VIGA-utrustning för enkelbrännare

Innehållsförteckning

Välkommen till den ultimata guiden om VIGA-utrustning (vakuum-induktionsgasatomisering) med en enda ugn. Om du vill fördjupa dig i avancerad metallurgi och metallpulverproduktion har du kommit helt rätt. Vi kommer att gå igenom allt du behöver veta om VIGA-system med en enda brännare, deras funktionalitet, fördelar, tillämpningar och mycket mer.

Översikt över VIGA-utrustning för enkelbrännare

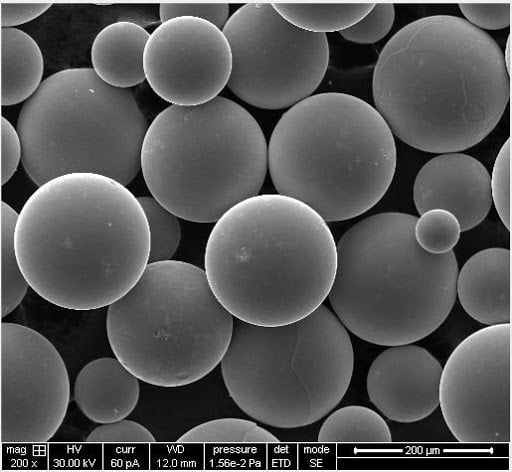

VIGA-utrustning med en enda ugn är en toppmodern metod för att tillverka metallpulver av hög kvalitet. Dessa system utnyttjar induktionssmältning i vakuum i kombination med gasatomisering för att skapa fina, sfäriska pulver med överlägsna egenskaper. Denna teknik är avgörande för industrier som kräver exakta materialegenskaper, t.ex. flyg- och rymdindustrin, bilindustrin och den biomedicinska sektorn.

Typer av metallpulver som produceras av VIGA med en enda ugn

Låt oss börja med att titta på några specifika metallpulvermodeller som tillverkas av VIGA-utrustning med en enda ugn. Här är en detaljerad lista så att du kan bekanta dig med dem:

| Metallpulvermodell | Sammansättning | Viktiga egenskaper | Tillämpningar |

|---|---|---|---|

| 316L rostfritt stål | Fe, Cr, Ni, Mo | Korrosionsbeständighet, hög hållfasthet | Medicinska implantat, marin utrustning |

| 17-4 PH rostfritt stål | Fe, Cr, Ni, Cu, Nb | Hög hållfasthet, korrosionsbeständighet | Delar till flyg- och rymdindustrin, kemisk bearbetning |

| Ti-6Al-4V titanlegering | Ti, Al, V | Högt förhållande mellan styrka och vikt, biokompatibilitet | Flyg- och rymdkomponenter, medicintekniska produkter |

| Inconel 718 | Ni, Cr, Fe, Nb, Mo | Värmebeständighet, oxidationsbeständighet | Delar till jetmotorer, kärnreaktorer |

| Kobolt-kromlegering | Co, Cr, Mo, W | Slitstyrka, hög hårdhet | Tandimplantat, ortopedisk utrustning |

| AlSi10Mg Aluminiumlegering | Al, Si, Mg | Lättvikt, goda gjutegenskaper | Bildelar, konstruktioner för flyg- och rymdindustrin |

| Maråldrat stål | Fe, Ni, Co, Mo | Hög hållfasthet, utmärkt seghet | Verktyg, strukturer för flyg- och rymdindustrin |

| Haynes 282 | Ni, Cr, Co, Mo, Ti | Kryphållfasthet, termisk stabilitet | Gasturbiner, värmeväxlare |

| Kopparlegering C18150 | Cu, Cr, Zr | Hög elektrisk ledningsförmåga, god hållfasthet | Elektriska komponenter, svetselektroder |

| Superlegering av nickel Nimonic 90 | Ni, Cr, Co, Ti, Al | Oxideringsbeständighet, hållfasthet vid höga temperaturer | Turbinblad, avgasventiler |

