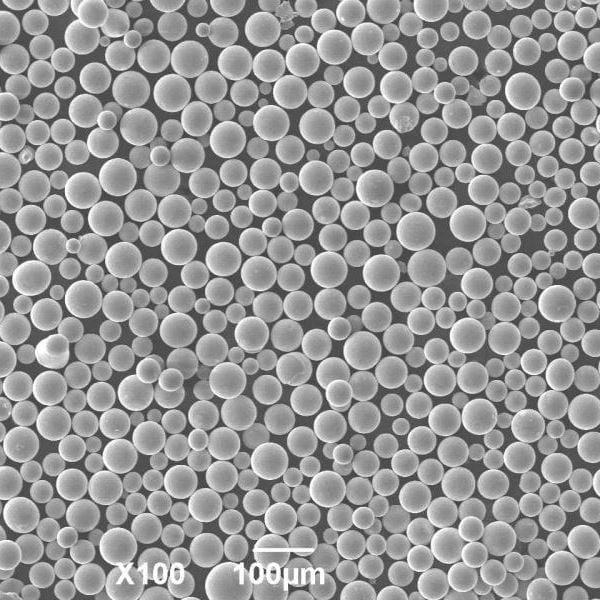

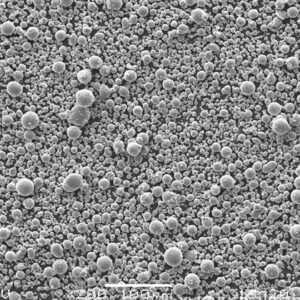

| Partikelns form | Sfärisk eller oregelbunden |

| Storleksintervall | 10-150 mikrometer |

| Skenbar densitet | Upp till 60% av verklig densitet |

| Flytbarhet | Bra |

| Hårdhet | 60-62 HRC vid värmebehandling |

| Tålighet | Mycket bra |

D2:s exceptionella kombination av hårdhet, styrka och slagtålighet gör den till förstahandsvalet för kallbearbetningsverktyg som kräver lång livslängd.

D2 Pulversammansättning

Typisk sammansättning av pulver av D2 verktygsstål:

D2 Pulversammansättning

| Element | Vikt % |

|---|---|

| Järn (Fe) | Balans |

| Krom (Cr) | 11-13% |

| Kol (C) | 1.4-1.6% |

| Molybden (Mo) | 0.75-1.2% |

| Vanadin (V) | 0.7-1.2% |

| Mangan (Mn) | 0.3-0.6% |

| Kisel (Si) | 0.15-0.4% |

- Järn ger den ferritiska matrisen

- Krom bidrar till hårdhet och slitstyrka

- Kol ger hög hårdhet i värmebehandlat tillstånd

- Molybden och vanadin bildar karbider som förbättrar slitstyrkan

- Mangan och kisel förbättrar förstärkning av fast lösning

Sammansättningen är utformad för att uppnå en optimal kombination av hårdhet, seghet och slipbarhet som krävs i verktygstillämpningar.

D2 Pulver Fysikaliska egenskaper

D2 Pulver Fysikaliska egenskaper

| Fastighet | Värde |

|---|---|

| Täthet | 7,7 g/cc |

| Smältpunkt | 1460-1500°C |

| Termisk ledningsförmåga | 21 W/mK |

| Elektrisk resistivitet | 0,7 μΩ-m |

| Curie-temperatur | 1010°C |

| Maximal driftstemperatur | 180-200°C |

- Hög densitet ger möjlighet till miniatyrisering av komponenter

- Bibehåller hög hårdhet och hållfasthet vid förhöjda temperaturer

- Blir paramagnetisk över Curie-punkten

- Relativt låg driftstemperatur på grund av anlöpningseffekten

Egenskaperna gör att D2 kan användas i verktyg för kallbearbetning vid höga hårdhetsnivåer.

D2 pulver Mekaniska egenskaper

D2 pulver Mekaniska egenskaper

| Fastighet | Värde |

|---|---|

| Hårdhet | 60-62 HRC |

| Tvärgående brotthållfasthet | 1900-2100 MPa |

| Draghållfasthet | 2050-2200 MPa |

| Sträckgräns | 1700-1900 MPa |

| Töjning | 8-11% |

| Slagseghet | 12-15 J/cm2 |

- Exceptionell hårdhet vid värmebehandling

- Mycket hög hållfasthet med rimlig duktilitet

- Utmärkt slagseghet för ett verktygsstål

- Hög utmattningshållfasthet för längre verktygslivslängd

- Värdena för hållfasthet och seghet beror på värmebehandlingen

Egenskaperna gör D2 lämplig för de mest krävande kallbearbetningsverktyg och matriser som kräver extrem slitstyrka.

