Titan Ti6242 pulver

Titanium Ti6242 Powder är en alfa-beta-titanlegering med utmärkt styrka, korrosionsbeständighet och hög temperaturprestanda. Det är en av de mest använda titanlegeringarna och har tillämpningar inom flyg-, bil-, marin-, kemisk process- och biomedicinsk industri.

Fördelar

- Utmärkt förhållande mellan styrka och vikt

- God korrosionsbeständighet

- Användbar vid måttligt höga temperaturer

- Lägre kostnad än Ti64 eller Ti55531

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

Översikt

Titanium Ti6242 Powder är en alfa-beta-titanlegering med utmärkt styrka, korrosionsbeständighet och hög temperaturprestanda. Det är en av de mest använda titanlegeringarna och har tillämpningar inom flyg-, bil-, marin-, kemisk process- och biomedicinsk industri.

Några viktiga egenskaper och kännetecken för Titan Ti6242 pulver:

Ti6242 pulver sammansättning

| Element | Vikt % |

|---|---|

| Titan (Ti) | Balans |

| Aluminium (Al) | 6% |

| Vanadin (V) | 4% |

| Tenn (Sn) | 2% |

| Zirkonium (Zr) | 2% |

Egenskaper för Ti6242-pulver

| Fastighet | Beskrivning |

|---|---|

| Styrka | Utmärkt hållfasthet jämförbar med stållegeringar |

| Hårdhet | 36 HRC efter åldrande värmebehandling |

| Motståndskraft mot korrosion | Motståndskraftig mot de flesta syror och kloridmiljöer |

| Prestanda vid höga temperaturer | Användbar upp till ca 550°C i luft |

| Täthet | 4,43 g/cc |

| Partikelstorlek | 15-45 mikrometer |

Egenskaper för Ti6242-pulver

| Karaktäristisk | Detaljer |

|---|---|

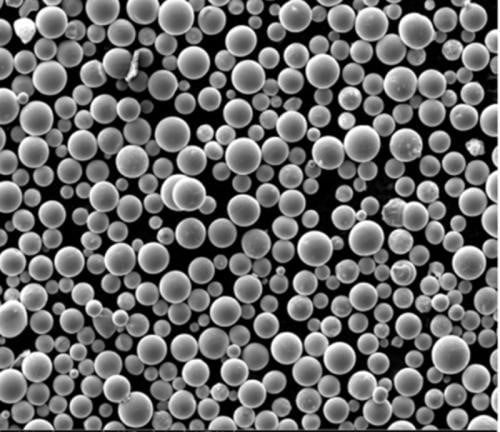

| Tillverkningsprocess | Gasatomiseringsprocess |

| Morfologi | Sfäriska pulverpartiklar |

| Flytbarhet | Bra tack vare sfärisk form |

| Skenbar densitet | 2,5-3,0 g/cc |

| Tappdensitet | 3,5-4,0 g/cc |

Användningsområden för Ti6242-pulver

Några av de viktigaste användningsområdena för Ti6242-pulver inkluderar:

Tillämpningar inom flyg- och rymdindustrin

- Motorkomponenter som lameller, skivor, distanshållare

- Delar och strukturer till flygplanskroppar

- Fästelement, hydraulslangar

Fördelar

- Högt förhållande mellan styrka och vikt

- Tål höga temperaturer och påfrestningar

- Korrosionsbeständighet

Tillämpningar inom fordonsindustrin

- Ventilfjädrar, ventillyftare, vevstakar

- Komponenter för motorsport

Fördelar

- Minska vikten på rörliga komponenter

- Tål temperaturer under huven

- Hög utmattningshållfasthet

Kemisk processindustri

- Värmeväxlare, reaktionskärl

- Pumpar, ventiler, rör och rördelar

Fördelar

- Utmärkt korrosionsbeständighet mot syror, klorider

- Tål högt tryck och höga temperaturer

Biomedicinsk industri

- Kirurgiska instrument, implantat

- Ortopediska hjälpmedel

Fördelar

- Biokompatibilitet

- Tål sterilisering

- Hög utmattningshållfasthet

Jämförelse mellan Ti6242 och andra titanlegeringar

| Legering | Styrka | Motståndskraft mot korrosion | Kapacitet för höga temperaturer | Kostnad |