Tillämpningar av VIGA-utrustning för enkelbrännare

Mångsidigheten hos VIGA-utrustning med en enda panna framgår tydligt av dess breda användningsområde. Här är några specifika användningsområden:

| Industri | Tillämpning | Fördelar |

|---|---|---|

| Flyg- och rymdindustrin | Turbinblad, strukturella komponenter | Högt förhållande mellan styrka och vikt, motståndskraft mot höga temperaturer |

| Fordon | Motordelar, lättviktskonstruktioner | Förbättrad bränsleeffektivitet och hållbarhet |

| Biomedicinsk | Implantat, kirurgiska instrument | Biokompatibilitet, precision |

| Energi | Komponenter till kärnreaktorer, värmeväxlare | Motståndskraft mot korrosion och höga temperaturer |

| Verktyg | Gjutformar, matriser | Slitstyrka, lång livslängd |

| Elektronik | Konduktiva komponenter | Hög elektrisk ledningsförmåga, tillförlitlighet |

Detaljerade specifikationer, storlekar och standarder

Att förstå specifikationerna och standarderna för metallpulver som produceras av VIGA-utrustning är avgörande för att välja rätt material för dina behov. Här är en uppdelning:

| Metallpulvermodell | Partikelstorleksintervall | Standarder | Typiska tillämpningar |

|---|---|---|---|

| 316L rostfritt stål | 15-45 µm | ASTM F138, ISO 5832-1 | Medicinsk, marin |

| 17-4 PH rostfritt stål | 20-63 µm | AMS 5643, ASTM A693 | Flyg- och rymdindustrin, kemisk industri |

| Ti-6Al-4V titanlegering | 15-45 µm | ASTM F1472, ISO 5832-3 | Flyg- och rymdindustrin, medicinteknik |

| Inconel 718 | 20-53 µm | AMS 5662, ASTM B637 | Jetmotorer, kärnkraft |

| Kobolt-kromlegering | 10-50 µm | ASTM F1537, ISO 5832-12 | Dental, ortopedisk |

| AlSi10Mg Aluminiumlegering | 20-60 µm | ISO 3522, ASTM B85 | Fordon, flyg- och rymdindustrin |

| Maråldrat stål | 10-45 µm | AMS 6514, ASTM A538 | Verktyg, flyg- och rymdindustrin |

| Haynes 282 | 20-53 µm | AMS 5918, ASTM B637 | Gasturbiner, värmeväxlare |

| Kopparlegering C18150 | 15-45 µm | ASTM B820, AMS 4596 | El, svetsning |

| Superlegering av nickel Nimonic 90 | 20-53 µm | AMS 5829, ASTM B637 | Turbinblad, avgasventiler |

Leverantörer och prisuppgifter

När det gäller inköp av metallpulver som produceras via VIGA-utrustning med enkelbrännareär det viktigt att känna till sina leverantörer och deras prissättning. Här är en lista över några framstående leverantörer och deras ungefärliga prissättning:

| Leverantör | Modeller av metallpulver | Prissättning (per kg) | Ytterligare tjänster |

|---|---|---|---|

| Höganäs | 316L, Ti-6Al-4V, Inconel 718 | $50-$200 | Anpassad storlek, teknisk support |

| Snickeriteknik | 17-4 PH, maråldrat stål | $60-$250 | Metallurgisk rådgivning, speciallegeringar |

| Sandvik | Kobolt-krom, Haynes 282 | $80-$300 | Kvalitetstestning, FoU-stöd |

| LPW-teknik | AlSi10Mg, kopparlegering C18150 | $40-$150 | Livscykelhantering för pulver, spårbarhet |

| AP&C (GE Additive) | 316L, Ti-6Al-4V, Inconel 718 | $55-$220 | Avancerad karakterisering, återvinningstjänster |

| Praxair Ytteknologi | Inconel 718, Nimonic 90 | $70-$280 | Applikationsteknik, beläggningslösningar |

