H13 verktygsstål pulver

H13 verktygsstålspulver är en otroligt mångsidig och hållbar kvalitet på verktygsstålspulver som ofta används för att tillverka verktyg för varmbearbetningsprocesser. Den här artikeln ger en omfattande översikt över H13-pulvermetallurgi, inklusive sammansättning, egenskaper, bearbetning, specifikationer, tillämpningar, fördelar/nackdelar och leverantörer.

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

H13 verktygsstålspulver är en otroligt mångsidig och hållbar kvalitet på verktygsstålspulver som ofta används för att tillverka verktyg för varmbearbetningsprocesser. Den här artikeln ger en omfattande översikt över H13-pulvermetallurgi, inklusive sammansättning, egenskaper, bearbetning, specifikationer, tillämpningar, fördelar/nackdelar och leverantörer.

Översikt

H13 verktygsstålspulver är ett mångsidigt legerat krom-molybden-vanadiumstål som har utmärkta egenskaper mot termisk chock och termisk utmattning. Det uppvisar också god duktilitet i varmbearbetningstillämpningar, hög härdbarhet och är exceptionellt segt.

H13 motstår uppmjukning vid temperaturer upp till 540°C (1000°F), vilket gör det till ett utmärkt val för tillverkning av verktyg som klarar de påfrestningar som är förknippade med pressgjutning av aluminium, smidesverktyg, extruderingsverktyg med mera.

Vid tillverkning med pulvermetallurgiska tekniker ger H13-pulver förbättrade övergripande egenskaper jämfört med konventionellt producerat H13-verktygsstål. Viktiga fördelar inkluderar:

- Fin, homogen mikrostruktur

- Bristande segregering

- Överlägsna mekaniska egenskaper

- Bättre dimensionell kontroll

- Högre hårdhetspenetration

- Utmärkt polerbarhet

Sammansättning

Verktygsstål H13 anses vara ett kromhaltigt varmbearbetningsverktygsstål. Här följer en genomgång av den kemiska sammansättningen i viktprocent:

| Element | Sammansättning % |

|---|---|

| Kol (C) | 0.32-0.45 |

| Krom (Cr) | 4.75-5.50 |

| Molybden (Mo) | 1.10-1.75 |

| Vanadin (V) | 0.80-1.20 |

| Mangan (Mn) | 0.20-0.50 |

| Kisel (Si) | 0.80-1.20 |

| Järn (Fe) | Balans |

Kombinationen av krom-, molybden- och vanadinkarbider i mikrostrukturen ger H13 utmärkt slitstyrka vid förhöjda temperaturer upp till 1000°F.

Fastigheter

Här följer en översikt över de viktigaste fysikaliska och mekaniska egenskaperna hos H13 verktygsstålspulver:

Fysikaliska egenskaper

- Densitet: 7,3 g/cm3

- Smältpunkt: 1530°C (2785°F)

Mekaniska egenskaper

- Draghållfasthet:

- Glödgad: 900 MPa (131 000 psi)

- Härdad och anlöpt: 300.000 psi (2070 MPa)

- Utbytesstyrka:

- Glödgad: 525 MPa (76 000 psi)

- Härdad och anlöpt: 262.000 psi (1800 MPa)

- Förlängning: 8%

- Minskning av område: 35%

- Hårdhet:

- Glödgad: 217 HB

- Härdad och anlöpt: 54 HRC

Egenskaperna gör H13 till ett utmärkt val för varmbearbetningsformar och verktyg. Det bibehåller hög hållfasthet och hårdhet vid förhöjda temperaturer.

Bearbetning

H13 verktygsstål finns som konventionellt och pulvermetallurgiskt stångmaterial samt som standardpulver för additiv tillverkning.

Här följer en översikt över hur H13-pulver tillverkas och bearbetas för att skapa formar, verktyg och komponenter:

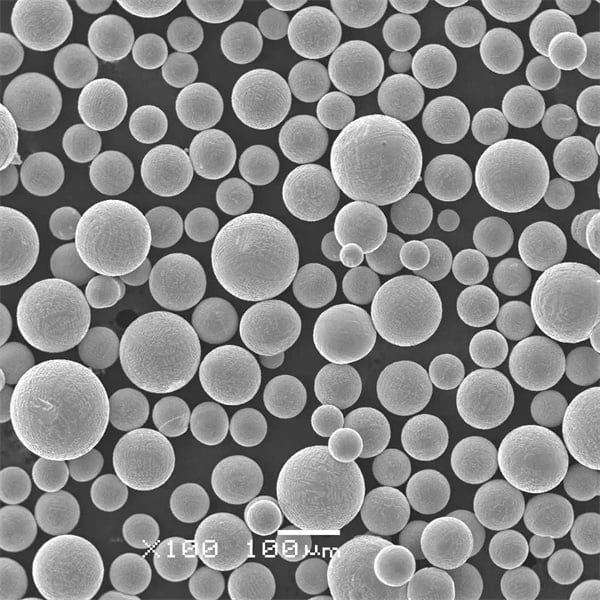

1. Atomisering

Vakuuminduktionssmältning används för att skapa en flytande form av H13 som sedan finfördelas till fina sfäriska pulver. Vanliga pulverstorlekar varierar från 10 μm till 45 μm.

2. Packning

H13-pulvren komprimeras i en form med hjälp av pressar som levererar upp till 100 tons tryck. Detta bildar en tät grön kompakt som är redo för sintring.