D2 Pulver Tillämpningar

Typiska användningsområden för D2 verktygsstålspulver är bl.a:

D2 Pulver Tillämpningar

| Industri | Exempel på användningsområden |

|---|---|

| Tillverkning | Pressverktyg, stansar och matriser |

| Fordon | Blank-, hål-, trim- och formningsverktyg |

| Flyg- och rymdindustrin | Formverktyg, fixturer |

| Konsumentvaror | Rakblad, knivar, saxar |

| Industriell | Dragverktyg, gängrullningsverktyg |

Vissa specifika produktanvändningar:

- Kallbearbetningsverktyg för tillverkning av fästelement

- Myntningsverktyg för prägling av exakta delar

- Gängvalsningsverktyg för bulttillverkning

- Dragning, stansning, stansverktyg för olika sektorer

- Kirurgiska verktyg och bestick

- Verktyg för pelletering

D2 är det främsta verktygsstål för pulvermetall som används för kallbearbetningsverktyg, metallformningsverktyg och precisionskomponenter med lång livslängd inom alla branscher.

Specifikationer för D2-pulver

Viktiga specifikationer för D2 verktygsstålpulver:

D2 Pulverstandarder

| Standard | Beskrivning |

|---|---|

| ASTM A681 | Standard för verktygsstål och legeringar |

| DIN 1.2379 | Motsvarar AISI D2 |

| JIS G 4404 | Verktygsstål för kallbearbetning |

| ISO 4957 | Verktygsstål |

| GOST 5950 | Stålsorter för verktyg |

Dessa definierar:

- Gränsvärden för kemisk sammansättning för D2-stål

- Nödvändiga mekaniska egenskaper i värmebehandlat tillstånd

- Tillåtna föroreningar

- Godkända produktionsmetoder som gasatomisering

- Protokoll för test av efterlevnad

- Förpackning, identifieringskrav

D2-pulver tillverkat enligt dessa specifikationer garanterar lämplighet för verktygstillämpningar som kräver maximal slitstyrka, slagseghet och dimensionsstabilitet.

D2 Pulver Partikelstorlekar

D2 Pulver Partikelstorleksfördelning

| Partikelstorlek | Egenskaper |

|---|---|

| 10-22 mikrometer | Ultrafin kvalitet ger högsta densitet |

| 22-53 mikrometer | Vanligast förekommande storleksintervall |

| 53-105 mikrometer | Grovare storlek ger god flytbarhet |

- Finare partiklar möjliggör större förtätning under sintringen

- Grovare partiklar förbättrar pulverflödet in i verktygshålrummen

- Storleken väljs utifrån de egenskaper som krävs för den slutliga detaljen

- Både gas- och vattenatomiserade partiklar används

Genom att kontrollera storleksfördelningen optimeras pressbeteendet, sintringens densitet och den slutliga komponentens prestanda.

D2 Pulver skenbar densitet

D2 Pulver skenbar densitet

| Skenbar densitet | Detaljer |

|---|---|

| Upp till 60% av verklig densitet | För sfärisk pulvermorfologi |

| 4,5-5,5 g/cc typiskt | Högre densitet förbättrar flöde och kompressibilitet |

- Sfärisk pulverform ger hög skenbar densitet

- Oregelbundet pulver har lägre densitet runt 50%

- Högre skenbar densitet förbättrar pressfyllningseffektiviteten

- Möjliggör enklare komprimering i komplexa verktygsgeometrier

Högre skenbar densitet leder till bättre tillverkningsproduktivitet och komponentkvalitet.

Produktionsmetod för D2-pulver

Produktion av D2-pulver

| Metod | Detaljer |

|---|---|

| Atomisering av gas | Inert gas under högt tryck bryter upp smält legeringsström till fina droppar |

| Induktionssmältning i vakuum | Insatsmaterial med hög renhet som smälts under vakuum |

| Flera omsmältningar | Förbättrar kemisk homogenitet |

| Siktning | Klassificerar pulver i olika fraktioner av partikelstorlek |

- Gasatomisering ger sfärisk pulverform

- Vakuumsmältning eliminerar gasformiga föroreningar

- Flera omsmältningar förbättrar enhetligheten

- Efterbearbetning möjliggör anpassning av partikelstorlek

Helautomatiserade processer i kombination med strikt kvalitetskontroll säkerställer tillförlitliga och konsekventa egenskaper hos D2-pulver som är avgörande för verktygens prestanda.

Prissättning av D2-pulver

Prissättning av D2-pulver

| Faktor | Påverkan på priset |

|---|---|

| Renhetsgrad | Högre renhet ökar kostnaden |

| Partikelstorlek | Ultrafint pulver dyrare |

| Orderkvantitet | Priset sjunker med större volym |

| Egenskaper för pulver | Pulver med högre densitet kostar mer |

| Ytterligare tjänster | Anpassning medför extra kostnader |

Indikativ prissättning

- D2 sfäriskt pulver: $15-25 per kg

- D2 oregelbundet pulver: $10-20 per kg

- Priset för stora volymer kan vara 40% lägre

Priset beror på renhet, partikelstorlek och -form, orderkvantitet, densitet och eventuella ytterligare anpassningar.

