Pulver av TiNbZrSn-legering

TiNbZrSn-legeringspulver är ett avancerat kompositmaterial med exceptionella egenskaper som gör det lämpligt för ett brett spektrum av krävande applikationer. Den här artikeln ger en omfattande översikt över TiNbZrSn-pulver inklusive dess sammansättning, egenskaper, produktionsmetoder, applikationer, leverantörer och mer.

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

TiNbZrSn legering pulver sammansättning

TiNbZrSn legeringspulver består av följande element:

| Element | Vikt % |

|---|---|

| Titan (Ti) | 35-40% |

| Niob (Nb) | 35-40% |

| Zirkonium (Zr) | 5-10% |

| Tenn (Sn) | 5-10% |

Denna exakta kombination av titan, niob, zirkonium och tenn resulterar i en legering med enastående styrka, hårdhet och elasticitet jämfört med konventionella legeringar. I synnerhet niobinnehållet förbättrar den mekaniska prestandan avsevärt.

Genom att noggrant kontrollera förhållandet mellan de ingående metallerna kan legeringspulverets egenskaper optimeras för olika applikationer som kräver hög hållfasthet i förhållande till vikt, korrosionsbeständighet, biokompatibilitet eller hållbarhet vid höga temperaturer.

Egenskaper för pulver av TiNbZrSn-legering

TiNbZrSn legeringspulver uppvisar följande exceptionella egenskaper:

| Fastighet | Beskrivning |

|---|---|

| Hög hållfasthet | Ger hållfasthet över 1400 MPa, i nivå med avancerade legeringar för flyg- och rymdindustrin |

| Låg densitet | Densitet ca 6,5 g/cm3, mycket lägre än stål |

| Utmärkt elasticitet | Young's modul runt 100 GPa, vilket möjliggör flexibilitet |

| Hög hårdhet | Vickers-hårdhet över 450 HV, bättre nötningsbeständighet än rostfritt stål |

| God korrosionsbeständighet | Motstår korrosion i tuffa miljöer |

| Biokompatibilitet | Giftfri och lämplig för medicinska implantat |

| Hög smältpunkt | Smälter över 2500°C vilket gör den lämplig för högtemperaturapplikationer |

Kombinationen av hög hållfasthet, låg vikt, hårdhet och elasticitet är sällsynt och gör TiNbZrSn till ett extremt mångsidigt material. Det överträffar konventionella legeringar som rostfritt stål i flera egenskaper.

Produktion av pulver av TiNbZrSn-legering

TiNbZrSn-legeringspulver kan produceras med hjälp av följande avancerade metoder:

| Metod | Beskrivning |

|---|---|

| Atomisering av gas | Smält legering sprutas till fina droppar som stelnar till pulver |

| Process med roterande elektrod och plasma (PREP) | Elektroden roterar snabbt i plasmabågen för att sönderdelas till pulver |

| Hydrid-dehydrid (HDH) | Legeringen hydreras, krossas mekaniskt till pulver och avhydreras sedan |

Gasatomisering ger kontroll över partikelstorleksfördelningen och resulterar i ett jämnt sfäriskt pulver som är idealiskt för additiv tillverkning. PREP- och HDH-metoderna möjliggör ekonomisk produktion av oregelbundet pulver som lämpar sig för pressning och sintring.

Legeringssammansättningen kan bibehållas exakt i dessa pulverproduktionsprocesser, vilket säkerställer konsekventa egenskaper. Atmosfärer med inert gas med hög renhet förhindrar kontaminering.

TiNbZrSn legeringspulver Tillämpningar

Tack vare sina välbalanserade materialegenskaper används TiNbZrSn-legeringspulver i följande applikationer:

| Industri | Tillämpning |

|---|---|

| Flyg- och rymdindustrin | Komponenter till flygplan och raketmotorer, rymdsystem |

| Fordon | Ventilfjädrar, fästelement, ställdon |

| Medicinsk | Implantat, proteser, hjälpmedel |

| Försvar | Pansar, ammunition, ballistik |

| Additiv tillverkning | 3D-utskrivna delar med hög hållfasthet |

| Kemisk bearbetning | Korrosionsbeständiga kärl, rörledningar |

Kombinationen av styrka, hårdhet och biokompatibilitet gör TiNbZrSn lämplig för lastbärande implantat som höft- och knäleder. Dess korrosionsbeständighet gör att det passar för marina applikationer som utsätts för havsvatten. Och dess hållbarhet vid höga temperaturer är en fördel i jetmotorer och turbiner.