3. Sintring

Gröna kompakter bränns vid temperaturer mellan 1175-1260°C (2150-2300°F). Detta smälter samman stålpartiklarna och skapar >90% täta H13 verktygsstålsdelar.

4. Värmebehandling

Precis som smidesstål H13 genomgår pulvermetallurgiskt H13 glödgning, härdning och anlöpning för att uppnå de önskade mekaniska egenskaperna.

5. Efterbehandling

Sintrade H13-produkter bearbetas, slipas och poleras till slutliga toleranser med konventionell eller EDM-teknik.

Korrekt värmebehandling och ytbehandling säkerställer att delarna har lämplig kompatibilitet med aluminium-, zink-, bly-, tenn-, koppar-, järn-, nickel- och titanlegeringar som vanligtvis används i applikationer för varmbearbetning.

Specifikationer

Pulverprodukter av verktygsstål H13 tillverkas för att uppfylla olika klassificeringar:

- ASTM A681

- ISO 4957 X40CrMoV5-1

- DIN 1.2344

Typiska storleksintervall inkluderar:

| Form | Storlekar |

|---|---|

| Pulver | 10-45 μm |

| Gröna kompakter | Upp till 40" x 20" x 6" |

| Sintrade delar | Varierande beroende på applikation |

Tillämpningar

Här är några av de vanligaste tillämpningarna som utnyttjar de unika egenskaperna hos H13 verktygsstålspulver:

Verktyg för varmbearbetning

- Gjutning av aluminium

- Smidesverktyg

- Verktyg för strängsprutning

Verktyg för plastgjutning

- Formsprutningsverktyg

- Blåsformar

- Vakuumformning

Bearbetning vid höga temperaturer

- Hantering av smälta material

- Håller termisk energi

H13 pulververktygsstål är mycket effektivt för alla verktyg, formar och komponenter som måste klara den extrema miljön i maskiner och utrustning för heta arbeten.

H13 pulver vs gjutet H13 verktygsstål

Det finns några viktiga skillnader mellan H13 som tillverkas med konventionella gjutmetoder och H13 som tillverkas med pulvermetallurgiska tekniker:

| Parameter | H13 Avgjutning | H13 Pulver |

|---|---|---|

| Kontroll av sammansättning | Mindre konsekvent sammansättning | Mycket konsekvent komposition |

| Segregation | Hög grad av segregation | Ingen segregering |

| Enhetlighet | Inte homogent | Mycket homogen |

| Täthet | 90-92% | Upp till 100%-densitet |

| Typisk hårdhet | 50-51 HRC | Upp till 56 HRC |

| Dimensionell noggrannhet | +/- 0.5% | +/- 0,1% eller bättre |

| Polering av ytfinish | Måttlig | Utmärkt |

Den molekylära konsistensen och regelbundenheten hos H13-stålpulver möjliggör överlägsna övergripande mekaniska egenskaper. Som ett resultat ger pulverbaserat H13-verktygsstål bättre prestanda och längre livslängd jämfört med gjutna produkter av verktygskvalitet.

Leverantörer

Här är en tabell som visar några av de största globala leverantörerna som erbjuder H13 verktygsstålpulverprodukter:

| Företag | Produktkvaliteter | Ledande tidningar |

|---|---|---|

| Hoeganaes | AncorSteel 1000, AncorSteel 2000, AncorSteel 3000, AncorSteel 5000 | 4-6 veckor |

| Höganäs | Digitala metaller 47-H13 | 10 arbetsdagar |

| Sandvik | Osprey H13 | Lager till 8 veckor |

| Praxair | TAFA 95HS, 98HS, 88HS, 99HS | 6-8 veckor |

| Carpenter Pulverprodukter | CP 800, CP 1000 | 6-12 veckor |

H13 Verktygsstål Pulver Prissättning

Priserna för H13 verktygsstålpulver varierar ganska mycket beroende på:

- Leverantör

- Ordervolym

- Ledtider

- Anpassning

- Produktkvalitet

- Ytterligare mervärdestjänster

Här följer en översikt över prisklasserna:

| Form | Prisintervall |

|---|---|

| H13 Pulver | $14-22/lb |

| H13 Gröna kompakter | $18-26/lb |

| H13 Sintrade delar | $22-35/lb |

Tänk på att kostnaderna kan variera över tiden på grund av förändringar i råvarupriser, efterfrågan och allmänna marknadsförhållanden. Se till att begära formella offerter för budgetplaneringsändamål.

Vanliga frågor

Fråga: Vad är skillnaden mellan verktygsstålsorterna H11, H12, H13 och H14?

S: De främsta skillnaderna gäller den kemiska sammansättningen, vilket ger varierande värme- och slitstyrka. H13 erbjuder en bra balans mellan seghet, hårdhet och termiska egenskaper för de flesta varmbearbetningskrav.

F: Kan du 3D-printa med H13 verktygsstålpulver?

S: Ja, H13 är lätt att svetsa med hjälp av additiv teknik för laserpulverbäddfusion och bindemedelsstrålning för att tillverka komplexa geometrier som är omöjliga med konventionella metoder.

F: Är H13 verktygsstål pulver korrosionsbeständigt?

A:H13 verktygsstål är känt för sin imponerande styrka och hårdhet, vilket är anledningen till att det ofta används i applikationer med hög belastning som formsprutning och pressgjutning. När det gäller korrosionsbeständighet är H13 dock inte särskilt anmärkningsvärt. Det är inte lika sårbart som vissa andra stål, men det är inte heller särskilt motståndskraftigt.

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731