D2 pulver leverantörer

D2 pulver leverantörer

| Företag | Plats |

|---|---|

| Höganäs | Sverige |

| Erasteel | USA, Europa |

| Carpenter Pulverprodukter | USA |

| Sandvik Osprey | STORBRITANNIEN |

| Jingdong nytt material | Kina |

| CNPC Pulver | Kina |

Viktiga faktorer för val av leverantör:

- Pulverkvaliteter erbjuds

- Produktionskapacitet

- Fördelning av partikelstorlek

- Karaktärisering och testning av pulver

- Prissättning och minsta orderkvantitet

- Förpackning och ledtider

- Teknisk support för kunder

D2 Pulverhantering och förvaring

D2 Pulverhantering

| Rekommendation | Anledning |

|---|---|

| Säkerställ tillräcklig ventilation | Förhindra exponering för fina metallpartiklar |

| Använd skyddsutrustning | Undvik oavsiktlig förtäring |

| Jorda all utrustning | Förhindra statiska gnistor |

| Undvik antändningskällor | Risk för brandfarligt damm |

| Använd verktyg som inte slår gnistor | Förhindra antändning under hantering |

| Följ säkra protokoll | Minska brand-, explosions- och hälsorisker |

Rekommendationer för lagring

- Förvara förslutna behållare i ett svalt och torrt utrymme

- Begränsa exponeringen för fukt, syror, klorider

- Håll temperaturen under 27°C

Korrekta försiktighetsåtgärder vid hantering och lagring bidrar till att bevara renheten och förhindra hälso- eller brandrisker.

Inspektion och provning av D2-pulver

Testning av D2-pulver

| Test | Detaljer |

|---|---|

| Kemisk analys | Verifierar sammansättningen med hjälp av optisk eller ICP-spektroskopi |

| Fördelning av partikelstorlek | Bestämmer storlekar med hjälp av laserdiffraktion eller siktning |

| Skenbar densitet | Mätt med Hall-flödesmätare enligt ASTM B212 |

| Morfologi för pulver | SEM-bildtagning för att bestämma partikelform |

| Analys av flödeshastighet | Gravitationsflöde genom specificerad tratt |

| Tappdensitetstest | Densitet uppmätt efter mekanisk knackning av pulverprov |

Testningen säkerställer att pulvret uppfyller kraven på kemisk sammansättning, fysiska egenskaper, partikelstorleksfördelning, morfologi, densitet och flödeshastighet.

Fördelar och nackdelar med D2-pulver

Fördelar med D2-pulver

- Exceptionell hårdhet vid värmebehandling

- Utmärkt slit- och nötningsbeständighet

- Mycket hög hållfasthet i kombination med god slagseghet

- Dimensionsstabilitet vid kallbearbetning

- Bra slipbarhet jämfört med andra verktygsstål

- Relativt kostnadseffektivt

Begränsningar av D2-pulver

- Måttlig korrosionsbeständighet utan ytbehandling

- Begränsad hållfasthet och krypmotstånd vid höga temperaturer

- Kräver noggrann värmebehandling av erfarna leverantörer

- Ej svetsbar med konventionella svetsmetoder

- Stora sektioner kan uppleva försprödning

- Spröd brottmod begränsar kallformbarheten

Jämförelse med S7 Verktygsstål Pulver

D2 vs S7 Verktygsstål Pulver

| Parameter | D2 | S7 |

|---|---|---|

| Hårdhet | 60-62 HRC | 63-65 HRC |

| Tålighet | Mycket bra | Bra |

| Slitstyrka | Utmärkt | Utestående |

| Korrosionsbeständighet | Måttlig | Låg |

| Kall styrka | Utmärkt | Mycket bra |

| Kostnad | Låg | Hög |

- D2 har något lägre hårdhet men mycket bättre seghet

- S7 ger maximal slitstyrka

- D2 har bättre korrosionsbeständighet obelagd

- S7 har högre varmhårdhet och varmhållfasthet

- D2 är mer kostnadseffektivt

Vanliga frågor om D2-pulver

F: Vilka är de viktigaste användningsområdena för D2 verktygsstålpulver?

A: De huvudsakliga användningsområdena är kallpressningsverktyg, stans- och klippverktyg, myntpräglingsverktyg, gängvalsverktyg, kirurgiska verktyg, knivar, industriknivar samt precisionsslipade axlar och stift.

F: Vilken värmebehandling används för D2 verktygsstålpulver?

S: D2 värmebehandlas vanligen genom austenitisering vid 1010-1040°C, kylning i olja eller luft och anlöpning vid 150-350°C för att uppnå en hårdhet på 60-62 HRC.

F: Hur förbättrar vanadin egenskaperna hos D2-stål?

A: Vanadin bildar fina karbider med järn och krom som ger betydande slitstyrka och nötningsbeständighet samtidigt som de förbättrar slagsegheten.

F: Vilka försiktighetsåtgärder bör vidtas när man arbetar med D2-pulver?

S: Rekommenderade försiktighetsåtgärder omfattar ventilation, inert atmosfär, undvikande av antändningskällor, jordning av utrustning, användning av gnistfria verktyg, skyddsutrustning och säker förvaring skyddad från fukt och föroreningar.

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731