Jämfört med konventionella legeringar möjliggör TiNbZrSn lättare, starkare och mer hållbara komponenter, vilket ger en fördel i krävande industrier.

Specifikationer för legeringspulver TiNbZrSn

Pulver av legeringen TiNbZrSn är kommersiellt tillgängligt med följande specifikationer:

| Attribut | Detaljer |

|---|---|

| Partikelstorlekar | 15-45 mikrometer, 45-106 mikrometer, 106-250 mikrometer |

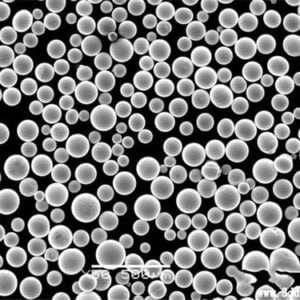

| Partikelns form | Sfärisk, oregelbunden |

| Renhet | Upp till 99,9% |

| Syrehalt | Under 2000 ppm |

| Pulverkvaliteter | Årskurs 5, 23, 23 ELI |

| Leveransformulär | Löst pulver, sintrade förformar |

Både gasatomiserat sfäriskt pulver och oregelbundet pulver från HDH eller PREP finns tillgängligt. Mindre pulver på 15-45 mikron lämpar sig för additiv tillverkning med krav på bra flöde och packning. Större pulver på 106-250 mikron pressas och sintras vanligtvis.

Standarder som ASTM F1805 och ISO 5832 anger gränser för sammansättning och erforderliga egenskaper för biomedicinskt 23 ELI-pulver. Anpassade legeringskompositioner och partikelstorlekar kan också produceras för att uppfylla applikationskrav.

TiNbZrSn legeringspulver leverantörer

Några ledande globala leverantörer av TiNbZrSn-legeringspulver är bl.a:

| Leverantör | Plats |

|---|---|

| AMETEK | USA |

| CNPC Pulver | Kina |

| GKN Hoeganaes | Europa |

| LPW-teknik | STORBRITANNIEN |

| Sandvik Osprey | STORBRITANNIEN |

Välrenommerade leverantörer som dessa har avancerade interna pulverproduktionsanläggningar som använder gasatomisering eller hydrid-dehydridprocesser. De kan tillhandahålla olika partikelstorleksfördelningar och anpassa legeringssammansättningen efter behov.

Små mängder för prototyptillverkning till stora kommersiella volymer är tillgängliga. Strikt kvalitetskontroll och testning genomförs av leverantörerna för att säkerställa att pulvret uppfyller specifikationerna.

Priser för pulver av legeringen TiNbZrSn

TiNbZrSn-pulver är en avancerad speciallegering som betingar ett högt pris:

| Pulverkvalitet | Prisintervall |

|---|---|

| Betyg 5 | $350-$500 per kg |

| Betyg 23 | $450-$650 per kg |

| Grad 23 ELI | $550-$750 per kg |

Priset beror på orderkvantitet, partikelstorleksfördelning, form och sammansättning. Mindre kvantiteter av fint sfäriskt pulver är dyrare. Oregelbundet pulver och större batchstorlekar ger kostnadsbesparingar.

Priset är flera gånger högre än för vanliga legeringar som 316L rostfritt stålpulver. De överlägsna egenskaperna motiverar dock den högre kostnaden för kritiska applikationer som kräver maximerad prestanda.