|---|---|---|---|---|

| Ti6242 | Utmärkt | Utmärkt | Bra | Måttlig |

| Ti64 | Utmärkt | Måttlig | Utmärkt | Hög |

| Ti55531 | Utmärkt | Utmärkt | Måttlig | Mycket hög |

Specifikationer och standarder

Ti6242 överensstämmer med följande specifikationer och standarder:

| Standard | Detaljer |

|---|---|

| AMS 4928 | Materialspecifikation för flyg- och rymdindustrin utfärdad av SAE |

| ISO 5832-11 | Internationella specifikationer för kirurgiska implantattillämpningar |

| ASTM F3001 | Specifikation för additiv tillverkning med pulverbäddsfusion |

| ASTM B348 | Specifikation för pulver av titan och titanlegeringar |

Ti6242 pulverstorlekar tillgängliga

| Storlek | Detaljer | Tillämpningar |

|---|---|---|

| 15-45 mikrometer | Fin pulverstorlek | AM, HIP |

| 45-106 mikrometer | Grov pulverstorlek | Press & Sinter |

Leverantörer och prissättning

Några ledande globala leverantörer av Ti6242-pulver är bl.a:

Ti6242 pulver leverantörer

| Leverantör | Plats |

|---|---|

| AP&C | Kanada |

| Snickare Tillsats | Förenta staterna |

| GKN Hoeganaes | Europa |

| Praxair | Förenta staterna |

Priser för Ti6242-pulver

| Pulverkvalitet | Partikelstorlek | Pris ($/kg) |

|---|---|---|

| Betyg 23 | 15-45 mikrometer | $75-100 |

| Betyg 23 | 45-106 mikrometer | $50-75 |

| Betyg 5 | 15-45 mikrometer | $100-150 |

Priserna beror på ordervolym, partikelstorleksfördelning och kemitoleranser.

För- och nackdelar med att använda Ti6242-pulver

Fördelar

- Utmärkt förhållande mellan styrka och vikt

- God korrosionsbeständighet

- Användbar vid måttligt höga temperaturer

- Lägre kostnad än Ti64 eller Ti55531

Nackdelar

- Inte lika värmetålig som nickellegeringar

- Svårbearbetad i fullt härdat tillstånd

- Känslig för gnissling utan ytbehandling

- Högre kostnad än stål

Vanliga frågor

Vad är innehållet i Ti6242-legeringen?

Ti6242 innehåller 6% aluminium, 4% vanadin, 2% tenn och 2% zirkonium, resten titan. Denna sammansättning ger en utmärkt kombination av styrka, seghet och korrosionsbeständighet.

Vilken värmebehandling används för Ti6242?

En typisk värmebehandling är lösningsbehandling vid 955°C, följt av åldring vid 595°C för att uppnå optimal hållfasthet. Detta resulterar i en mikrostruktur som innehåller alfa- och betafaser.

Vad är draghållfastheten för Ti6242?

Draghållfastheten hos smidd Ti6242 är cirka 900 MPa (130.000 psi) i glödgat tillstånd. Efter värmebehandling kan den uppgå till cirka 1100 MPa (160.000 psi).

Vad är densiteten för titanlegeringen Ti6242?

Densiteten för Ti6242 är 4,43 g/cc, vilket ligger mellan stål- och aluminiumlegeringar. Detta ger ett utmärkt förhållande mellan styrka och vikt.

Vad är skillnaden mellan Grade 5 och Grade 23 Ti6242-pulver?

Grade 5-pulver har lägre interstitiella elementnivåer (särskilt syre och kväve) än Grade 23, vilket gör att det är att föredra för kritiska applikationer, men det har en högre kostnad.

Vilka standarder uppfyller Ti6242-pulver?

Viktiga standarder för titanpulver är ASTM B348, AMS 4999, ISO 5832-3, ASTM F3049, ASTM F3001. Dessa omfattar kemi, partikelstorleksfördelning, morfologi, flödesegenskaper etc.

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731