Fördelar och nackdelar med VIGA-utrustning för enkelbrännare

Låt oss titta närmare på för- och nackdelarna med att använda VIGA-system med en enda ugn för metallpulverproduktion:

| Fördelar | Nackdelar |

|---|---|

| Hög renhet: Vakuummiljön minimerar kontaminering. | Kostnad: Höga initiala investerings- och driftskostnader. |

| Enhetlig partikelstorlek: Konsekvent pulverkvalitet. | Komplexitet: Kräver kvalificerade operatörer och underhåll. |

| Mångsidighet: Lämplig för ett brett spektrum av metallegeringar. | Energiförbrukning: Betydande strömförbrukning. |

| Förbättrade materialegenskaper: Förbättrade mekaniska egenskaper hos pulver. | Begränsad kapacitet: En enda ugn begränsar produktionsvolymen jämfört med uppställningar med flera ugnar. |

Vanliga frågor

| Fråga | Svar |

|---|---|

| Vad används VIGA-utrustning för enkelbrännare till? | Den används för att producera högkvalitativa metallpulver för olika industrier som flyg- och rymdindustrin, bilindustrin och biomedicin. |

| Hur fungerar VIGA-utrustning med enkelbrännare? | Den använder induktionssmältning i vakuum i kombination med gasatomisering för att producera fina, sfäriska metallpulver. |

| Vilka är fördelarna med att använda VIGA för produktion av metallpulver? | Fördelarna är hög renhet, enhetlig partikelstorlek och förbättrade materialegenskaper. |

| Vilka metaller kan bearbetas med VIGA-utrustning? | Ett brett sortiment med bland annat rostfritt stål, titanlegeringar och superlegeringar av nickel. |

| Finns det några begränsningar för användning av VIGA-utrustning för en enda panna? | Ja, bland annat höga kostnader, komplexitet och begränsad produktionskapacitet. |

| Vilka branscher har störst nytta av VIGA-tillverkade pulver? | Flyg-, fordons-, biomedicinsk-, energi-, verktygs- och elektronikindustri. |

| Vilka är de typiska partikelstorlekarna för VIGA-tillverkade pulver? | Partikelstorleken varierar normalt från 10 till 63 mikrometer, beroende på legering och specifika krav. |

| Hur står sig VIGA i jämförelse med andra metoder för pulverproduktion? | VIGA ger högre renhet och bättre kontroll över partikelstorleken, men kan vara dyrare och mer komplicerad än andra metoder, t.ex. vattenatomisering. |

Slutsats

VIGA-utrustning med en enda ugn förändrar spelplanen inom metallpulverproduktion och erbjuder oöverträffad renhet, konsistens och mångsidighet. Oavsett om du arbetar inom flyg-, fordons- eller biomedicinsk industri kan en förståelse för VIGA-tekniken hjälpa dig att fatta välgrundade beslut och dra nytta av fördelarna med högkvalitativa metallpulver.

Om du har några fler frågor eller behöver specifik information är du välkommen att kontakta oss. Dyk in i den avancerade metallurgins värld med VIGA-utrustning för en enda ugn och lyft din materialkapacitet till nya höjder!

Dela på

MET3DP Technology Co, LTD är en ledande leverantör av lösningar för additiv tillverkning med huvudkontor i Qingdao, Kina. Vårt företag är specialiserat på 3D-utskriftsutrustning och högpresterande metallpulver för industriella tillämpningar.

Förfrågan för att få bästa pris och anpassad lösning för ditt företag!

Relaterade artiklar

Högpresterande segment för munstycksvingar: Revolutionerande turbineffektivitet med 3D-utskrift i metall

Läs mer "Om Met3DP

Senaste uppdateringen

Vår produkt

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731