TiNbZrSn-legering Pulverhantering

För säker hantering av TiNbZrSn-legeringspulver:

- Förvara förseglade behållare i en sval, torr miljö för att förhindra oxidation och hydrering

- Undvik spill för att förhindra att pulver ansamlas och utgör en explosionsrisk

- Jorda all utrustning för pulverhantering och alla transportkärl

- Använd handskar och andningsskydd vid hantering av pulver

- Använd gnistfria verktyg och vakuumsystem med täckning av inert gas

- Använd ventilation och punktutsug där så krävs

Den fina partikelstorleken gör TiNbZrSn-pulver brandfarligt när det dispergeras. Noggrann hantering enligt säkerhetsprotokoll är avgörande. Automatiserad hantering i handskbox och inneslutningssystem rekommenderas.

Inspektion av pulver av TiNbZrSn-legering

TiNbZrSn-legeringspulver bör inspekteras för:

| Parameter | Metod | Kriterier för acceptans |

|---|---|---|

| Fördelning av partikelstorlek | Laserdiffraktion, siktning | Uppfyller specificerat intervall |

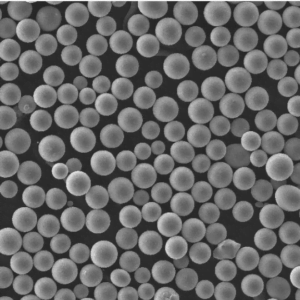

| Partikelns form | SEM-avbildning | Sfäriska, släta ytor |

| Partikelkemi | EDX/EDS, ICP-OES | Överensstämmer med specificerad sammansättning |

| Syre/nitrogen | Fusion med inert gas | Under 2000 ppm syre |

| Skenbar densitet | Hall-flödesmätare | Bättre flöde för högre densitet |

| Flödeshastighet | Hall-flödesmätare | Flödar fritt genom öppningen |

Dessa tester säkerställer att pulvret uppfyller de specifikationer för storlek, form, kemi, renhet och flytbarhet som krävs för AM- eller press- och skäranvändning.

Testning av pulver av TiNbZrSn-legering

Följande ytterligare tester kan göras för att kvalificera TiNbZrSn-legeringspulver:

| Test | Metod | Syfte |

|---|---|---|

| Kompressibilitet | Enaxlig pressning | Bedömning av packningsreaktion |

| Grön styrka | Tvärgående brotthållfasthet | Mät hållfastheten före sintring |

| Densitet efter sintring | Dimensionell mätning | Säkerställa fullständig konsolidering |

| Mikrostruktur | Optisk mikroskopi, SEM | Bedömning av smältning, porositet, korn |

| Hårdhet | Vickers/Rockwell-test | Verifiera mekaniska egenskaper |

| Draghållfasthet | ASTM E8 | Mät UTS, sträckgräns, töjning |

Det är klokt att testa komprimerade och sintrade prover för att bekräfta pulverets bearbetbarhet och de slutliga mekaniska egenskaperna i förhållande till konstruktionskraven.

Fördelar och nackdelar med TiNbZrSn-legeringspulver

| Fördelar | Nackdelar |

|---|---|

| Exceptionellt förhållande mellan styrka och vikt | Dyrt jämfört med vanliga legeringar |

| Högre elasticitet än andra höghållfasta legeringar | Lägre duktilitet än titanlegeringar |

| Utmärkt hårdhet och slitstyrka | Kräver försiktig hantering på grund av reaktivitet |

| Motstår korrosion i tuffa miljöer | Svårt att bearbeta och slipa |

| Biokompatibel för medicinsk användning | Begränsade leverantörer och tillgänglighet |

| Tål extremt höga temperaturer | Behöver varm isostatisk pressning för full konsolidering |

För kritiska tillämpningar där prestanda väger tyngre än kostnaden ger TiNbZrSn-legeringspulver egenskaper som inte överträffas av andra legeringar. De största begränsningarna är kostnad och tillgänglighet.

Jämförelse mellan TiNbZrSn och andra legeringar

Hur står sig TiNbZrSn jämfört med andra högpresterande legeringspulver?

Jämfört med rostfritt stål:

- 2x högre hållfasthet

- 70% lägre densitet

- 5x högre hårdhet

- Bättre korrosionsbeständighet

Jämfört med titanlegeringar:

- 50% högre elasticitet

- 20% högre hårdhet

- Bättre motståndskraft mot krypning

- Lägre duktilitet

Jämfört med kobolt-kromlegeringar:

- Lägre densitet

- Inga toxiska effekter

- Högre driftstemperatur

- Lägre seghet

Jämfört med Ni-baserade superlegeringar:

- Enklare bearbetning

- Lägre kostnad

- Kapacitet för lägre temperaturer

- Lägre kryphållfasthet

TiNbZrSn har därför en optimal balans mellan egenskaper som inte finns i andra legeringar, vilket gör den lämplig för de mest krävande tillämpningarna.

Insikter om användning av TiNbZrSn-legeringspulver

Här följer några viktiga insikter om hur man använder TiNbZrSn på ett effektivt sätt:

- Gasatomiserat pulver med kontrollerad partikelstorleksfördelning flyter och packas bäst för AM

- Oregelbundet pulver kräver högre tryck för komprimering och sintring

- Isostatisk varmpressning ger maximal densitet och egenskaper

- Glödgning kan användas för att skräddarsy duktilitet och seghet efter behov

- Nära nätformade delar minimerar kostsam bearbetning av sintrade komponenter

- Ytbehandlingar förbättrar slitstyrkan för applikationer med glidande kontakt

- Sammanfogning av olika material till TiNbZrSn kräver val av lämplig process

- Stränga leverantörskvalifikationer och tester bidrar till att säkerställa pulverkvalitet och prestanda

Det är viktigt att förstå sambanden mellan bearbetning, mikrostruktur och egenskaper för att kunna utnyttja den fulla potentialen hos denna exceptionella legering.

Vanliga frågor och svar

Här är några vanliga vanliga frågor om TiNbZrSn-legeringspulver:

F: Är TiNbZrSn-pulver kompatibelt med 3D-utskrifter?

S: Ja, gasatomiserad TiNbZrSn med kontrollerad partikelstorlek och hög sfäricitet kan användas för pulverbäddsfusion och AM-processer med riktad energideposition. Parametrarna behöver optimeras för att uppnå hög densitet.

F: Vilken partikelstorlek är bäst för additiv tillverkning?

A: 15-45 mikron rekommenderas, vilket säkerställer bra pulverflöde och packning. Större storlekar upp till 106 mikrometer har också framgångsrikt tryckts för vissa applikationer som kräver tjockare lager.

F: Kräver TiNbZrSn varm isostatisk pressning efter AM?

S: HIP bidrar till att maximera densiteten, eliminera inre porer och förbättra de mekaniska egenskaperna. Men för vissa mindre krävande applikationer kan as-printade TiNbZrSn-delar uppfylla kraven utan HIP.

F: Kan du bearbeta och slipa TiNbZrSn-legering?

S: Ja, men det kräver rigida inställningar, kylmedel under högt tryck, vassa hårdmetallverktyg och fina slipmedel. Matningshastigheter och varvtal måste vara lägre än för konventionella legeringar på grund av dess hårdhet.

F: Är TiNbZrSn lämpligt för biomedicinska implantat?

S: Ja, det har använts för benplattor, höft- och knäimplantat tack vare sin biokompatibilitet, låga modul och höga hållfasthet som är idealisk för lastbärande anordningar. ELI-pulver av klass 23 ger den renhet som behövs.

F: Vilka är de vanligaste användningsområdena för TiNbZrSn-legeringen?

A: Flyg- och rymdkomponenter som landningsställ, fjädrar och fästelement för bilar, biomedicinska implantat, pansarplåtar, turbiner för kraftproduktion samt verktyg för gjutning och stansning av plåt.

Slutsats

Sammanfattningsvis erbjuder TiNbZrSn-legeringspulver extraordinär styrka i kombination med låg densitet, elasticitet och hårdhet till skillnad från alla andra konventionella eller avancerade legeringar. Även om kostnaderna är högre motiverar många applikationer med kritiska prestanda utgifterna där optimerade materialegenskaper är av största vikt. Med utökad tillgänglighet och pågående innovationer kommer TiNbZrSn:s unika egenskaper att utnyttjas inom fler branscher under de kommande åren.

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731